July 2012 - Iowa Pork Producers Association

July 2012 - Iowa Pork Producers Association

July 2012 - Iowa Pork Producers Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

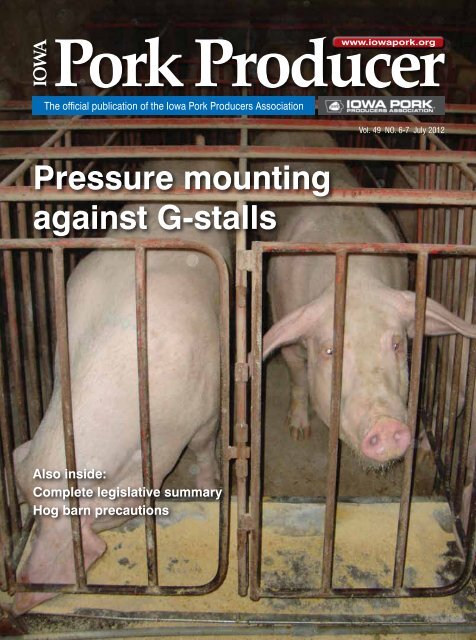

<strong>July</strong> Highlights05 Randomly Speaking – A message from the president08 IPPA welcomes new staff member10 ISU students join IPPA as summer interns12 U.S. pork exports post strong Q1 growth14 IPPA co-sponsors Tokyo pork seminar16 ISU graduate student receives national award18 A summary of the 84th <strong>Iowa</strong> General Assembly22 <strong>Producers</strong> share thoughts on gestation stall usePressure to end the pork industry’s use ofgestation stalls is mounting. A series of articleson the g-stall issue starts on page 22.23 One producer’s experience with group housing24 USDA to look at economics of sow housing transition26 McDonald’s outlines plan for ending gestation stall use27 Grocery, restaurant execs surveyed about animal ag issues28 USDA to survey hog farmers on swine health managementpracticesPrograms are made available to porkproducers without regard to race, color,sex, religion or national origin. The <strong>Iowa</strong><strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong> is an equalopportunity employer.The <strong>Iowa</strong> <strong>Pork</strong> Producer is the officialpublication of the <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong><strong>Association</strong> and sent standard mail fromDes Moines, <strong>Iowa</strong>, to <strong>Iowa</strong> pork producersby the first week of the month of issue. Thepublisher cannot guarantee the correctnessof all information or the absence of errorsand omissions, nor be liable for content ofadvertisements.All <strong>Iowa</strong> <strong>Pork</strong> Producer inquiries should bedirected to the Editor at:<strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>P.O. Box 71009Clive, IA 50325-0009Phone: (515) 225-7675<strong>Iowa</strong> Toll-free: (800) 372-7675FAX: (515) 225-0563e-mail: info@iowapork.org29 Ogden family celebrates opening of new hog barn30 Precautions you should take when performing normal hogbarn tasksIn Every Issue06 <strong>Pork</strong> Industry News and Updates32 All-around <strong>Iowa</strong>34 National <strong>Pork</strong> <strong>Producers</strong> Council News36 National <strong>Pork</strong> Board News38 Coalition to Support <strong>Iowa</strong>’s Farmers News40 <strong>Pork</strong> Recipes42 <strong>Producers</strong>’ MarketMISSION STATEMENTThe <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong> is an industry inclusive organization whosemission is to provide a unified voice to promote and educate for a sustainable,socially responsible, profitable and globally competitive pork industry.JULY <strong>2012</strong>3

IPPA invites you to volunteerat the <strong>Iowa</strong> State fairThere’s no better way to promote your professionthan to serve as an <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong><strong>Association</strong> volunteer at the <strong>Iowa</strong> State Fair. Thereare nearly a million opportunities at the fair to tellthe pork story and IPPA invites you to join us.Opportunities are available at the <strong>Iowa</strong> <strong>Pork</strong> Tent,Chop stands, Swine Barn, Agriculture Buildingand the Animal Learning Center. If one of thesevenues appeals to you, please let us know. Wewill provide free fair admission for the day and afood and drink ticket for the <strong>Iowa</strong> <strong>Pork</strong> Tent.The <strong>2012</strong> <strong>Iowa</strong> State Fair will be held Aug. 9-19in Des Moines.If you can help in the <strong>Pork</strong> Tent, please contact Mary Lea Hampton(mhampton@iowapork.org), For the other venues, ask for Lea Clemenson(lclemenson@iowapork.org). You can reach us at (515) 225-7675or (800) 372-7675.<strong>2012</strong>AdvertisersThe <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>would like to thank our advertisersfor supporting us. Be sure to keepthem in mind as you plan yourpurchases throughout the year!Absolute Insemination.............................2Alltech....................................................15Boehringer Ingelheim .............................9Boyce Livestock Co. LLC......................42Central Life Sciences.............................13Chore-Time............................................27Compart’s Boar Store............................42Elanco....................................................25Hog House Alarms................................43IPSC.......................................................17International Boar Semen......................42Katolight.................................................37Kerns Farms...........................................43Land O’Lakes.........................................11LSG Health Systems..............................43Marvin Wuebker.....................................43Pit Charger...............................................7PMT........................................................43<strong>Producers</strong> Livestock..............................43SFP........................................................20Stutsman................................................39Truline Genetics.....................................42Uddertech..............................................29Waldo Farms, Inc...................................42Whiteshire Hamroc................................43ZFI Swine Semen Services....................31<strong>2012</strong> Board of DirectorsIPPA StaffExecutive CommitteePresidentBill TentingerPresident-electGreg Lear, SpencerVice President ofOperationsDavid Struthers, CollinsVice President ofResourcesMark Meirick, ProtivinVice President of MarketDevelopmentMark Johnson, LelandVice President ofProducer ServicesJamie Schmidt, GarnerPast PresidentLeon Sheets, IoniaNPPCHoward Hill, <strong>Iowa</strong> FallsJohn Weber,DysartNational <strong>Pork</strong> BoardConley Nelson, AlgonaDerrick Sleezer, CherokeeDirectorsDistrict 1 Joe Rotta, MerrillDistrict 4 Al Wulfekuhle, QuasquetonDistrict 5 Curtis Meier, ClarindaDistrict 6 Gene Moody, MaxwellDistrict 7 David Calderwood, TraerDistrict 8 Heather Hora, WashingtonNW Region Marv Rietema, SiouxCenterSE Region Joel Huber, WellmanNE Region Brenda Schmitt, RuddAllied Ryan Bailey, State CenterStakeholder Craig Rowles, CarrollEx-officio Directors<strong>Iowa</strong> Secretary of AgricultureThe Honorable Bill Northey<strong>Iowa</strong> Department of Agricultureand Land StewardshipHarold Hommes<strong>Iowa</strong> <strong>Pork</strong> Industry CenterDr. John Mabry, Executive Director<strong>Iowa</strong> State UniversityDr. Maynard HogbergDr. Lisa Nolan<strong>Iowa</strong> <strong>Pork</strong> Youth TeamQueen, Lindsay Reth, ManchesterPrincess, Sterling Schnepf,GranvilleAmbassador, Jacob Swanson,OttumwaDirectorsRich Degner, ExecutiveTyler Bettin, Producer EducationRon Birkenholz, CommunicationsDoug Fricke, Trade ShowMarketingJoyce Hoppes, ConsumerInformationCody McKinley, Public PolicyKelly Sheets, Producer OutreachKelsey Sutter, Marketing/ProgramsJeff Vande Kieft , AccountingAssistantsSheryl Christensen, AdministrativeLea Clemenson, ProgramsMary Lea Hampton, PromotionsAndrea Wright, TechnicalMagazine design and layout byMindz Eye Design4 JULY <strong>2012</strong>

Randomly Speaking –A message from the presidentGreetings, Fellow <strong>Pork</strong> <strong>Producers</strong>!Bill TentingerIPPA PresidentI am writing this after spending several days at World <strong>Pork</strong> Expo. I always enjoy thetime spent checking out new ideas to take home and learning more about somethingI might already be using. I also enjoy visiting with and meeting other producers andlearning from them as well. Sometimes I learn more after hours. It wouldn’t be Expo ifI didn’t have a little fun too!This year, like others, talk seemed to center around the growing crops and the rains, or mostly the lack of. The recentrecovery in the markets also was mentioned often and the fact most producers have found a way to survive tight margins.All of this is serious stuff and needs to be addressed. There are a couple of issues that have really taken hold and thatwould be animal welfare, along with our right to operate. Those two issues seem to be very critical because if they’re notdealt with correctly, we could all see major changes in the way we do business, if we’re allowed to operate at all.There is a very small percentage of our population that is convincing our customers that we cannot be trusted to care for ouranimals in the most humane way. All while having a hidden agenda of creating a meat-free society. They are trying to getour customers to allow those who know nothing about animal agriculture to dictate how we operate, even convincing someto come up with new science. While our industry is focused on that issue, they also are working in Washington to gain newfriends and, if allowed to, will legislate to us too. I for one think that we need to push this train back to the station and havesomeone else drive. I believe that the consumer DOES still care about safe, affordable food and that they do not want thecost of their food to go up. If we’re forced to make major changes in the way we care for and handle our animals, the cost ofproducing will increase. With tight margins, I don’t see the producer or the packer being able to absorb much.I believe the only way to stop what is happening is to engage consumers and those in public office. We need to get the facts tothem. But, before we can really engage those folks, we need to fully engage our producers. This is not just a farrower’s problem.This is everybody that derives a living from animal agriculture and includes barn workers, lenders and all those who supply ourfarms. If we lose the right to house sows in the best way known, what might be next? We already have problems in our harvestfacilities. Our truckers are having nightmares! The animal handlers in those facilities are walking on tight ropes.I believe that we all have to step up to the plate and defend what we’re doing. Don’t wait for leadership or yourorganization to do it all, some things can only be accomplished with personal producer contact. Use every opportunity inyour everyday life to show that you are doing the right thing every day. It might catch on and who knows how far it mighttravel or who might hear it. It is a small world out there. We all have contacts all over this great country. Good news travelsfar. Have an open house or invite people out. Welcome questions about what you do. Thank those who support animalagriculture and try to influence those who may not. These things are going to take a long time to achieve and that’s why allof us must be engaged. We must live the “We Care” pledge every day.All of these issues prove to me the importance of our state and national organizations. NPPC’s SIP program andIPPA’s grassroots program allow fundraising that can be used to protect our industry from these attacks. If you areserious about your business, you need to get involved in protecting it. If you have been or are ever asked to participate,consider it. DO THE RIGHT THING.Like always, if you have any concerns or questions, feel free to call IPPA, any member of the board of directors or myself.Bill TentingerIPPA PresidentJULY <strong>2012</strong>5

<strong>Pork</strong> Industry News and UpdatesIndependent panel issuesassessment of Wyominghog farm videoThe Animal Care Review Panel, apanel of animal well-being experts,created to analyze undercovervideo investigations at livestockfarms, calls animal mistreatmentseen in a video released May8 from a Wyoming hog farm“unacceptable and indefensible.”The panel that examined theWyoming video was comprisedof Dr. Temple Grandin, ColoradoState University; Dr. CandaceCroney, Purdue University; andDr. John Deen, University ofMinnesota.“There’s definitely abusive animalhandling shown in that video,” saidGrandin. “Kicking and throwingpiglets? This farm definitely hasmanagement issues. A well runoperation would not be doing thesekinds of things.”“This video was an incrediblydisturbing, saddening and horrificexample of the worst kind ofanimal handling,” said Croney.“What I saw is the antithesisof every professional standardfor animal care and handlingpublished in any industry guidelineor any certification program. Icannot imagine that anyone inthe swine industry who considersthemselves a responsible actorcould support what is seen in thatvideo. The handling of the animalsshown is scientifically and morallyindefensible.”“It’s unacceptable,” said Deen.“It’s not consistent with handlingpractices in training programsthat have been created and withexpectations by the farmingcommunity. The actions seen in thisvideo are abusive to the pigs andunacceptable to society as a whole. “The experts noted the video wascomprised of brief excerpts andthat being allowed to view uneditedfootage might possibly have allowedthem to place the case in bettercontext.Grandin noted that undercovervideo obtained from an <strong>Iowa</strong> hogfarm that was reviewed by thepanel in February did not show anyanimal mistreatment.The farm in question tookimmediate steps to address thesituation and was implementingunannounced inspections of thefacility by the farm’s consultingveterinarian.The Center for Food Integrity (CFI)created the panel of animal wellbeingexperts to examine video andprovide their expertise for foodretailers, the pork industry and themedia, as well as other sectors ofanimal agriculture as they showinterest.Animal rights groupsusing disturbing videos topush agendaOn Friday, May 11 The SacramentoBee published an article titled “NewAnimal Rights Push Pay People toWatch Disturbing Videos.”Key points of the article share howmembers of the non-profit FarmAnimal Rights Movement (FARM),based in Maryland, are sponsoringthe unusual national campaign. In it,they offer people $1 to watch a shortvideo that shows gruesome scenes ofslaughter and abuse of chickens, pigsand cows at unidentified farmingoperations. The images people willwatch on video are graphic enough,organizers hope, that individualswill turn away and stop eating meat.Organizers boast that it is the largestand “most audacious” effort yetdesigned to discourage people fromconsuming animal products.On a bus equipped with 32 screens,FARM is bringing the video tocollege campuses, festivals, fairsand other public places around thecountry this summer. FARM wasthe first to target public gatheringspots, but the tactic is catching onwith other organizations such as TheAnimal Rights Coalition and Mercyfor Animals. PETA has long airedshocking images in DVDs and onbillboards.6 JULY <strong>2012</strong>

New swine ID tags nowavailableMetal swine identification tags, longa bane of the industry, may soon be athing of the past.<strong>Iowa</strong> State University Extension andOutreach swine veterinarian JamesMcKean said the <strong>Iowa</strong> Departmentof Agriculture and Land Stewardshiphas developed a new plastic versionas a replacement for metal tags.This will be good news for manyproducers.“The tags are available from <strong>Iowa</strong>practicing veterinarians and areconsidered official ID for bothintrastate and interstate transportof swine,” McKean said. “Theplastic tags should be easier toapply and retain for show pigs,feeder pigs and others that may bemoved.”The new tags, manufactured byAll-Flex, are triangular in shape,approximately an inch and a halffrom top to bottom and from sideto side at the widest point.European gestationstall ban will decreaseproductionEven though the United Kingdomalready is fully compliant witha European sow stall ban thattakes effect Jan. 1, 2013, industryestimates are that fewer than halfof the EU member states will be atthat stage come the first of next year.Those farmers unable tocomply, described as “significantnumbers,” are expected to leavethe production business. Fewerproducers means fewer animalsto market and higher prices forconsumers.A recent report from BPEX warnsof the legislation’s consequences,“BPEX has for some time beenwarning of the likelihood oftighter supply and higher pricesas pig herds across Europe declinein numbers as a direct result ofthe new legislation. … This reportmakes clear that the pig herd inthe EU will decline, that supplyof pig meat will tighten and thatcosts will increase. It looks at anumber of possible outcomesfollowing the introduction of thenew rules on 1 January 2013.”JULY <strong>2012</strong>7

IPPA welcomes new staff memberFrom helping out on the family’s diversified farm toher community involvement activities, Kelsey Sutteris not one to rest on her laurels, or rest at all for thatmatter! To say she has a lot on her plate would be anunderstatement.Kelsey is the new marketing and programs directorfor the <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>. Shejoined the association May 16 and replaces AlisonSwanson, who resigned this spring.The Pleasantville native will work closely with theIPPA Restaurant & Food Service, Promotions, <strong>Pork</strong>Tent and Youth Committees in her new role. Shecoordinates the Taste of Elegance competitions andwill assist in the operation of the <strong>Iowa</strong> <strong>Pork</strong> Tentduring the <strong>Iowa</strong> State Fair. Her responsibilities alsoinclude managing all youth programs, including the<strong>Iowa</strong> <strong>Pork</strong> Queen, Princess and Premier <strong>Pork</strong> YouthAmbassador contests and the <strong>Iowa</strong> <strong>Pork</strong> YouthTeam. Sutter serves as IPPA’s social media expertand provides regular communications throughIPPA’s Facebook and Twitter accounts.family farms 6,000 acres of corn and soybeansand raises hogs on contract for Cargill in twofamily owned finishing barns. Kelsey handlesgrain marketing duties for the family farm andshe and Jacob also have their own commercialcow-calf herd.Kelsey finds additional time to serve ascommunications chair for the newly createdPleasantville FFA Alumni Chapter and, alongwith her husband, serves on the Marion CountyFarm Bureau Board of Directors.“It can be trialing to juggle the farm andcommunity involvement with working fulltime,but I love being involved with our familyoperation and I find being involved in the industryand my local community so rewarding that thebenefit far outweighs the struggle,” Sutter said.“I am thrilled to have the opportunity to join theIPPA family and to help promote and strengthenthe pork industry in the state of <strong>Iowa</strong>,” Sutter said.“It is amazing to think about the changes the porkindustry has made in the past 10 years and it’sexciting to be a part of such a progressive industry.<strong>Iowa</strong> is the place to be when it comes to porkproduction and I feel truly blessed to be selected forthis position.”Sutter came to IPPA from the <strong>Iowa</strong> FFA Foundationin Ankeny where she served as facility coordinatorfor the FFA Enrichment Center for a little more thana year. She graduated from <strong>Iowa</strong> State Universityin December 2010 with a bachelor’s degree inagricultural education with a communicationsoption emphasizing animal science.When she’s not on the job, Kelsey is involved in thefamily farm with her husband, Jacob. Along withparents, grandparents and Jacob’s brother, the SutterKelsey Sutter8 JULY <strong>2012</strong>

JULY <strong>2012</strong>9

ISU students join IPPAas summer internsTwo <strong>Iowa</strong> State University students are getting afirst-hand look at the workings of the <strong>Iowa</strong> <strong>Pork</strong><strong>Producers</strong> <strong>Association</strong> this summer. StephanieCarlson and Colton Jones are serving theirinternships and their presence not only benefitsIPPA, but they gain valuable insight into theorganization and how it serves the pork industry.The interns started in May and are actively involvedin day-to-day activities.Stephanie CarlsonLegislative internCarlson began thesummer with asix-week stint inWashington, D.C.,as an intern in theoffice of <strong>Iowa</strong> Sen.Charles Grassley.Most of her effortsthere were focusedon the <strong>2012</strong> FarmBill. She returned toIPPA in early <strong>July</strong> andis helping plan andprepare for the <strong>Iowa</strong> State Fair venues. She also willassist with the daily operation of the <strong>Iowa</strong> <strong>Pork</strong> Tentduring the fair.“I am very thankful for the experience andconnections that I have made through thisopportunity with the <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong><strong>Association</strong>, which are invaluable to my futurecareer aspirations in the swine industry,” saidCarlson.Stephanie will return to <strong>Iowa</strong> State University thisfall to complete her animal science degree. Sheis active in Alpha Zeta, Block and Bridle Cluband the College of Agriculture and Life SciencesStudent Council. She wants to pursue a career inthe pork industry and production agriculture aftergraduation next May.Carlson is from Stratford and a diversified grain andlivestock farm.Colton Jones<strong>Pork</strong> Checkoff internJones has enjoyedworking in the porkindustry for the lastcouple years and isvery excited to be the<strong>Pork</strong> Checkoff internat the <strong>Iowa</strong> <strong>Pork</strong><strong>Producers</strong> <strong>Association</strong>this summer. He willbe working to helpeducate producers andconsumers about porkthrough his time spentat the World <strong>Pork</strong> Expo, <strong>Iowa</strong> 4-H Round-Up andthe <strong>Iowa</strong> State Fair.Colton is a senior at <strong>Iowa</strong> State University pursuingmajors in agricultural business and economics. In2010, he worked full-time as a farrowing assistantat <strong>Iowa</strong> Select Farms near Jewell. Over the past year,he has spent time working as a student fundraiserfor the <strong>Iowa</strong> State University Foundation. He enjoysreading and playing guitar in his spare time. Coltonwill graduate in December of 2013 and hopes topursue a career in the pork industry.A native of Audubon, Jones worked for Audubon-Manning Veterinary Clinic throughout high schoolas a part-time sow technician. He stayed involvedin the pork industry during his first two years ofcollege. He worked during summer breaks takingcare of a small nursery-finishing operation near ElkHorn.10 JULY <strong>2012</strong>

JULY <strong>2012</strong>11

U.S. pork exports post strongQ1 growthU.S. pork exports finished the first quarter 8 percent higherin volume (598,058 metric tons) and 20 percent higher invalue ($1.66 billion) than last year’s record pace, accordingto statistics released by the USDA and compiled by the U.S.Meat Export Federation (USMEF) in May.March pork export volume of 198,972 metric tons was8 percent lower than a year ago, but up 6 percent fromFebruary <strong>2012</strong>. Export value of $570.5 million was 3percent higher than last year and up 8 percent fromthe previous month. These results were led by excellentgrowth in the China/Hong Kong region and by strongperformance in Mexico, Japan and Canada.“A 20 percent increase in pork export value for the firstquarter is extraordinary, especially considering the recordperformance of last year,” said USMEF President andCEO Philip Seng.March pork export value was particularly strong on a perhead-slaughteredbasis, reaching $59.92. This was nearly$4 higher than a year ago and set a new monthly record,surpassing the previous high of $59.53 set in November2011. Exports equated to 27.8 percent of total U.S.production of muscle cuts plus variety meat, and 24 percentwhen including muscle cuts only.Mexico remains the leading market for U.S. pork on avolume basis, with first quarter exports up 17 percentin both volume (162,721 metric tons) and value ($299.7million). Exports to Japan, which nearly reached the $2billion mark in 2011, were up just 1 percent in volume(122,899 metric tons) but also achieved a 17 percentincrease in value to $530.6 million. Exports to the ChinaHong/Kong region, which came on very strong in thesecond half of 2011, were 30 percent higher in volumein the first quarter (115,642 metric tons) and surged 82percent in value to $234.9 million.up 20 percent in volume (15,510 metric tons) and 36percent in value ($47.9 million).• Led by a strong performance in Colombia, exports to theCentral and South America region expanded 9percent in volume (20,603 metric tons) and 16 percent invalue ($53.5 million).In South Korea, pork exports surged in the early months of2011 because of culling of the domestic swine herd(due to foot-and-mouth disease) and a temporary duty-freetariff rate quota for some cuts of imported pork.Consequently, year-over-year exports to Korea were lower inthe first quarter of <strong>2012</strong> – down 27 percent in volume (53,590metric tons) and 12 percent in value ($154 million). It isimportant to note, however, that these totals were still morethan double the volume and triple the value recorded in thefirst quarter of 2010.“While domestic supplies are recovering in Korea, we arestill creating new opportunities for U.S. pork.” Sengsaid. “The lower tariffs made possible by the Korea-U.S.FTA will enhance the competitiveness of U.S. pork interms of price, and help us further expand the presence ofchilled pork and value-added pork products in the retailand foodservice sectors. These marketing strategies haveproven very effective in Japan, and I believe we can havesimilar success across north Asia.”Other first quarter market highlights included:• Exports to Canada were up 26 percent in volume(55,916 metric tons) and were one-third higher in valueat just under $200 million.• In Russia, where U.S. pork now has better potential forexpansion under a global tariff rate quota, exports were12 JULY <strong>2012</strong>

JULY <strong>2012</strong>13

IPPA co-sponsors USMEF porkseminar and tasting sessionin TokyoThe United States Meat ExportFederation held an American <strong>Pork</strong>Trade Seminar and Tasting SessionApril 27 at Tokyo’s Hotel Okura.An overflow crowd of 220 meatindustry executives attended theseminar, which was conductedthrough support from the <strong>Pork</strong>Checkoff, the <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong><strong>Association</strong>, the <strong>Iowa</strong> CornPromotion Board and the USDAMarket Access Program (MAP).USMEF President and CEO PhilipSeng provided opening remarks,expressing appreciation to Japaneseimporters, traders and otherindustry partners. Seng notedthat because of well-establishedrelationships in the Japaneseindustry, U.S. pork has been theleading supplier of pork to Japanfor seven consecutive years andhas captured a dominant share ofthe imported chilled pork market.Geoffrey Wiggin, AgricultureBecca Hendricks of the National <strong>Pork</strong> Boardaddresses seminar attendees in Tokyo.Minister-Counselor at the U.S.Embassy in Japan, also sharedwelcoming remarks with attendees.The first featured lecture was aU.S. pork outlook provided by Dr.James Mintert of Purdue University.He explained that the U.S. porkindustry relies on exports to enhanceprofitability. The Japanese marketis particularly important, as itprovides exceptional returns for U.S.producers. He projected U.S. porkproduction in <strong>2012</strong> to grow 1 percentto 2 percent over the previous year,with prices remaining relatively soliddue to strong demand in overseasmarkets.Becca Hendricks, assistant vicepresident of international marketingfor the National <strong>Pork</strong> Board,provided a lecture titled “America’s<strong>Pork</strong>.” She discussed the advantagesand attributes of the U.S. porkindustry, including an integratedproduction system, a strong PQAPlus® program,disease preventionand managementmeasures andreliable feed grainsupplies.Tazuko Hijikata,USMEF-Tokyosenior manager ofconsumer affairs,outlined USMEF’sconsumer publicrelations activitiesand consumerresearch insights. TakemichiYamashoji, USMEF seniormarketing director, followed witha discussion of U.S. pork demandtrends and current USMEFpromotional activities.A tasting session featuring a varietyof U.S. pork cuts followed theseminar and drew several favorableresponses from attendees.Following these lectures, USMEFheld a tasting session where itintroduced branded U.S. porkproducts in cooperation with 10local distributors. Hotel Okurachefs prepared roast pork dishesusing U.S. boneless and bone-inpork loin, CT butt and pork belly,drawing very favorable responsesfrom seminar attendees.U.S. pork exports to Japan reachednew heights in 2011, totaling493,313 metric tons (1.09 billionpounds) valued at $1.96 billion.Through the first quarter of <strong>2012</strong>,exports to Japan were up just 1percent in volume (122,899 metrictons) but achieved a 17 percentincrease in value to $530.6 million.14 JULY <strong>2012</strong>

JULY <strong>2012</strong>15

ISU animal science graduate studentreceives national awardWhen Caitlyn Abell received word that she’d won the 2011Lauren L. Christian Graduate Student Award from the NationalSwine Improvement Federation (NSIF), she did a double take.The <strong>Iowa</strong> State University (ISU) student had just recently startedher doctoral program in animal science and thought the awardwas beyond her reach.“This was a big surprise because my major professor told memost past recipients had finished or nearly finished their Ph.D.and I had just started my program,” Abell said. “I knew he hadsent in a nomination, but figured it was just a formality.”As the award recipient, she received a cash award of $500, aplaque and expenses for attending the annual NSIF conferencein Omaha in December. She also gave a presentation at theconference about her work.As it turned out, Abell is the 10th ISU recipient of the award,presented annually since 1993. NSIF president Clint Schwabreceived the award as an ISU graduate student in 2005, and saidit is considered among themost prestigious rewards forgraduate students in the fieldof swine genetics.“The objective of her current research project is todetermine the economic value of genomic selection forswine genetic companies,” he said. “And she’s alreadyworked on using the litters per sow per year figure toreduce non-productive days of a sow in a breeding herd.Results will help producers make better decisions withtheir sow herds.”Already Abell has three referred journal articles and twosuccessful grants to her name, and said she chose ISUfor her graduate degree program because of its strongreputation in the animal breeding and genetics program.She has a double major in animal breeding and genetics,and statistics, and hopes to pursue a career with a swinebreeding company after graduation.The <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong> was a partialsponsor of the research upon which Abell’sapplication was submitted.“For me, it was an incrediblehonor to be added to the listof recipients – many of whomI looked up to during mygraduate career,” Schwab said.“Caitlyn is a great addition tothe list of recipients, and is asolid representation of LaurenChristian’s contributions to thefield of swine genetics.”Abell’s major professor, animalscience professor and ISUExtension swine specialist KenStalder, said he nominated herfor the award because of herwork with litters per sow peryear.Clint Schwab (left), president of the National Swine Improvement Federation, congratulatesCaitlyn Abell as the winner of the 2011 Lauren L Christian Graduate Student Award as ISUAnimal Science professor and Extension swine specialist Ken Stalder looks on.Photo courtesy of National Swine Improvement Federation16 JULY <strong>2012</strong>

JULY <strong>2012</strong>17

20JULY <strong>2012</strong>

JULY <strong>2012</strong>21

<strong>Producers</strong> share thoughtson g-stall useIt seems as if everyone is suddenlyan expert on how to raise pigs, butno one is bothering to consult thosewho know best: the producers!McDonald’s, Burger King, Wendy’s,Safeway and several other U.S. porkcustomers have all announced plansthis year to discontinue purchasesof pork from suppliers that usegestation stalls to house pregnanthogs. These ill-advised decisionshave come under pressure from theHumane Society of the United States.Domino’s Pizza shareholders rejectedan HSUS proposal earlier this year.<strong>Iowa</strong> pork producers are frustratedand rightly concerned about the pushto ban gestation stalls.“I have raised pigs in everything frombedded, outside barns to pens insideand now crates in environmentallycontrolled barns andI don’t want to go topens,” said Dean Frazer, a600-sow farrow-to-finishproducer from Conrad.“If gestation crates werebanned, I would get outof the business, whichwould directly affect thefull-time or part-timejobs of more than 10people.”Anyone who has beenin the business for anylength of time has likelyhoused pigs insideand out, in stalls andin pens. They knowthe advantages anddisadvantages of thevarious systems and most22 JULY <strong>2012</strong>are convinced inside, in stalls is betterfor the animals.Dave Hommel of Eldora has had sowsoutside and likes it better now. He has140 sows and has used gestation stallssince 2001.“I think our operation does a betterjob treating and handling themindividually,” he said. “We saw athree-fold increase in productioncompared to pen-breeding outside.“If we’re forced through legislation toremove g-stalls, I probably won’t befarrowing.”The hard-working men and womenwho have farrowing operations takeoffense to others trying to tell themhow to do their job.“The farmers take care of theiranimals and I think we should havethe choice on the best way to carefor our animals,” said Mike VerSteeg, who has an 850-sow unit inInwood.”We’re the professionals.”Sean Dolan of Coggin has a 580-sowbreed-to-wean unit and has used pengestation in combination with stallssince 2007. He applauded Domino’sfor listening to what the veterinariansare saying.“I wish everyone else would basetheir [decisions] on some of thefacts and science behind animalwelfare and have a little faith in theAmerican farmers that they’re doingwhat’s best for the animals,” Dolansaid. “If the animal rights people feltso strongly about this, I wish they’dwork with us to try to find solutionsif they think there’s a problem. I don’tsee the problem!”

Been there, doing that.A northeast <strong>Iowa</strong> producer’s experience with pen gestationSean Dolan built a breed-to-weansow unit in southeastern BuchananCounty in 1997. After 10 years, thecement water troughs were leaking,some of the 568 gestation stalls werestarting to create problems and he waslooking at major repairs. He made thedecision to convert to pen gestation.Dolan’s system has 98 farrowing crates,48 breeding stalls and 60 gilt stalls. He’sconsidering adding 70 more gilt stalls.The unit has two large gestation pens.One holds 210 of the older, larger andmore aggressive sows while the othercan house 195 bred gilts and parity oneand two females. He also has a smalltraining pen that helps acclimate bredgilts to the trickle feeding system.“Our sows are in stalls or a farrowingcrate for about 31 days out of a 145-day cycle,” Dolan said. “Gilts areprotected in stalls a little longer. Wetry not to introduce females into pensduring the implantation phase of theirgestation and keep the gilts away fromthe older, more aggressive sows.”The 2007 Master <strong>Pork</strong> Producer’s unitincludes an electronic tag readingstation, which helps in sorting andmarking for vaccination, and makesit one of the most unique systemsanywhere.“Pen gestation has allowed me to usemore technology with mobile recordkeepingand real-time data I can usewhen I’m in the barn,” Dolan said.“I’m the only one in the world withthis type of automatic gestationsystem that I’m aware of.”With the pen gestation system inplace for nearly five years, Dolansaid it has good and bad points. Headds it can be frustrating and thereare days he regrets converting to thepen system, especially when he hasto do a mass vaccination because it’sdangerous for him and his brotherwhen the sows are trying to avoidthem. He’s also experienced morelameness and increased mortalities.Dolan fears a major PRRS outbreakand how he would identify sows thataborted if it were to occur.“I think I’m giving up two pigsper sow [with pen gestation],”added Dolan. “We’re running realclose to what we were doing withgestation stalls, but with the geneticimprovement in the sows, we shouldbe doing better than that.”Dolan said his veterinarian said it best.“He said pigs are natural nesters andthe stall is their own nest,” Dolan said.“They don’t have that opportunityto have their own natural nest inmy system and they’re forced to beextremely social, even when theydon’t want to be. Gestation stalls areprobably more humane than the waywe have it.”The Coggin-area farmer has raisedpigs for nearly 16 years and has usedgestation stalls for most of his career.He said he can see the benefits of havinggestation stalls over pen housing.“I think it’s better for the pigs andbetter for the workers,” he said.“[Gestation stalls] need to have aplace in the pork industry.”That’s about as far as the positives onpen gestation go for Dolan.Sean Dolan converted his operation to pen gestation in 2007.JULY <strong>2012</strong>23

USDA to look at economics of sow housingtransitionRecent publicity surrounding sow housing hascaught the attention of the U.S. Department ofAgriculture and one of its economists, who plans tostudy what it would cost the nation’s hog farmers toconvert to open or group housing of sows.Several fast food restaurants, food servicecompanies and Safeway Stores have all announcedplans to eventually discontinue purchases of porkfrom suppliers that use gestation stalls to housesows. The decisions have all come amid pressurefrom the Humane Society of the United States.All of this noise coming about recently fromMcDonald’s, Burger King, Wendy’s, Denny’s; Ithought I had better take a look at this because itappears to be the shape of things to come and howpork production is going to look sometime in thefuture, said Mildred Haley, livestock-meat economistin USDA’s EconomicResearch Service.Haley says she’sconducting the researchas part of her Situationand Outlook researchprogram and not as anexplicit directive fromUSDA.“I’m always on thelookout for things thatmight impact supplyand demand for porkand hogs,” she said.Basically, I’m goingto look at what’s outthere now and takeevery opportunityto talk to people inthe U.S. who plan tomake the transitionor have already madethe transition, and basically report what I see, Haleyadded.She planned to visit two <strong>Iowa</strong> hog farms as part of herstudy in early June. Both farms have transitioned togroup housing from g-stalls.Haley recently authored an article for the May 16issue of USDA’s Livestock, Dairy and Poultry Outlooktitled “U.S. pork industry moving toward open sowhousing as an alternative to gestation stalls.” Theauthor used current research to summarize thesow housing issue, including the pros and cons ofgestation stalls and alternative housing options.The economist says she should have somethingready for publication by the end of the year that willdescribe what the transition will look like for the porkindustry.24 JULY <strong>2012</strong>

JULY <strong>2012</strong>25

McDonald’s outlines 10-year plan for endinggestation stall useMcDonald’s USAannounced May 31 its10-year plan to workwith its pork suppliersto phase out the use ofgestation stalls in itsU.S. pork supply.In February,McDonald’s announced its commitment to workwith its pork suppliers to assess the current state ofsow housing andto develop nextsteps for gestationstall phase out.“We value our relationship withour suppliers, and our sharedcommitment to animal welfare.” -The goal ofMcDonald’s 10-year plan, whichwas developedwith input fromits suppliers, porkproducers andanimal welfareexperts, is tosource all pork forits U.S. business from producers that do not housepregnant sows in gestation stalls by the end of 2022.Dan Gorsky, senior vice president of McDonald’sNorth America Supply Chain Management.As an interim step, by 2017, McDonald’s will seekto source pork for its U.S. business only fromproducers who share its commitment to phaseout gestation stalls. To achieve this, McDonald’swill work with producers and suppliers to developneeded traceability systems that will verify porksourced from non-gestation stall supply chains andassess how to best support producers migratingaway from gestation stalls.“We value our relationship with our suppliers, andour shared commitment to animal welfare,” said DanGorsky, senior vice president of McDonald’s NorthAmerica Supply Chain Management. “Our approachseeks to build on the work already in place, and we arealso sensitive to the needs of the smaller, independentpork producers in phasing out of gestation stalls.”“This change is complex and will require additionalresources. The 10-year timeline that McDonald’s hasoutlined is necessary to research and identify betterhousing alternatives and ensure proper training ofemployees,” said Dr.Temple Grandin,renowned animalwelfare scientistat ColoradoState Universityand memberof McDonald’sAnimal WelfareCouncil. “Thisis really goodforward thinking,and I commendMcDonald’s fordoing it.”“Any system will have animal welfare concerns, but I seereal opportunity for innovation and better alternatives,”said Dr. Ed Pajor, professor of animal welfare, Universityof Calgary and member of McDonald’s Animal WelfareCouncil. “This plan provides a 10-year window forMcDonald’s producers and suppliers to develop practicaland sustainable implementation steps to achieve thephase out of sow gestation stalls.”McDonald’s will continue to work with its suppliernetwork and subject matter experts to refine andimplement this plan.26 JULY <strong>2012</strong>

Grocery, restaurant executives surveyed aboutanimal agriculture issuesResults of a recent survey of grocery and restaurantexecutives signals an opportunity for the supply chain toprovide retailers better support and alignment to addresschallenging issues in animal agriculture.Conducted by the Center for Food Integrity (CFI),the survey asked questions of QSR and procurementmanagers from 10 leading food industry retailers,including Walmart, McDonalds, Burger King, MarshSupermarkets, Bob Evans, Giant Eagle, Wakefern FoodCorp., Sodexo, Inc., Brinker International and HarrisTeeter.Using quantitative and qualitative methods, conductedboth by phone and online, the survey was intended toprovide feedback and stimulate discussion in an effort toimprove supply chain alignment on critical issues facinganimal agriculture.chain alignment and serve as a resource for retailerson challenging issues,” says Charlie Arnot, CEO of theCenter for Food Integrity. “Retailers can then serveas a direct point-of-contact, providing consumers theinformation they need to make informed choices.”Specifically regarding meat, milk and eggs, eachrespondent was asked for their thoughts regardingpractices “on farm” and “during processing” that resultin safe food; humane treatment of animals; sustainableprotection of natural resources; and the nutrition ofproducts. Further, the survey asked about their thoughtson the safety of food derived from animals treated withantibiotics; animals treated with hormones; and foodsusing biotechnology in their production.Responses to each of those questions showed a significantneed for additional, fact-based information about theseissues, created to support retailers and restaurateurs.“I see it in our stores. People are examining labels. I findmyself doing it too. Consumers want to know what’sin their food,” said one survey respondent, noting thatanimal agriculture can provide that support. “We needto help them with positive information on why they cantrust what they’re buying from us.”“This research illustrates a significant opportunityfor those in animal agriculture to provide greatercoordination and communication to help improve supplyJULY <strong>2012</strong>27

USDA to survey hog farmers on swinehealth management practicesThe U.S. Department ofAgriculture’s National AnimalHealth Monitoring System(NAHMS), in collaborationwith the National AgriculturalStatistics Service (NASS), istaking an in-depth look at swineoperations in the United Statesto providethe industrywith updatedinformationlast collectedduring theNAHMS Swine2006 Study.The graphis just oneexample ofthe type ofinformationthat will beupdated.ConductedthroughUSDA’s National Animal HealthMonitoring System, the Swine<strong>2012</strong> study will contact smalland large swine operationsto obtain important healthmanagement and productivityinformation to characterizemanagement practices inthe swine industry. During<strong>July</strong>, NASS will phone or visitrandom swine operations with100 pigs or more in 13 states andmail questionnaires to a randomsample of swine operations withfewer than 100 pigs in 31 states.By participating in the Swine<strong>2012</strong> Study, producers can helpcontribute to:• Produce current estimates onmanagement practices, healthstatus and productivity, anddescribe trends over the last 20years;• Help industry researchersupdate the economic impact ofPRRS;• Determine the prevalence ofpathogens other countries useas trade barriers; and• Help guide future research andeducation efforts.“Swine <strong>2012</strong> will provide the porkindustry with valuable informationon levels of disease; farrow-tofinishproducers; all-in and all-outmanagement; biosecurity practices;etc. I wholeheartedly encourage anyproducer who can participatein the NAHMS Swine <strong>2012</strong>Study to do so.” explainedJim Niewold chair of theNational <strong>Pork</strong> Board’s SwineHealth Committee and apork producer from Illinois.As with allNAHMSstudies,individualresponses arekept strictlyconfidentialand usedonly incombinationwith otherresponsesto reportregionaland U.S.estimates.This assuresthat nomatter the size, participatingoperations cannot beidentified when the results ofthe study are reported.For additional information,contact the NationalAgricultural Statistics Service<strong>Iowa</strong> Field Office at (800)772-0825 or visit the NASSweb site at www.nass.usda.gov to see all NASS reports,as well as a vast array ofother data on every facet ofU.S. agriculture.28 28 JULY <strong>2012</strong>

Ogden hog farmers celebrate new hog barnwith open houseEric and Emily Crosman filled theirnew hog-finishing barn in earlyJune, but it was with people, nothogs. Nearly 200 neighbors, friendsand farm leaders toured theirnew 2,400 head hog building nearOgden during an open house June5, just days before the first load ofpigs was scheduled to arrive.The event — sponsored by theCoalition to Support <strong>Iowa</strong>’sFarmers (CSIF), Cargill <strong>Pork</strong>,Quality Ag Inc., the <strong>Iowa</strong> <strong>Pork</strong><strong>Producers</strong> <strong>Association</strong>, BooneCounty <strong>Pork</strong> <strong>Producers</strong> and CityState Bank, an office of AmesCommunity Bank — featureda short program, tour of thebuilding and a pork burger lunchto honor Boone County’s newestbusiness.“The turnout today is unbelievable,”said Eric, while speaking to thecrowd. “I appreciate everyone’ssupport and think it’s great thatyou are all here to see first-handwhat we are doing and how we areraising hogs today. Agriculturehas changed a lot in the 109 yearsthis farm has been in our familyand I’m sure itwill continueto change asour sons growup and workinto the familyoperation.”Before theCrosmans startedconstruction,they turned tothe coalitionfor advice inchoosing a goodlocation and aplan for talkingto their neighborsabout putting upthe barn on theircentury farm.“The coalitionwas very helpfuland was there forEmily and I fromstart to finish,”said Eric. “I can’t emphasize enoughhow important it is to talk to yourneighbors before you start to buildand address any concerns they mayhave. Emily and I want to be the bestEric and Emily Crosman and family.neighbors we can be because we plan tobe on this farm for a very long time.”“This hog building will have a $1.5million impact on Boone County inthe first year alone,” said BrianWaddingham, CSIF executivedirector. “This event helped localresidents understand the positiveimpacts of livestock farming in theircommunities. Although many peopledrive by hog barns, few have any ideawhat actually occurs in one. This openhouse gave people an opportunity tostep inside and feel how the air moveson a hot day and see how comfortablethe pigs really are.”JULY <strong>2012</strong>29

Sorting, load out and power washing:Essential jobs, but proceed with cautionBy Kelley J. Donham DVM, director, <strong>Iowa</strong>’s Center for Agricultural Safety and HealthSeveral years ago, I wasdiscussing with a pork producerclient (we will call him B.W.)who was complaining aboutgetting sick every time he andhis brother sorted and loadedout hogs to market. Hecomplained that symptomsset in during the afternoon orevening almost every time hesorted and loaded hogs. After awhile, he just accepted gettingsick was a part of this job. Hecalled it swine sorters flu. Hissymptoms included headache,muscle aches and pains, lowgrade fever, chest tightness andextreme fatigue. He would getbetter the next day then be backto normal the following day,only to become sick again thenext time he sorted and movedhogs.Because of the health issuesexperienced by B.W. as wellas the many other producerswe worked with, we beganresearching these issues. Wenow know what this specificcondition that B.W. experiencedis. It has even been given a real“scientific name:” Organic dusttoxic syndrome (ODTS) (I sortof liked swine sorters flu). Wealso know that the major agent inthe swine dust that is causing theproblem is endotoxin. Endotoxinsare a component of the cell wallof Gram-negative bacteria. Theseorganisms thrive in the intestinaltract of animals, so swine manure isa great source forthem.Endotoxin causesinflammation ofhuman and animaltissues. Long-termexposures cancause coughingand phlegmformation, thesame symptomsof bronchitis. Itcan cause chesttightness andwheezingwhen breathing,particularlyassociated withworking insidethe building (a form of non-allergicasthma). These symptoms andconditions can possibly get worseand even become permanent insome persons. It also can cause thecondition that B.W. experienced(organic dust toxic syndrome orODTS). There is a variance inhow people react to endotoxin. Ifyou happen to have the geneticsthat make you less susceptible toendotoxin, you will have fewersymptoms compared to anotherperson who does not have the“protective” genetics.Now, let’s get back to B.W. He got sickwith his swine sorters flu (actuallyODTS) because when you sort andmove hogs, a lot more dust thanHalf-faced respirator30 JULY <strong>2012</strong>

usual is kicked up. Endotoxin iscontained in the dust, thus thehigh concentrated exposurescan cause this condition in somepersons. We have measuredproducer exposure whenmoving and loading hogs; theconcentrations of dust andendotoxin can be up to five to 10times higher than backgroundlevels.Another activity where highendotoxin exposures occur isduring power washing inside swinefacilities. We have measured up to30 times higher concentrations ofendotoxin when power washingcompared to background levels.What happens is that when thepressurized water hits the slatsand other surfaces, it blows dustparticles in the air. They becomeincorporated into droplets at thistime. These droplets can contactthe eyes, nose, throat and perhapsinhaled into the respiratorytract. We have not determinedif this exposure can cause healthproblems in producers, but it ispossible. We want to promotesome caution, and suggest usingrespiratory protection whenpower washing until we have moreinformation on this subject.and sorting and moving hogs arecritical tasks when a dust maskshould be used. One model of adisposable respirator that may bebetter to use while power washing isa NIOSH-approved N95 (95%efficient) dust mask that has anintegrated plastic mesh. OneMoldex N95 dust maskexample is the Moldex N95. Theplastic mesh will help to keepthe mask from collapsing onthe face in the wet conditions ofpower washing. Another choiceis a non-disposable half-facedrespirator with dust filters.Power washing and sorting andmoving hogs are essential to swineproduction, and they are not goingto stop. However, the word isprecaution when doing this.Presoaking the building beforepower washing can help as it willdecrease the amount of time andeffort to clean and thus reduceoverall exposure. Although werecommend wearing a dust maskwhen working in swine buildingsgenerally, power washingJULY <strong>2012</strong>31

All Around<strong>Iowa</strong>One of the reasons the <strong>Iowa</strong> pork industry is so successfulis because of the promotional work done by many of thecounty pork producer groups throughout the year. Here isa summary of what the county groups have been doing topromote pork and the pork industry.Scott CountyThe Scott County <strong>Pork</strong> <strong>Producers</strong> were quite active thisspring, participating in several events to help promoteagriculture and pork production.In April, representatives took part in Ag in the Classroompresentations at two Davenport schools. Suzy Ven Horst,<strong>2012</strong> county <strong>Pork</strong> Queen Nicole Dierickx and 2011 county<strong>Pork</strong> Queen Lynsey Chapman talked about how pigs areraised, offered pork facts, answered questions and handedout “gummy” pork bi-product treats. Each student alsoreceived a sticker and pork information in their gift bag.<strong>Producers</strong> partnered with the Scott County Farm BureauAg Committee for a three-day promotion at a DavenportHy-Vee food store April 26-28. Hy-Vee held a saluteto farming and agriculture and invited the ag groupsto participate. <strong>Pork</strong> recipe booklets, temperature sticksand 145º cooking temperature information was handedout to shoppers by Suzy Ven Horst and Kathy Claussen.<strong>Producers</strong> also gave away 10, $5 pork discount couponspurchased from the <strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>.Young children also could be pictured as a young farmerin a specially designed ag display.<strong>2012</strong> Scott Co. <strong>Pork</strong> Queen Nicole Dierickx (left) and 2011 Scott Co. <strong>Pork</strong> Queen Lynsey Chapman talk toDavenport elementary school students about hog farming as part of an Ag in the Classroom presentation.32 JULY <strong>2012</strong>

Suzy Ven Horst (left) and Hy-Vee employee Vickie Wilson display newUSDA pork cooking guidelines and a pork cooking guide.<strong>2012</strong> Scott Co. <strong>Pork</strong> Queen Nicole Dierickx (left) andCarrie Keppy participated in a pork promotionat a Davenport Fareway store April 28.Scott Co. producers did a promotion at a DavenportFareway store April 28. Consumers were giveninformation about the new 145 º cookingtemperature and invited to try pork loin samples thatwere grilled for the occasion.We always welcome receivinginformation and photos of yourevents and activities. You cansend information to the editor at:<strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>Attn: Ron Birkenholz1636 N.W. 114th StreetClive, <strong>Iowa</strong> 50325E-mail: info@iowapork.orgPhone: (800) 372-7675Scott Co. pork producer Kathy Claussenwelcomes consumers to a Davenport Hy-Vee’sfarming salute in late April.JULY <strong>2012</strong>33

News from theNational <strong>Pork</strong> <strong>Producers</strong> CouncilNPPC disappointed with McDonald’sdecisionThe National <strong>Pork</strong> <strong>Producers</strong> Council expresseddisappointment with McDonald’s decision to move forwardwith requiring its pork suppliers to phase out the use ofindividual sow housing. The fast food firm announced itwants 100 percent of its suppliers to be gestation stall-free in10 years.“While we’re disappointed with its decision, McDonald’s –unlike other food companies – did the research to find outhow complex this issue is,” said NPPC President R.C. Hunt,a pork producer from Wilson, N.C. “At least it discussedits plans with the pork industry and has concerns with theavailable pork supply from stall-free operations and withthe transition away from stalls that would be required ofproducers.”NPPC suggested other food companies consider the supplychain realities of the pork industry before makingsimilar decisions.“We’d be glad to discuss with food companies challengescaused by a transition in production systems,” Huntsaid. “But the bottom line is, regardless of any difficulties,the issue of sow housing is about providing the best carepossible for our animals. Individual sow housing allows usan option to give that best care.”Response to Safeway decisionSafeway Stores of Pleasanton, Calif., one of North America’slargest food retailers, announced May 7 that it wasformulating plans to have a gestation stall-free supply chain.The National <strong>Pork</strong> <strong>Producers</strong> Council issued thefollowing statement in response to the announcement:“America’s hog farmers are committed to producing safe,affordable and healthful foods for consumers, usingindustry practices that have been designed with input fromveterinarians and other animal-care experts. Providinghumane and compassionate care for their pigs at every stageof life is one of the ethical principles to which U.S.hog farmers adhere.”“With regard to Safeway’s decision to give preference topork suppliers who phase out individual sow housing,the National <strong>Pork</strong> <strong>Producers</strong> Council is concerned thatsimilar actions taken by governments – or other restaurantor grocery chains – have increased production costs andconsumer prices. These actions have forced some hogfarmers out of business or caused them to reduce operations,with no demonstrable health benefits to sows. (A study onthe United Kingdom’s ban on individual sow housing foundthat the pork supply in the UK has dropped 40 percent sincethe ban took effect in 1999, with a rise in pork productioncosts that were running 12 percent above the EuropeanUnion average in 2009 and a rise in the price of pork by 25percent between 1999 and 2004.) In this country, when hogfarmers have gone out of business or scaled back operationsin the past, it has led to consolidation.”“NPPC supports the position taken by the AmericanVeterinary Medical <strong>Association</strong> and the American<strong>Association</strong> of Swine Veterinarians, which recognizegestation stalls and group housing systems as appropriatefor providing for the well-being of sows during pregnancy.In fact, the key factor that most affects animal wellbeingis husbandry skills – that is, the care given to eachanimal. There is no scientific consensus on the best wayto house gestating sows because each type of housingsystem has inherent advantages and disadvantages, so nostandard should be imposed on the industry by activistorganizations.”“While NPPC respects the right of companies to makebusiness decisions that are in their best interests, it seemsthat Safeway was intimidated by an animal rights groupwhose ultimate goal is the elimination of food-animalproduction. The Humane Society of United States, whichhas filed shareholder lawsuits against food companies, hasno concern for the hog farmers who care for their pigsevery day, for families struggling to purchase food or forthe hog farms that struggle to stay in business or may goout of business – costing rural America thousands of jobs –because of its campaign against America’s farmers.”34 JULY <strong>2012</strong>

NPPC corrects Pew misinformation onantibiotic use in livestockThe National <strong>Pork</strong> <strong>Producers</strong> Council in May sought tocorrect misinformation about the use of antibiotics inthe pork industry.A full-page ad was placed in Roll Call, a Capitol Hillnewspaper, laying out the real facts about antibiotic use inlivestock production. The ad included points from Dr. H.Scott Hurd, associate professor at <strong>Iowa</strong> State UniversityCollege of Veterinary Medicine and former U.S.Department of Agriculture deputy undersecretary forfood safety.Your participation in the StrategicInvestment Program allows theNational <strong>Pork</strong> <strong>Producers</strong> Council andstate organizations to enhance and defend your opportunities tocompete at home and abroad.Negotiate for fair trade (import/export)Fight for reasonable legislationFight for reasonable regulationInform and educate legislatorsProvide producers direct access to lawmakersProactive issues management with mediaSecure and guide industry research fundingEnhance domestic and global demandProvide producer information and educationStrategicInvestmentProgramMandatory<strong>Pork</strong>CheckoffFunding $0.10/$100 $0.40/$100Your voluntary investment is NPPC’s primary source of funding;Checkoff dollars cannot be used for public policy funding.The National <strong>Pork</strong><strong>Producers</strong> Council (NPPC)conducts public policyoutreach on behalf of its44 affiliated stateassociation membersenhancingopportunities for the success of U.S. porkproducers and other industry stakeholders byestablishing the U.S. pork industry as a consistentand responsible supplier of high quality pork to thedomestic and world market.NPPC placed the ad in response to a Pew Campaign onHuman Health and Industrial Farming Washingtonlobbying and media event on antibiotic resistance andthe unnecessary feeding and overuse of antibiotics inlivestock.NPPC is primarily funded through the StrategicInvestment Program, a voluntary producer investmentof $.10 per $100 of value that funds state and nationalpublic policy and regulatory programs on behalf of U.S.pork producers.For more information on NPPC, visit www.nppc.org.JULY MaY <strong>2012</strong>35

News from theNational <strong>Pork</strong> BoardCheckoff responds to McDonald’sdecisionThe president of the National <strong>Pork</strong> Board said he’sdisappointed in the announcement by McDonald’sCorp. May 31 that sets a 10-year timeline for sourcingall of its pork from farms that do not use individualstalls to house pregnant pigs.McDonald’s decision could put significant pressureon smaller farmers who use gestation stalls to carefor their animals, said Everett Forkner, a farmerfrom Richards, Mo., and president of the National<strong>Pork</strong> Board. “For a producer who has built a newbarn in the past few years, McDonald’s announcedtimeline could force them to make significant newinvestments,” said Forkner.Forkner said publicly held pork productioncompanies with access to capital and bond marketsmay be able to make the conversion more easily. “Andthat’s fine if that’s what they choose to do,” he said.“We believe consumers ultimately are likely to paythese higher production costs. But in the meantime,the additional expenses on farmers forced to makethis conversion could increase the risk of them havingto leave the business.”Forkner said the National <strong>Pork</strong> Board’s positioncontinues to be that peer-reviewed research showsoverwhelmingly that both individual stalls and openpens are appropriate ways to provide good care topregnant sows. These decisions mean that farmers arebeing told by others which of the two systems worksbest on their arms, he said.New board appointees announcedAgricultural Secretary Tom Vilsack has announcedfive new appointments to the 15-member National<strong>Pork</strong> Board. The appointees will each serve a threeyearterm.The new appointees chosen to represent porkproducers are Craig Mensink, Preston, Minn., andCarl Link, Fort Recovery, Ohio. The reappointedmembers of the board are Brad Greenway, Mitchell,S.D.; Dale Norton, Bronson, Mich.; and Lisa Colby,Newburyport, Mass.“I am pleased that these individuals have agreed toprovide their time and expertise,” Vilsack said. “I amconfident that pork producers and importers will bewell served by them.”The National <strong>Pork</strong> <strong>Producers</strong> Delegate Bodynominated eight pork producers during its Marchmeeting in Denver from which the five appointeeswere selected. The newly appointed and reappointedboard members join 10 current members, includingVice President Conley Nelson of Algona and DerrickSleezer of Cherokee.Revised PQA Plus ® program coming in2013The changing needs of pork producers, packers,retailers and consumers are being addressed in arevamped <strong>Pork</strong> Quality Assurance® Plus (PQA Plus®)program set for 2013.Program enhancements will be rolled out at the 2013World <strong>Pork</strong> Expo and include:• Testing – Open-book test questions will relateto animal well-being and pork safety. “Theaddition of a testing component will demonstrateproducers’ commitment to continuousimprovement and education and enhance thepork industry’s credibility,” said Dinah Peebles,manager of certification programs for the <strong>Pork</strong>Checkoff.• Online certification – First-time certificationswill still need to be obtained through face-tofacetraining with a PQA Plus advisor or trainer.36 MaY JULY <strong>2012</strong>

However, individuals who wish to renew theirPQA Plus certification will be able to do soonline.• Site assessment – After completing a siteassessment in the revised PQA Plus program,producers will need to submit a corrective actionplan for all non-compliances and follow up withthe PQA Plus advisor to receive site assessmentstatus. Site assessments will remain at the threeyearrenewal time frame.The National <strong>Pork</strong> Board will finalize and approvethe new PQA Plus program, which will be submittedto USDA’s Agricultural Marketing Service for finalapproval.The National <strong>Pork</strong> Board has responsibility for Checkofffundedresearch, promotion and consumer informationprojects and for communicating with pork producers andthe public. Through a legislative national <strong>Pork</strong> Checkoff,pork producers invest $0.40 for each $100 value ofhogs sold. The <strong>Pork</strong> Checkoff funds national and stateprograms in advertising, consumer information, retailand foodservice marketing, export market promotion,production improvement, technology, swine health, porksafety and environmental management. For informationon Checkoff-funded programs, pork producers can call the<strong>Pork</strong> Checkoff Service Center at (800) 456-7675 or checkthe Internet at www.pork.org.New producer guide addresses sowinjection protocolsUsing proper injection techniques will help increaseproduct efficacy and absorption, while reducinginjection-site reactions, broken needles, andresidues.If correct dosage of a product is more than 10mL, as indicated by the label or as directed by aveterinarian, Checkoff research indicates you shouldfollow these steps to prevent a violative residue.Failing to do so can cause a delay in absorption thatmay result in a violative residue in the meat.• Never deposit more than 10 mL of an injectableantimicrobial product in one site.• To deliver the appropriate does, separateinjection sites by at least 3 inches when multipleinjections must be.• Separate injection sites by at least 3 inches fromthe previous day’s injection site when multipledaytherapy is needed.To view and download a copy of the producer guide,go to pork.org and click on the “Research” tab or call(800) 456-7675.JULY MaY <strong>2012</strong>37

Coalition to Support <strong>Iowa</strong>’s FarmersNews and Notes<strong>Iowa</strong>: A place for agriculture and FFAmembers to growA survey of nearly 200 <strong>Iowa</strong> FFA members finds thatan increasing majority of them want to farm andlive in <strong>Iowa</strong> upon completion of their education.The survey finds that 94 percent want to pursue anag-related career, which is up from 77 percent in2005 (the survey’s inaugural year). They also have anextremely positive outlook about agriculture and theopportunities it can provide to those who are willingto work hard to accomplish their goals.occurring from the state, 82 percent of <strong>Iowa</strong> FFAmembers indicated they plan to obtain at least a 4-yearcollege degree, an all-time high. Additionally, 90 percentof the respondents said they plan to live in <strong>Iowa</strong>.Brooke Bodkins, a senior at Davis County, believes thesky is the limit. She plans to not only get a bachelor’sdegree, but also pursue a degree in veterinarymedicine. “I want to do something in agriculturebecause I know it’s something I’ll enjoy,” she said.After completing her education, she hopes to return toher home area and start her own business. “The peoplein <strong>Iowa</strong> are just friendlier than some other places,”Bodkins said, explaining why she doesn’t want to leavethe state.The 18-year-old Bloomfield native is currently servingas secretary of her FFA chapter. Additionally, shehelps on the family’s corn, soybean and cattle farm. Inaddition to her future career in agriculture, Bodkins ispersonally invested in the industry. She and a siblingrecently purchased several breeding heifers to starttheir own cow-calf herd.“There are so many more people to feed now.Agriculture will have to continue to improve,” she said.“<strong>Iowa</strong> is a good place for agriculture to be.”The findings, garnered from a survey conductedby the Coalition to Support <strong>Iowa</strong>’s Farmers at the<strong>Iowa</strong> FFA Conference held in Ames on April 23-24,highlights the exceptional role agriculture can playin helping <strong>Iowa</strong> retain some of its best and brightestyoung people while reinforcing the importance ofhigh school agricultural education programs.FFA helps students develop interpersonal skills,build character and learn leadership skills. Contraryto the suggestion that there is a “brain drain”Bodkins isn’t the only one excited about the future ofagriculture. In fact, 97 percent of <strong>Iowa</strong> FFA memberssay they have a positive or very positive attitude aboutthe future of agriculture in the state.Of the 194 respondents, 77 percent indicated theywould like to farm after completing their educationand 89 percent of those would like to raise livestock.Hartley-Melvin-Sanborn senior Austin Peterson isone of them. “Farming is in my blood,” he said. “Youhave so many different careers all in one – some days38JULY <strong>2012</strong>

you’re a mechanic, other days you’re a market analyst,or teacher, or vet.”In addition to serving as president of the local FFAchapter, Peterson works on the family farm, helpingat the feedlot and with the corn, soybean and alfalfaoperations. Additionally, the young entrepreneurmanages a hog barn, works for other area farmers andis in the process of starting his own cow-calf herd.“We have all the resources here to raise livestock –we grow enough feed that we don’t have to importanything,” the Hartley native said. “Additionally,agriculture provides so many jobs for people in ourcommunity.”In fact, the growth of animal agriculture in <strong>Iowa</strong>by families like the Petersons has led to an increaseof $3.6 billion in economic output, $601 million inhousehold wages, 19,200 jobs and $176 million inadditional tax revenue in the last decade (“AnimalAgriculture Economic Analysis Report,” UnitedSoybean Board).Other findings from the survey of FFA membersinclude:• Of those wanting to farm, 49 percent say they wouldgrow crops and raise livestock, 23 percent raiselivestock and work part-time off the farm, 17 percentraise livestock only, 7 percent raise crops and workpart-time off the farm and 3 percent grow crops only.• Seventy-six percent of the respondents live andwork on a farm, and 24 percent do not. Ofthose that live on a farm, 68 percent have cropsand livestock, 23 percent livestock only and 9percent crops only.• Although only 76 percent of survey respondentslive and work on a farm, 94 percent want topursue an ag-related career.Last year, the coalition assisted 289 families ingrowing their livestock farms. The organizationhas now helped nearly 1,900 families who raiselivestock since its launch in 2004. CSIF is a nonprofitorganization that assists livestock farmerswho want help interpreting rules and regulations,guidance on good site locations for barns, counselon enhancing neighbor relations and tips on howto protect the environment at no cost.This positive, solutions-based approach to helpinglivestock farmers grow is a collaborative effortinvolving the <strong>Iowa</strong> Cattlemen’s <strong>Association</strong>, <strong>Iowa</strong>Corn Growers <strong>Association</strong>, <strong>Iowa</strong> Farm Bureau,<strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>, <strong>Iowa</strong> Soybean<strong>Association</strong>, <strong>Iowa</strong> Turkey Federation and theMidwest Dairy <strong>Association</strong>.The Coalition to Support <strong>Iowa</strong>’s Farmers doesnot develop policy, lobby or charge for theirservices. Families wanting confidential assistancein growing their livestock farms responsibly andsuccessfully are encouraged to contact CSIF at(800) 932-2436 or visit www.supportfarmers.com.JULY <strong>2012</strong>39

<strong>Pork</strong>RECIPESCrispy MandarinRiblets4 pounds pork spareribs, sawed inthirds across bones*1/4 cup lite soy sauce2 tablespoons dry sherry1 clove garlic , crushedCut ribs into 1-rib pieces. Place insteamer basket or on steamer rack.Set basket over boiling water; coverpanand steam 30 minutes. MeanwhileNutrition FactsCalories: 564 caloriesProtein: 36 gramsFat: 36 gramsSodium: 950 milligramsCholesterol: 143 milligramsSaturated Fat: 13 gramsCarbohydrates: 19 gramscombine soy sauce, sherry and garlic in large bowl; addribs and stir to coat each rib well. Marinate 1 hour, stirringfrequently. Remove ribs from marinade (discard marinade)and place, meaty side up, on rack of broiler pan. Bake in425 degree F. oven 15 minutes, or until brown and crispy.Serve with warm mandarin peach sauce. Serves 6. (Askyour butcher to cut spareribs in thirds across the bones.)Calypso <strong>Pork</strong>Chops6 boneless pork chops, about 4ounces each, 3/4-inch thick1 cup chicken broth1/2 cup orange juice2 tablespoons dark rum,(optional)2 tablespoons lime juice2 tablespoons brown sugar1 clove garlic, minced1/2 teaspoon salt1/2 teaspoon ground ginger1/4 teaspoon ground nutmeg1/4 teaspoon ground clovesNutrition FactsCalories: 247 caloriesProtein: 31 gramsFat: 9 gramsSodium: 386 milligramsCholesterol: 93 milligramsSaturated Fat: 3 gramsCarbohydrates: 31 gramsCombine all ingredients in a self-sealing plastic bag; sealbag and refrigerate for 4-24 hours. Remove chops frommarinade; discarding leftover marinade. Grill chops quicklyover indirect heat in covered grill about 8-9 minutes, turningonce to brown both sides until internal temperature on athermometer reads 145 degrees F. followed by a 3-minuterest time. Serves 6.FirecrackerBarbecue <strong>Pork</strong>2 pound boneless pork loin roast3/4 cup barbecue sauce1/3 cup orange marmalade1/2 teaspoon hot pepper sauce1 teaspoon grated horseradish,(optional)Nutrition FactsCalories: 192 caloriesProtein: 28 gramsFat: 5 gramsSodium: 382 milligramsCholesterol: 70 milligramsSaturated Fat: 1 gramsCarbohydrates: 12 gramsSeason roast with salt and pepper;place over indirect heat in mediumhotgrill. Stir remaining ingredientstogether and baste every 8-10 minuteswith mixture, until roast is done about 30-40 minutes(20 minutes per pound), until internal temperature on athermometer reads 145 degrees F. Remove roast fromoven; let rest about 10 minutes before slicing to serve.Discard any leftover basting mixture. Serves 4-6 withleftovers.40 JULY <strong>2012</strong>

Florentine <strong>Pork</strong>in French BreadBoats2 pork tenderloin,(about 12 ounces each)1/3 cup Italian dressing,(reduced calorie)1 teaspoon vegetable oil2 medium tomato, seeded and diced3 ounces spinach, washed and trimmedNutrition FactsCalories: 325 caloriesProtein: 31 gramsFat: 9 gramsSodium: 420 milligramsCholesterol: 76 milligramsSaturated Fat: 3 gramsCarbohydrates: 29 gramsFiber: 3 grams3 French bread (6 inch pieces), split lengthwise in half4 teaspoons Parmesan cheese, gratedOne-Skillet <strong>Pork</strong>with Wild Rice andHerbs1 pound pork tenderloin, lean, cut intobite-sized pieces1 8-oz package sliced white mushrooms,OR brown mushrooms1 1/2 cups chicken broth, reduced-sodium1 cup uncooked white and wild rice blend*Nutrition FactsCalories: 350 caloriesProtein: 32 gramsFat: 3 gramsSodium: 330 milligramsCholesterol: 75 milligramsSaturated Fat: 1 gramsCarbohydrates: 45 gramsFiber: 3 grams1 tablespoon Italian herbs, herbes de Provence OR otherdried herb blend1 1/2 cups frozen mixed vegetables, thawedSalt and black pepperIn a large skillet or sauté pan with a tight-fitting lid over highheat, combine pork, mushrooms, broth, rice and herbs. Bringto a boil, reduce to a simmer, cover, and cook 15 minutes.Stir in mixed vegetables and continue to cook until liquid hasabsorbed, rice is tender and pork is cooked through, about 5minutes. Season with saltand pepper to taste and serve. Serves 4. *Note: To make surethey’ll be done at the same time, use an already-combinedmixture of white and wild rice. Look for a blend that has acooking time of about 20 minute.Cut pork into slices 1/4-inch thick. Place pork in plasticbag; add dressing, turning to coat. Tie bag securely andmarinate at least 15 minutes (no longer than 1 1/2 hours).Remove pork from marinade and discard marinade.Brown pork in oil in nonstick skillet over medium-high heat,about 4-5 minutes. Add tomatoes and spinach. Covertightly and cook over medium-high heat 2-3 minutes oruntil spinach is wilted. Pour off liquid. Meanwhile removesoft centers from bread to form “boats”. Spoon 1 cup porkmixture into each boat. Sprinkle each with equalamount of cheese. Serves 6.JULY <strong>2012</strong>41

P R O D U C E R S ’ M A R K E TPlaceyour adhere!ADVERTISINGWORKS.THEIOWA PORK PRODUCERSELLS!Contact Doug Fricke for moreinformation on how to reach<strong>Iowa</strong>’s pork producers.(800)372-7675dfricke@iowapork.org42 JULY <strong>2012</strong>

P R O D U C E R S ’ M A R K E TJULY <strong>2012</strong>43

<strong>Iowa</strong> <strong>Pork</strong> <strong>Producers</strong> <strong>Association</strong>P.O. Box 71009Clive, IA 50325-0009NON-PROFIT ORG.U.S. POSTAGEPAIDDES MOINES, IAPERMIT NO. 191144 JULY <strong>2012</strong>