Monolayer Coatings for Commercial Vehicles - Emil Frei GmbH & Co.

Monolayer Coatings for Commercial Vehicles - Emil Frei GmbH & Co.

Monolayer Coatings for Commercial Vehicles - Emil Frei GmbH & Co.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

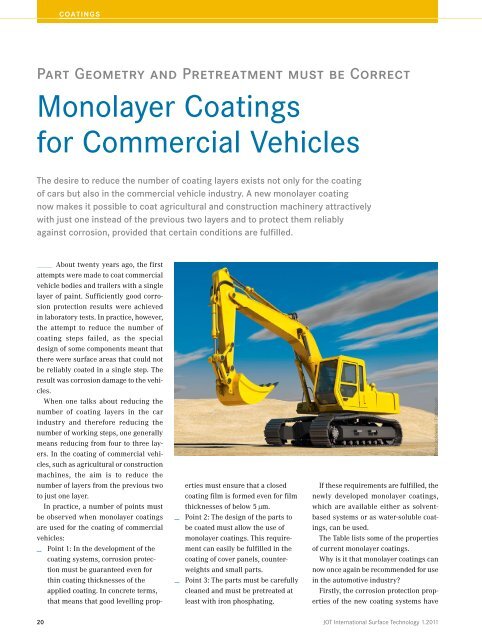

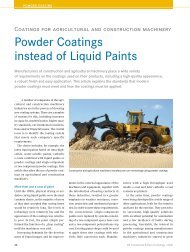

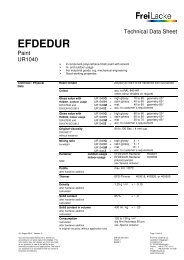

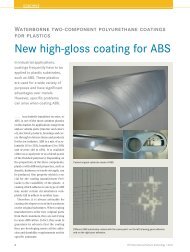

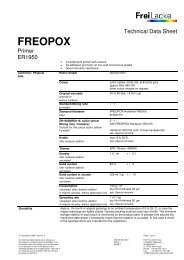

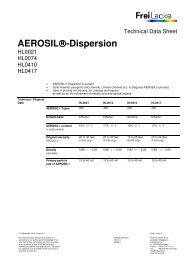

coatingsPart Geometry and Pretreatment must be <strong>Co</strong>rrect<strong>Monolayer</strong> <strong><strong>Co</strong>atings</strong><strong>for</strong> <strong><strong>Co</strong>mmercial</strong> <strong>Vehicles</strong>The desire to reduce the number of coating layers exists not only <strong>for</strong> the coatingof cars but also in the commercial vehicle industry. A new monolayer coatingnow makes it possible to coat agricultural and construction machinery attractivelywith just one instead of the previous two layers and to protect them reliablyagainst corrosion, provided that certain conditions are fulfilled._____ About twenty years ago, the firstattempts were made to coat commercialvehicle bodies and trailers with a singlelayer of paint. Sufficiently good corrosionprotection results were achievedin laboratory tests. In practice, however,the attempt to reduce the number ofcoating steps failed, as the specialdesign of some components meant thatthere were surface areas that could notbe reliably coated in a single step. Theresult was corrosion damage to the vehicles.When one talks about reducing thenumber of coating layers in the carindustry and there<strong>for</strong>e reducing thenumber of working steps, one generallymeans reducing from four to three layers.In the coating of commercial vehicles,such as agricultural or constructionmachines, the aim is to reduce thenumber of layers from the previous twoto just one layer.In practice, a number of points mustbe observed when monolayer coatingsare used <strong>for</strong> the coating of commercialvehicles:__ Point 1: In the development of thecoating systems, corrosion protectionmust be guaranteed even <strong>for</strong>thin coating thicknesses of theapplied coating. In concrete terms,that means that good levelling propertiesmust ensure that a closedcoating film is <strong>for</strong>med even <strong>for</strong> filmthicknesses of below 5 µm.__ Point 2: The design of the parts tobe coated must allow the use ofmonolayer coatings. This requirementcan easily be fulfilled in thecoating of cover panels, counterweightsand small parts.__ Point 3: The parts must be carefullycleaned and must be pretreated atleast with iron phosphating.Photo: apfelweile - Fotolia.comIf these requirements are fulfilled, thenewly developed monolayer coatings,which are available either as solventbasedsystems or as water-soluble coatings,can be used.The Table lists some of the propertiesof current monolayer coatings.Why is it that monolayer coatings cannow once again be recommended <strong>for</strong> usein the automotive industry?Firstly, the corrosion protection propertiesof the new coating systems have20 JOT International Surface Technology 1.2011

BIS ZU60%ENERGIE SPARENMIT ENERCOAT ®www.wurster.netPropertiesSolvent-basedmonolayer coatingWater-solublemonolayer coatingRequired film thickness 80 μm 70 μmMinimum film thickness 25 μm 25 μmSubstrate preparation Blasting (SA2½) and ironphosphatingBlasting (SA2½) and ironphosphatingMaximum degree of gloss > 90 GE 60° measuring angle > 85 GE 60° measuring angle<strong>Co</strong>rrosion protection<strong>Co</strong>rrosivity category C3/C4DIN EN ISO 12944The properties of solvent-based and water-soluble monolayer coatings<strong>Co</strong>rrosivity category C3/C4DIN EN ISO 12944been improved to enable sufficient protectionto be achieved even with thin layers.That means that a continuous coatingfilm is produced and a certain corrosionprotection is available even at thoseareas that are difficult to access duringthe application of the coating. However,where there is no coating at all, there isno corrosion protection.Secondly, the fact that <strong>Frei</strong>Lackefocuses on special coating problems inindividual industrial sectors has resultedin more expertise and understanding<strong>for</strong> what customers demand of a coating.Knowledge about design-related corrosionprotection, <strong>for</strong> example avoidingdifficult to access components, avoidingsharp edges or eliminating the joining ofdifferent materials, makes it easier toassess together with the customerwhether a monolayer coating can beused <strong>for</strong> a component or whether it isbetter, <strong>for</strong> reasons of corrosion protection,to use a conventional primer-surfacerand a top coat.Furthermore, there is a greater understandingamong users today, comparedto even a few years ago, that the surfacesto be coated must be prepared <strong>for</strong> thecoating; in other words, they must beOBERFLÄCHENTECHNIKnews +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news TOP-NEWS +++ news +++ news of surface +++ news +++ technology!news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news Order +++ news now! +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news www.jot-oberflaeche.de+++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++ news +++pretreated if good corrosion protection isto be achieved.<strong>Co</strong>nclusionImprovements in the properties of coatingsystems with regard to the corrosionprotection of thin coating layers and thelessons learned from experience withthe first coating results have made theuse of monolayer coatings in automotivefinishing possible and practical onceagain. It is important that, be<strong>for</strong>e monolayercoatings are used, the part geometryand the pretreatment are preciselyanalysed and evaluated by the user andthe coating manufacturer, and ifrequired also by the manufacturer of theapplication equipment.Once all questions have been satisfactorilyanswered and practical tests havebeen successfully completed, monolayercoatings can be used today <strong>for</strong> cost-effectivefinishing.__|The Author:Herwig Brietzke,<strong>Emil</strong> <strong>Frei</strong> <strong>GmbH</strong> & <strong>Co</strong>. KG, Bräunlingen, Germany,Tel. +49 7707 151-304,h.brietzke@freilacke.de, www.freilacke.deJOT International Surface Technology 1.2011 21