Mine Closure Planning - WME magazine

Mine Closure Planning - WME magazine

Mine Closure Planning - WME magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

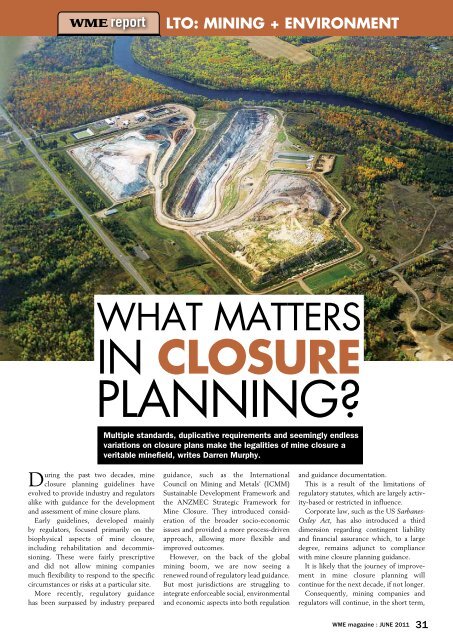

eportLTO: MINinG + ENVIRONMENTWhat mattersin closureplanning?During the past two decades, mineclosure planning guidelines haveevolved to provide industry and regulatorsalike with guidance for the developmentand assessment of mine closure plans.Early guidelines, developed mainlyby regulators, focused primarily on thebiophysical aspects of mine closure,including rehabilitation and decommissioning.These were fairly prescriptiveand did not allow mining companiesmuch flexibility to respond to the specificcircumstances or risks at a particular site.More recently, regulatory guidancehas been surpassed by industry preparedMultiple standards, duplicative requirements and seemingly endlessvariations on closure plans make the legalities of mine closure averitable minefield, writes Darren Murphy.guidance, such as the InternationalCouncil on Mining and Metals’ (ICMM)Sustainable Development Framework andthe ANZMEC Strategic Framework for<strong>Mine</strong> <strong>Closure</strong>. They introduced considerationof the broader socio-economicissues and provided a more process-drivenapproach, allowing more flexible andimproved outcomes.However, on the back of the globalmining boom, we are now seeing arenewed round of regulatory lead guidance.But most jurisdictions are struggling tointegrate enforceable social, environmentaland economic aspects into both regulationand guidance documentation.This is a result of the limitations ofregulatory statutes, which are largely activity-basedor restricted in influence.Corporate law, such as the US Sarbanes-Oxley Act, has also introduced a thirddimension regarding contingent liabilityand financial assurance which, to a largedegree, remains adjunct to compliancewith mine closure planning guidance.It is likely that the journey of improvementin mine closure planning willcontinue for the next decade, if not longer.Consequently, mining companies andregulators will continue, in the short term,<strong>WME</strong> <strong>magazine</strong> : june 2011 31

LTO: mining + environmentto be frustrated by multiple standards,duplicative requirements and seeminglyendless variations on closure plans to satisfydifferent internal and external obligationsacross geographies and jurisdictions.It is not uncommon for companies toprepare two closure plans, one for theregulator and another for corporate.Some larger mining companies haveattempted to solve this problem by establishinginternal standards and guidancethat try to deliver an integrated planningprocess that satisfies all obligations.These standards are starting to build onearlier guidance and capture the essence ofboth regulatory and industry requirements.Early signs are now visible that regulatoryguidance may follow suit.Despite the frustration, it is notsurprising that the common elements ofindustry and regulatory guidance that arenow emerging are based on common senseand sound planning logic.The challenge remains how to integratethese seemingly non-core business planningactivities into both day-to-day and strategicplanning activities, such that mine closurebecomes a mutually beneficial outcomerather than an apparently cumbersomecompliance target.Corporate and regulatory balanceSo what are the key aspects of closureplanning that matter and that deliver bothregulatory and corporate success?They generally cover both biophysicaland socio-economic elements andinvolve multi-disciplinary collaboration.They are overseen by empowered steeringcommittees with strong links to stakeholderreference groups. And, withoutdoubt, they require commitment by thecompany and trust by the regulator.The aspects that matter are as follows:n Developing a technically soundknowledge base and prioritised program toaddress critical knowledge gaps;n Establishing a clear vision for closureaddressing broad company and stakeholderexpectations and aspirations;n Progressive investigation, and risk-basedassessment, of alternative closure optionsagainst sustainability principles and agreedcompletion criteria (see Fact File);n Continual refinement of prescriptivemeasures and activities to achieve thepreferred closure option;n Establishing functionally-based closuremanagement plans linked to managementperformance criteria and accountabilities;andfact file: Weighing up closure configurations<strong>Mine</strong> closure planning tools can help balance negative impacts and risks with the positiveopportunities and legacies among the complex range of possible configurations.The method used by SKM integrates the techniques of multi-criteria analysis, risk analysisand cost-benefit analysis into a single approach to the planning process.The key is the identification and prioritisation of decision criteria to provide a balancedscorecard of statutory requirements, corporate policies, potential risks and desiredobjectives. Each configuration is assessed against these criteria using a transparent processbased on weighting (to avoid bias), relative rank and cost.Once the preferred closure configuration is decided, the technique also helps identify riskand opportunity management strategies to ensure the configuration reaches its full potential.Early versions of the tool relied heavily on traditional risk assessment methodologies, butthese were found to be cumbersome. SKM risk professionals working in different industrysectors, particularly in the Australian Defence Force, were consulted to investigate alternativeand lateral approaches. The Kepner Trego Multi-Criteria was adopted and adapted to theneeds of mine closure planning.n Preparing well-documented and probabilisticallyassessed closure cost estimates.The degree to which each of theseplanning aspects is developed, and thedetail in which the mine closure plan ispresented, will vary depending on thephase of project development, as wellas the context of the environmental andsocio-economic setting.These aspects are iterative and it wouldbe expected that both short-term andlong-term planning cycles are establishedto ensure robustness and improvementwithin the mine closure plan.Construction and closure meetWhile there may be some contentionbetween a regulator and a mining companyregarding the level of mine closure planningrequired at each phase of mine life, it isgenerally expected that a closure plan atthe time of mine construction should beat a level equivalent to an engineering prefeasibilitystudy, with progressive planningactivities leading toward an engineeringfeasibility level of study within the firstfive years of mine life.The mine closure plan would then beexpected to develop in its complexity anddetail as a mining operation progressesthrough its life, with an execution levelof detail being reached five years beforescheduled closure.Regardless of the developmental phase,a mine closure plan must identify, addressand prioritise activities based on significantrisks. As with many other aspects of projectdevelopment, mine closure planningprovides opportunity for significant risksto be designed out, or mitigated throughengineered controls, such that operationalcompliance issues are minimised.These risks may vary based on the environmentaland social setting of the specificsite. Common risks however include acidmine drainage, reduced visual amenity, landsubsidence and erosion, reduced quality ofbeneficial groundwater resources, loss ofemployment opportunities and limitationof community capacity.Darren Murphy is principal environmentalscientist and mine closure specialist withSinclair Knight Merz.32 JUNE 2011 : <strong>WME</strong> <strong>magazine</strong>