Avery® 900 Super Cast Series (PDF) - Spandex

Avery® 900 Super Cast Series (PDF) - Spandex

Avery® 900 Super Cast Series (PDF) - Spandex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

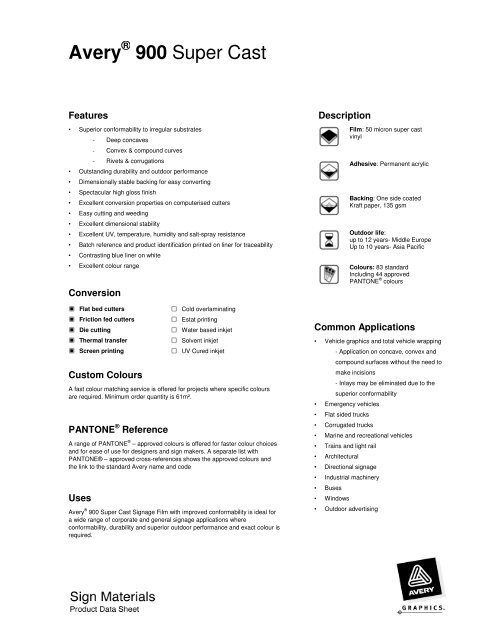

Avery ® <strong>900</strong> <strong>Super</strong> <strong>Cast</strong>Features• <strong>Super</strong>ior conformability to irregular substrates- Deep concaves- Convex & compound curves- Rivets & corrugations• Outstanding durability and outdoor performance• Dimensionally stable backing for easy converting• Spectacular high gloss finish• Excellent conversion properties on computerised cutters• Easy cutting and weeding• Excellent dimensional stability• Excellent UV, temperature, humidity and salt-spray resistance• Batch reference and product identification printed on liner for traceability• Contrasting blue liner on white• Excellent colour rangeConversionFlat bed cuttersFriction fed cuttersDie cuttingThermal transferScreen printingCustom ColoursCold overlaminatingEstat printingWater based inkjetSolvent inkjetUV Cured inkjetA fast colour matching service is offered for projects where specific coloursare required. Minimum order quantity is 61m².PANTONE ® ReferenceA range of PANTONE ® – approved colours is offered for faster colour choicesand for ease of use for designers and sign makers. A separate list withPANTONE® – approved cross-references shows the approved colours andthe link to the standard Avery name and codeUsesAvery ® <strong>900</strong> <strong>Super</strong> <strong>Cast</strong> Signage Film with improved conformability is ideal fora wide range of corporate and general signage applications whereconformability, durability and superior outdoor performance and exact colour isrequired.DescriptionFilm: 50 micron super castvinylAdhesive: Permanent acrylicBacking: One side coatedKraft paper, 135 gsmOutdoor life:up to 12 years- Middle EuropeUp to 10 years- Asia PacificColours: 83 standardIncluding 44 approvedPANTONE ® coloursCommon Applications• Vehicle graphics and total vehicle wrapping• Emergency vehicles• Flat sided trucks• Corrugated trucks• Marine and recreational vehicles• Trains and light rail• Architectural• Directional signage• Industrial machinery• Buses• Windows- Application on concave, convex andcompound surfaces without the need tomake incisions- Inlays may be eliminated due to thesuperior conformability• Outdoor advertisingGraphics & Reflective Products Division Asia Pacificwww.averygraphics.com

Avery ® <strong>900</strong> <strong>Super</strong> <strong>Cast</strong> 09/08GeneralCaliper, facefilm ISO 534 50 micronCaliper, facefilm & adhesive ISO 534 80 micronDimensional stability DIN 30646 0.15 mm maxTensile strength DIN 53455 1.0 kN/m minElongation DIN 53455 150%Gloss ISO 2813, 20º 50%Adhesion, initial FINAT FTM-1, stainless steel 540 N/mAdhesion, ultimate FINAT FTM-1, stainless steel 720 N/mFlammabilityShelf life Stored at 22° C/50-55 % RH 2 yearsAccelerated ageing SAE – J 19602000 hours exposureSelf extinguishingNo negative impacton film performanceImportantInformation on physical characteristics isbased upon tests we believe to be reliable.The values listed herein are typical valuesand are not for use in specifications.They are intended only as a source ofinformation and are given withoutguarantee and do not constitute awarranty. Purchasers should independentlydetermine, prior to use, the suitability ofany material for their specific use.All technical data is subject to changewithout prior notice.WarrantyDurability **ThermalVertical exposureBlack & whiteColours & transparentMetallics10 years9years5 yearsAvery ® materials are manufactured undercareful quality control and are warranted tobe free from defect in material andworkmanship. Any material shown to oursatisfaction to be defective at the time ofsale will be replaced without charge. Ouraggregate liability to the purchaser shall inno circumstances exceed the cost of thedefective materials supplied. No salesman,representative or agent is authorised togive guarantee, warranty, or make anyrepresentation contrary to the foregoing.Application temperatureTemperature rangeMinimum: + 10 o C- 50 o C to + 110 o CAll Avery ® materials are sold subject to theabove conditions, being part of ourstandard conditions of sale, a copy ofwhich is available on request.Chemical**DurabilityHumidity resistance 120 hours exposure No effectCorrosion resistance 120 hours exposure No contribution tocorrosionWater resistance 48 hours immersion time No effectSea water resistanceChemical Solvent Resistance1 year half tide immersionBS5609:1978No effectTest Fluid: Immersion Time: Adhesion:Gasoline 1 hour 400 N/mDiesel oil 24 hours 500 N/mDurability is based on exposure conditionsin the Asia Pacific region. Actualperformance life will depend on substratepreparation, exposure conditions andmaintenance of the marking. For instance,in the case of signs facing north in thesouthern hemisphere or south in thenorthern hemisphere; in areas of long hightemperature exposure such as northernAustralia; in industrially polluted areas orhigh altitudes, exterior performance willbe decreased.Transformer oil 24 hours 500 N/mAntifreeze 24 hours 500 N/mSAE Motor oil 24 hours 500 N/mKerosene 24 hours 500 N/mDistilled water (65 o C) 24 hours 600 N/mDetergent solution (65 o C) 8 hours 600 N/m***Information unavailable at time ofprinting.Test MethodsDimensional stability:Is measured on a 150 x 150 mm aluminium panel to whicha specimen has been applied; 72 hours after applicationthe panel is exposed for 48 hours to + 70°C, after whichthe shrinkage is measured.Adhesion:(FTM-1, FINAT) is measured by peeling a specimen at a180° angle from a stainless steel or float glass panel, 24hours after the specimen has been applied understandardised conditions. Initial adhesion is measured 20minutes after application of the specimen.Flammability:A specimen applied to aluminium is subjected to the flameof a gas burner for 15 seconds. The film should stopburning within 15 seconds after removal from the flame.Temperature range:A specimen applied to stainless steel is exposed at highand low temperatures and brought back to roomtemperature. 1 hour after exposure the specimen isexamined for any deterioration. Note: Prolongedexposure to high and low temperatures in the presence ofchemicals such as solvents, acids, dyes, etc. mayeventually cause deterioration.Chemical Resistance:All chemical tests are conducted with test panels to whicha specimen has been applied. 72 hours after applicationthe panels are immersed in the test fluid for the given testperiod. 1 hour after removing the panel from the fluid, thespecimen is examined for any deterioration.Corrosion Resistance:A specimen applied to aluminium is exposed to saline mist(5% salt) at 35ºC. After exposure, the film is removed andthe panel is examined for traces of corrosion.Graphics & Reflective Products Division Asia Pacificwww.averygraphics.com