EM Auger Compactor - Komar Industries

EM Auger Compactor - Komar Industries

EM Auger Compactor - Komar Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

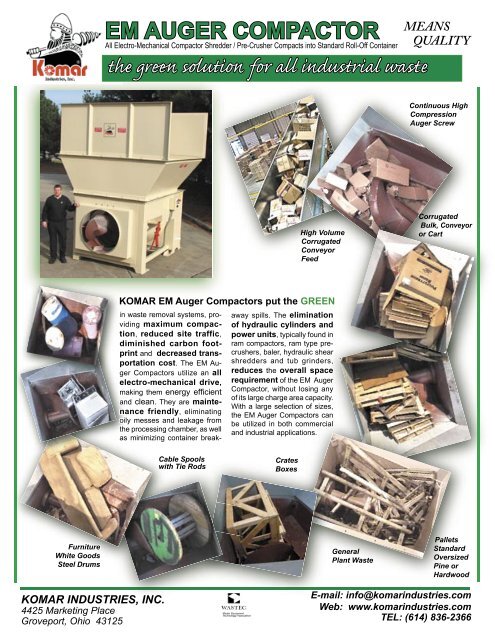

Since 1977<strong>EM</strong> AUGER COMPACTORAll Electro-Mechanical <strong>Compactor</strong>/Shredder Process Directly into Standard Roll-Off Containersthe green solution for industrial wasteOPENHOPPERS<strong>EM</strong>-2-40-WMoving Company8 to 10.5 Tons<strong>EM</strong>-2-40-WGlassManufacturer8 to 10.5 Tons<strong>EM</strong>-1-20-GFurnitureDistribution8 to 9 TonsFeatures of the <strong>Komar</strong> <strong>EM</strong> <strong>Auger</strong>The <strong>EM</strong> <strong>Auger</strong> features an all electro-mechanicaldrive, Allen Bradley controls, solid forged alloyshaft, high capacity roller bearings and comes ina variety of sizes and classifications to fit almost anyapplication. Sizes range from .75 to 9 cubic yard chargecapacity, with ample selection of open feed hoppers,enclosed plug-in dock hoppers and chutes. Machinesare offered in Class 1 & 2 designs to meet customerapplication needs.Class 1 is ideally suited for standard service requirementssuch as small industrial, commercial operations,hospitals, retail stores, grocery stores, shopping malls,etc.Class 2 is for heavier usage such as manufacturingfacilities, distribution centers, moving companies,municipalities, etc.<strong>EM</strong>-2-40-WRV Manufacturer8 to 10.5 Tons<strong>EM</strong>-2-40-WManufacturer9 to 10.5 TonsPallets & GraniteCratesBoxesPallets<strong>EM</strong>-2-40-WManufacturer8.5 to 10 TonsFlared HopperSidesIndustrial Mfg.Page 2

KOMARAROUND THE WORLDINSTALLATIONSStandard Plug-In & Open Hoppers / Engineered Chutes & Enclosuresputs the green in ryclingPLUG-IN DOCKHOPPERSSince 1977<strong>EM</strong>-2-15-WPallets7.5 to 8.5 tonsHow does the <strong>Komar</strong> <strong>EM</strong> <strong>Auger</strong> work?The <strong>EM</strong> <strong>Auger</strong> <strong>Compactor</strong>s’ uniquemethod of processing waste eliminatesair by reducing the material size andcomposition, increasing in density as itis processed thru a compression tubeto the receiving container, providingthe right combination for reduction andtransportation of plant waste. Materialssuch as corrugated, industrial wooddunnage, furniture, as well as mostother products are easily handledwith its large pitch compression augerscrew, which pulls the material downpre-crushing and tearing the materialas it is moved to the front wall. Theauger forces the material through theextrusion tube, further shredding andincreasing the density of the material.The high compression force of the augerscrew is intensified by the small surfacearea of the hardened compression flight,which provides approximately 10 timesthe direct compact force of conventionalram compactors. The <strong>EM</strong> <strong>Auger</strong> <strong>Compactor</strong>sproduce waste loads from 8 to12 tons per roll-off receiving container.Remember, the more abundant the airin your waste, the more containers needto be transported, utilizing energy whichadds to the carbon in the air and cost tothe bottom line.<strong>EM</strong>-1-20-GCorrugated8 to 9 Tons<strong>EM</strong>-2-75-GFEEDCHUTESLARGEENCLOSUREHigh SpeedConveyor FeedElectro-MechanicalCart Dumpers<strong>EM</strong>-2-40-CF9 to 12 TonsDistribution Centers, Corrugated<strong>EM</strong>-2-25-G8.5 to 10.5 TonsPage 3

SPECIFICATIONS& Some Optional Equipmentthe green solution for industrial wood wasteStandard hopper shown;Special hoppers designed to your applicationBaseUnitCu.Yd.<strong>Auger</strong>Forcelbs.<strong>Auger</strong>ShaftRPMHPTEFC240/ 460V*40 cu.yd.Load Wt.TonsChargeOverall Dim.Wt.ModelsOpeningL”x W”x H”lbs.<strong>EM</strong>-1-10-G 1.75 50”x60” 56,050 8 78”x 70”x 89” 10 4,480 6 to 7<strong>EM</strong>-1-15-G 2.75 53”x60” 76,900 8.6 83”x 70”x 93” 15 6,250 7 to 8<strong>EM</strong>-2-15-W 2.75 53”x60” 96,170 7 83”x 83”x 93” 15 6,800 7 to 8<strong>EM</strong>-1-20-G 4.75 66”x69” 110,000 6 108”x 83”x 93” 20 10,275 7 to 8<strong>EM</strong>-2-25-G 5 67”x69” 146,000 6 117”x 83”x 102” 25 11,200 8 to 11<strong>EM</strong>-2-40-G 6 76”x75” 178,363 8 121”x 90”x 102” 40 14,200 8.5 to 12<strong>EM</strong>-2-40-CF 6 76”x75” 110,000 14.5 121”x 90”x 102” 40 14,200 8.5 to 12<strong>EM</strong>-2-40-W 6 76”x75” 178,363 8 121”x 90”x 102” 40 14,750 8.5 to 12<strong>EM</strong>-2-75-G 9 96”x76” 219,000 9 152”x 96”x 117” 75 27,000 9 to 12Flared HopperSidesMachine MountedControl BoxRectangularC o n t a i n e rVarious Sizes to fitYour Needs* Load weights are based on actual customer usage; however, results may vary depending on materials, loading method or scheduled pick-ups.OPTIONSCall your local dealer or factoryrepresentative for additional optionsAll electro-mechanical cart dumpers1,000 lb. or 2,000 lb. capacityRemote MountedControl BoxHeavy DutyMotor DriveGuard<strong>Komar</strong> Octagonal CompactionReceiving ContainersAvailable in 29, 32, 36, 40 & 44 cu.yd. capacity with quick-close sideswing door for feed tube openingPatent: # 4253615, # 5108040KOMAR INDUSTRIES, INC.4425 Marketing PlaceGroveport, Ohio 43125TEL: (614) 836-2366FAX: (614) 836-9870Page 4E-mail info@komarindustries.comWeb: www.komarindustries.com©KI-51040830G