You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fender system designed by BERGER/ABAM Engineers, Inc.Fender installation: Seattle, WA

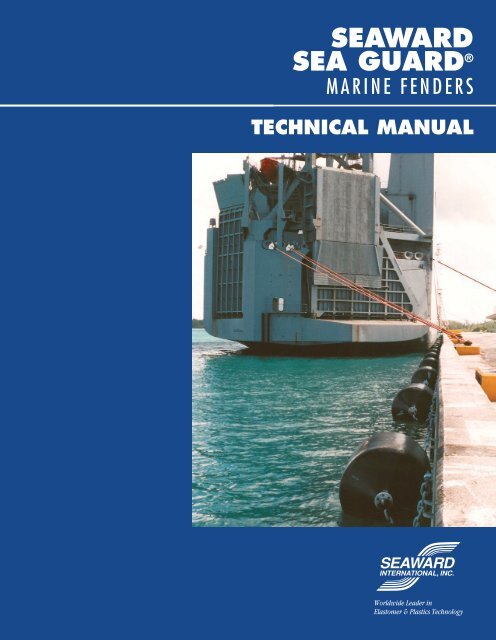

Fender installation: Puerto Rico<strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-5360

Photo courtesy of Blaylock Engineering <strong>Marine</strong> GroupFender installation: San Diego, CA<strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-5360

1. IntroductionThe first of its kind when developed in 1979, the Seaward <strong>SEA</strong><strong>GUARD</strong> ® foam-filled marine fender sets the standard in theindustry and meets the most stringent quality and performancedemands. It continues to lead the industry in reliability, qualityand customer acceptance. Seaward International, Inc. hasdelivered thousands of <strong>SEA</strong> <strong>GUARD</strong> marine fenders. Large orsmall, floating or fixed, Seaward <strong>SEA</strong> <strong>GUARD</strong> fenders are in usefrom the tropics to the Arctic, providing tough heavy-dutyfendering systems for harbor, offshore and ship-to-shipapplications. The resilient foam-filled construction provides anunsinkable fender body that permits high energy absorptionwith a relatively low reaction force as compared to most otherfendering systems.The <strong>SEA</strong> <strong>GUARD</strong> fender combines quality assurance standardswith new elastomer technologies, making it the answer to mostfendering system requirements. Its urethane skin is unique inthat it is reinforced with nylon, which is wrapped in a helicalpattern and integrated within the skin itself. This techniquegives the <strong>SEA</strong> <strong>GUARD</strong> fender’s skin a tear strength up to sixtimes greater than non-reinforced skin.Available in a wide variety of diameters and lengths, fromthe 2 ft x 4 ft (0.6 m x 1.2 m) to the tanker-scaled 14 ft x 28 ft(4.3 m x 8.5 m), all Seaward fenders meet the operationalperformance expectations the industry has grown to depend on.<strong>SEA</strong> <strong>GUARD</strong> fenders are manufactured exclusively by SeawardInternational, Inc. — a worldwide leader in innovative uses ofplastics and elastomer technology. Seaward International is arecipient of the President’s Export “E” Award for excellence inexporting fenders and related products. Seaward continues todevelop and supply the marine technologies that keep you oncourse. <strong>Co</strong>ntact Seaward’s technical staff to solve your specificfendering needs through the time-tested applications ofSeaward’s marine fenders.Fender installation: Baltimore, MD<strong>SEA</strong> <strong>GUARD</strong> ® is a registered trademark of ChemRay-Seaguard <strong>Co</strong>rp., used underlicense by Seaward International, Inc.<strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-53601

Seaward manufacturing plant, Clearbrook, VA2 <strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-5360

2. Features and Advantages<strong>SEA</strong> <strong>GUARD</strong> fenders are fabricated from a closed-cell resilientfoam that absorbs significant quantities of energy whencompressed. The foam is protected by a thick, filamentreinforcedouter elastomer skin. This construction offers anumber of important features and advantages:2.1 HIGH ENERGY ABSORPTION WITHLOW REACTION FORCE<strong>SEA</strong> <strong>GUARD</strong> fenders have both high energy absorption andlow reaction force. Reaction forces at rated compressions arelower than most other fenders at comparable energy levels.The low reaction force of the <strong>SEA</strong> <strong>GUARD</strong> fender is animportant consideration in the design of quay walls, wheresignificant economies can be made if forces on the walls canbe kept to a minimum. Other economies are produced byeliminating the need for load-spreading panels, which arerequired for most large hard rubber fenders. <strong>SEA</strong> <strong>GUARD</strong>fenders dissipate a significant portion of energy internally anddo not cause the vessel to rebound from the berth as readily aspneumatic or hard rubber fenders.2.2 TOUGH OUTER SKIN<strong>SEA</strong> <strong>GUARD</strong> fenders have a rugged polyurethane elastomerouter skin, with nothing to snag hull protrusions or dockfittings. To provide added strength, the thick skin is reinforcedwith nylon filaments.2.3 CUSTOM SIZES AND COLORSIn addition to our traditional fender sizes, which are listed inSection 5, Seaward’s manufacturing process allows for customsizes and colors to be designed and built to variousspecifications, including metric sizes.2.4 LABORATORY AND FIELD TESTS<strong>SEA</strong> <strong>GUARD</strong> fenders have been extensively tested to verify theirperformance, ruggedness and durability. <strong>Co</strong>mpression tests areconducted in a certified laboratory on sizes up to 7 ft x 14 ft(2.1 m x 4.3 m), using one of the world‘s largest compressiontesting machines. These fenders consistently excel in all otherrequired tests, including energy absorption; capacity andreaction forces; ultimate compression; cyclic compression(dynamic and sustained loading); transverse pull tests; andlongitudinal pull tests.Years of field tests with <strong>SEA</strong> <strong>GUARD</strong> fenders have confirmedthe ability of these fenders to take the rugged service for whichthey are designed.Formulated by Seaward chemists specifically for marinefenders, the skin undergoes strict quality control at the SeawardInternational plant.Urethane skin reinforced with nylonwrapped in a helical pattern.Fender testing at Lehigh University, Fritz Engineering Lab, Lehigh, PA<strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-53603

2.5 QUALITYSeaward’s quality system incorporates a fully documentedinspection system that meets U.S. Government requirements,including a calibration system in accordance with ANSI/NCSLZ540 (ISO 10012-1).Materials testing, verification and inspection are in accordancewith the standards and practices of:• ASTM (American Society for Testing and Materials)• ISO (International Organization for Standardization)• AWS (American Welding Society)• AISC (American Institute of Steel <strong>Co</strong>nstruction)• SSPC (Steel Structures Painting <strong>Co</strong>uncil)Statistical techniques include statistical process control andsampling plans.Seaward’s quality system has been audited and approved bythe following U.S. Government organizations:• ABS (American Bureau of Shipping — system andtype approvals)• DCMC (Defense <strong>Co</strong>ntract Management <strong>Co</strong>mmand —formerly DCAS)• DGSC (Defense General Supply Center — QualityVendor Awards)2.6 SIMPLE INSTALLATIONInstallation of <strong>SEA</strong> <strong>GUARD</strong> fenders is simple compared to hardrubber fenders, which require specialized mounting fixtures.<strong>SEA</strong> <strong>GUARD</strong> fenders use standard chain pendants attached ateach end of the fender. Load-spreading panels between the shipand the fender are not required. Fender transportation usingstandard rigging methods is easily accomplished.2.7 TOTAL BUOYANCYThe natural buoyancy of <strong>SEA</strong> <strong>GUARD</strong> fenders allows them tobe installed in a floating position between ship and dock oranother vessel. This is particularly beneficial in areas with largetidal or seasonal water level fluctuations since, unlike fixedfendering, the floating <strong>SEA</strong> <strong>GUARD</strong> fender can rise and fallwith changing water levels. The floating fender remains at thewater line of the vessel for optimum fendering.2.8 BURST RESISTANCEWhen a <strong>SEA</strong> <strong>GUARD</strong> fender is compressed, the compressionforce is resisted by the pressurization of many small,completely closed foam cells and by the buckling of the cellwalls. Because of the strength of the cell walls, the resistance tocell bursting is very high. The <strong>SEA</strong> <strong>GUARD</strong> fender skin is not apressure containment boundary; therefore, there is no need forpressure relief valves or inflation valves on the outer cover.2.9 SAFETYBecause of the <strong>SEA</strong> <strong>GUARD</strong> fender’s unique design, it will notexplode or sink. It retains its energy absorbing and standoffcapabilities even if the skin is damaged. This extra margin ofsafety can be vitally important in docking, marine salvage,offshore construction or ship-to-ship transfer and lighteringoperations.2.10 LOW MAINTENANCEThe <strong>SEA</strong> <strong>GUARD</strong> fender has been designed to resistenvironmental conditions. The exterior is highly resistant toozone, hydrocarbons, ultraviolet radiation, sea water and otherenvironmental factors, and the skin color is integrated into theelastomer. Therefore, there is no need to cover or otherwiseprotect the fenders when in use or in storage.2.11 RELIABLE PERFORMANCEYears of successful performance in the field have establishedthe <strong>SEA</strong> <strong>GUARD</strong> fender as the standard fendering solution forthe industry.4 <strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-5360

3. <strong>Co</strong>nstruction FeaturesThe <strong>SEA</strong> <strong>GUARD</strong> fenders are filled with a resilient, closed-cell foam. The skin is constructed of a urethane elastomer which is reinforcedwith nylon filament in a continuous winding process. To transmit tensile loads through the fender, the <strong>SEA</strong> <strong>GUARD</strong> fender contains aninternal chain connecting the end fittings. A thick layer of filaments and elastomer around the end fitting safely transmits the tensileloads from the end fitting to the fender body. These construction features, protected by U.S. and foreign patents, are shown in thedrawing below.<strong>SEA</strong> <strong>GUARD</strong> FENDER — SETTING THESTANDARD FOR THE INDUSTRYA. The <strong>SEA</strong> <strong>GUARD</strong> fender‘s polyurethane skin is a uniqueelastomer, formulated by Seaward specifically for fenderapplications. It is integrally reinforced with multiple layersof nylon filaments, giving it a tear strength up to sixtimes greater than non-reinforced skin.B. Quality control testing of the highest quality closed-cellfoam available, combined with our special laminatingprocess, ensures the integrity of every fender core.C. The special bond between the elastomer skin and thefoam core is stronger than the foam itself, resulting in aunitized fender free of delaminations and voids.D. Seaward staff chemists have successfully formulated ahigh-strength skin material that protects the fender andkeeps it performing under the harshest conditions aroundthe world.E. Integral galvanized steel end fittings swivel to reducehardware stress and permit easy installation. The heavydutyinternal chain provides all <strong>SEA</strong> <strong>GUARD</strong> fenders withthe pull-through strength and durability needed toprovide years of dependable service.<strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-53605

Photo courtesy of W.B. Arnold <strong>Co</strong>., Inc.Fender installation: Oakland, CA6 <strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-5360

5. Fender Data5.1 FENDER DATA SUMMARYSpecifications and performance data for standard <strong>SEA</strong> <strong>GUARD</strong>fender sizes ranging from 2 ft x 4 ft (0.6 m x 1.2 m) to 14 ft x28 ft (4.3 m x 8.5 m) are shown on pages 10–29. Metric sizesfrom 700 mm x 1 500 mm to 3 300 mm x 10 600 mm arehighlighted in the charts and tables on pages 30–37.Although the data highlights standard fender diameters invarious lengths, fender sizes can be varied to meet specificcustomer requirements. Information on High Capacity and LowReaction <strong>SEA</strong> <strong>GUARD</strong> fenders can be found in Section 6.All fender dimensions and performance values are nominal.The values presented in this section are based on theMAXIMUM RECOMMENDED WORKING COMPRESSIONOF 60 %. This compression should not be exceeded.Actual values may vary plus or minus 15 % from stated valuesdue to variations in material properties, dimensional tolerances,temperature and speed of compression. Tons are metric tons of2 205 lb. The energy and reaction force ratings are derivedfrom laboratory test results of numerous performance tests on avariety of fender sizes. Energy and force ratings for other sizesof <strong>SEA</strong> <strong>GUARD</strong> fenders are available upon request, or may beapproximated by interpolation of, or extrapolation from, thedata shown.5.2 DEFINITIONSThe terms used in the charts and tables on the following pagesare detailed as follows:ENERGY ABSORPTIONEnergy absorption in marine fender systems is the transferenceand safe dissipation of kinetic energy generated by a movingvessel into a fender to protect both the vessel and the shorefacility. The primary purpose of any fender system is to safelyand effectively absorb this kinetic energy and bring the vesselto a stop.REACTION FORCEReaction force in marine fender systems is the force exerted onthe ship’s hull and the shore facility structure as the fender iscompressed between them. Reaction pressure is the reactionforce divided by the area (or footprint) over which it is applied.FOOTPRINTFootprintMaximumWidthFootprintMaximum LengthThe footprint area is defined as the total contact area of thefender when it is compressed. The shape of the footprint isindicated in the drawing above. Values for the footprint areaand the maximum length and width of the footprint, at 60 %compression, are given for each size <strong>SEA</strong> <strong>GUARD</strong> fender in thefollowing pages.SAFE WORKING END-PULL LOADThe safe working end-pull load is the axial tensile load on theend of the fender that should not be exceeded during thenormal deployment. Specific values for each fender size arelisted in the following pages in this section.STANDOFF DISTANCEThe amount of space between the vessel and the side of a pier.<strong>SEA</strong> <strong>GUARD</strong> ® MARINE FENDER TECHNICAL MANUAL (540) 667-5191 • 1 (800) 828-53609

<strong>SEA</strong>WARD INTERNATIONAL, INC.3470 Martinsburg Pike, P.O. Box 98Clearbrook, VA 22624-0098 USA1 (800) 828-5360Phone: (540) 667-5191Fax: (540) 667-7987