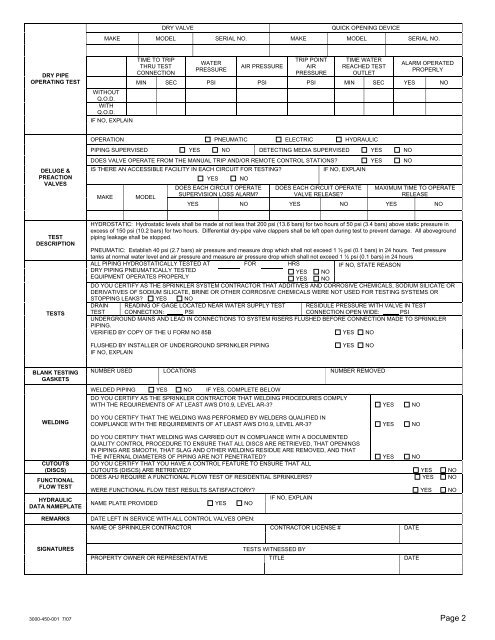

Contractors' Materials and Test Report for Aboveground Piping

Contractors' Materials and Test Report for Aboveground Piping

Contractors' Materials and Test Report for Aboveground Piping

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DRY VALVEQUICK OPENING DEVICEMAKE MODEL SERIAL NO. MAKE MODEL SERIAL NO.DRY PIPEOPERATING TESTWITHOUTQ.O.D.WITHQ.O.D.IF NO, EXPLAINTIME TO TRIPTHRU TESTCONNECTIONWATERPRESSUREAIR PRESSURETRIP POINTAIRPRESSURETIME WATERREACHED TESTOUTLETALARM OPERATEDPROPERLYMIN SEC PSI PSI PSI MIN SEC YES NODELUGE &PREACTIONVALVESOPERATION PNEUMATIC ELECTRIC HYDRAULICPIPING SUPERVISED YES NO DETECTING MEDIA SUPERVISED YES NODOES VALVE OPERATE FROM THE MANUAL TRIP AND/OR REMOTE CONTROL STATIONS? YES NOIS THERE AN ACCESSIBLE FACILITY IN EACH CIRCUIT FOR TESTING?MAKEMODELYESNODOES EACH CIRCUIT OPERATESUPERVISION LOSS ALARM?IF NO, EXPLAINDOES EACH CIRCUIT OPERATEVALVE RELEASE?MAXIMUM TIME TO OPERATERELEASEYES NO YES NO YES NOTESTDESCRIPTIONTESTSHYDROSTATIC: Hydrostatic levels shall be made at not less that 200 psi (13.6 bars) <strong>for</strong> two hours of 50 psi (3.4 bars) above static pressure inexcess of 150 psi (10.2 bars) <strong>for</strong> two hours. Differential dry-pipe valve clappers shall be left open during test to prevent damage. All abovegroundpiping leakage shall be stopped.PNEUMATIC: Establish 40 psi (2.7 bars) air pressure <strong>and</strong> measure drop which shall not exceed 1 ½ psi (0.1 bars) in 24 hours. <strong>Test</strong> pressuretanks at normal water level <strong>and</strong> air pressure <strong>and</strong> measure air pressure drop which shall not exceed 1 ½ psi (0.1 bars) in 24 hoursALL PIPING HYDROSTATICALLY TESTED ATFORHRSIF NO, STATE REASONDRY PIPING PNEUMATICALLY TESTEDYES NOEQUIPMENT OPERATES PROPERLYYES NODO YOU CERTIFY AS THE SPRINKLER SYSTEM CONTRACTOR THAT ADDITIVES AND CORROSIVE CHEMICALS, SODIUM SILICATE ORDERIVATIVES OF SODIUM SILICATE, BRINE OR OTHER CORROSIVE CHEMICALS WERE NOT USED FOR TESTING SYSTEMS ORSTOPPING LEAKS? YES NODRAIN READING OF GAGE LOCATED NEAR WATER SUPPLY TEST RESIDULE PRESSURE WITH VALVE IN TESTTEST CONNECTION: PSICONNECTION OPEN WIDE: PSIUNDERGROUND MAINS AND LEAD IN CONNECTIONS TO SYSTEM RISERS FLUSHED BEFORE CONNECTION MADE TO SPRINKLERPIPING.VERIFIED BY COPY OF THE U FORM NO 85BYES NOFLUSHED BY INSTALLER OF UNDERGROUND SPRINKLER PIPINGIF NO, EXPLAINYESNOBLANK TESTINGGASKETSNUMBER USED LOCATIONS NUMBER REMOVEDWELDED PIPING YES NO IF YES, COMPLETE BELOWDO YOU CERTIFY AS THE SPRINKLER CONTRACTOR THAT WELDING PROCEDURES COMPLYWITH THE REQUIREMENTS OF AT LEAST AWS D10.9, LEVEL AR-3?YESNOWELDINGDO YOU CERTIFY THAT THE WELDING WAS PERFORMED BY WELDERS QUALIFIED INCOMPLIANCE WITH THE REQUIREMENTS OF AT LEAST AWS D10.9, LEVEL AR-3?YESNOCUTOUTS(DISCS)FUNCTIONALFLOW TESTHYDRAULICDATA NAMEPLATEREMARKSDO YOU CERTIFY THAT WELDING WAS CARRIED OUT IN COMPLIANCE WITH A DOCUMENTEDQUALITY CONTROL PROCEDURE TO ENSURE THAT ALL DISCS ARE RETRIEVED, THAT OPENINGSIN PIPING ARE SMOOTH, THAT SLAG AND OTHER WELDING RESIDUE ARE REMOVED, AND THATTHE INTERNAL DIAMETERS OF PIPING ARE NOT PENETRATED?YES NODO YOU CERTIFY THAT YOU HAVE A CONTROL FEATURE TO ENSURE THAT ALLCUTOUTS (DISCS) ARE RETRIEVED? YES NODOES AHJ REQUIRE A FUNCTIONAL FLOW TEST OF RESIDENTIAL SPRINKLERS? YES NOWERE FUNCTIONAL FLOW TEST RESULTS SATISFACTORY? YES NOIF NO, EXPLAINNAME PLATE PROVIDED YES NODATE LEFT IN SERVICE WITH ALL CONTROL VALVES OPEN:NAME OF SPRINKLER CONTRACTOR CONTRACTOR LICENSE # DATESIGNATURESTESTS WITNESSED BYPROPERTY OWNER OR REPRESENTATIVE TITLE DATE3000-450-001 7/07 Page 2