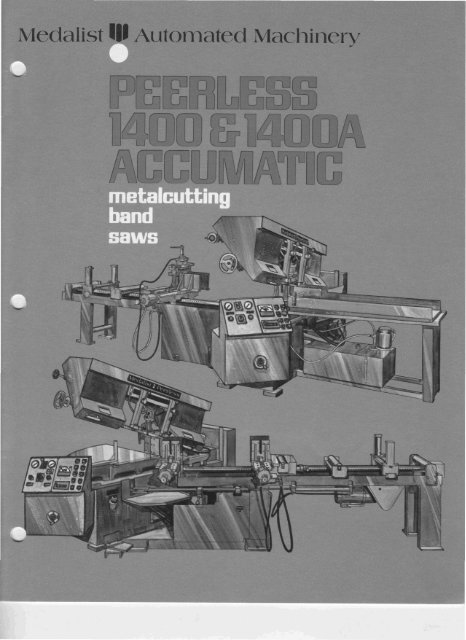

Peerless 1400 and 1400A Accumatic Metal Cutting Bandsaws

Peerless 1400 and 1400A Accumatic Metal Cutting Bandsaws

Peerless 1400 and 1400A Accumatic Metal Cutting Bandsaws

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BASIC DESIGNFEATURESMODEL <strong>1400</strong>Medalist <strong>Peerless</strong> <strong>1400</strong> series high speed horizontalb<strong>and</strong> saws incorporate many proven design featuresthat meet application requirements in a wide varietyof cut off operations. Both the <strong>1400</strong> <strong>and</strong> <strong>1400</strong>Amodels include:HEAVY DUTY CONSTRUCTION begins with a ruggedsaw frame fabricated from ~ " steel plate. The viseis cast iron. The conveyor <strong>and</strong> discharge tables arestructured with 18 inch wide 45 pound channel iron,<strong>and</strong> the carriage components are made of durablecastings <strong>and</strong> fabricated steel.BLADE DRIVE WHEELS are 18 inches in diameter<strong>and</strong> are made from cast ductile iron. The two wheelsrotate on heavy duty ball bearings, an important factorin maintaining proper blade tension.SAW FRAME is set at a unique 45 ° angle reducingblade twist <strong>and</strong> minimizing stress <strong>and</strong> wear. The framepivots on two wide-spread anti-friction bearingsassuring necessary stability. Accuracy is± .00 2 per inch of cut.ROLLER BEARING BLADE GUIDES <strong>and</strong> power drivencleaning brush help assure longer blade life. Bladechanging is quick <strong>and</strong> convenient, keeping "downtime"to a minimum.TWENTY GALLON COOLANT SYSTEM deliverscoolant at a rate of 3 gallons per minute to thecritical area during operation.MODEL <strong>1400</strong>AThe <strong>Peerless</strong> <strong>1400</strong>A includes all the above basicdesign features. In addition, this saw is capable ofcutting angles down to 37° by incorporating aPRECISE BLADE TENSIONING on <strong>Peerless</strong> sawscan be accomplished w ith a st<strong>and</strong>ard manually adjustedspring loaded system or an optional hydraulicpowered device is available if required . A safetyswitch that shuts the saw down in case of bladebreakage is st<strong>and</strong>ard.HEAVY DUTY BALANCE SPRING neutralizes theweight of the saw frame allowing positive controlledfeed that is not effected by outside forcesor disturbances.POSITIVE HYDRAULIC FEED measured from 0-400pounds makes it possible to select the best feedpressure for various machineable materials, thushelping to preserve blade life.VERSATILE-FRAME CONTROL SYSTEM providescontrolled rate of descent when cutting various shapes<strong>and</strong> cross sections. It also includes a unique slowapproach <strong>and</strong> slow exit system that protects blades<strong>and</strong> minimizes deburring operations.ACCURATE AUTOMATIC INDEXING of stock in 1,;8 "to 72" lengths in one shuttle stroke. Saves time!Conveyor indexing accuracy is ± .0 0 2 , whichoften can save material <strong>and</strong> time <strong>and</strong> eliminatesecondary operations.VARIABLE VISE PRESSURE system allows proper<strong>and</strong> exact pressures for clamping solids or tubing.Holding materials firm for accurate cutting withoutdistortion or damage is an important consideration.hydraulically controlled pivot mounted base . Desiredangle settings are quick <strong>and</strong> simple to make, withaccurate read out on a linear protractor. Material feedis from the opposite direction of the Model <strong>1400</strong><strong>and</strong> control panels on both machines are located sothat when set in pairs, one operator can monitor bothmachines. (See DIMENSIONAL DATA) .

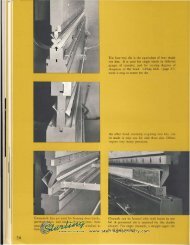

BLADE GUIDES: <strong>Peerless</strong> roller bearing blade guideseliminate sliding friction that causes stress on blades.The side rollers are easily adjusted to accommodatevarious blade thicknesses. A grooved pressure rollersupports the blade at the top edge, <strong>and</strong> carbide facedwipers help dampen vibration <strong>and</strong> clean the bladesurfaces. This guide system is one of the best,contributing to accurate <strong>and</strong> economic cutting <strong>and</strong>longer blade life.BLADE DRIVE: A variable speed sheave mechanismconnected to a 5 horse power, 1800 RPM motorprovides blade speed range of 50 to 450 FPM. Desiredblade speed is selected at the operators control panelwhere a tachometer monitors the settings. Directlinkage between the speed selector h<strong>and</strong> wheel <strong>and</strong> thespeed sheave mechanism makes this operation fast<strong>and</strong> accurate. A massive belt-slack tensioner transfersthe power from the motor <strong>and</strong> sheave mechanism to agear box that houses a ring <strong>and</strong> pinion drive to theblade. Integral with this blade drive housing is thepivot point of the saw frame, assuring maximumstrength at this critical point.FEED SYSTEM: <strong>Peerless</strong> designincorporates a counter balance springto neutraIize the weight of the sawframe. This enables the frame controlcylinder to exert a positive <strong>and</strong> virtuallyconstant force, uneffected by gravity,throughout the entire downwardmovement of the saw frame. The rateof descent is always under controlthrough a hydraulic metering devicein the frame control valve. Whencutting tubing or structural shapes it isextremely important to be able to varythe rate of descent but not the feedforce. The <strong>Peerless</strong> feed system assuresproper feed force <strong>and</strong> rate throughboth dense <strong>and</strong> thin area s of materialin the same cut.

MODEL<strong>1400</strong>ACUTTING AREA: The cutting area of the <strong>Peerless</strong> <strong>1400</strong>ser ies b<strong>and</strong> saws inc lude such st<strong>and</strong>ard features as:A n ad justable stock guide that prevents material fromrolling back under the blade after cut-off. A cuttingarea work light. Replaceable wea r plates in the visebase <strong>and</strong> jaws. A var ia bl e height selector fo r settingdesir ed fr ame height ret urn after each cut. A gangswitch housing th at in cludes t he f rame up - framedown co nt rol as we ll as the cam actuators that con tro lthe slow approach/exit feature. A retractable bla deguard t hat covers the unused portion of the blade• Vise jaws that are pre-drilled <strong>and</strong> tapped to acceptthe ove rhead clamping accessory (shown aboveon the <strong>1400</strong>A).The operator control panels are conveniently locatedat the end of the saws, in a fixed position away fromthe cutting area. Once the initial stock length setting ismade <strong>and</strong> the guide arms <strong>and</strong> vise jaws are properlypositioned for different size stock, all operationsare selected at this central panel. Electrical <strong>and</strong>hydraulic components are separated, a feature thatmakes service <strong>and</strong> inspection easy. The followingcontrols are shown in the photograph (fromleft down to right).1. Blade feed pressure indicator (0-400 psi).2. Variable blade pressure valve.3. Frame control lever (up-hold-down) .4. Frame descent selector (three varied rates) .5. Variable vise pressure indicator (60-165 Ibs .).6. Variable vise pressure valve.7. Blade speed tachometer (50-450 FPM).8. Preset counter, press button count-down type.9 . Double shuttle selector switch (optional).10. Automatic cycle indicator light.11. Four position selector switch.(1) Clamp carriage vise for manual stockmovement.(2) Indicates all functions neutral.(3) Clamp machine vise.(4) Automatic cycle mode.12 . Slow approach/exit switch.13. Main power "on" indicator light.14. Double shuttle function indicator light.15. Hydraulic & coolant pump, <strong>and</strong> blade start switch.16. All STOP button.17. Manual carriage "in" selector.18. Manual carriage " out " selector.19. Variable blade speed control h<strong>and</strong>wheel.20. Location of coolant flow valve.

AUTOMATICNDEXING ANDCONVEYORSYSTEMJThe <strong>Peerless</strong> st<strong>and</strong>ard automatic indexing systemwill index from 1,Ia" up to 72" length settings in onesingle shuttle. This saves time in production cutting.Optional double shuttle feature is available forindexing up to 144". The conveyor frame is massiveenough to support 6000 Ibs . of material, <strong>and</strong> longenough to eliminate the need for auxiliary stock rollertables in most cases . The spring cushioned visecarriage mechanism houses a horizontal stock ro ller<strong>and</strong> is chain driven to positive stops at both ends ofthe conveyor table, assuring indexing accuracy of ±.002". The carriage vise moves on roller bearingwheels tracked with enough lateral tolerance toaccommodate crooked stock. Variable vise pressureis a st<strong>and</strong>ard feature on the carriage vise as wellas the base vise.THE CARRIAGE CHAIN DRIVE is powered by a 1 hp. .1200 RPM, T.E.F.e. motor, integrally housed withan electric brake <strong>and</strong> reduction unit providingcarriage travel of 12 FPM.THE CARRIAGE INDEX length setting adjustmentprovides for one inch incremental settings with" thum b-screw pin". Fine setting to thous<strong>and</strong>ths of aninch is made with a 1Y2"-16 threaded collar<strong>and</strong> lock nut.

OPTIONS &ACCESSORIESHYDRAULIC BLADE TENSIONING may be desiredunder certain operating conditions. It can easily beincluded in the basic saw <strong>and</strong> comes with factory setposition indicators provid ing accurate automaticadjustments.OVERHEAD CLAMPING FIXTURES for nest ed, orstacked stock cutting are avai lable with "qui ck connectcouplings" f or any v ise on the machine . Capacity7" high x 10 " wide.AUTOMATIC CHIP CONVEYOR hydraulically driven,with a bin cart provides efficient <strong>and</strong> fast removalof chips.•DOUBLE SHUTTLE CONVEYOR indexing systemfor automatic indexing up to 144" is available as anoption to the st<strong>and</strong>ard 72" indexing system.VERTICAL GUIDE ROLLERS or extra Horizontal StockRollers are available where nesting or heavy stockh<strong>and</strong>ling is anticipated.OTHER OPTIONS INCLUDE:Outboard ViseRoller Stock Tables1~" Blade18" Width Capacity (<strong>1400</strong>)Special ElectricsSpecial PaintSpecial H<strong>and</strong>ling Equipment

<strong>1400</strong>ASCALED DIMENSIONS<strong>1400</strong> <strong>1400</strong>AA 90" A 95"B 52" B 57"C 29" C 34"D 132" D 134"E 183" E 170"F 103" F 105"G 80" G 82"H 52" H 32"I 106" I 114"11EIldr== I-.!= \;;;;l~ ~E<strong>1400</strong>A<strong>1400</strong>~r-r- --,, -,,,,\\--,,~HG-----l~F-----;oG .1F:1

MODEL <strong>1400</strong> <strong>1400</strong>ACAPACITIES 12"x 16" 12"x18"12%" round 12%" round45 ° -9"x11%"BLADE SIZE 1" x .035" x 144" 1" x .035" x 148"BLADE DRIVE WHEELSBLADE DRIVE MOTORBLADE SPEED - VARIABLECast ductile iron, 18" diameter with double ball bearings <strong>and</strong> grease f itting.5 HP (3.75kw) 1800 RPM50-450 Feet Per M inuteBLADE TWIST ANGLE 45°BLADE TENSION CONTROLBLADE GUIDE SYSTEMSpring loaded-manualRoller bearing blade guides with carbide faced wipers.HYDRAULIC SYSTEM 11 gallon capacity tank with replaceable filter; 3 GPM vane pump with1 HP (.75 kw) 1800 RPM motor.COOLANT SYSTEMSTOCK INDEXING SYSTEMCONTROL PANEL1/10 HP (.075kw) TENV motor self contained with 3 GPM submerged pumpin 20 gallon tank.Chain driven carriage by 1 HP (.75kw) 1200 RPM TEFC motor integrallyhoused with electric brake <strong>and</strong> reducti on un it providing 12 FPM carriagetravel. Gauging adjustable from .125" -72" in thous<strong>and</strong>ths.Fixed location at machine's end with sepa rate oil proof enclosures for electrical<strong>and</strong> hydraulic controls .ELECTRICALMachine wired for 230 or 460 volt, 60 cycle, 3 phase current, NEMA 12 enclosure<strong>and</strong> accordance to J.I.C. EGP-1 (1967) .STANDARD COLORS Vista Green, Safety Blue or Machine Grey.-jWORK TABLE HEIGHT 29" 34"NET WEIGHTSTANDARD EQUIPMENT55001bs.6000 1bs.Work light. power driven blade brush. flushing hose. blade breakage limitswitch. electric tachometer. preset 4 digit counter. conveyor out of stockshut off • vise jaws with replaceable wear plates. variable vise pressure• slow approach & exit of blade. saw blade guard. chip d rawer & rake• variable height frame return selector • hydraulic fluid • saw blade• auxiliary horizontal stock roller.r-90"ANGLETHE COMPLETE LINE OF PEERLESS HIGHSPEED BAND. POWER HACK AND MECHANICUT SAWS IS AVAILABLE FROM YOURMEDALIST REPRESENTATIVE:H EI GHT18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0W IDTHANGLE CUT CAPACITY CHART EXAMPLE:At 50 '0, hei ght capacity is 9", width ca paci ty is 12%",<strong>and</strong> round capacity is 11".Medalist III Automated Machinery•P.O BOX 2708 OSHKOSH, WISCONSIN 54901(414)231-4100LITHO IN U.S.A .B-<strong>1400</strong>-A -576-5M