DUROSEAL Swelling Waterstops

DUROSEAL Swelling Waterstops

DUROSEAL Swelling Waterstops

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

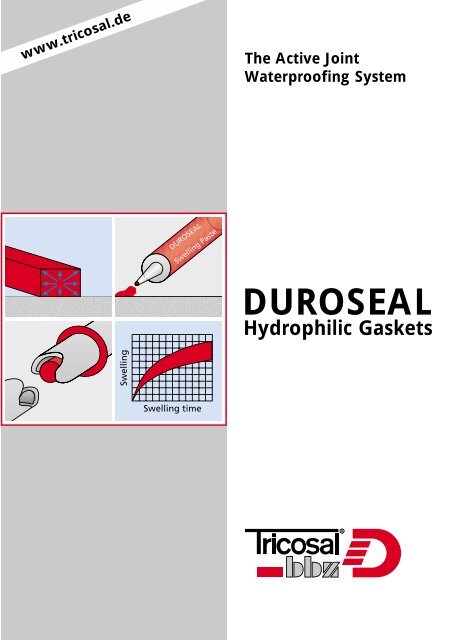

www.tricosal.deThe Active JointWaterproofing System<strong>DUROSEAL</strong>Hydrophilic Gaskets

<strong>DUROSEAL</strong> <strong>Swelling</strong> <strong>Waterstops</strong>The active pre-formed sealing system<strong>DUROSEAL</strong> swelling waterstops are waterstops which can swell and areused in concrete structures for the systematic sealing of constructionjoints (fig. 1). On contact with water, the <strong>DUROSEAL</strong> swelling waterstopsswell and seal the construction joint against water penetration.<strong>DUROSEAL</strong> swelling waterstops are characterised by:1✔ reliable swelling capacity✔ reversible swelling process✔ outstanding chemical resistance✔ drinking water compatibilityMaterialThe base material of the <strong>DUROSEAL</strong> swellingwaterstops is tough and flexible acrylate polymerswhich can store water in their molecularstructure with accompanying increase in volume(fig. 2).How it worksVolume enlargement (three-dimensional) of upto about 170 % on contact with water, with noassociated change in the homogeneous structureof the polymer matrix.During the swelling processthe <strong>DUROSEAL</strong> swelling waterstops exertpressure on the surrounding surfaces and sealsthe construction joint against water penetration.Theswelling operation and the swelling pressureit produces are illustrated in fig. 3 and fig. 4.2<strong>DUROSEAL</strong> swelling waterstops show excellent resistance to many chemicals.The following table lists a selection of the test liquids to which<strong>DUROSEAL</strong> hydrophilic gaskets are classified resistant.Resistancy list (extract)3Test liquidPetrol, unleaded, standardDieselToluolMethanol, 50 % in waterIsopropanol, 50 % in waterEthyl acetateMethylisobutylcetoneFormaldehyde, 36 % in waterReference of following mediaMotor fuelsDiesel and heavy heating oilAromatic solventsAlcoholsAliphatic esterAliphatic cetoneAldehydeAcetic acid, 10 % in water Organic acids up to 10 %Caustic soda (pH = 11 - 12)corresponding to pH value inconcrete4Common salt, 20 % in water Saline solutions up to 20 %Sulphuric acid, 20 % Mineral acids up to 20 %2

<strong>DUROSEAL</strong> <strong>Swelling</strong> <strong>Waterstops</strong>Processing instructions✗5678StorageSubstratepreparationApplicationConcreting✔ <strong>DUROSEAL</strong> hydrophilic gaskets should be storedaway from moisture.✔ The substrate must be free of grease, dust andloose particles (fig. 5).✔ Standing pools of water must be dried off thesurface before attaching the swelling gasket, forexample by blowing with compressed air.✔ Application should take place shortly beforeconcreting (avoid premature swelling caused byrainfall).✔ The swelling gasket should be covered with foilin horizontal joints where pools of water canstand for some time. Rainwater will flow out ofvertical joints, so there is less risk of prematureswelling.✔ <strong>DUROSEAL</strong> swelling waterstops are fully bondedto the prepared base using <strong>DUROSEAL</strong> MKassembly adhesive (fig. 6).Mechanical fastening at intervals of about 20 cm(8“) can be employed as an alternative.✔ <strong>DUROSEAL</strong> Type U expanding joint paste may beused for bonding of gaskets on very uneven orrough surfaces.✔ The entire length of the swelling gasket must bebonded flat onto the base (fig. 7) to prevent anyleakage at a later stage.✔ The concrete covering should be at least 8 cm(3’’) thick (fig. 8). The swelling gasket should beplaced at the centre of walls which are up to 30cm (1’) thick and on the water-facing side of thewall if the wall is more than 30 cm (1’) thick,taking into account the aforementioned minimumconcrete covering.✔ Joints between two <strong>DUROSEAL</strong> swelling waterstopsshould be buttjointed.✔ When concreting, take care to ensure that theswelling gasket is fully covered by the concrete.<strong>DUROSEAL</strong> MK<strong>Swelling</strong> Gasket Adhesive<strong>DUROSEAL</strong> MK is an MS polymer-based, solvent-free, single-componentassembly adhesive used to bond swelling gaskets to normal structuralbases (fig. 9).9AdhesivecapacityUseSafety✔ Adheres to dry and moist bases such as concrete,metals and various plastics.✔ <strong>DUROSEAL</strong> MK is supplied ready for use in 310ml cartridges and can be applied using a standardcommercially available caulking gun.✔ See product data sheet3

<strong>DUROSEAL</strong> Type U <strong>Swelling</strong> PasteThe swelling gasket that comesout of a tube.Great for constructionprogress, cures in around30minutes.<strong>DUROSEAL</strong> Type U swelling paste is a two-component expanding pastebased on tough, flexible acrylate polymers, suitable all-round for thesealing of construction joints in concrete structures (fig. 10).1011121314How it worksUseAdvantagesExamples ofuseMixinginstructions✔ On contact with water, the cured swelling gasketpaste swells and seals the construction jointagainst water penetration.✔ An increase in volume of up to around 170 %produced by storage of water in paste’s molecularstructure (see swelling curve in fig. 3).✔ <strong>DUROSEAL</strong> swelling paste is supplied in 750 mlcartridges along with appropriate hardeningpowder. The paste can be applied with a suitablehand-held gun.✔ The substrate must be free of grease, dust andloose particles.✔ The swelling paste should be protected againstpremature swelling.✔ When concreting, take care to ensure that theexpanding paste is fully covered by concrete.✔ Short cure time (approx. 20 minutes at 20 °C /68°F), so subsequent work is not delayed.✔ Adapts readily to all construction work situationsand surfaces.✔ Good adhesion to dry and moist surfaces (concrete,steel and plastics).✔ Same swelling capacity and chemical resistanceas <strong>DUROSEAL</strong> swelling waterstops.✔ Construction joints of every kind (fig. 11).✔ Junctions between concrete and steel girders(fig. 12).✔ Connecting joints in sheet pilings (fig. 13) ordiaphragm walls.✔ Sealing of bell butt joints.✔ Wall penetration for metal, plastic and concretepipes (fig. 14), cable bushing.✔ Bonding of <strong>DUROSEAL</strong> swelling waterstops onvery uneven or rough surfaces.✔ Insert the cartridge into the mixing base and fixin place.✔ Fit the colloidal mixer into a drilling machine.✔ Take off the slip lid, open and pour the hardenerpowder into the cartridge.✔ Stir the contents of the cartridge with the colloidalmixer until they become uniform colour.✔ Insert the sealing cover into the open cartridge,insert the cartridge in the gun, puncture theopening and screw on the grouting nozzle. Cutnozzle accordingly to required size of paste tobe applied.✔ The expanding paste is now ready to work(workability time at 20 °C about 20 minutes)4

<strong>DUROSEAL</strong> Sealing Rings and Plugsfor sealing formwork braces in concreteconstructions<strong>DUROSEAL</strong> sealing rings and <strong>DUROSEAL</strong> sealing plugs are sealing elementsspecially developed for the sealing of formwork braces made offibre concrete or plastic (figs. 15, 16).151617MaterialHow theyworkStorageApplicationeasy, fast andsafeConcreting✔ The base material of <strong>DUROSEAL</strong> sealing ringsand <strong>DUROSEAL</strong> sealing plugs is tough and flexibleacrylate polymers which can store waterin their molecular structure with an accompanyingincrease in volume.✔ Volume enlargement (three-dimensional) of upto about 170 % on contact with water, withoutthe associated change in the homogeneousstructure of the polymer matrix.✔ During the swelling process the <strong>DUROSEAL</strong> sealingring or sealing plug exerts pressure on thesurrounding surfaces and seals the joint againstwater penetration (fig. 17).✔ <strong>DUROSEAL</strong> sealing rings and <strong>DUROSEAL</strong> sealingplugs should be stored away from damp.✔ The <strong>DUROSEAL</strong> sealing ring is slipped onto themiddle of the formwork braces before theseare put in place.✔ The <strong>DUROSEAL</strong> sealing plug is slipped into thecentre of the formwork stay after the formworkis removed.✔ After the formwork is removed, fill both endsof the formwork stays (fig. 17) with non-shrinksealing mortar (e.g. Tricopac 52).✔ When concreting, take care to ensure that the<strong>DUROSEAL</strong> sealing ring is fully enclosed in concreteSFR crack inducers combined with<strong>DUROSEAL</strong> swelling waterstopsfor sealing cracks and dummy joints<strong>DUROSEAL</strong> swelling gaskets can also be used in combination withSFR crack inducers (fig. 18).The crack inducer’s intentional weakening of the cross section allows acontrolled crack to be made in the dummy-joint line and prevents anuncontrolled cracking. Sealing is provided by a <strong>DUROSEAL</strong> swellingwaterstop fixed on the crack inducer.See appropriate product data sheet for detailed information on theSFR crack inducer.185

<strong>DUROSEAL</strong> Hydrophilic GasketsTender SpecificationsItem Qty. Designation/Text Unit pr. Total pr.runningmetreSupply and prepare proper installation according to manufacturer’s instructions.of❑ Typ U 2005 (20 mm x 5 mm) = (3/4’’ x 1/4’’)❑ Typ U 2010 (20 mm x 10 mm) = (3/4’’ x 3/8’’)❑ Typ U 2025 (20 mm x 25 mm) = (3/4’’x 1’’)For❑ planned sealing of construction joints❑ Base slab/Wall connection❑ Base slab/Base slab connection❑ Wall/Wall connection❑ Pipe penetrations❑ Connection old/new building❑ .........................................The <strong>DUROSEAL</strong> swelling waterstop shall be fixed on the concrete substrateby using <strong>DUROSEAL</strong> MK adhesive of as alternative steel dowels.price per m .....................................runningmetreSupply and prepare proper installation according to manufacturer’s instructions.of<strong>DUROSEAL</strong> Type U swelling paste (2 component)for❑ Base slab❑ Base slab/Wall connection❑ Wall/Wall connection < 2.50 m (= 8.2’)❑ Wall/Roof slab connection❑ Pipe penetrations❑ Slurry diaphragm wall/Base slab connection❑ Sheet pile wall/Base slab connection❑ Connection old/new building❑ .................................................price per m .....................................6

<strong>DUROSEAL</strong> Hydrophilic GasketsTender SpecificationsGeneral InstructionsItem Qty. Designation/Text Unit pr. Total pr.pcs.Supply of Sealing Rings for formwork braces made of fiber concrete orplastic.❑ <strong>DUROSEAL</strong> Sealing Ring Type FZ (internal diameter 43 mm = 1 3 ⁄4’’)❑ <strong>DUROSEAL</strong> Sealing Ring Type KS (internal diameter 26 mm = 1’’)pcs.Supply of<strong>DUROSEAL</strong> Sealing Plug Type FZ/KS for formwork braces made of fiber concreteor plastic (diameter 23 mm = 7/8’’)runningmetreSupply and prepare proper installation according to manufacturer’s instructions.ofSFR crack inducer combined with <strong>DUROSEAL</strong> swelling waterstops❑ Typ SRF 150 Q❑ Type SRF Q/V with injection capFor unit/wall thickness of .........................................The crack inducer shall be fixed at a distance of 0.5 m (20’’) by using hooks,stirrups or other suitable means.price per m .........................................runningmetreInjection of SRF crack inducer with <strong>DUROSEAL</strong> INJEKT (acrylate resin, waterswelling).The unit price shall include for site attendance of technical staff and applicators,injection equipment together with accessories and a material consumptionrate of 0.3 kg/m (0.03 gallons per foot), and the re-injection withinthe gel time. Payment is based on the length of the installed SRF crack inducer.price per m .........................................General InstructionsBrochure details/applicationAll details made in this brochure are product descriptions. They consist of generalinformation based on our experience and tests, and do not take account of specificapplications. No claims for compensation may be derived from these details.Please consult our technical department if required. Individual tests of specialproperties for specific applications can be carried out by our laboratory on request,in addition to the standard tests.Technical alterationsInstructionsDrawingsSubject to technical alterations based on latest findingsOur instructions and working recommendations are to be observedThe drawings in this brochure are shown in diagram form and may deviate fromthe actual installation situation.7

<strong>DUROSEAL</strong> Hydrophilic GasketsDelivery ProgrammeProduct Group Product DescriptionSizes Packing Units<strong>Swelling</strong>waterstops<strong>DUROSEAL</strong> <strong>Swelling</strong> WaterstopType U 200520 mm x 5 mm(3/4’’ x 1/4’’)1 carton = 6 rolls of 20 m(66’) = 120 m (394’)<strong>DUROSEAL</strong> <strong>Swelling</strong> WaterstopType U 201020 mm x 10 mm(3/4’’ x 3/8’’)1 carton = 6 rolls of 10 m(33’) = 60 m (197’)<strong>DUROSEAL</strong> <strong>Swelling</strong> WaterstopType U 201520 mm x 15 mm(3/4’’ x 5/8’’)1 carton = 8 rolls of 7 m(23’) = 56 m (184’)<strong>DUROSEAL</strong> <strong>Swelling</strong> WaterstopType U 202520 mm x 25 mm(3/4’’x 1’’)1 carton = 6 rolls of 5 m(16’) = 30 m (98’)Adhesive forswellingwaterstops<strong>DUROSEAL</strong> MK(one component type)Manual Gun for<strong>DUROSEAL</strong> MKpaste(for 310 mlcartridge)1 carton = 12 cartridgesof 310 ml1 unit<strong>Swelling</strong> Paste<strong>DUROSEAL</strong> <strong>Swelling</strong> Paste(two component type)paste1 carton = 5 cartridges of750 mlManual Gun for<strong>DUROSEAL</strong> <strong>Swelling</strong> Paste(for 750 mlcartridge)1 unitMixing Stand for<strong>DUROSEAL</strong> <strong>Swelling</strong> Paste-1 unitSpiral Mixer for<strong>DUROSEAL</strong> <strong>Swelling</strong> Paste-1 unitSealing Ringand SealingPlug<strong>DUROSEAL</strong> Sealing Ring Type FZ(for fiber concrete formwork braces)<strong>DUROSEAL</strong> Sealing Ring Type KS(for plastic formwork braces)Internal diameter43 mm (1 3 ⁄4’’)Internal diameter26 mm (1’’)1 carton = 5 plastic bags,50 pcs. per plastic bag1 carton = 5 plastic bags,50 pcs. per plastic bag<strong>DUROSEAL</strong> Sealing Plug Type FZ/KS(for fiber concrete and plastic formworkbraces)Diameter 23 mm (7/8’’)1 carton = 5 plastic bags,50 pcs. per plastic bagCrack InducerCrack Inducer Type SRF 150 Q(combined with <strong>DUROSEAL</strong><strong>Swelling</strong> Waterstop)Width of crack inducerrail150 mm (6’’)Standard length:2,60 m = 8.5’Crack Inducer Type SRF Q/V withinjection cap(combined with <strong>DUROSEAL</strong> <strong>Swelling</strong>Waterstop and reinjectable cap)Width of crack inducerrail150 mm (6’’)Standard length:2,60 m = 8.5’Tricosal GmbH · P.O. Box 3052 · D - 89253 IllertissenPhone: 0049/7303/180-0 · Fax 0049/7303/180-355E-mail: export@tricosal.dewww.tricosal.deTricosal BBZ AGGewerbezentrum RotfarbP.O. Box 31 · CH-9213 HauptwilPhone: 0041/714221111 · Fax: 0041/714225815E-mail: info@bbz-ag.ch2’ · January 2002