ETAG 001

ETAG 001

ETAG 001

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

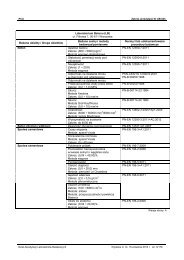

Base material conditionAny limitations on the condition of base material shall be stated. For instance if anchors may not be installed incracked concrete or may not be installed in holes filled with water.Hole cleaningInstructions for hole cleaning shall specify in detail the type of cleaning equipment to be used, e.g. the volume ofblow out pump and diameter and material of brush, together with the precise cleaning procedure including thenumber and order of blowing/brushing actions.Temperature limitsThe following temperature limits shall be specified:Installation ambient temperature rangeBonding material installation temperature range.Operational time limitsOpen time and curing time shall be stated in relation to the relevant temperature limits, e.g.:Open time related to bonding material installation temperatureCuring time in relation to installation ambient temperatureIf tables are used to indicate times-versus-temperature ranges, they shall be inclusive so that the relevant time isclear for all temperatures within the appropriate range. An accepted example is given in the following:Installation ambientCuring timetemperature °C(minutes)e.g. 5 - 15 120 min16 - 25 60 minThe following example is not accepted:Installation ambientCuring timetemperature °C(minutes)5 120 min15 60 minWhen curing times are stated it shall be made clear that this is the earliest time that the anchor may be torquedor loaded. A longer waiting time may be recommended for proof of ultimate load tests on site, if so, this shall bestated.Where anchors are installed using adapters attached to the anchor rod or socket, then the precise time whensuch adapters may be removed shall be stated.Mixing instructionFor bulk components mixed by the operator it shall be stated that part mixing is not allowed and all componentsshall be mixed in the quantities as supplied.The mixing equipment, its maintenance and the mixing procedures shall be described in sufficient detail toensure thorough mixing as required. The point at which mixing is complete shall be clearly stated whether this bea mixing time or a mixed condition such as an even colour throughout the mix.Bonding material placement controlled by the installerFor systems where the volume of material is controlled by the installer, e.g. injection and bulk systems, theinstructions shall advise the user on how to insert the correct volume and ensure that the annulus is completelyfilled.Instructions for placement shall describe how to ensure that air is not entrapped during placement of the resin orinsertion of the rod.9 THE ETA CONTENTIn addition to the requirements of Part 1, 9.1.3:<strong>ETAG</strong> <strong>001</strong>-5- 32 -