Section 4: Composite artefacts (PDF 20858kb) - National Museum of ...

Section 4: Composite artefacts (PDF 20858kb) - National Museum of ...

Section 4: Composite artefacts (PDF 20858kb) - National Museum of ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

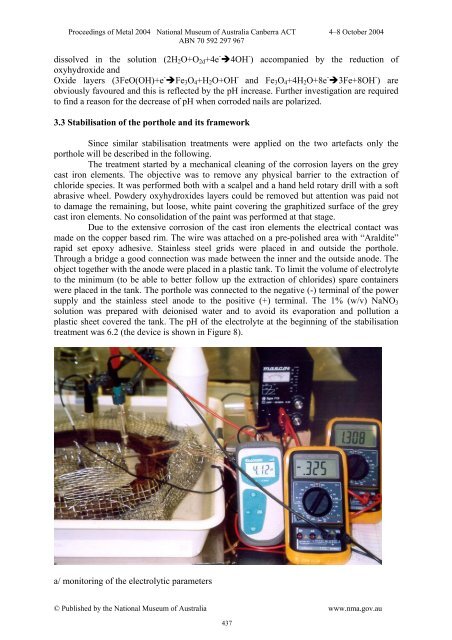

Proceedings <strong>of</strong> Metal 2004 <strong>National</strong> <strong>Museum</strong> <strong>of</strong> Australia Canberra ACT 4–8 October 2004ABN 70 592 297 967dissolved in the solution (2H 2 O+O 2d +4e - 4OH - ) accompanied by the reduction <strong>of</strong>oxyhydroxide andOxide layers (3FeO(OH)+e - Fe 3 O 4 +H 2 O+OH - and Fe 3 O 4 +4H 2 O+8e - 3Fe+8OH - ) areobviously favoured and this is reflected by the pH increase. Further investigation are requiredto find a reason for the decrease <strong>of</strong> pH when corroded nails are polarized.3.3 Stabilisation <strong>of</strong> the porthole and its frameworkSince similar stabilisation treatments were applied on the two <strong>artefacts</strong> only theporthole will be described in the following.The treatment started by a mechanical cleaning <strong>of</strong> the corrosion layers on the greycast iron elements. The objective was to remove any physical barrier to the extraction <strong>of</strong>chloride species. It was performed both with a scalpel and a hand held rotary drill with a s<strong>of</strong>tabrasive wheel. Powdery oxyhydroxides layers could be removed but attention was paid notto damage the remaining, but loose, white paint covering the graphitized surface <strong>of</strong> the greycast iron elements. No consolidation <strong>of</strong> the paint was performed at that stage.Due to the extensive corrosion <strong>of</strong> the cast iron elements the electrical contact wasmade on the copper based rim. The wire was attached on a pre-polished area with “Araldite”rapid set epoxy adhesive. Stainless steel grids were placed in and outside the porthole.Through a bridge a good connection was made between the inner and the outside anode. Theobject together with the anode were placed in a plastic tank. To limit the volume <strong>of</strong> electrolyteto the minimum (to be able to better follow up the extraction <strong>of</strong> chlorides) spare containerswere placed in the tank. The porthole was connected to the negative (-) terminal <strong>of</strong> the powersupply and the stainless steel anode to the positive (+) terminal. The 1% (w/v) NaNO 3solution was prepared with deionised water and to avoid its evaporation and pollution aplastic sheet covered the tank. The pH <strong>of</strong> the electrolyte at the beginning <strong>of</strong> the stabilisationtreatment was 6.2 (the device is shown in Figure 8).a/ monitoring <strong>of</strong> the electrolytic parameters© Published by the <strong>National</strong> <strong>Museum</strong> <strong>of</strong> Australia www.nma.gov.au437