T22B_HlogSplit - Gearmore, Inc.

T22B_HlogSplit - Gearmore, Inc.

T22B_HlogSplit - Gearmore, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

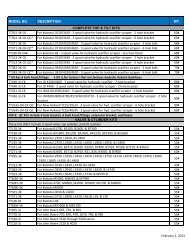

5 MAINTENANCE 6 SPECIFICATIONSBy following a good maintenance program, yourequipment will last for many years.1. Consult the operating and maintenanceinstructions of the engine manufacturer forengine care and maintenance.2. Always check the oil level of the hydraulicreservoir before operation. Operating the LogSplitter without an adequate oil supply willcause severe damage to the pump.3. Change the oil filter after the first 25 hours ofoperation. Thereafter, change the oil filterevery 100 hours or seasonally, whichevercomes first.4. If the wedge becomes dull or nicked, a grinderor sharpening tool can be used to sharpen itwhile still attached to the cylinder. If it isnecessary to remove the wedge, the stripperplate (71)* must be taken off by removing the3/ 8" bolts (68)*. Then remove the cylindersupport (66)* by taking out the 3 / 8" bolts (63)*.Then remove the 1 / 2" x 3 1 / 2" bolt (51)* thatconnects the wedge to the cylinder. Thereturn hose (53)* may need to be disconnectedfrom the valve. Loosen hose clamp (18)* andpull the hose off the fitting. Lift up thecylinder carefully and slide the wedge out ofthe channel.Splitting Force:22 TonsBeam Size: 6" x 6"Cylinder Size: 4" x 24"Valve Type:Auto-ReturnPump:2-Stage, 11 GPMEngine:Honda 5.5 H.P. orBriggs & Stratton 6 H.P.Filter:ReplaceableHoses & Fittings:<strong>Inc</strong>ludedTires:4.80 x 8" Road SpeedSafety Chains:<strong>Inc</strong>ludedGround Stand:<strong>Inc</strong>ludedCoupler:2" BallWedge Height: 7"Cycle Time:•13 SecondsMax. Log Length: 26"Total Reservoir Capacity: 17 QuartsHeight:39" Horizontal62" VerticalLength: 77 1 / 2"Width: 44"Built-In Log Cradle:YesShipping Weight: T22H - 430 lbs.<strong>T22B</strong> - 430 lbs.• Ideal case cycle times. Actual cycle times varydepending on temperature, engine speed, pumpefficiency, altitude, etc.5. Clean the breather cap after 25 hours ofoperation. Clean it more often when operatedin dusty conditions. To clean, remove thebreather from the tank and flush withkerosene or liquid detergent to remove thedirt.6. See also Repair and Maintenance Safety inthe Safety Information section of this manual.7. All replacement parts must meetmanufacturer's specifications.* See Parts Breakdown (Pages 15 - 17)in this manual.14