Road Pavement Crack Sealing: Experiences in the Republic of ...

Road Pavement Crack Sealing: Experiences in the Republic of ...

Road Pavement Crack Sealing: Experiences in the Republic of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

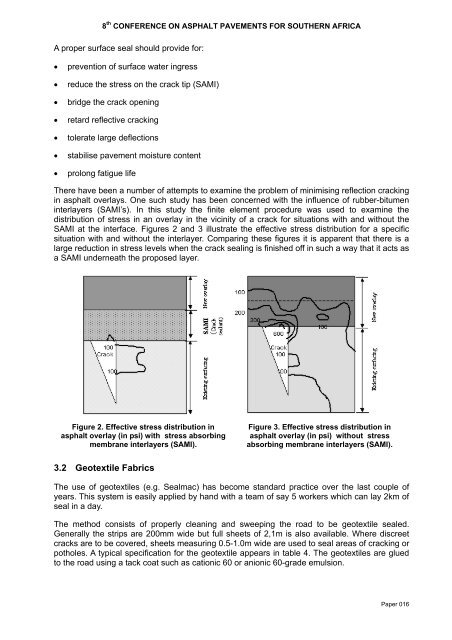

8 th CONFERENCE ON ASPHALT PAVEMENTS FOR SOUTHERN AFRICAA proper surface seal should provide for:• prevention <strong>of</strong> surface water <strong>in</strong>gress• reduce <strong>the</strong> stress on <strong>the</strong> crack tip (SAMI)• bridge <strong>the</strong> crack open<strong>in</strong>g• retard reflective crack<strong>in</strong>g• tolerate large deflections• stabilise pavement moisture content• prolong fatigue lifeThere have been a number <strong>of</strong> attempts to exam<strong>in</strong>e <strong>the</strong> problem <strong>of</strong> m<strong>in</strong>imis<strong>in</strong>g reflection crack<strong>in</strong>g<strong>in</strong> asphalt overlays. One such study has been concerned with <strong>the</strong> <strong>in</strong>fluence <strong>of</strong> rubber-bitumen<strong>in</strong>terlayers (SAMI’s). In this study <strong>the</strong> f<strong>in</strong>ite element procedure was used to exam<strong>in</strong>e <strong>the</strong>distribution <strong>of</strong> stress <strong>in</strong> an overlay <strong>in</strong> <strong>the</strong> vic<strong>in</strong>ity <strong>of</strong> a crack for situations with and without <strong>the</strong>SAMI at <strong>the</strong> <strong>in</strong>terface. Figures 2 and 3 illustrate <strong>the</strong> effective stress distribution for a specificsituation with and without <strong>the</strong> <strong>in</strong>terlayer. Compar<strong>in</strong>g <strong>the</strong>se figures it is apparent that <strong>the</strong>re is alarge reduction <strong>in</strong> stress levels when <strong>the</strong> crack seal<strong>in</strong>g is f<strong>in</strong>ished <strong>of</strong>f <strong>in</strong> such a way that it acts asa SAMI underneath <strong>the</strong> proposed layer.Figure 2. Effective stress distribution <strong>in</strong>asphalt overlay (<strong>in</strong> psi) with stress absorb<strong>in</strong>gmembrane <strong>in</strong>terlayers (SAMI).Figure 3. Effective stress distribution <strong>in</strong>asphalt overlay (<strong>in</strong> psi) without stressabsorb<strong>in</strong>g membrane <strong>in</strong>terlayers (SAMI).3.2 Geotextile FabricsThe use <strong>of</strong> geotextiles (e.g. Sealmac) has become standard practice over <strong>the</strong> last couple <strong>of</strong>years. This system is easily applied by hand with a team <strong>of</strong> say 5 workers which can lay 2km <strong>of</strong>seal <strong>in</strong> a day.The method consists <strong>of</strong> properly clean<strong>in</strong>g and sweep<strong>in</strong>g <strong>the</strong> road to be geotextile sealed.Generally <strong>the</strong> strips are 200mm wide but full sheets <strong>of</strong> 2,1m is also available. Where discreetcracks are to be covered, sheets measur<strong>in</strong>g 0.5-1.0m wide are used to seal areas <strong>of</strong> crack<strong>in</strong>g orpotholes. A typical specification for <strong>the</strong> geotextile appears <strong>in</strong> table 4. The geotextiles are gluedto <strong>the</strong> road us<strong>in</strong>g a tack coat such as cationic 60 or anionic 60-grade emulsion.Paper 016