GENERAL CATALOG - Tsubaki

GENERAL CATALOG - Tsubaki

GENERAL CATALOG - Tsubaki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

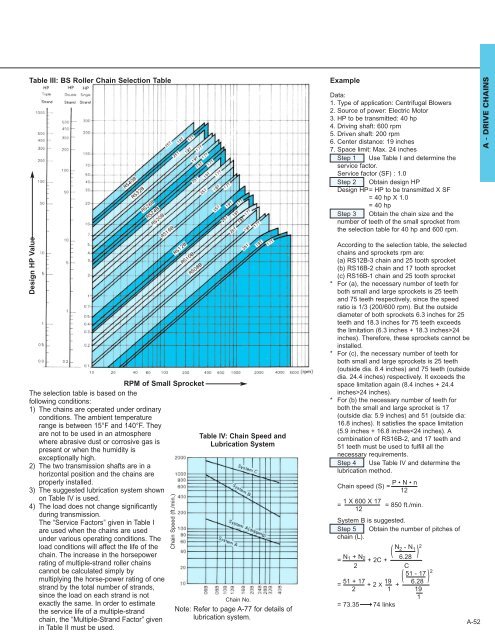

Table III: BS Roller Chain Selection TableExampleData:1. Type of application: Centrifugal Blowers2. Source of power: Electric Motor3. HP to be transmitted: 40 hp4. Driving shaft: 600 rpm5. Driven shaft: 200 rpm6. Center distance: 19 inches7. Space limit: Max. 24 inchesStep 1 Use Table I and determine theservice factor.Service factor (SF) : 1.0Step 2 Obtain design HPDesign HP= HP to be transmitted X SF= 40 hp X 1.0= 40 hpStep 3 Obtain the chain size and thenumber of teeth of the small sprocket fromthe selection table for 40 hp and 600 rpm.A - DRIVE CHAINSDesign HP ValueRPM of Small SprocketThe selection table is based on thefollowing conditions:1) The chains are operated under ordinaryconditions. The ambient temperaturerange is between 15°F and 140°F. Theyare not to be used in an atmospherewhere abrasive dust or corrosive gas ispresent or when the humidity isexceptionally high.2) The two transmission shafts are in ahorizontal position and the chains areproperly installed.3) The suggested lubrication system shownon Table IV is used.4) The load does not change significantlyduring transmission.The “Service Factors” given in Table Iare used when the chains are usedunder various operating conditions. Theload conditions will affect the life of thechain. The increase in the horsepowerrating of multiple-strand roller chainscannot be calculated simply bymultiplying the horse-power rating of onestrand by the total number of strands,since the load on each strand is notexactly the same. In order to estimatethe service life of a multiple-strandchain, the “Multiple-Strand Factor” givenin Table II must be used.Chain Speed (ft./min.)Table IV: Chain Speed andLubrication SystemChain No.Note: Refer to page A-77 for details oflubrication system.According to the selection table, the selectedchains and sprockets rpm are:(a) RS12B-3 chain and 25 tooth sprocket(b) RS16B-2 chain and 17 tooth sprocket(c) RS16B-1 chain and 25 tooth sprocket* For (a), the necessary number of teeth forboth small and large sprockets is 25 teethand 75 teeth respectively, since the speedratio is 1/3 (200/600 rpm). But the outsidediameter of both sprockets 6.3 inches for 25teeth and 18.3 inches for 75 teeth exceedsthe limitation (6.3 inches + 18.3 inches>24inches). Therefore, these sprockets cannot beinstalled.* For (c), the necessary number of teeth forboth small and large sprockets is 25 teeth(outside dia. 8.4 inches) and 75 teeth (outsidedia. 24.4 inches) respectively. It exceeds thespace limitation again (8.4 inches + 24.4inches>24 inches).* For (b) the necessary number of teeth forboth the small and large sprocket is 17(outside dia: 5.9 inches) and 51 (outside dia:16.8 inches). It satisfies the space limitation(5.9 inches + 16.8 inches