Slotless Brushless DC Motors - Elinco

Slotless Brushless DC Motors - Elinco

Slotless Brushless DC Motors - Elinco

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

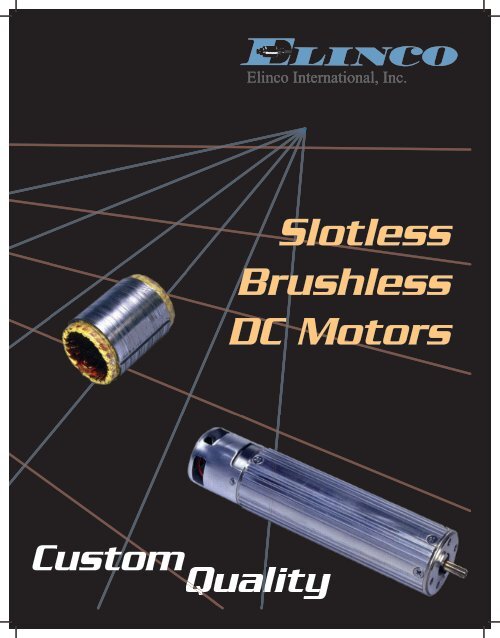

<strong>Elinco</strong> International, Inc.<strong>Slotless</strong><strong>Brushless</strong><strong>DC</strong> <strong>Motors</strong>Custom Quality

What is an <strong>Elinco</strong> slotlessbrushless <strong>DC</strong> (SBL<strong>DC</strong>) motor?An <strong>Elinco</strong> slotless brushless <strong>DC</strong> (SBL<strong>DC</strong>) motorconsists of a stator winding positioned inside alaminated stator ring (without conventional teeth)and a permanent magnet motor. This providesmore peripheral space for the stator winding.This also allows more magnet surface area andux. Powerful rare earth magnetsprovide high torque to motor weight ratios. Theabsence of stator teeth enables more windingcopper and power density which can developmore torque. It also eliminates torque coggingand minimizes audible noise.We are experts in the designand fabrication of custom SBL<strong>DC</strong>motors and rotor/stator sets.<strong>Elinco</strong> exibility,responsiveness, and expertise in the design andfabrication of custom SBL<strong>DC</strong> motors. There arefew restrictions on physical dimension choicessince stator laminations are simple annularrings, economical to produce, and high energymagnets are readily available in arcs and slabsof all sizes. There is freedom to choose magneticand mechanical air gaps, number of poles, polespans, backiron thickness, magnetic densities, andc application.When others say they can't, wesay we can... and do!Whether the issue is speed, power, weight, size,ciency, noise, torque ripple, heat rise, etc.,each or all are optimized to achieve customperformance with relatively short design andresponse time.Tooling charges for custom prototypes arenominal. <strong>Elinco</strong> has produced a wide range of sizesfrom 1” to over 10” in diameter, and basic toolingof many sizes is already available.<strong>Elinco</strong> ed OEMdesigns. Bearings, housings and alignmentproblems are eliminated, thus providing cost-As the energy product of magnets increases andcosts decrease, and the manufacture of the statorective,the slotless motor technology will be the logicalchoice for many brushless <strong>DC</strong> motor applications.Housingsgurations and Mounting Means to Suit thec Application. Optional Fluting for Maximum HeatTransfer and Cooling.ShaftsHardened Stainless Steel or otherSpecialty Alloys, Precision Gorund,Custom Designed Extensions.Stators<strong>Slotless</strong> with Low Inductance and Lowciencies, andCogless, Jitter Free Operation at both Highand Low Speeds.BalancingBalancing Washers for PrecisionBalancing to Quality Grade ANSI G-0.4or better.CoversProtect Feedback Devicesand Provide AuxiliaryMounting Areas.BearingsPrecision Class 5&7 - Precision Preload,Bearing Type and Lubrication Selectedto Match Application.RotorsPermanent Magnet with High EnergyRare Earth Magnets for Maximum EnergyDensity and High Power to Size Ratios.Covered by Sleeve for Strength andElimination of Windage LossesCommutationPrecision Located and Supported HallSwitches. Separate Sensor Magnets forThermal Stability.

FeaturesBenefitsCapabilitiesBasic frame sizes available(frame no./nominal dia.)1400/1.4” 3400/3.4”1800/1.8” 4400/4.4”2300/2.3” 5800/5.8”Custom sizes available.Zero-cogging and lower torqueripple... no preferred rotor position due to absence ofstator teeth.High efficienciesll enables reduced statorresistance and winding losses.... no stator tooth saturation and reduced corelosses due to less stator iron.HP ranges (nominal)Subfractional to 10 HP, and beyondTorque ConstantsVoltage Constantsgured foreach application: typically, KT’s of 1 through 600oz.-in/amp and KE’s of 1 through 450 volts/1000RPM.Low noise levelselectrical hum.ux changes to generateLow speed performance... smooth, cogless, jitter-free direct driveoperation down to a few degrees per minute.High speed performance... no high frequency teeth losses for increasedciency.

Since 1926, <strong>Elinco</strong> International, Inc.ed variety of customspecialty electric motors in the fractional and lowintegral HP ranges to the highest quality and reliabilitystandards for military and industrial requirements.<strong>Elinco</strong>’s overall specialty motor capabilities also include:• <strong>Slotless</strong> <strong>Brushless</strong> motors - Form Wound• <strong>Slotless</strong> <strong>Brushless</strong> motors - Random Wound• Custom Air Moving Devices• <strong>Brushless</strong> <strong>DC</strong> <strong>Motors</strong><strong>Elinco</strong> International, Inc.Custom Quality480 Barnum Ave. BLDG 5, Box 4Bridgeport, CT 06608Phone: (203) 275-8885 • Fax: (203) 212-3747www.elincoinc.comSpecialty Electronic <strong>Motors</strong>Call, fax, or write to uswith your requirements