Fire Safety Log Book - Northern Ireland Fire & Rescue Service

Fire Safety Log Book - Northern Ireland Fire & Rescue Service

Fire Safety Log Book - Northern Ireland Fire & Rescue Service

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

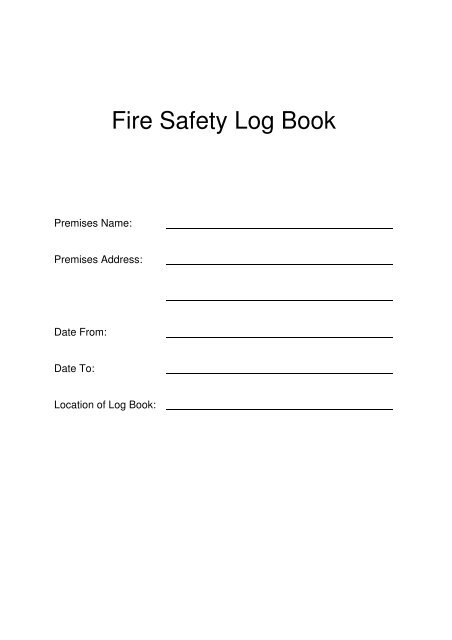

<strong>Fire</strong> <strong>Safety</strong> <strong>Log</strong> <strong>Book</strong>Premises Name:Premises Address:Date From:Date To:Location of <strong>Log</strong> <strong>Book</strong>:

CONTENTSPART 1 FIRE SAFETY ADVICE 1PART 2 FIRE PRECAUTIONS 2Section 1 Guidance on <strong>Fire</strong> Risks and Preventative Measures 2Section 2 Guidance on <strong>Fire</strong> Detection and Warning Systems 3Section 3 Guidance on <strong>Fire</strong>fighting Equipment 4Section 4 Guidance on Escape Routes 7Section 5 Guidance on Emergency Escape Lighting 7Section 6 Guidance on Signs and Notices 8Section 7 Guidance on Informing, Instructing and Training 8PART 3 FIRE SAFETY MAINTENANCE CHECKLISTS 9Daily Check Advice 9Record <strong>Log</strong>s• <strong>Fire</strong> Detection 10• False <strong>Fire</strong> Alarms 11• <strong>Fire</strong> Extinguisher 12• Hose Reel 13• Sprinkler System 14• Emergency Escape Lighting 15• Miscellaneous Equipment 16• <strong>Fire</strong> Instruction 17• <strong>Fire</strong> Drill 18• <strong>Fire</strong> <strong>Safety</strong> Inspection Visits 19Replacement log books and additional parts can be downloaded from fireSAFE, inthe Guidance Documents section at www.nifrs.org.Template adapted with permission from Essex <strong>Fire</strong> and <strong>Rescue</strong> <strong>Service</strong>.

PART 1 FIRE SAFETY ADVICEThe advice given in this document is intended to assist you and your staff inpreventing an outbreak of fire, or if it does occur, assist you in preventing injury orunnecessary damage to the premises. This is not a comprehensive guide andtherefore it is recommended you consult the appropriate guidance book for yourpremises.Guides in the series:Offices and ShopsFactories and WarehousesSleeping AccommodationResidential Care PremisesEducational PremisesSmall and Medium Places of AssemblyLarge Places of AssemblyTheatres, Cinemas and Similar PremisesOpen Air Events and VenuesHealthcare PremisesTransport Premises and FacilitiesAnimal Premises and StablesMeans of Escape for Disabled PeopleThese guidance documents are available to view and download free on the NIFRSwebsite from fireSAFE, in the Guidance Documents section.The fire safety records included in this book, a suitable and sufficient fire riskassessment and well thought out emergency plans will lead to a good fire safetyculture and a quality safety management structure. Record keeping will providevaluable resources to assist you in two areas:• Effectively managing the fire strategy for your premises.• Providing evidence to enforcing authorities or the courts that you have doneeverything that could be reasonably expected to ensure safety within thepremises and to comply with the law.1

PART 2 FIRE PRECAUTIONSSection 1Guidance on <strong>Fire</strong> Risks and Preventative MeasuresFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.BUSINESS PREMISES: Common causes of fireElectricity – Is a source of heat and a frequent cause of fire in buildings. Somecontributing factors are the misuse of electrical equipment and poor maintenance.With the increasing number of electrical appliances we use, consideration of theneed for additional sockets or upgrading of electrical circuits may be necessary, anannual inspection of the electrical system by a competent electrician will help toidentify any areas of concern. Inspection of electrical equipment should revealwhether:• It is installed and maintained correctly.• Sockets and extension cables are overloaded.• The correct fuses are used.Ensuring electrical equipment is switched off and unplugged when not in use willassist to reduce the risk of fire occurring.Rubbish – When left to accumulate in the workplace, could not only increase thechance of fire occurring, it may assist a fire to spread throughout the premises a lotquicker. Adopt a good housekeeping regime to ensure rubbish is taken out of thepremises as quickly and as often as possible and contained within lidded metal bins.Ensure external rubbish bins are sited away from buildings reducing the risk of a firespreading to the building and ensure that they do not obstruct either your escaperoutes or those of neighbouring premises.Smoking – Careless disposal of smoking materials is a major cause of fire.Implementation of a smoking policy could ensure:• People only smoke in designated areas.• Provision of non-combustible and substantial ashtrays.• Daily disposal of the content of ashtrays into a non-combustible wastereceptacle ensuring that all debris is fully extinguished first.• End of day checks or checks before leaving rooms which will be unoccupiedfor long periods (people may be sleeping) are undertaken.Heaters – If placed near furniture or combustible materials can start a fire. Ensurethat they are positioned carefully and used appropriately. Keep boiler houses clearof accumulations of combustible materials and avoid using them as an extrastoreroom. If you have open fires in your premises, never use flammable liquids tolight them, always have them securely guarded and sweep chimneys twice per yearor more if wood is burned.2

Dangerous Goods – Most correction, duplicator fluids and most aerosols areflammable and aerosols can explode if they become too hot and must be kept wellaway from any heat sources. The careful use and storage of any flammable liquid orgas is essential to maintain a safe working environment.Deliberate <strong>Fire</strong> Setting – Help protect your premises by securing any combustiblewaste in an appropriate receptacle and locking away any flammable liquids or gases.Considering the potential problem of deliberate fire setting is an important aspectand is one that should not be underestimated as it is not only a major cause of firebut frequently a problem when the premises are unoccupied. End of day checks toensure all windows and doors are secure can help to manage the risk of arson.Further information on reducing the risk of deliberate fire setting can be found on thewebsite www.arsonpreventionbureau.org.uk.Section 2Guidance on <strong>Fire</strong> Detection and Warning SystemsFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.Also British Standard 5839:1.The fire alarm system is required to be monitored and tested by a nominatedresponsible person. The responsible person should have sufficient information andtraining in order to carry out all aspects of routine testing and supervision of thesystem.Regular tests are vital to ensure that there has not been any major failure of theentire or a significant part of the system.It is essential that if the alarm is linked to an alarm signal receiving centre, it iscontacted immediately before, and immediately after, any tests to ensure thatunnecessary attendance of the fire and rescue service is avoided and that anassessment of whether fire alarm signals are correctly received at the alarmreceiving centre.• Inspect the alarm panel daily for normal operation of the system (this does nothave to be recorded). If any defects are found then record in the log book andreport it to a responsible person. It should be ensured that any faultsrecorded have received appropriate attention.• Every week a different manual call point should be operated (same time eachweek) during normal working hours. In premises where employees work outof these hours, an additional test should be carried out at least once a monthto ensure familiarity with the sound of the fire alarm. There is no maximumlimit for the period of time it takes to test the system in rotation.• Automatic door releases that are connected to the fire alarm system shouldbe tested weekly in conjunction with the fire alarm test, checking that all doorsare being released and close fully onto the door rebates.3

• If emergency generators are used as standby power, simulation of powerfailure to activate generators on load for at least one hour each month will benecessary. Where vented batteries are used as standby power, carry out avisual inspection of batteries and connections including electrolyte level.• Quarterly and annual inspections and tests can only be undertaken by acompetent person with the relevant technical knowledge and training. Thismay be done by the installer, a qualified in-house maintenance person orsome other competent person.Regular visual inspection of manual call points and fire detectors is required toensure that:• Manual call points are unobstructed and conspicuous.• A clear space of 500mm is maintained below each automatic fire detector andis not impeded by any other means, ie, accumulation of dust in detector heador layers of paint.False alarms should be recorded and positive action taken to manage the problem.Categories of False Alarms• Unwanted alarms.• Equipment false alarms.• False alarms with good intent.• Malicious false alarms.Section 3Guidance on <strong>Fire</strong>fighting EquipmentFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.Also British Standard 5309:3 and BS EN3.All testing of equipment should be in accordance with the manufacturer’sinstructions.Portable <strong>Fire</strong> ExtinguishersMonthly InspectionIt is recommended that a regular visual inspection of all extinguishers is carried outby the responsible person or other nominated competent person not less thanmonthly.4

Inspection checks should include:• Are extinguishers located in the designated place?• Are extinguishers visible and unobstructed?• Are operating instructions legible and do they face outwards?• That extinguishers have not been used and have no obvious damage.• That pressure gauges/indicators are reading within operational and safetylimits.• That the seals and tamper indicators are not broken or missing.Corrective action should be arranged where necessary.Annual <strong>Service</strong> and Inspection by a Competent PersonThe user should ensure that extinguishers, gas cartridges and replacement chargesare inspected, serviced and maintained as recommended in current BritishStandards. These procedures should be carried out by a competent person capableof conducting them according to the recommendations of this code and any specialprocedures recommended by the manufacturers using recommended tools,equipment and materials at least annually.Schedule of MaintenanceType of ExtinguisherBasic<strong>Service</strong>Extended <strong>Service</strong>with Discharge TestOverhaul andRechargingWater (Stored Pressure)Water (Gas Cartridge)Every Year Every 5 Years ---Foam (Stored Pressure)Foam (Gas Cartridge)Every Year Every 5 Years ---Powder (Stored Pressure)Powder (Gas Cartridge)Every Year Every 5 Years ---Carbon Dioxide Every Year --- Every 10 YearsHose ReelsFor further information see British Standard EN 671:3.These should be inspected at intervals depending on the environment/fire risks by acompetent person for obvious leaks and corrosion. Regular visual checks shouldalso be carried out to ensure that the hose reel is unobstructed, clearly visible andoperating instructions are present.5

Annual <strong>Service</strong> and Inspection by a Competent PersonThe hose should be completely run out and subjected to operational water pressureto ensure that the hose is in good condition, that all couplings are water tight and thenozzle is easy to operate. A flow test should be carried out to ensure a steady andsufficient flow (use of a flow indicator and pressure gauge is recommended).Sprinkler Systems (Automatic)For further information see BS EN 671:3.Weekly RoutineThe following checks should be recorded:• Water and air pressure gauge reading on installations, trunk mains andpressure tanks and water levels in elevated private reservoirs, rivers, canals,lakes, water storage tanks and all gauge readings and levels recorded.• That each water motor alarm has been sounded for at least 30 seconds.• Fuel and oil levels of diesel engines used to power automatic pumps.• That automatic pumps start when the water pressure is reduced to thespecified level and, if powered by diesel engines, the oil pressure, the flow ofcooling water through open-circuit cooling systems or the water level in theprimary circuit of closed-circuit cooling systems, and whether the engines willrestart, using the manual start test button.• The electrolyte level and density of all acid battery cells and if the density islow that the battery charger is working correctly. Ensure that the affectedcells have been replaced.• The operation of the mode monitoring system for stop valves in life safetyinstallations.• The continuity of connection between the alarm switch and the control unitand between the control unit and the fire service (usually via a remotemanned centre) for automatically monitored connections.• The correct functioning of trace heating systems provided to prevent freezingin the sprinkler system.Quarterly, half yearly, yearly and three yearlyArrange for inspections and tests of the sprinkler system to be carried out by acompetent person, for any defects found to be logged and ensure any necessaryaction is taken. Ensure that certificates of satisfactory testing are received.6

Section 4Guidance on Escape RoutesFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.You should ensure that on a daily basis the escape routes are:• Free from obstruction, slip or trip hazards (stored or temporary items).• Clearly indicated to ensure relevant people can use them easily andimmediately.• Equipped with fire doors, that are not wedged open or have self-closingdevices removed, to prevent the spread of fire, heat and smoke.• Final exit doors can be opened quickly and easily by means of push bars,push pads or similar device, but not with the use of a key.• Areas outside the final exit doors are kept clear from obstruction.• Available for access by the emergency services.Section 5Guidance on Emergency Escape LightingFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.For further information see BS 5266:1.The emergency escape lighting system is required to be monitored and tested by anominated competent person. This person should have sufficient information andtraining in order to carry out all aspects of routine testing and supervision of thesystem. Due to the possibility of a failure of the normal lighting shortly after a periodof testing of the emergency lighting system or during the subsequent rechargeperiod, all tests should be undertaken at times of minimum risk.• Inspect the system daily and ensure that every indicator lamp in a maintainedunit is lit. If any defects are found then record in the log book and report it to aresponsible person. It should be ensured that any previous faults recordedhave received urgent attention.• Monthly test of all self-contained luminaires by simulating normal lightingfailure. The period of simulated failure should not exceed one quarter therated duration of the luminaire or sign and all luminaires/signs should bevisually examined to ensure correct function.• Six-monthly test of self-contained luminaires, internally illuminated signs andcentral battery systems by a power failure simulation of 1 hour for 3 hourduration units and 15 minutes for 1 hour units. During the test check allluminaires for proper function.• Three yearly test for full duration of self-contained and central batterysystems. During the test check all luminaires and at the end when the supplyis restored ensure that any indicator lamp or device is showing normal supply.• Subsequent annual tests should be undertaken following the same practice asthe three yearly test or at the discretion of the enforcing authority.7

Section 6Guidance on Signs and NoticesFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.All signs and notices will need illumination to ensure they are conspicuous andlegible. Appropriate signage will take into account the type of people who may needto use them. Regular checks are required to ensure that all signs and notices areclearly visible and unobstructed enabling relevant people to use them in anemergency.Section 7Guidance on Informing, Instructing and TrainingFurther guidance can be found in Part 2 of the appropriate premises guidesunder the above heading.Are all relevant people aware of their responsibilities in the event of an emergency?Ensure that they know:• What action to take on discovering a fire and on hearing the fire alarm.• How to raise the alarm.• How to contact the <strong>Fire</strong> <strong>Service</strong>.• Correct evacuation procedures and location of the assembly points.• Only tackle a fire if it is safe to do so (when fire is small and correctextinguisher is available).• Aware of the contents of the <strong>Fire</strong> Risk Assessment.Employees should receive training during working hours when they startemployment, following any changes to the emergency plan or to the workplace and ifthere are changes to work practices and processes.What to do in the case of a fireOn the sounding of the fire alarm the building must be evacuated following youremergency plan. Where possible try to contain the fire by shutting doors andwindows; this will help to reduce draughts that may fan and spread the fire. Contactthe fire service immediately ensuring the name and address of the premises is givenclearly. Try not to position yourself too close to fire bells/sirens if possible whenmaking the emergency call. It can become very difficult for all parties to hear vitalinformation. When the fire service arrives ensure the responsible person meetsthem to collate information. Do not re-enter the building for any reason.8

PART 3 FIRE SAFETY MAINTENANCE CHECKLISTSDaily Check AdviceThe daily check advice below is not a comprehensive list, but it is a good example ofhow you could adopt a maintenance checklist to fit your needs in supporting your firesafety policy. All the listed checks below do not have to be recorded and are tasksthat can be undertaken as part of the working day.Daily Checks (not normally recorded) Yes NoEscape Routes• Can all fire exits be opened immediately and easily?• Are fire escape doors clear of obstruction?• Are escape routes clear?<strong>Fire</strong> Warning System• Is the indicator panel showing normal?• Are whistles, gongs or air horns in place?Escape Lighting• Are luminaires and exit signs in good condition and undamaged?• Is emergency lighting and sign lighting working correctly?<strong>Fire</strong>fighting Equipment• Are all fire extinguishers in place?• Are fire extinguishers clearly visible?• Are any vehicles blocking fire hydrants?Record <strong>Log</strong>sTo be completed as indicated or as required (see over):9

FIRE DETECTION TEST RECORD(Weekly)DateCall Pointlocation ornumber<strong>Fire</strong> AlarmSatisfactoryYes/NoAutomatic DoorReleaseSatisfactoryYes/NoAutomatic DetectorsLocationor numberSatisfactoryYes/NoRemedialAction TakenSignaturePage __ of __10

RECORD OF FALSE FIRE ALARMS<strong>Fire</strong> Alarm Call Point/DetectorDate Time Location orTypeNumber <strong>Fire</strong> FAAction Taken Name SignaturePage __ of __11

FIRE EXTINGUISHER TEST RECORD(Monthly, Annually)DateLocation orNumberInspected Results Corrector Tested Yes NoDetails of Fault andAction TakenNameSignaturePage __ of __12

HOSE REEL TEST RECORDDateLocation orNumberInspected Results Corrector Tested Yes NoDetails of Fault andAction TakenNameSignaturePage __ of __13

SPRINKLER SYSTEM TEST RECORD(Weekly)DateWater &AirPressureGaugesCorrectWaterLevels inSystemCorrectWater MotorAlarmCorrectAutomaticPump StartCorrectDieselEngineRestartingCorrectYes No Yes No Yes No Yes No Yes NoDetails of Fault & ActionTakenNameSignaturePage __ of __14

EMERGENCY ESCAPE LIGHTING TEST RECORD(Monthly, Six Monthly, Annually)DateTest AllLuminairesOperatingCorrectTestCentralBatterySystemCorrectTestGeneratorOperatingCorrectTest Engineof GeneratorOperatingCorrectYes No Yes No Yes No Yes NoDetails of Fault & Action Taken Name SignaturePage __ of __15

MISCELLANEOUS EQUIPMENT TEST RECORDDateItem TestedSatisfactoryYes/NoDetails of Fault & ActionTakenNameSignaturePage __ of __16

FIRE INSTRUCTION RECORDDateInstructionDurationPerson ReceivingInstructionNature of Instruction Name SignaturePage __ of __17

FIRE DRILL RECORDDateNature ofDrillPerson/SectionTaking PartEvacuationTimeDetails of Deficiencies &Action TakenNameSignaturePage __ of __18

FIRE SAFETY INSPECTION VISITSDateInspecting OfficerInspecting OfficerSignatureCommentsPage __ of __19