Lending a Hand to Customers in Need 10 - Inside Edison

Lending a Hand to Customers in Need 10 - Inside Edison

Lending a Hand to Customers in Need 10 - Inside Edison

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

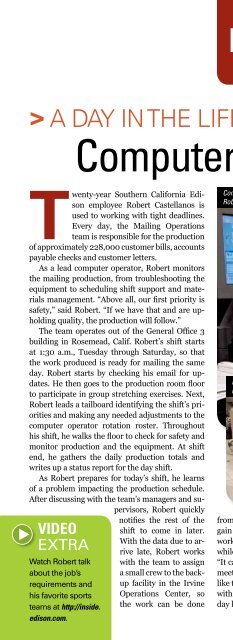

A Day <strong>in</strong> the Life of aComputer Opera<strong>to</strong>rTwenty-year Southern California <strong>Edison</strong>employee Robert Castellanos isused <strong>to</strong> work<strong>in</strong>g with tight deadl<strong>in</strong>es.Every day, the Mail<strong>in</strong>g Operationsteam is responsible for the productionof approximately 228,000 cus<strong>to</strong>mer bills, accountspayable checks and cus<strong>to</strong>mer letters.As a lead computer opera<strong>to</strong>r, Robert moni<strong>to</strong>rsthe mail<strong>in</strong>g production, from troubleshoot<strong>in</strong>g theequipment <strong>to</strong> schedul<strong>in</strong>g shift support and materialsmanagement. “Above all, our first priority issafety,” said Robert. “If we have that and are uphold<strong>in</strong>gquality, the production will follow.”The team operates out of the General Office 3build<strong>in</strong>g <strong>in</strong> Rosemead, Calif. Robert’s shift startsat 1:30 a.m., Tuesday through Saturday, so thatthe work produced is ready for mail<strong>in</strong>g the sameday. Robert starts by check<strong>in</strong>g his email for updates.He then goes <strong>to</strong> the production room floor<strong>to</strong> participate <strong>in</strong> group stretch<strong>in</strong>g exercises. Next,Robert leads a tailboard identify<strong>in</strong>g the shift’s prioritiesand mak<strong>in</strong>g any needed adjustments <strong>to</strong> thecomputer opera<strong>to</strong>r rotation roster. Throughouthis shift, he walks the floor <strong>to</strong> check for safety andmoni<strong>to</strong>r production and the equipment. At shiftend, he gathers the daily production <strong>to</strong>tals andwrites up a status report for the day shift.As Robert prepares for <strong>to</strong>day’s shift, he learnsof a problem impact<strong>in</strong>g the production schedule.After discuss<strong>in</strong>g with the team’s managers and supervisors,Robert quicklynotifies the rest of thevideoextraWatch Robert talkabout the job’srequirements andhis favorite sportsteams at http://<strong>in</strong>side.edison.com.shift <strong>to</strong> come <strong>in</strong> later.With the data due <strong>to</strong> arrivelate, Robert workswith the team <strong>to</strong> assigna small crew <strong>to</strong> the backupfacility <strong>in</strong> the Irv<strong>in</strong>eOperations Center, sothe work can be doneComputer Opera<strong>to</strong>rRobert Castellanos.Pr<strong>in</strong>ted bills fold <strong>in</strong><strong>to</strong> stacks,ready for <strong>in</strong>sert<strong>in</strong>g.from both locations simultaneously, help<strong>in</strong>g themga<strong>in</strong> back time. The strategy works. With teamwork,the day’s production goal is met on time,while also m<strong>in</strong>imiz<strong>in</strong>g the need for overtime labor.“It can be <strong>to</strong>ugh sometimes hav<strong>in</strong>g daily targets <strong>to</strong>meet with chang<strong>in</strong>g conditions,” said Robert, “but Ilike the challenge of stay<strong>in</strong>g flexible and com<strong>in</strong>g upwith solutions, and there’s noth<strong>in</strong>g like end<strong>in</strong>g theday know<strong>in</strong>g that our team met its goals.”http://<strong>in</strong>side.edison.com • august 2012 9