EX1200-6 - Hitachi

EX1200-6 - Hitachi

EX1200-6 - Hitachi

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Built to last.Best in field.<strong>Hitachi</strong> mining excavators are designed, engineered,and manufactured to provide outstanding productivityand the lowest competitive cost of operation. Thenew EX-6 Series is based on the proven qualities of theUH Series of the 1970s, the first EX Series introduced in1988, and all subsequent improvements suggested byreal-life experiences from mines around the world.Many <strong>Hitachi</strong> shovels are still being efficiently operatedpast the 100,000-hour mark. And more than a few haveoutlasted the pit and sometimes even the mine theystarted to dig! It’s that legacy that has made the <strong>Hitachi</strong>mining excavators the leading brand year after year.2

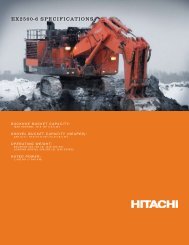

Engine — Cummins Tier 2PowerWeight — shovelWeight — BE backhoe<strong>EX1200</strong>-6QSK23C760 hp251,300 lb.(114 000 kg)246,900 lb.(112 000 kg)Bucket capacity — shovel 7.7–8.5 yd 3(5.9–6.5 m 3 )Bucket capacity — backhoe 3.93–8.8 yd 3(3.0–6.7 m 3 )3

Better all around.n SWITCHABLE POWERMODES: A power-modepackage produces moredeep-end power while allowingyou to also move to afuel-saving mode for lessdemanding work.n STRONGER BOOM, BIGGERBUCKET: Both standard andBE booms have thicker platesteel. Buckets are strongerand larger. Refined mechanismsproduce increased liftcapacity.n A FOUNDATION WITHMORE BRAWN: The largerdiameterswing bearingprovides increased reliabilityand durability, as well asimproved stability.4

n FASTER FRONT-ATTACHMENT SPEED,INCREASED OPERATING WEIGHT, ANDDIGGING FORCE: A combination of anew engine and an improved hydraulicsystem increases raise/swing speedsand digging force, while increasedoperating weight helps improve overallproduction.n ADDED FILTRATION:New in-line filtration on thedelivery side of the mainpumps enhances hydraulicsystem protection.n BETTER CAB ENVIRONMENT:Features include redesignedseat, armrests, short-strokefingertip-control levers, higher-capacity air conditioner, enlargedside window, rearviewmonitoring camera, and Alldigital,multifunction monitor.n SIMPLIFIED MAINTENANCE:Access walkway facilitatesservicing the engine andprimary filter elements.Inspection doors open wide.An auto dust ejector extendsair cleaner life.5

n Easy access to routine checkpoints and critical components.n Inspection doors openwide for easy maintenance.n Auto lubrication is standardfor the front attachment.n Easy to inspect side-by-sideradiator, oil cooler, and swingoutA/C condenser.6

Ensured reliabilitythrough strong dealers,simplified maintenance.It’s a big commitment.<strong>Hitachi</strong> mining excavators are sold and supported by a network oflocal dealers backed by the full force of <strong>Hitachi</strong>.The level of support provided depends on you, the excavator owner.Of course, through the warranty period, mechanics literally standby to ensure your shovel or backhoe provides full satisfaction. Butbeyond the warranty period, your <strong>Hitachi</strong> dealer is ready to provide,at a minimum, training, parts management, component rebuilds,and on-demand mechanic services. At the same time, each dealer isfully trained on equipment maintenance, repairs, and troubleshooting,and is capable of providing a full Maintenance and Repair Contract(MARC) for support at a competitive cost.<strong>Hitachi</strong> provides, on a worldwide basis, satellite-based remotemonitoring of all service functions, either separate or in conjunctionwith a variety of mine-management systems. Additionally, <strong>Hitachi</strong>provides parts backup both at the factories and at strategic partsdepots. The company factory-support managers are assigned tospecific mines and provide oversight to help ensure performanceregardless of the level of support chosen by the mine.n Control valves now featurean in-line filter to safeguardagainst contaminants.n Auto dust ejector extendsthe life of the filter.n A/C filter by cab door foreasy replacement.7

8n The all-new Rinko facility in <strong>Hitachi</strong>City uses a sophisticated demand-flowtechnology manufacturing system sothat each excavator is built to orderusing proven, assembly-line methodsand fixtures.

Bulletproofengineering.n The factory is located veryclose to port to ease logisitics.n All <strong>Hitachi</strong> mining excavators are made in Japan.Building the best machinesfor designated results.To maintain <strong>Hitachi</strong>’s leadership position in the field of miningexcavators, every component of each model is thoroughlyengineered, tested, revised, and tested again. Only then isthe machine allowed to go into the field as a preproductionmodel for a minimum of one year while <strong>Hitachi</strong> engineersconstantly monitor all components for correctness in designfunctionality. If all tests are passed, the model is introducedfor sale. The new EX-6 Series is no different. Preproductionmodels have been operating at select mines throughoutthe world, in varying conditions. During that period, variouscomponents have been modified and tested again. So theEX-6 model you buy really is not “new” — it’s the result ofthousands of hours of rugged use.In each of the multiple <strong>Hitachi</strong> manufacturing plants buildingmining excavators, state-of-the-industry tools, jigs, andmanagement processes are in place to ensure that each componentand each completed model, when assembled at theplant, is tested before final paint and is 100-percent “<strong>Hitachi</strong>ready” to go to work in your mine, quarry, or construction site.9

Exceptionallygreat production.Why do customers choose <strong>Hitachi</strong>?n High availabilityn Low operating costn Better fuel economyn Lower maintenance requirementsWe build machines designed to earn your trust. We believethat with <strong>Hitachi</strong>, you’re getting the best-operating hydraulicmining shovel or backhoe money can buy. Obviously a lotof customers agree. We have delivered over 600 units ofthe <strong>EX1200</strong> model and over 400 units of the previous modelsin the 90- to 110-ton class size to all parts of the world, manyto repeat customers.Less downtime means more production — and the EX-6Series features cutting-edge technologies for reducingdowntime and maintenance costs. For example, all modelsare equipped with a highly sophisticated monitoring system.The LCD monitor displays large gauges, warning lights, anddetailed information about maintenance intervals with pushbuttonease. There is also a convenient plug-in for downloadingthis same information to a PDA or laptop computer.Exceptional production also comes from the length of timeit takes to fill a truck. <strong>Hitachi</strong> mining shovels feature anexclusive auto-level crowd mechanism, allowing for easyone-lever crowding of the bucket into the material at a constantlevel, to keep a cleaner floor and increase bucket fill.<strong>Hitachi</strong>’s unique hydraulic system tops the industry forsmooth, combined bucket-tilt, boom-raise, and machineswingaction. The result is a consistent 25- to 30-secondloading effort, pass after pass, day after day.n BOOM-RECIRCULATION SYSTEM:Oil is efficiently recirculated in theboom circuit when the boom lowers,delivering more pressurizedoil to the arm from the pump toincrease arm-lowering speed incombined operation of the boomand arm.40-ton ADT EH750-3 EH1100-3Passes to fill Backhoe: 3–4 3–5 5–7<strong>Hitachi</strong> truck Front Shovel: 5–6 6–7Truck capacities 40-ton ADT EH750-3 EH1100-340 ton (35.7 tonnes) 42 ton (38.0 tonnes) 65 ton (59.0 tonnes)10

n BOOM/SWING MODES: The boomprioritymode increases boom-raisespeed to reduce cycle time whenswing angle is small in a cycle ofdigging, swinging, and dumping. Theswing-priority mode increases swingspeed when the swing angle is large.n MULTIFUNCTION: <strong>Hitachi</strong> hydraulicsare best-in-class for multifunctiontilt, raise, swing action, and fastpass speeds.n ERGONOMIC CONTROLS: Shortthrowpilot controls provide smooth,predictable fingertip operation withless movement and effort.11

Ergonomicexcellence.Comfort built right in.High production and low operating costs also come viakeeping an aggressive pace through-out the entire 10- to12-hour shift — no easy task regardless of operator skill level.n Short-throw levers providefingertip control.The ultra-comfortable, low-effort pilot controls of <strong>Hitachi</strong>EX-6 Series Excavators provide precise boom and bucketcontrol with less movement.The roomier seat and cab allow operators of all sizes tofeel comfortable and well-supported, with plenty of roomfor legs and feet.Each cab is well-insulated and temperature-controlled.The pressurized cab keeps dust out while maintaining acomfortable temperature, regardless of outside conditions.The heated, multi-position, air-suspension seat travels 10 1 /2inches, together or independently of the control console,so the operator can customize his working environment.n The color LCD monitordisplays operating andmachine-event information.n With standard remotecameras, the operator hasvirtually no blind spot.n Optional slide ladder giveseasier access to the cab andworking platform.12

n Elastic fluid-filled mountsreduce vibration and noise.n Controls are logically positioned within easy reach.The ergonomic layout of the cab means the operatorwill do less stretching and reaching when usingthe controls. Less operator fatigue means a moreaggressive pace at shift hours six through ten.The entire cab rests on a package of fluid-filledelastic mounts for reduced vibration and a morecomfortable ride.The cab design provides excellent visibility left, right,in front, and at a elevated height, so the operator islooking into the bed of the highest truck.13

14n IDLER PEDESTAL:Contact length is longer by 90percent to increase strengthand service life.n ENLARGED TRACK LINKS:Track links are enlarged toincrease strength for greaterdurability.n SOLID TRACK FRAME:A solid forged pedestal mountfor the swing bearing on thecenter track frame providesimproved reliability — a <strong>Hitachi</strong>exclusive.

A record ofhigh availability.All around the world.<strong>Hitachi</strong> mining excavators have gone to work around the worldsince 1979, and most are still in service. A package of five EX5500Shovels have worked thousands of hours each at the YanacochaMine, where they continue to be the only shovels used, with over96-percent availability. The PT Kaltim Prima Coal Mine has recognizedmultiple milestones beyond 100,000 hours of continuous operationwith their fleet of EX3500-class mining shovels.Simply put, mine operators find <strong>Hitachi</strong> excavators to be the mostdurably built machines in their class.n RIGID BOX-FRAME DESIGN:Resists bending and twisting forcesthanks to computer-aided analysis.n OPTIONAL FULL-LENGTHTRACK GUARDS:Protect the tracks against rocksand other objects.n SOFT-GROUND OPTIONS:Wider track shoes and longer undercarriageframes are available toimprove flotation in soft conditions.15

Worldwideequipmentmonitoring.High production comes from high uptime.Now, all appropriate personnel can haveinstant access via the Internet to informationfor preventive maintenance decisions.Anywhere. Anytime.For a number of years, each <strong>Hitachi</strong> excavator has been equippedwith a “black box” that continuously records engine-load factorsdisplayed in 15-minute increments, machine alarms and faults suchas high oil temperature, and daily operational hours.<strong>Hitachi</strong> has taken this to the next level by creating Global e-Service.In addition to the above, Global e-Service also tracks suggestedmaintenance intervals, dealer-input maintenance/service records,and GPS-based map information of machine location.Every day information is uploaded from the excavator via satelliteand made available for downloading and viewing through the Internet.Each time your local <strong>Hitachi</strong> dealer makes an inspection of themachine, his report is added to the information available for download.These reports can include nearly all possiblepredictive-testing results such oil sampling, vibrationanalysis, ultrasound, and thermographic studies.Managers at all levels within your organizationas well as anyone you designate, such as your<strong>Hitachi</strong> dealer and <strong>Hitachi</strong> corporate, can reviewthe information simultaneously for group discussionand planning. Preventive maintenance is the nameof the game, and this tool helps ensure there arefew, if any, surprises.It is <strong>Hitachi</strong>’s goal that unplanned maintenanceor repairs are minimized. We believe maintenanceshould be done with considerable forethought,which includes planned parts arrival, scheduledmechanics, and predetermined costs.Satellites(Option)MachineDATA LoggerDLUMMSREPORTSDownloadvia CablePC and PDAPDA*Download ProgramTransmit Downloaded DataPCData Viewer ProgramUploadvia InternetInternet(Server)Upon RequestCustomerDealers16

Global e-Service.e-Service allows you to gather critical data and more via your <strong>Hitachi</strong>onboard MIC — through the Internet — without any expensive software.The information available includes:n Machine location through GPS and Google Mapsn Current machine hoursn Machine-operation historyn Machine alarm and faultsn Maintenance historyn When you log in, a menuscreen will give you selectionoptions.n You can see how long andhard the machine has beenoperated on a daily basis.MachineInformationCenter (MIC)n The MIC continuouslyrecords the performanceof the engine and thehydraulic system. Therecord can then bedownloaded to a PDAor computer.n You can download theMIC data for viewing in theData Viewer program.n The EX-6 Series Excavatorsrecord four times more informationthan the EX-5 Series.n Track component hours forengine, pumps, and swing andtravel motors for maintenance.n Google Maps show the unit’slongitude and latitude.17

As good or betterthan OEM at less cost.High production requires scheduled maintenance on apredictive basis. Remanufacturing existing componentsis a <strong>Hitachi</strong> standard.Critical components totallyremanufactured to originalspec, and guaranteed.We embrace and encourage the quality remanufacturingof expensive components. Rarely are suchunits totally worn-out. <strong>Hitachi</strong> engineers provide allthe technical information necessary to enable the<strong>Hitachi</strong> Reman Center and your local <strong>Hitachi</strong> dealerto remanufacture critical components.*The <strong>Hitachi</strong> Reman Center, a totally owned in-housefacility that is ISO 9002-certified, tests and remanufacturesa wide range of hydraulic components,and provides a one-year, unlimited-hour (parts, labor,and collateral damage) warranty when installation isprovided an authorized dealer. These componentsare then inventoried at multiple factory locations forprompt shipment.Many <strong>Hitachi</strong> mining dealers have a significantindividual investment in remanufacturing technology,equipment, and manpower. They offer more localswap-out programs covering higher-maintenancecomponents such as cylinders and motors, as wellas the most common engine components.All <strong>Hitachi</strong> EX-6 Series Mining Excavators featureCummins engines, partly because of the significantremanufacture programs embraced by Cummins,with the worldwide Genuine ReCon Parts and othersupportive programs. These factory-remanufactured,tested, and warranted engine components provideguaranteed advantages to owners of <strong>Hitachi</strong> excavatorsvia timely and efficient before-failure maintenanceprograms.*All Reman components will have the latest design upgrades.n A fully computer-controlled operatingtest module tests components at maximumflows and pressures.18

<strong>Hitachi</strong> Reman CenterThis ISO 9002-certified center providesexpert remanufacturing of hydraulicpiston pumps, motors, cylinders, androtary manifolds (center joints) for<strong>Hitachi</strong> mining excavators.n Upon disassembly, hydraulicpumps and motors are thoroughlyinspected. Any part not meetingspec is discarded.n All cylinders are remanufacturedto original specifications for futurefield repairs.Support and trust.Your local <strong>Hitachi</strong> dealer is dedicated to making your<strong>Hitachi</strong> mining excavator the productive machine itwas built to be. To that end, each dealer has investedsubstantially to provide the mechanics, repair equipment,and service parts required for total maintenance, whereveryour mine might be.Through the Global e-Service program, you, your dealer,and <strong>Hitachi</strong> can ensure major preventive-maintenancecomponent replacements — new or remanufactured —arrive in a timely manner no matter the remotenessof the mine.Your satisfaction is our goal — your continued businessis our intention.n Center joints are remanufacturedto the latest <strong>Hitachi</strong> designspecifications.Cummins ReConn Cummins engines are factoryremanufactured to meet newengine-performance specifications.19

We are as passionate as ever about this industry.We are dedicated to building the best equipment in theworld, and we continue to support and improve them.ALWAYSPRODUCTIVEDKB1200HT Litho in U.S.A. (09-11)