Plasma Outside Deposition Service - Heraeus Quarzglas

Plasma Outside Deposition Service - Heraeus Quarzglas

Plasma Outside Deposition Service - Heraeus Quarzglas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

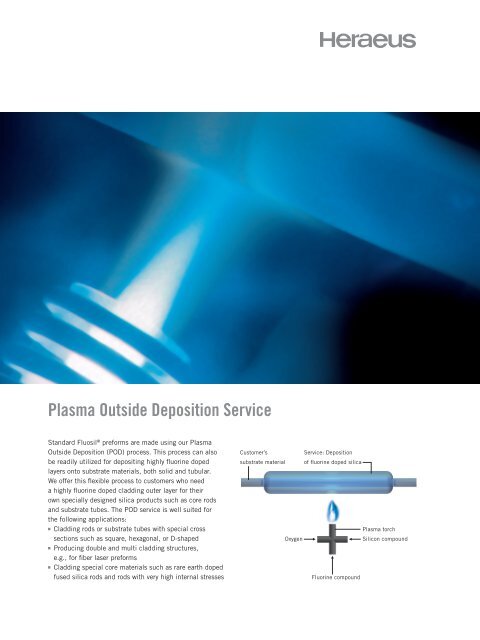

<strong>Plasma</strong> <strong>Outside</strong> <strong>Deposition</strong> <strong>Service</strong>Standard Fluosil ® preforms are made using our <strong>Plasma</strong><strong>Outside</strong> <strong>Deposition</strong> (POD) process. This process can alsobe readily utilized for depositing highly fluorine dopedlayers onto substrate materials, both solid and tubular.We offer this flexible process to customers who needa highly fluorine doped cladding outer layer for theirown specially designed silica products such as core rodsand substrate tubes. The POD service is well suited forthe following applications:Cladding rods or substrate tubes with special crosssections such as square, hexagonal, or D-shapedProducing double and multi cladding structures,e.g., for fiber laser preformsCladding special core materials such as rare earth dopedfused silica rods and rods with very high internal stressesCustomer’s<strong>Service</strong>: <strong>Deposition</strong>substrate material of fluorine doped silica<strong>Plasma</strong> torchOxygenSilicon compoundFluorine compound

Performance of CladdingFluorine content [ppm] 0 … 70,000Refractive index* 0 … -23 x 10 -3Numerical aperture (NA)** up to 0.28Cladding to substrate diameter ratio (CCDR)Minimum diameter of substrate materialMinimum length of substrate materialMaximum length of substrate material* Difference to un-doped fused silica (<strong>Heraeus</strong> Standard)** For un-doped silica substratesPODno upper limitations10 mmsubstrate diameter dependentsubstrate diameter dependentThe cladding to core diameter ratio (CCDR) is definedfor cylindrical geometries by the ratio of the claddingoutside diameter to the substrate material diameter.Though the POD process is very flexible, non-uniformityin cladding thickness for non-circular rods (D-shaped,square, etc.) has been observed. Therefore, customizedcladding thickness specifications have to be defined fornon-circular geometries prior to the deposition services.Typical Preform Cross SectionsFlexibility in refractive index cladding profilesDue to the flexibility of the POD process, simple or complexrefractive index cladding layers can be deposited on theouter diameter of customer supplied substrate materials.A uniformly doped cladding, referred to as a “U-type”,can be applied with fluorine concentrations from 0 to 7%.In contrast, double or multiple cladding structures, referredto as “S-type”, consisting of layers of differing indices ofrefraction, can be deposited to create complex claddingprofiles. Customer-specific substrate materials can alsobe overclad either by an un-doped F300 tube or a fluorinedoped Fluosil ® tube.Cross Section and Refractive Index Profile ExamplesRI of core rodRefractive indexU-typeRefractive indexS-type<strong>Heraeus</strong> Pod <strong>Service</strong> 01.2012/V1.0_E/LunisCladding, F dopedCustomer´s core1. Cladding, F dopedCustomer´s coreCylindric rodD-shaped rod2. Cladding, F dopedor tubeSquare rodor tubeHexagonal rodor tubeRadiusRadiusRI of pure silicaRI of customer´s coreS-typeCladding, F doped Customer´s coreRefractive indexJacket F300RadiusThe data given here is correct as of January 2012 and is subject to change.POD-Cladding, F dopedCustomer’s substrate materialOctagonal rodor tubeGermany<strong>Heraeus</strong> <strong>Quarzglas</strong> GmbH & Co. KGQuarzstraße 863450 HanauPhone +49 (0) 6181.35-6324Fax +49 (0) 6181.35-6261fiber-optic-sales-de@heraeus.comwww.heraeus-quarzglas.comUSA<strong>Heraeus</strong> Tenevo LLC100 <strong>Heraeus</strong> Blvd.Buford, GA 30518Phone +1 678.804-1021Fax +1 678.804-1023fiber-optic-sales-us@heraeus.comwww.heraeus-quarzglas.comAbout us<strong>Heraeus</strong> is the key global supplier of high puritysynthetic fused silica products for optical fiber manufacturing.We have been a reliable partner in the worldtelecommunications industry since 1976.We are certified for ISO 9001:2000 and our TotalQuality Management system is based on the BusinessExcellence Model of the European Foundation forQuality Management (EFQM).