Download - Koma Precision, Inc.

Download - Koma Precision, Inc.

Download - Koma Precision, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

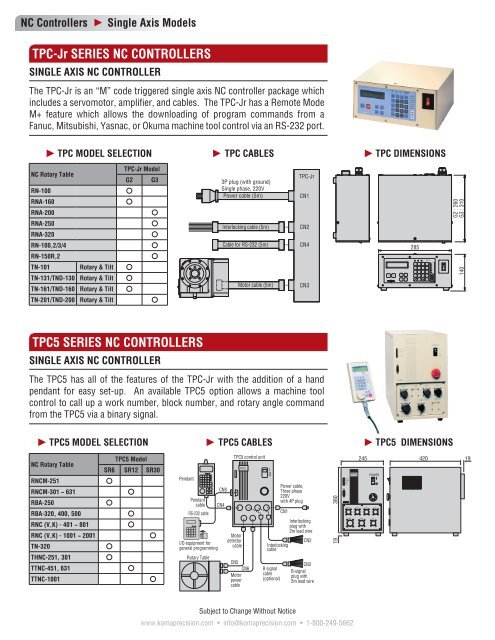

CNBREADYALARMRUNSTOPSTSPMZRN+JOGWZRN-JOG2nd . FθDGN2nd . F+NW No.CALM-MLKRUNGPRG7USER4COPY1INS0STOPFPOS8FEED5CLR2DELRREM9PRM6SCH3DIRCRMODEAUTOSINGLECHECKPROGMDIJOGNC ControllersSingle Axis ModelsTPC-Jr SERIES NC CONTROLLERSSINGLE AXIS NC CONTROLLERThe TPC-Jr is an “M” code triggered single axis NC controller package whichincludes a servomotor, amplifier, and cables. The TPC-Jr has a Remote ModeM+ feature which allows the downloading of program commands from aFanuc, Mitsubishi, Yasnac, or Okuma machine tool control via an RS-232 port.TPC MODEL SELECTION TPC CABLES TPC DIMENSIONSNC Rotary TableRN-100RNA-160RNA-200TPC-Jr ModelG2 G33P plug (with ground)Single phase, 220VPower cable (5m)TPC-JrCN1G2 : 260G3 : 310RNA-250RNA-320Interlocking cable (5m)CN2RN-100,2/3/4RN-150R,2TN-101TN-131/TND-130TN-161/TND-160Rotary & TiltRotary & TiltRotary & TiltCable for RS-232 (5m)Motor cable (5m)CN4CN3285TPC-Jr140TN-201/TND-200Rotary & TiltTPC5 SERIES NC CONTROLLERSSINGLE AXIS NC CONTROLLERThe TPC5 has all of the features of the TPC-Jr with the addition of a handpendant for easy set-up. An available TPC5 option allows a machine toolcontrol to call up a work number, block number, and rotary angle commandfrom the TPC5 via a binary signal.TPC5 MODEL SELECTION TPC5 CABLES TPC5 DIMENSIONSNC Rotary TableRNCM-251RNCM-301 ~ 631RBA-250RBA-320, 400, 500RNC (V,K) - 401 ~ 801RNC (V,K) - 1001 ~ 2001TN-320THNC-251, 301TTNC-451, 631TTNC-1001TPC5 ModelSR6 SR12 SR30PendantPendantcableRS-232 cableI/O equipment forgeneral programmingRotary TableCN8CN4TPC5 control unitTPC5MotordetectorcableCN5CN6MotorpowercableIOInterlockingcableB signalcable(optional)Power cable,Three phase220Vwith 4P plugCN1Interlockingplug with2m lead wireCN2CN3B-signalplug with2m lead wire38019245TPC5POWERCN4 CN3 CN2 CN1CN5 CN6 CN7420 19Subject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsTPC-Jr FUNCTIONSOPERATION PANELLCD display 20 characters × 2 lines(Program & current position)Power switchMode display lampsMode selection keysOPERATION MODEAUTOSINGLECHECKPROGMDIJOG: Automatic operation by anM code signal from themachining center.: Single operation of TPC-Jr. Bypressing ST , the indexing isdone one time.: Block number call, programcheck and self diagnosis.: Program input edit.: One block program carryingout. Useful when setting upworkpiece.: Manual feed, step feedOperation keysProgram edit keysPROGRAM EDIT KEYS2nd•F+N Workpiece No. (Program No.) 0000 ~ 9999 100 programs registrableW NoN Block No. 000 ~ 999W NoG Operation command G0 ~ G4: Movement command G5 ~ G9: Secondary functionsPRGF Feedrate select command F0: Rapid positioning speed F1 ~ F9: Cutting feedratePOSRREMDefines “G” code functionθDGNMovement amount command (angle value, divisions, or repetition #)G code R code q codeNo. Command No. Command Command SettingG0 Direct angle command001~999 Number of repetitions (INC) Command angle ±000.000° ~ ±999.999°000 (ABS) Command angle ±000.000° ~ ±360.000°G1 Direct indexing number command 001~999 Number of repetitions # of divisions for 360° ±1 ~ ±999,999 div.G2 Arc-indexing number command 001~999 Number of divisions/repetitions Arc-angle indexed ±000.001° ~ ±360.000°G3 Lead cutting command 000~045 Number of table rotations Command angle ±0 ° ~ ±360.000°000 1st zero point return (mechanical zero point)G4 Zero point return command001 2nd zero point returnNot required002 3rd zero point returnG5 Sub-program call command 000~999 Number of repetitions Sub-program No. 0000~ 9999G6 Sub-program return command Not required Not requiredG7 Program end command Not required Target address 000~999G8 Workpiece coordinate system setting command Not required Reference coordinate ±0° ~ ±360.000°000 No operation001/002 Clamp OFF/ONNot required003/004 Dwell OFF/ON Dwell time 000 ~ 999 (x10msec)005/006 Indexing group control OFF/ONG9 Declaration command007/008 Directional positioning OFF/ONNot required009/010 Completion signal control command OFF/ON Completion signal selection011 Program display selection command012 Current position display selection commandNot required013 Remaining angle display selection commandSubject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsTPC5 FUNCTIONSOPERATION PANEL5LCD display1 2 3 4RDY W0000 S9999 ABSN000 G0 F0 R0000POS Ø + 000° 00’ 00”OT OVR150% MZRN Status display line Program display line Program/current position display line Control display lineProgram edit keysMultiple jog dial678Status display line: 13TPC status 2 Workpiece numberSubprogram number 4 Command system.Program display line: TPC5 program in 2 lines5 Current position/remaining POS/REM.Control display line: 678OvertravelOverride/machine lock/manual interruptZero point return MZRN/WZRN/TZRN.Modedisplay LED’sOPERATION MODEAUTO : Automatic operation with machining centerSINGLE : Single operation of TPC5CHECK : Program check and self-diagnosisPROG : Program editMDI : Program operation for set-upHANDLE : Manual pulse operation/jog modeMode selection keysOperation keysPROGRAM EDIT KEYS2nd•F+N Workpiece No. (Program No.) 0000 ~ 9999 100 programs registrableW NoN Block No. 000 ~ 999W NoG Operation command G0 ~ G4: Movement command G5 ~ G9: Secondary functionsPRGF Feedrate select command F0: Rapid positioning speed F1 ~ F9: Cutting feedratePOSRREMDefines “G” code functionθDGNMovement amount command (angle value, divisions, or repetition #)G code R code q codeNo. Command No. Command Command SettingG0 Direct angle command0001~9999 Number of repetitions (INC) Command angle ±000.000° ~ ±999.999°0000 (ABS) Command angle ±000.000° ~ ±360.000°G1 Direct indexing number command 0001~9999 Number of repetitions # of divisions for 360° ±1 ~ ±999,999 div.G2 Arc-indexing number command 0001~9999 Number of divisions, Number of divisions/repetitions Arc-angle indexed ±000.001° ~ ±360.000°G3 Lead cutting command 0000~0045 Number of table rotations Command angle ±0° ~ ±360.000°0000 1st zero point return (mechanical zero point)G4 Zero point return command0001 2nd zero point returnNot required0002 3rd zero point returnG5 Sub-program call command 0000~9999 Number of repetitions Sub-program No. 0000 (0001) ~ 9999G6 Sub-program return command Not required Not requiredG7 Program end command Not required Target address 000~999G8 Workpiece coordinate system setting command Not required Reference coordinate ±0° ~ ±360.000°0000 No operation0001/0002 Clamp OFF/ONNot required0003/0004 Dwell OFF/ON Dwell time 000 ~ 999 (x10msec)0005/0006 Indexing group control OFF/ONG9 Declaration command0007/0008 Directional positioning OFF/ONNot required0009/0010 Completion signal control command OFF/ON Completion signal selection0011 Program display selection command0012 Current position display selection commandNot required0013 Remaining angle display selection commandSubject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsSPECIFICATIONS OF TPCTPC-JrTPC5Control Axis1 axisServo MotorAC Servo: ABS DetectorCommand Unit 0.001° (Decimal) 1 sec,0.001°,0.0001° (Decimal)Indexing Direct Indexing1~999999 even indexingNumber Arc-Indexing 1~999 even indexing 1~9999 even indexingMax. Command Angle ±999.999° ±999°59’59”,±999.999°,±999.9999Command SystemINC, ABS, Shortcut ABS, INC/ABS mixed systemInput SystemMDIProgram Control Workpiece No. (W0000 to 9999)Program Capacity 1,000 blocks (total of main & sub programs) 2,000 blocks (total of main & sub programs)Positioning Speed Max. motor rotation speed: 3,000rpm Max. motor rotation speed: 3,000rpmAUTO: Operation interlocked w/ mach. ctr. AUTO: Operation interlocked w/ mach. ctr.SINGLE: Single operation of TPC SINGLE: Single operation of TPCOperation ModeCHECK: Program check & call CHECK: Program check & callPROG: Program edit PROG: Program editMDI: Set-up operation MDI: Set-up operationJOG: Manual feed, step feed JOG: Manual pulse operationDisplay LCD screen: 20 figures x 2 lines LCD screen: 20 figures x 4 linesDirect Indexing # CommandMove angle is directly commandedRepetitionCommand of # of move amount repetitions 999 (TPC-Jr) 1~9999 (TPC5)Direct Indexing # Command Indexing number of 6 digits for 360°Arc-Indexing # Command Command of arbitrary 3-digit angle (TPC-Jr) or 4-digit angle (TPC5)Lead Cutting Command Interlocked operation with one axis of the machining center in the open loop statusZero Point Return CommandAllows return to the first, second or third-zero pointFeedrate Command F0: positioning speed F1~9: cutting feedrateFeedrate Setting1. By radius and surface speed setting2. By move amount per secondSub-ProgramUp to 8 levels of nesting are possibleWorkpiece coordinateSystem SettingAllows a workpiece coordinate to be set at any pointDwellAllows output of a positioning completion signal to be delayedSingle Directional PositioningAllows positioning of one directionBacklash Compensation In increments of 0.001° In increments of detecting unitSoft Limit FunctionSets a soft limit measured from the 1 st zero positionAutomatic Setting atpower ON1. Mode selection, AUTO/CHECK2. Workpiece number setting 3. Block number settingEdit Function 1. Insert 2. Delete 3. Copy1. Program format errors2. Program memory errors3. Communication ErrorsAlarm4. Soft limit alarms5. Overtravel6. Servo motor alarms7. Overheat in the cabinet (TPC5)Override Function X 5~200% 5% stepsJOG/HANDLE Feeding Jog feed, step feed Manual pulse feed, jog feedOvertravelThe rotation range of the rotary table can be limited by limit switches. (Std. tilting axis)Manual 2 nd ZeroSettingInput/Output Signal CheckContrastPowerEarth(less than 100 ohmearth resistance)EnvironmentalConditionsExternal DimensionsExternal OutputSignalEnables the 2nd zero position to be set and changed at any point inthe JOG (HANDLE) modeFIN1FIN2FIN3FIN4Workpiece numbersetting completionIn AUTO modeLEVELALARMExternal input signalSTARTSTOPINTERLOCK4-digit BCD code or16bit BINBF(strobe signal)M-signalMDI lockZero point returnManual pulsegeneratorFull-closed feedbackcontrolMP scaleEncoderSerial ChannelTPC-JrTPC5Positioning completion signal during interlocking operationOutput of G7 completion or workpiece # setting completion (selectable by parameters)(AUTO mode)Output of G7 completion or workpiece # setting completion (selectable by parameters)XOutput of zero position (selectable by parameters)XOutput at workpiece # setting completion (selectable by parameters)XOutput in AUTO modeXOutput during positioning (selectable by parameters)(Rotary table zero position)Output in AUTO modeFrom machining center to TPC(External power 24VDC is also available)Positioning start signal during interlocking operation (M-signal)Input to stop rotary tableInput to interlock rotary tableXWorkpiece number can be set externally(16 kinds)Strobe signal for setting workpiece number externallyXFixed indexing angle input system by M-signalXInput for locking MDI key operationX1 st zero return commandManual operation can be performed with a manual pulse generatorX (movement magnification:X1,X10,X100)XEnable full-closed control (highly precise)with the inductsyn or rotary encoderDetecting unit 0.0001° (360 poles) or 0.00005 (720 poles)XDetecting unit 0.0001° or 0.00005°XTPC program, feed rate and parameters can be stored in an external deviceFormat: IISOFormat: IISO or EIA(RS-232) (RS-232 or RS-422)Between rotary table and TPC5 (2 pcs)Between rotary table and TPC-Jr (1 pc)For motor power supply: 5mFor motor: 5mFor motor detector: 5m- Between TPC5 and MDI unit: 7mPower cable: 5mPower cable: 5mInterlocking cable: 5mInterlocking cable: 5mCable supplied(standard)The concentration on the LCD screen can be adjusted1ø200/220V±10% 50/60Hz 3ø200/220V±10% 50/60HzModel Pwr Capacity Fuse Rating Model Pwr Capacity Fuse RatingCables of different lengths are availableJr G2 1.2KVA 8A TPC5-SR6 2.3KVA 10ACable suppliedRS-232 cable: 5mInterlocking cable: 5mJr G3 2.2KVA 12A TPC5-SR12 4.3KVA 15A(option)- B signal cable: 5mTPC5-SR30 5.9KVA 20A- RS-232 cable: 5mAmbient temperature: 0-40° • Relative humidity: 20-80% (nocondensation • Vibration: 0.3G or less, no corrosive gasJr G2 Unit Weight: 7.2kg/16lbs Control Unit Weight: 22kg/48lbs- Standard285mm (w) x 260mm (d) x 128mm (h) 245mm (w) x 420mm (d) x 380mm (h)- Optional interlocking cables are suppliedJr G3 Unit Weight: 8.1kg/18lbs MDI Unit Weight: 0.5kg/1lb285mm (w) x 310mm (d) x 128mm (h) 111mm (w) x 30mm (d) x 1998mm (h)- Optional units and parts are suppliedFrom TPC to machining centerContact ratings: 24VDC, 0.5A or lessSubject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsTPC OPTIONTPC5Full-Featured Interlocking Cable5m3mRequired for the following functions:• Stop or interlock input signal• Positioning completion 2,3,4• AUTO mode• Positioning• Alarm signal• Full-featured interlocking cable(Standard length: 5m)TPC5B Signal Cable5m3mRequired for the following functions:• External input of workpiece numbers• External input of angles• Fixed indexing angle input system byM-signal• Full-featured interlocking cable(Standard length: 5m)TPC-JrTPC5RS-232 CableInput and output of program, parameterand feed data for TPC5 and TPC-Jr, anddata printout are carried out throughexternal equipment, which is to beprepared by the customer.• RS-232 cable(Standard length: 5m)• RS-422 cable(Standard length: 5m)TPC5High Resolution CapabilityRotary Encoder TypeFully-closed loop control is possible bythe feed-back from the rotary encoder.• Rotary encoders• IBV unit(by HEIDENHAIN)• TPC5 RETPC5High Resolution CapabilityMP Scale TypeFully-closed loop control is possible bythe feed-back from the MP scale.• MP scale• Pre-amplifier• A/D converter(Mitsubishi Heavy Industries)• TPC5 RETPC-JrTPC5“Remote Mode” SpecificationAvailable for measuring systemconstruction. To be connected with apersonal computer using serial channel.• RS-232 cableTPC-JrTPC5“Remote Mode + M” Specification A function to unify the program to startthe rotary table by M-signal, by feedinga command for the indexing angle fromthe RS-232 port at the NC controller ofthe machining center.Note: This function may not be available for somemachining centers.Subject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662• RS-232 cable

NC ControllersSingle Axis ModelsTPC MACHINING PROGRAM EXAMPLESDirect angle command: G090°NW No000G0F0R002θ90.000CRPositioning at 90° twiceQuick Repetition # Indexing angle/timeDirect indexing number command: G1 (even indexing)90°90°90°90°90°NW NoNW NoNW No001GPRG 7θDGN 000CRReturn toNW No 000 at the program endEnd of program000GPRG 1FPOS 0RREM 004θDGN 000004d CR Dividing 360° by 4, four timesDividing 360° by 4001GPRG7θDGN000 CR Return toN000 at the program endArc-indexing number command: G2 (even indexing by an arbitrarily-set angle)120°NW NoNW No000G2F0R005θ120.000CRDividing 120° by 5, five timesDivision # Arc-angle for dividing001GPRG 7θDGN 000CRReturn toN000 at the program endUneven indexing NW No 000GPRG 0FPOS 0RREM 001θDGN 70.00074.635°70°NW No 001GPRG 0FPOS 0RREM 001θDGN 90.000NW No 002GPRG 0FPOS 0RREM 001θDGN 125.365N90°W No 003GPRG 0FPOS 0RREM 001θDGN 74.635125.365°NW No 004GPRG 7θDGN 000(-) direction indexingCRCRCRCRCRPositioning at 70° oncePositioning at 90° oncePositioning at 125.365° oncePositioning at 74.635° onceReturn toNW No000 at the program end-90°NW NoNW No000GPRG0FPOS0RREM001θDGN-90.000 CR Positioning at -90° onceReverse001 GPRG7 θDGN000 CR Return toNW No000 at the program endZero point return command: G4Zero pointNW No000 G 4 R 000 Return to 1st zero positionPRGREMZero returnTo 1st zero positionREMOTE MODE + M SPECIFICATIONNC controller of machineThe TPC control is capable of receiving indexing information from the machiningcenter control via the RS-232 ports. An “M” code is required to execute the movecommand. An RS-232 cross cable is provided with the TPC control. Machiningcenter requirements: an RS-232 connector and Custom Macro B (optional) (forFANUC).TPC-JrRS-232CommandFINM-signalby TPC-Jr90°90°POPEN: = RS-232 port opensDPRINT[/MOVA90.]: = Command of absolute positioning at 90° is transmitted to TPCM70: = Positioning startsGO1Z100.F200: = Machining center in operationDPRINT[/MOVA180.]: = Command of absolute positioning at 180° is transmitted to TPCM70: = Positioning startsGO1Z100.F200: = Machining center in operationPCLOS: = RS-232 port closesSubject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsINSTALLATION OF TPC CONTROLLERAir SupplyM-signalPower SupplyStand1Air Supply A pneumatic or air/hydraulic clamp system is available for an NC rotarytable mounted with the TPC5 or TPC-Jr controller, and air supply isRegulator/Filterrequired.Air Hose CouplingThe following are to be provided by customers.Air supply• Air filter and regulator (Air pressure: 72 psi)• Air hose• Joint coupler (1/4” NPT fitting for the table)Coupling1/4” NPT2M-signalWhen a machining center controls the rotary table, the command isnormally made by M-signal. All machine tool M-signal cables mustbe connected to a terminal block in the machine tool cabinet. Forconnection with an interlocking cable, see examples on .3Power supply The TPC-Jr controller is supplied with a NEMA L6-20P plug (20 amp, 1phase, 250V). The TPC5 controller is supplied with a NEMA L15-20Pplug (20 amp, 3 phase, 250V).If connectors other than the above are used, they are to be supplied by the customer.For the power requirements of TPC controllers, refer to the TPC specifications page.The TPC controller should be connected to the machine tool emergency stop circuit. Ifthe available power supply voltage is different from the required voltage, a transformermust be used. See the TPC specifications page for complete power requirements.4StandA stand for the TPC controller should be provided by the customer.For the dimensions and weight of the controller, refer to the TPCspecifications page.Subject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsTPC CONTROLLERS TO INTERLOCK WITH MACHINING TOOLSTPC-JrInterlocking cable (Standard length: 5m)Connector hole diameterfor machining center cabinetØ215m2mStandard interlocking cable set-up: when a start signaland an indexing completion signal are used.All features cable set-up: when the signals available onan interlocking cable are used.Electric cabinet of machining centerM-signal terminal blockAT71M70 StartAT70AT85 M-signal completionAT84Output signal commonNote 1: When completion signals are received by a relay, the power supply should be 24VDC.Do not use AC100V or 200V.2: By changing the switch in the controller, a start signal is also available with a 24VDC externalpower supply.3: Be sure to take countermeasures against electric noise by attaching surge killers to relays on themachining center.Electric cabinet of machining centerM-signal terminal blockAT71AT75AT76AT91AT92AT93AT73AT72AT70AT85AT82AT88AT89AT84M70StartM71Zero returnB1B2B4B8BFEmergency stopInput signal commonFIN1 Completion signal 1FIN2 Completion signal 2LVLALMLevel signalAlarm signalOutput signal commonTPC5Interlocking cable (Standard length: 5m)5m2mStandard interlocking cable set-up: for interlocking only with M-signal and the completion signal.Connector hole diameterfor machining center cabinet4 - M3Electric cabinet of machining center27Ø 26AT71AT72AT70AT85AT84M70MIXFINStartStopInput signal commonPositioning completedOutput signal commonSubject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsTPC CONTROLLERS TO INTERLOCK WITH MACHINING TOOLS (cont.)All features interlocking cable set-up (optional)A variety of signals, such as a stop or interlock input signal and a level or alarm output signal are available with this cable. A “B” signalcable is required with the setting functions for the workpiece number and angle data are used, or when the fixed indexing angle inputsystem by an M-signal is used. Contact KOMA for complete information.Connector hole diameterfor machining center cabinetØ 304 - M329.5Electric cabinet of machining centerAT71AT75AT73AT76AT72AT74AT77AT70AT85AT81AT82AT86AT88AT87AT89AT84FIN‚QFIN‚SAUTOM70StartM71Zero returnM72M73FIN‚PFIN‚RLVLALMWork number jumpingResetStopInterlockMDI lockInput signal commonPositioning completion‚PPositioning completion‚QPositioning completion‚RPositioning completion‚SPositioningAUTO mode selectedAlarm signalOutput signal commonNote 1: When completion signals are received by a relay, the power supply should be 24VDC. Do not use AC100V or 200V.2: By changing the switch in the controller, a start signal is also available with a 24VDC external power supply.3: Be sure to take countermeasures against electric noise by attaching surge killers to relays on the machining center.TIME CHARTStartPositioning completionoutputServo motorClamp completionUnclamp completionNote 1: A start input signal, in the form of either a pulse signal (of more than 10 msec) or level signal can be accepted.2: During an interlock operation with a machining center by means of an M-signal, the positioning completion should coincidewith the M-signal completion.Subject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsRN-100, RNA-160, 200, 250, 320 / TPC CONTROL SPECIFICATIONSTPC MODEL / TABLE & MOTOR SPEEDTable Model RN-100 RNA-160 RNA-200 RNA-250 RNA-320 RN-100,2 RN-100,3 RN-100,4TPC Model TPC-Jr G2 TPC-Jr G2 TPC-Jr G3 TPC-Jr G3 TPC-Jr G3 TPC-Jr G3 TPC-Jr G3 TPC-Jr G3Speed reduction ratio 1/36 1/72 1/72 1/120 1/180 1/36 1/60 1/60Table/Motor RPM 66.7/2,400 41.7/3,000 41.7/3,000 25/3,000 16.7/3,000 55.6/2,000 50/3,000 50/3,000Contact KOMA <strong>Precision</strong> for TPC use with continuous cutting or eccentric load applications.DimensionsRN-100R/TPC-Jr G2Drawings not to scale • Dimensions = mm70 19014518011045145RNA-160R/TPC-Jr G2RNA-200R/TPC-Jr G3RNA-250R/TPC-Jr G3RNA-320R/TPC-Jr G3370160357ø320110H78685H830606026080h713950H71522085135857090 105195280216100h71487 155100h755H715564245 9415440H81511027016010595115 120235340264120h77158165120h765H715664645 10416445H815285160 125272Ø 25075H75150H8120120 952403601581953045 10416419415210155155275430957203210404514920924915Subject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662

NC ControllersSingle Axis ModelsTN-101, 131, 161, 201, 320 / TPC CONTROL SPECIFICATIONSTPC MODEL / TABLE & MOTOR SPEEDTable Model TN-101 TN-131 TN-161 TN-201 TN-320Table axis Rotary Tilt Rotary Tilt Rotary Tilt Rotary Tilt Rotary TiltTPC model TPC-Jr G2 TPC-Jr G2 TPC-Jr G2 TPC-Jr G3 TPC5 SR6Speed reduction ratio 1/60 1/120 1/60 1/120 1/72 1/120 1/45 1/90 1/120 1/240Table rpm (motor @2,000) 33.3 16.7 33.3 16.7 27.8 16.7 44.4 27.8 16.7 8.3Contact KOMA <strong>Precision</strong> for TPC use with continuous cutting or eccentric load applications.DimensionsTN-101/TPC-Jr G2433Drawings not to scale • Dimensions = mm102100Ø 862773793232232231352259011512381 134 187100 100TN-131/TPC-Jr G2458102100Ø 9037927732422423515023686133146TN-161/TPC-Jr G2547112 134 212100 100240 110155129125365240285122100h755161 264105180285125 125TN-201/TPC-Jr G3633265 145157146145438293345157120h760192 284130210340145 145TN-320/TPC5 SR6859456 200656436Ø 320255 231486209190209 240 38030200 200Subject to Change Without Noticewww.komaprecision.com • info@komaprecision.com • 1-800-249-5662