Diesel Engine Fire Pump Controller Type EFP ... - Metron Eledyne

Diesel Engine Fire Pump Controller Type EFP ... - Metron Eledyne

Diesel Engine Fire Pump Controller Type EFP ... - Metron Eledyne

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

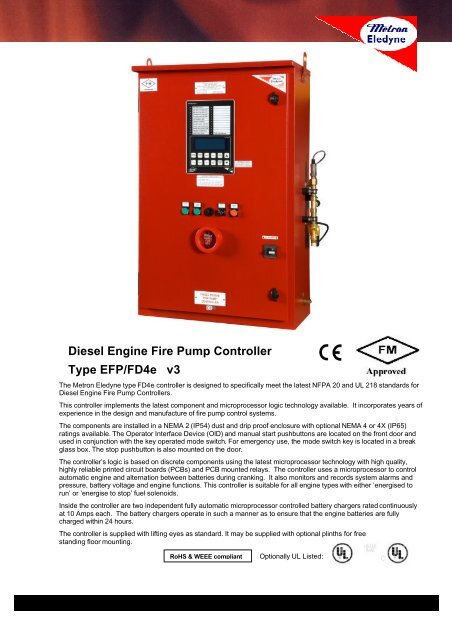

<strong>Diesel</strong> <strong>Engine</strong> <strong>Fire</strong> <strong>Pump</strong> <strong>Controller</strong><strong>Type</strong> <strong>EFP</strong>/FD4e v3The <strong>Metron</strong> <strong>Eledyne</strong> type FD4e controller is designed to specifically meet the latest NFPA 20 and UL 218 standards for<strong>Diesel</strong> <strong>Engine</strong> <strong>Fire</strong> <strong>Pump</strong> <strong>Controller</strong>s.This controller implements the latest component and microprocessor logic technology available. It incorporates years ofexperience in the design and manufacture of fire pump control systems.The components are installed in a NEMA 2 (IP54) dust and drip proof enclosure with optional NEMA 4 or 4X (IP65)ratings available. The Operator Interface Device (OlD) and manual start pushbuttons are located on the front door andused in conjunction with the key operated mode switch. For emergency use, the mode switch key is located in a breakglass box. The stop pushbutton is also mounted on the door.The controller’s logic is based on discrete components using the latest microprocessor technology with high quality,highly reliable printed circuit boards (PCBs) and PCB mounted relays. The controller uses a microprocessor to controlautomatic engine and alternation between batteries during cranking. It also monitors and records system alarms andpressure, battery voltage and engine functions. This controller is suitable for all engine types with either ‘energised torun’ or ‘energise to stop’ fuel solenoids.Inside the controller are two independent fully automatic microprocessor controlled battery chargers rated continuouslyat 10 Amps each. The battery chargers operate in such a manner as to ensure that the engine batteries are fullycharged within 24 hours.The controller is supplied with lifting eyes as standard. It may be supplied with optional plinths for freestanding floor mounting.RoHS & WEEE compliantOptionally UL Listed:

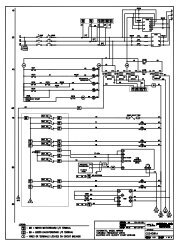

Standard FeaturesOperator Interface Device (OID) withLED Annunciator and Digital Display:General <strong>Controller</strong> DescriptionThe <strong>Fire</strong> <strong>Pump</strong> <strong>Controller</strong> conforms to allrequirements of the latest edition of NFPA20, NFPA 70 and UL218 and is approvedby Factory Mutual (FM).The controller shall be available for either12VDC or 24VDC operation. Included asstandard, the controller is suitable for250VAC to 110VAC input power at noadditional cost.<strong>Controller</strong> Standard Features• The controller includes two 10 Ampbattery chargers that are fullyautomatic.• Two crank pushbuttons and two batterycircuit breakers for protection and on/offoperation.• Key operated mode switch.• AUTO, MANUAL and TEST each havean illuminated LED for controller modeindication.• Operator Interface Device (OlD) with 4lines by 20 character display with largecharacter backlit LCD capable of beingread in both direct sunlight or darklighting conditions. English or Spanishlanguages are standard and selectablethrough the OlD.• The OlD includes 12 pushbuttons foreasy screen navigation, system modechanges, alarm reset, horn silencing,and lamp test.• The built in annunciator includesmulticolored LED’s for alarm and modeindications. The annunciation LED’shave removable labels that allow theuser to easily make changes, ifadditional alarms and/or languagechanges are needed.• All controller settings can beprogrammable through the OlD.Programming changes are protected bytwo levels of passwords to preventunauthorized modification.• All features are enabled or disabledthrough the OlD, so no jumpers orexternal wires are needed, makingcontrol logic field modification veryeasy.• The OlD displays System Pressure,Start Pressure, Battery 1 Voltage,Battery 2 Voltage, Battery 1 ChargerAmps, and Battery 2 Charger Ampsproviding the operator instant systemstatus. Other information that isdisplayed on the OlD is the Leadstarting battery, Current time and date,Number of starts, Total engine runhours, displayed countdown timers for:Sequential engine start and enginestop, and Time until AC Power fail start.• The state of the art microprocessorbased logic includes a real time/dateclock that can operate for a minimum of14 days without DC power connected tocontroller. The continuous pressurelog, event log and all user changeableset points and system data is stored innon-volatile flash memory andpermanently stored and not lost evenduring extended power losses.• One RS485 Serial Port is included asstandard.• If there is ever a need to change theinternal components all wiring to theinternal board is removable without theuse of any special tools or soldering.Auxiliary alarms and contactsAs standard the controller includes 6discrete auxiliary inputs, 9 form ‘C’auxiliary relay outputs. These auxiliaryinputs and outputs are in addition to thosemandated by NFPA 20. All auxiliaryinputs, outputs, and OlD LED’s are fieldprogrammable making it very easy tomake changes to the controller in thefield. Through the OlD the operator canselect any 9 of the following auxiliaryalarms which will be recorded in the eventlog and annunciated with an LED and/oroutput relay contact:ENGINE QUIT FAULTPRESSURETRANSDUCER FAULTPUMP ON DEMANDLOW DISCHARGEPRESSUREHIGH DISCHARGEPRESSUREREMOTE START SIGNALDELUGE VALVE STARTHIGH FUEL LEVELFUEL SPILLFUEL TANK RUPTURELOW PUMP ROOMTEMPERATURERESERVOIR LOWRESERVOIR EMPTYRESERVOIR HIGHFLOW METER ONRELIEF VALVE OPENLOW SUCTIONPRESSUREData logging:HIGH ENGINE OILTEMPERATURELOW JACKET WATERFLOWLOW JACKET WATERLEVELLOW HYDRAULICPRESSUREGAS DETECTIONLOW FIREWATERPRESSUREAIR DAMPER CLOSEDAIR DAMPER OPENLOW PURGE PRESSURELOW GEAR OILPRESSURELOW COOLANT LEVELHIGH GEAR OILTEMPERATUREHIGH VIBRATIONLOW FUEL PRESSUREHIGH EXHAUSTTEMPERATUREHIGH FUELTEMPERATUREPUMP ON DEMANDThe controller has two separate data logsfor storing system data. The logs arereadable through the OlD or printable onthe internal optional printer. These logsare as follows:Pressure Log: The Pressure log providesa continuous pressure recording for aminimum of 7 days. Depending onsettings determined by the operator thepressure log can store more than 30 daysof data. Each time the pressure logrecords a pressure it includes the timeand date of the reading and is stored inpermanent non-volatile flash memory on aSD memory card. The data recorded inthe pressure log can be searched by eachsample, by minute, or by hour allowing foreasy access to specific data.Alternatively, the data can be read on aPC computer via the SD memory card.

Event Log: The event log will store aminimum of 3000 events. These eventsinclude any of the followingevents/alarms:BATTERY 1 FAULTBATTERY 2 FAULTBATTERY 1 LOWVOLTAGEBATTERY 2 LOWVOLTAGECHARGER 1 FAULTCHARGER 2 FAULTAC POWER FAILENGINE OVERSPEEDENGINE FAILED TOSTARTENGINE QUITENGINE LOW OILPRESSUREENGINE HIGH WATERTEMPPRESSURETRANSDUCER FAULTSTOP PUSHBUTTONPRESSEDSYSTEM AUTO MODEENGINE LOCKOUTSIGNALSYSTEM AUTO MODESYSTEM MANUALMODESYSTEM OFF MODESYSTEM TEST RUNALARM RESETLOW PRESSURECONDITIONLOW PRESSURE STARTDELUGE STARTREMOTE STARTAC POWER FAIL STARTHORN SILENCEDPRESSURE DROPPlus any of the 9 programmable auxiliaryalarms listed above.Every event or alarm that is recordedincludes the following data with therecorded event or alarm:• Time and Date of Event or Alarm• System Pressure• Descriptive Text Message of theEvent/Alarm• System Auto Mode Status• <strong>Engine</strong> Running Status• Charger 1 Status• Charger 2 Status• Battery 1 Status• Battery 2 Status• AC Power Status• Fuel Level Status<strong>Controller</strong> OperationAutomatic Mode:Starting conditions such as pressure drop,and deluge valve start, will cause the useradjustable sequential start delay timer tobegin operation. After the start delay iscompleted the engine will start and theoperation will be recorded in the eventlog. In addition to the sequential starttimer the Automatic Weekly Test Start,AC Power Fail Start are programmable bythe user through the OlD. All systemstatistics are continuously monitored andchanges are logged into the internal logs.System statistics include, but are notlimited to, battery charger volts/amps,battery voltage, and system pressure iscontinuously monitored and changes arelogged in memory.Stopping conditions: Auto <strong>Engine</strong> Stopdelay, engine lockout, low suctionshutdown, automatic stop duringautomatic weekly test for low oil pressureand high water temperature are all OlDuser programmable features.Events and Alarms are recorded in theappropriate logs at the time of theiroccurrence. Pressure is continuouslymonitored and changes in voltage thatexceed user programmed amounts arelogged into memory.Manual Mode:If a control logic failure occurs, two crankpushbuttons are provided that will bypassall internal logic and allow manualoperation of the engine.OptionsOption A: Alternator diode blockAllows both batteries to be chargedsimultaneously from the alternator output.Maximum current carrying capacity is60A.Option E1: <strong>Engine</strong> heater outputCircuit breaker protected mains engineheater output, up to a maximum of 3kW.Option E2: <strong>Engine</strong> heater outputSecond engine heater output.Option G: Space HeaterInternally wired thermostat or humidistatand anti-condensation heater.Option N: 24v Louvre OutputA special fuse protected output togenerate a 24v louver control output on a12V controller.Option T1: Cabinet mounting lugsExternal mounting lugs for easierinstallation and mounting.Option T3: Plinth (Legs)Suitably sized legs to enable thecontroller to be floor mounted.Option T4: A.V Mounting kitAnti-vibration kit for mounting thecontroller directly onto the engine skid.Option Y : PrinterAn internally mounted printer to enablethe user to make hard copies of thevarious event and pressure logs.EnclosureThe following NEMA type enclosures arealso available: 4, 4X (Painted Cold RolledSteel), 4X (Unpainted 304 or 316Stainless Steel), and 12.<strong>Type</strong> Designation<strong>EFP</strong>/XX/YY/FD4e/ZZXX = Battery voltageYY = AC mains supply voltageZZ = Letter of options fitted

SpecificationsGeneral <strong>Controller</strong> DescriptionThe <strong>Fire</strong> <strong>Pump</strong> <strong>Controller</strong> shall be factoryassembled, wired and tested as a unit andshall conform to all requirements of thelatest edition of NFPA 20, NFPA 70 andUL218 and be Third Party approved byFactory Mutual (FM). The controller shallbe available for either 12VDC or 24VDCsystems.<strong>Controller</strong> Equipment Features:The controller shall include the followingstandard features:• Configurable from 250VAC to 110VACinput power without additional parts orwiring.• NEMA <strong>Type</strong> 2 drip proof metal wallmounting enclosure.• Dual Battery chargers, 10A• Two crank pushbuttons and batterycircuit breakers.• Key operated mode switch used inconjunction with the OID mode pushbuttons.• SD Memory card for event and waterpressure logs. All logs are to be storedin a simple text file for easy access via aPC computer.• AUTO, MANUAL and TEST each havean illuminated LED for controller modeindication.• Operator Interface Device (OID) with 4lines by 20 character display with largecharacter backlit LCD capable of beingread in both direct sunlight or darklighting conditions.• 12 pushbuttons for easy screennavigation, system mode changes,alarm reset, and horn silencing.• Multicolored LED’s for annunciation.• LEDs shall be labeled with removablelabels to allow for easy field modificationif additional alarms and/or languagechanges.• All controller settings shall beprogrammable through the OlD andshall be protected by two passwords.• All features shall be enabled or disabledthrough the OlD, no jumpers or externalwires shall be needed or allowed toactivate or deactivate a feature.• The system status data shall bedisplayed on the OlD.The displayed items shall include:System pressure, Battery 1 Voltage,Battery 2 Voltage, Battery 1 ChargerAmps, Battery 2 Charger Amps, Leadstarting battery, Current time and date,Number of starts, Total engine runhours, Displayed countdown timers for:Sequential engine start and engine stop,and Time until AC Power fail start.• Audible alarm with alarm silence featurefor muteable alarms.• Lamp test feature.• English or Spanish languages selectablethrough the OlD.• Microprocessor based logic with realtime/date clock capable of running aminimum of 14 days without DC powerconnected to controller and non-volatileflash memory to permanently store thecontinuous pressure log, event log, and alluser changeable set points and systemdata.• Input and output status LED’s to providevisual indication of each discrete input’sor output’s on/off status.• One RS485 Serial Port.• The controller shall be CE marked• Removable cable gland plates• Europe style earth point• All wiring terminals on PCB’s shall beremovable type.Auxiliary alarms:As standard the controller shall include 6discrete auxiliary inputs, 9 form ‘C’auxiliary relay outputs. These auxiliaryinputs and outputs are in addition to thosemandated by NFPA 20. All auxiliary inputs,outputs, and OlD LED’s shall be fieldprogrammable through the OlD. Thispermits a multitude of customizablecontroller configurations to meet eachinstallations unique requirements withoutadding cost to the controller. The use ofjumpers, soldering, or other externalcomponents is not necessary.The user can select any 9 of the followingauxiliary alarms that can be programmedand recorded in the event/alarm logs andannunciated with an LED and output relaycontact:ENGINE QUIT FAULTPRESSURETRANSDUCERFAULTPUMP ON DEMANDLOW DISCHARGEPRESSUREHIGH DISCHARGEPRESSUREREMOTE STARTSIGNALDELUGE VALVESTARTHIGH FUEL LEVELFUEL SPILLFUEL TANK RUPTURELOW PUMP ROOMTEMPERATURERESERVOIR LOWRESERVOIR EMPTYRESERVOIR HIGHFLOW METER ONRELIEF VALVE OPENHIGH ENGINE OILTEMPERATURELOW JACKET WATERFLOWLOW JACKET WATERLEVELLOW HYDRAULICPRESSUREGAS DETECTIONLOW FIREWATERPRESSUREAIR DAMPER CLOSEDAIR DAMPER OPENLOW PURGE PRESSURELOW GEAR OILPRESSURELOW COOLANT LEVELHIGH GEAR OILTEMPERATUREHIGH VIBRATIONLOW FUEL PRESSUREHIGH EXHAUSTTEMPERATUREHIGH FUELLOW SUCTIONPRESSUREData logging:TEMPERATUREPUMP ON DEMANDThe controller shall have two separatedata logs for storing system data that isreadable through the OlD or printable onthe internal printer. These logs shall be asfollows:Pressure Log: The controller shall have aPressure log with continuous pressurerecording of minimum of 7 days and becapable of storing more than 30 days ofdata. The pressure log samples shall betime and date stamped and stored inpermanent non-volatile SD memory card.The pressure log shall be searchable byeach sample, by minute, or by hour.Event Log: The event log shall be capableof storing no less than 3000 events.These events shall include any of thefollowing events/alarms:BATTERY 1 FAULTBATTERY 2 FAULTBATTERY 1 LOWVOLTAGEBATTERY 2 LOWVOLTAGECHARGER 1 FAULTCHARGER 2 FAULTAC POWER FAILSYSTEM AUTO MODEENGINE LOCKOUTSIGNALSYSTEM AUTO MODESYSTEM MANUALMODESYSTEM OFF MODESYSTEM TEST RUNALARM RESETENGINE OVERSPEEDLOW PRESSURECONDITIONENGINE FAILED TO LOW PRESSURESTARTSTARTENGINE QUITDELUGE STARTLOW OIL PRESSURE REMOTE STARTHIGH WATER TEMP AC FAILURE STARTTRANSDUCER FAULT HORN SILENCEDSTOP PB PRESSED PRESSURE DROP(Plus any of the 9 programmable auxiliaryalarms listed above)Each event that is recorded shall have thefollowing data recorded with theevent/alarm:• Time and Date of Event or Alarm• System Pressure• Descriptive Text Message of the Event/Alarm• System Auto Mode Status• <strong>Engine</strong> Running Status• Charger 1 Status•Charger 2 Status• Battery 1 Status•Battery 2 Status• Fuel Level Status •AC Power StatusThe internal logic of the controller shall becapable of operation in a temperaturerange of 0°C to 50°C and high, noncondensing,humidity levels.METRON ELEDYNE LTD18 Autumn Park, Dysart Road, Grantham,LINCS NG31 7DD, England.Phone (+44) (0) 1476 516120Fax (+44) (0) 1476 516121www.metroneledyne.co.uk