Industry Initiative

Industry Initiative

Industry Initiative

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

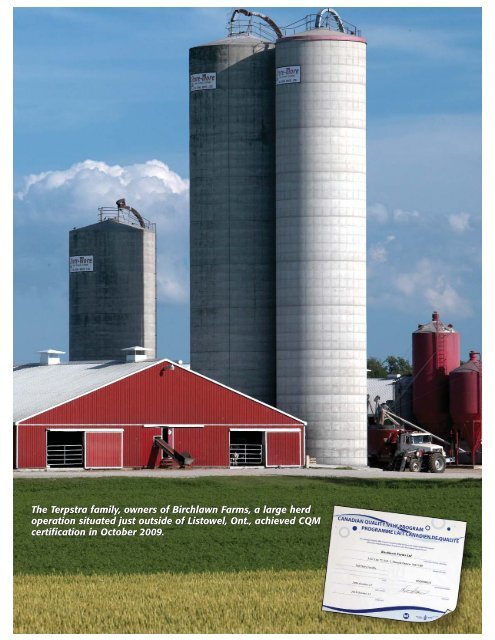

The Terpstra family, owners of Birchlawn Farms, a large herdoperation situated just outside of Listowel, Ont., achieved CQMcertification in October 2009.

COVERSTORY By Sharon Laidlaw/Photos By David Barr<strong>Industry</strong> <strong>Initiative</strong>How two farm families embraced Canadian Quality Milk programWhen Dairy Farmers of Canada (DFC)committed to develop a national onfarmfood safety program, dairyfarmer Brian Terpstra knew it was a move inthe right direction for the industry.The Canadian Quality Milk(CQM) program’s motto of doingwhat you say, saying what you do,then proving it, is a concept Brianfirmly believes in. These principlesare at the heart of Birchlawn Farms,a family farm operation run by Brian,his five siblings and parents.“By implementing the CQM program,you realize the benefits it canbring to your farm and the entireindustry,” says Brian. “I think thebenefits far outweigh the time it takesto go through the process.”Nestled in fertile land just outsideof Listowel, Ont., Birchlawn Farmsincludes a 1,200-head herd, 520 ofthem milking, a 900-sow farrowingunit, 300 veal calves, and more than2,000 acres of cropland. The Terpstrasalso raise their own heifers.Managing such a large operation isno small feat. Record-keeping andquality control are part of day-to-daymanagement on the farm, says Brian.He, his dad Nick, mom, Catherine,and siblings Darryl, Cheryl, Steve,Scott and Dwayne are all shareholders.The Terpstras also employ twofull-time and four part-time staff.From left to right, Brian Terpstra, mom, Catherine and dad, Nick, Listowel Vet Clinic veterinarian Dr. Kelly Barratt.MilkPRODUCER | April 2010 | 27

sumer trust,” says Kelvin,who milks 23 Holsteinson the 130-acre farm.“We, as producers, areresponsible to the consumerto provide theinformation to supportour claim that Canadianmilk is of high-quality.Consumers have choices,so we have to make surewe can compete.”“Producers need to startthinking beyond their ownfarm gate and to the entireindustry,” says Hamilton.“The program’s successdepends on the attitudesof every producer in thedairy industry.”“A large portion ofCQM is having permanentrecords of all treatments,”says Brian, whospoke about the programat the South WesternOntario Dairy Symposiumin February.“You don’t know whatworks and what doesn’t ifyou don’t know what thecow had for treatment.The more information youhave for yourself and youradvisers, the more you will knowabout what is happening in yourherd.”Do what you saythen back it upListowel Vet Clinic veterinarian Dr.Kelly Barratt praises the Terpstras fortheir record-keeping habits. She saysveterinarians can be instrumental inhelping producers get started.“Your veterinarian can help youwith initial set-up, such as establishingtreatment protocols and reviewingyour records,” she says. “Havingveterinary involvement is not mandatory,but it certainly could work toyour benefit.”She emphasizes a vet’s role goes farbeyond routine cow checks.“If you don’t keep records, or onlyrecord events when something goeswrong, then this could be a hugechange,” she says. “CQM should beDairy farmer Kelvin Kerr received his CQM certificate inDecember 2009. He says CQM lets producers demonstratethey’re doing best job they can.an ongoing conversation betweenyourself, your vet and any staff youmay have working on your farm.”Barratt also warns producers thatextra-label drug use will require a vetprescription identifying the drugbeing used, method of use and treatmentduration, as well as the appropriatewithdrawal dates for milk andmeat.“If there’s an issue, you can lookback and trace where the problembegan. Having proper documentationlets you compare records to see whatworks best,” she says.“It’s also a matter of traceability,”says Brian. The Terpstras workedclosely with Barratt to design treatmentprotocols, drug lists and writingscripts for their off-label treatments.“If the CFIA (Canadian FoodInspection Agency) does an investigationyou have something to standon—your records,” he says.Photo supplied by Kelvin Kerr.As part of the program,farmers have to developwritten standard operatingprocedures (SOPs) forpre- and post-milking,livestock medicines andanimal identification. Thisensures everyone followson-farm procedures basedon best-management practices,says Hamilton.Keeping records on howyou manage your dairyoperation is also required.And because many producersare already practisingmost CQM requirements,implementing theprogram should not overburdenproducers, headds.“It doesn’t have to becomplicated,” Hamiltonsays. “Sometimes the processcan be as simple asjotting down a note on acalendar. You can also usethe yellow CQM binderwith templates for all therecords you’ll need.”Pick your methodAnother option is theCanWest DHI log book,supplemented with some of the CQMtemplates. As well, five dairy managementsoftware programs are CQMapproved,and can provide mostrequired records.“You do not have to use the CQMtreatment record provided in theworkbook. You can use a journal orcomputer program to record treatments.The goal is to get it writtendown. That’s the focus,” Hamiltonsays.Corrective action plans (CAPs)contain detailed instructions on howto fix or follow-up on specific problems,such as your milk not coolingproperly, or a treated cow being accidentallymilked.Producers must record all needlesgiven to each cow. When giving multipleneedles to your whole herd, suchas a vaccination, only one entry inyour log book stating what type ofinjection was given is required.MilkPRODUCER | April 2010 | 29

“Most producers already recordtreatments so for the majority it’s nota lot of extra paper work. There arealso software programs and logbooks to make it easier,” saysHamilton.DairyComp 305, a software programmarketed in Canada by Can-West DHI, contains a CQM modulethat lets you set-up all your SOPs andcorrective action plans. However, acopy of your SOPs must also be onDFO’s online Wizard.“It (DairyComp) was fairly simpleto use,” says Brian. The Terpstrasstarted using the software in 1998.“Everything was listed and exampleswere used. I just had to change themto fit our set-up. There was really noextra labour required. The data onlyneeds to be reviewed yearly. Otherthings, such as the milking equipmentchecklist, only need to be donemonthly. Doing so means problemscan be detected well before theybecome a penalty.”Kelvin, who uses a farm recordkeepingprogram he developed 10years ago, says the biggest start-upcost was having his dealer come tothe farm to do a wash analysis. “Itcost us about $300,” he says.The wash analysis has to be doneevery year as a program requirement,along with yearly maintenance of themilking system, says Hamilton. Manyproducers already do this throughtheir dealers.Starting next year, the Kerrs will dothe wash analysis with their yearlymaintenance, eliminating the cost tohave their dealer come to the farm fora second visit. They also purchasedan animal-proof container to storetheir calf starter for about $75. “Tome, a total cost of $375 to implementthe program was very small consideringthe long-term benefits,” saysKelvin.Promoting safetyat program’s coreIn 1997, when DFC developed theCQM program, its goal was to createa program that was practical toimplement on the farm. Dairy producersare among 20 agricultural sectorsdeveloping or implementing onfarmfood safety programs in partnershipwith government.“Producers have many things comingat them—Johne’s, CQM, amongother issues—they’re intimidated andI understand their feelings of wantingto be their own boss,” says Brian.“However, we have to think aboutconsumers and the fact they want tofeel safer about the foods they’re consuming.Accepting this reality willhelp us see the big picture and realizethe positive impact this program willhave on the entire industry.”Record-keeping procedures can beas simple as jotting down a noteon a calendar or using the templatesin the yellow CQM binder.“We have to think about consumersand realize the positive impact thisprogram will have on the entireindustry.”— Brian Terpstra30 | April 2010 | MilkPRODUCER