Hamworthy Gas Systems AS - Digital Ship

Hamworthy Gas Systems AS - Digital Ship

Hamworthy Gas Systems AS - Digital Ship

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

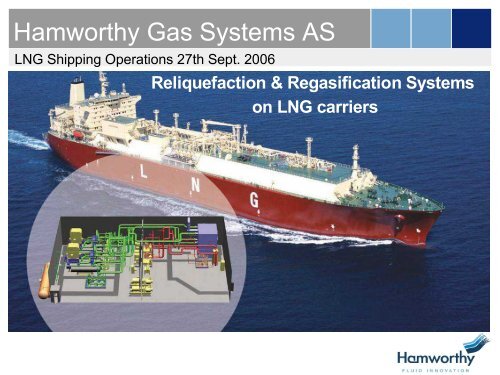

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

LNG <strong>Ship</strong>ping Operations 27th Sept. 2006<br />

Reliquefaction & Regasification <strong>Systems</strong><br />

on LNG carriers

Agenda<br />

LNG <strong>Ship</strong>ping Operations Sept. 27, 2006<br />

• Organization & references<br />

• Why LNG reliquefaction systems ?<br />

• LNG onshore pilot plant and other recent references<br />

• LNG RS recent orders<br />

• Equipement<br />

• Contol principles<br />

• Next generations<br />

• LNG regasification

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

�Owned by <strong>Hamworthy</strong> PLC with HQ in UK<br />

�<strong>Gas</strong> division located in Norway, approx 200 employees<br />

�International operations<br />

�UK, Norway, Denmark, Singapore, Germany, Korea, China,<br />

USA, India, Netherlands, Spain<br />

�Products mainly for production and transportation of oil & gas<br />

�<strong>Gas</strong> Division supplies high technology products for:<br />

�Cargo handling on gas carriers & FSO/FPSO’s<br />

�Reliquefaction systems for LPG, LEG & LNG<br />

�Inertgas- og Nitrogen-generators<br />

�Recovery of VOC from crude on shuttletankers/terminals<br />

�Condensation of VOC with 100% emission reduction<br />

�Regasification directly from LNG-carriers/FSRU<br />

�Test plant under construction in co-operation with ship owner<br />

�Onshore LNG production<br />

�Small scale plants e.g “Snurrevarden” (30 ton/day �)<br />

�Mini LNG-plants (Sintef) (8 – 40 ton/day)

<strong>Hamworthy</strong> plc<br />

Structure, products and sales<br />

<strong>Gas</strong><br />

<strong>Gas</strong> <strong>Systems</strong> Inert <strong>Gas</strong> <strong>Systems</strong><br />

40 years of gas system delivery references<br />

of liquid gas handling systems<br />

Process and systems design<br />

Pump <strong>Systems</strong><br />

General arrangement, fabrication and assembly<br />

<strong>Ship</strong>s integration<br />

Installation, commissioning and start-up<br />

Average sales last 3 years<br />

Wastewater<br />

Management <strong>Systems</strong><br />

Typical customers:<br />

Bergesen, Daewoo,<br />

Statoil, Exmar,<br />

ExxonMobil, <strong>Gas</strong>nor,<br />

Geogas, Hyundai, IHI,<br />

Kawasaki, Mitsui,<br />

Navion/Teekay, OSG,<br />

Pronav, Samsung,<br />

Solvang, Ugland, AP<br />

Møller, Sonatrac,<br />

Chevron, Leif Høegh.

LNG -Markets<br />

International gas trade by LNG tankers (1985)<br />

Alaska 1.4<br />

Exporting countries<br />

Existing LNG market<br />

50.9 bcm transported of which 73% to Japan<br />

0.7<br />

13.6<br />

Abu-Dhabi 3.1<br />

Brunei 6.9<br />

Indonesia 20<br />

Malaysia 5.9<br />

� LNG is a 40 years old industry dominated by few players and projects<br />

� Deregulation has opened up for new players and increased competition<br />

� New technology and players significant cost cuts in the LNG value chain

LNG -Markets<br />

International gas trade by LNG tankers (2004)<br />

Alaska 1.7<br />

Spot<br />

Exporting countries<br />

Existing LNG market<br />

Future LNG market<br />

177.5 bcm transported of which 43% to Japan<br />

13.9<br />

Brasil<br />

26.4<br />

12.6<br />

40.5<br />

India<br />

China<br />

70.7<br />

11.8

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong><br />

LNG Global Demand - Projections<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

North America<br />

Europe<br />

Asia Pacific<br />

2000 2005 2010 2015<br />

Source: WoodMackenzie<br />

LNG trade<br />

projected to grow<br />

at an average of<br />

7% to 363,5<br />

mtpa by 2015<br />

Key contributing<br />

factors;<br />

• Demand for<br />

energy<br />

• Demand for<br />

cleaner fuel<br />

• Security of supply

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong><br />

LNG Fleet Growth 1999 - 2010<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

7<br />

108<br />

12<br />

115<br />

1<br />

127<br />

10<br />

128<br />

14<br />

138<br />

24<br />

152<br />

18<br />

176<br />

19<br />

9<br />

194<br />

33<br />

222<br />

54<br />

255<br />

36<br />

309<br />

0<br />

1999 2001 2003 2005 2007 2009<br />

Basis no scrapping<br />

Based on orders as at 30 April 2006 Source: Drewry & Clarkson<br />

3<br />

345<br />

Orderbook<br />

Deliveries<br />

Fleet start

The LNG value chain<br />

LNG: a mean for concentrating & transporting energy (1/600 th of volume in gaseous state)<br />

Small scale Liquefaction plants<br />

Transportation: reliquefaction<br />

Floating regasification systems<br />

18-24% 32-36% 29-32% 14-15%

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

Forward Orderbook: LNG systems as off August 2006<br />

Client Type Site/<strong>Ship</strong>owner Delivery<br />

DSME 4 LNG Reliquefaction Plants (QG II ) Pronav 2006<br />

Hyundai 2 LNG Reliquefaction Plants (QG II) OSG 2006<br />

Samsung 2 LNG Reliquefaction Plants (QG II) OSG 2006<br />

Samsung 4 LNG Reliquefaction Plants (Rasgas III) Teekay 2006/07<br />

G<strong>AS</strong>NOR 1 LNG Plant 240 t LNG/day <strong>Gas</strong>nor, Kollsnes 2007<br />

Hyundai 3 LNG Reliquefaction Plants (Rasgas III) J5 NYK) 2006/07<br />

DSME 5 LNG Reliquefaction Plants (Rasgas III) J5 (MOL,KL) 2007<br />

Hoegh LNG 1 LNG Regasification plant prototype 2006<br />

Samsung 6 Regasification skids to 2 SRV’s Hoegh LNG/MOL 2008<br />

HHI 3 LNG Reliquefaction Plants (QGIII) QGTC 2008/09

Agenda<br />

LNG <strong>Ship</strong>ping Operations Sept. 27, 2006<br />

• Organization & references<br />

• Why LNG reliquefaction systems?<br />

• LNG onshore pilot plant and other recent references<br />

• LNG RS recent orders<br />

• Equipement<br />

• Contol principles<br />

• Next generations<br />

• LNG regasification

LNG carriers’ traditional propulsion system<br />

Why change ?<br />

Low efficiency of turbines<br />

high fuel consumption/cost<br />

Valuable cargo used as fuel<br />

Lack of crew to operate<br />

steam turbines<br />

Power required by large<br />

LNG carriers at boundary of<br />

existing turbine design<br />

Limited redundancy<br />

2 suppliers<br />

• Boil-Of-<strong>Gas</strong> (BOG) is a result of the LNG warming up during transportation.<br />

• All BOG now used as fuel in steam turbine propulsion systems.<br />

• Reliability in existing system considered to be very high.<br />

• Proven system with low lubrication and maintenance cost

Alternative to to-days practice<br />

BOG reliquefaction<br />

system in combination<br />

with 2 stroke diesel<br />

engine(s)<br />

The Moss RS reliquefies<br />

BOG and send LNG<br />

back to the cargo tanks<br />

Results in<br />

economical and<br />

technical advantages<br />

<strong>Hamworthy</strong> has<br />

worldwide rights to the<br />

patented Moss RS TM

LNG Reliquefaction system<br />

Two principle different solutions available for LNG carrier propulsion:<br />

1. Use BOG & LNG as fuel e.g steam turbines, dual-fuel diesel electric, gas engines<br />

2. Use efficient slow speed diesel engines and BOG reliquefaction, sell all LNG loaded onboard<br />

LNG level<br />

in tanks<br />

Maximum<br />

Minimum<br />

Ballast<br />

Pattern for ship’s using BOG & LNG as fuel for propulsion<br />

Minimum heel required for cool down of tanks<br />

Laden Ballast<br />

Fuel used during roundtrip<br />

(Natural BOG & forced)<br />

Additional LNG delivered<br />

with Slow Speed diesel and<br />

BOG Reliquefaction System<br />

27.08.03

LNG Reliquefaction system<br />

LNG & HFO prices<br />

$/mBTU<br />

7,00<br />

6,00<br />

5,00<br />

4,00<br />

3,00<br />

2,00<br />

1,00<br />

0,00<br />

1997 1998 1999 2000 2001 2002 2003 2004 2005<br />

Future price<br />

difference ??<br />

Japan CIF<br />

EU CIF<br />

US Henry Hub<br />

HFO price<br />

HFO always been competitive compared with natural gas prices in Europe, USA and Japan.<br />

<strong>Gas</strong> price in Europe and USA in average (1994-2001) 110% higher than HFO prices<br />

Japanese gas prices have been 160 % of HFO prices<br />

The gas prices have increased considerably compared with HFO the last years<br />

27.08.03

Propulsion alternatives & energy consumptions<br />

Source: Man B&W<br />

50<br />

40<br />

30<br />

Propulsion type Relative energy cons.<br />

Main + aux system (%)<br />

Slow Speed diesel 66<br />

Diesel electric 72<br />

<strong>Gas</strong> turbines 84<br />

Conventional steam turbine 100<br />

Best efficiency,<br />

Lowest total fuel consumption,<br />

Lowest value fuel (HFO)<br />

Improved efficiency,<br />

High value fuel (LNG or MDO)<br />

Improved efficiency,<br />

High value fuel (LNG)<br />

Lowest efficiency,<br />

Highest total fuel consumption,<br />

High value fuel (LNG) + HFO<br />

Example made by<br />

ship owner

LNG Reliquefaction system<br />

Slow speed diesel and reliquefaction system (RS) compared with alternatives:<br />

Lowest total operating cost (efficient propulsion using HFO, maintenance and lube oil)<br />

Additional sale of LNG<br />

4,00 %<br />

3,50 %<br />

3,00 %<br />

2,50 %<br />

2,00 %<br />

1,50 %<br />

1,00 %<br />

0,50 %<br />

0,00 %<br />

Relative increase annual LNG deliveries<br />

LNG sales price 3.5 $/Mbtu<br />

3.4 M$<br />

4.3 M$<br />

Steam turbine Diesel<br />

5.5 M$<br />

Avg. BOR 0,08%/day Avg. BOR 0,10%/day Avg. BOR 0,12%/day<br />

Slow speed diesel and RS competitive, in particular for large LNG Carriers<br />

Traditional size vessels, reason to believe steam still lowest

Agenda<br />

LNG <strong>Ship</strong>ping Operations Sept. 27, 2006<br />

• Organization & references<br />

• Why LNG reliquefaction systems ?<br />

• LNG onshore pilot plant and other recent<br />

references<br />

• LNG RS recent orders<br />

• Equipement<br />

• Contol principles<br />

• Next generations<br />

• LNG regasification

Snurrevarden LNG plant - Norway<br />

<strong>Hamworthy</strong> delivered a free<br />

standing mini LNG plant in<br />

March 2003 based on the<br />

same principles as the<br />

re-liquefaction system.<br />

The mini LNG plant uses<br />

same type of equipment<br />

as for re-liquefaction<br />

systems.<br />

Control functions are also<br />

much similar.<br />

The plant is designed for<br />

unmanned operation

LNG Reliquefaction system<br />

Snurrevarden LNG plant has resulted in awards of – 23 LNG RS for LNG Carriers !<br />

Onshore<br />

Main equipment<br />

plant vs<br />

same<br />

installation<br />

as for<br />

on<br />

the<br />

LNG<br />

ships;<br />

carrier;<br />

LNG<br />

Same<br />

production<br />

make of 3<br />

capacity<br />

stage centrifugal<br />

60 ton/day<br />

compressor<br />

(2500kg/hr)<br />

with expander for the refrigeration<br />

cycle<br />

Pre-treatment of feed gas, removal of CO2 & water (not on LNG carriers)<br />

Same cold box type (plate fin heat exchanger)<br />

Feed gas pressure to be reduced – no need for low duty compressors Storage tank<br />

Same control system principles<br />

<strong>Gas</strong> engine<br />

Cooling cycle<br />

compressor<br />

Instrument air &<br />

Nitrogen<br />

LPG separator &<br />

<strong>Gas</strong> condensation (LNG)<br />

H2O removal<br />

CO2 removal

LNG Reliquefaction system<br />

Approval in principle from DNV, Lloyds, BV, ABS

LNG Reliquefaction system<br />

Proven or unproven!<br />

� The system only use proven components - first class, high quality with extensive<br />

reference<br />

Process/system<br />

System<br />

status<br />

Risk<br />

area<br />

� Low duty compressors used on all LNG carriers<br />

Comfort factors<br />

Risk mitigation<br />

� Cold box (plate fin heat exchanger) widely used in onshore cryogenic installations.<br />

� Refrigeration & cargo cycle have been proven in operation<br />

� Analysis concludes 99.98 % availability<br />

� Approval in principle by several class societies<br />

� Independant HAZOP/HAZID with owners & class<br />

� <strong>Hamworthy</strong> has supplied a small scale LNG plant based on same principles.<br />

Operational experience since Mar 2003.

Agenda<br />

LNG <strong>Ship</strong>ping Operations Sept. 27, 2006<br />

• Organization & references<br />

• Why LNG reliquefaction systems ?<br />

• LNG onshore pilot plant and other recent references<br />

• LNG RS recent orders<br />

• Equipement<br />

• Contol principles<br />

• Next generations<br />

• LNG regasification

LNG Re-liquefaction<br />

- Refrigeration system<br />

- Redundancy considerations<br />

- Capacity control<br />

- Separation of N 2–rich vent gas<br />

- Functional diagrams<br />

- N 2 compander<br />

- Cryogenic heat exchangers<br />

- BOG compressor<br />

- LNG pump skid<br />

- N 2 booster skid<br />

Equipment and control system<br />

is defined and selected in order<br />

to ensure the best possible<br />

operation of the re-liquefaction<br />

system in accordance with<br />

class regulations

LNG Reliquefaction system<br />

Redundancy considerations<br />

IACS Rules for Redundancy for RS<br />

� Spare capacity of RS unit, or<br />

� Auxiliary boiler(s) for BOG, or<br />

� <strong>Gas</strong> oxidiser (GCU) for the BOG, or<br />

� Controlled venting<br />

Different configurations/alternatives<br />

• 2x100% capacity with 1 cold box<br />

• 1x100% capacity with gas oxidizer (GCU)<br />

• QGII ;<br />

2x100% capacity with GCU<br />

• Different configurations studied for new<br />

projects resulting in operational flexibility<br />

BOG FEED<br />

COOLING<br />

WATER<br />

+100<br />

0<br />

-100<br />

-200<br />

+100<br />

-100<br />

-200<br />

SUCTION THROTTLE<br />

0<br />

MAX<br />

MIN<br />

+100<br />

-100<br />

-200<br />

2 3<br />

1 E<br />

0<br />

NITROGEN<br />

RESERVOIR<br />

+100<br />

0<br />

-100<br />

-200<br />

RECYCLING<br />

BY-P<strong>AS</strong>S<br />

+100<br />

0<br />

-100<br />

-200<br />

+100<br />

0<br />

-100<br />

-200<br />

+100<br />

0<br />

-100<br />

-200<br />

MAX<br />

MIN<br />

+100<br />

0<br />

-100<br />

-200<br />

VENT<br />

+100<br />

0<br />

-100<br />

-200<br />

TO TANKS

LNG Re-liquefaction<br />

The Re-liquefaction system is based on the N 2-Brayton cycle<br />

This system has proven to be advantageous for several<br />

reasons:<br />

- simplicity (single component, single phase refrigerant)<br />

- short response time for capacity adjustments<br />

- dynamic type (centrifugal) machinery can be employed<br />

The <strong>Hamworthy</strong><br />

supplied<br />

Moss TM RS is a<br />

patent protected<br />

system.

Process Description – Cargo Cycle<br />

� BOG from the cargo<br />

tanks (1.06-1.15 bar a)<br />

by conventional LD<br />

compressors.<br />

� To enable stable<br />

temp at inlet cold<br />

box, BOG is<br />

pre-cooled upstream<br />

compressors<br />

� Discharge pressure from BOG compressor is<br />

4,5 bar and the BOG is cooled and condensed to<br />

LNG at this pressure in a 3-stream plate-fin<br />

cryogenic heat exchanger (cold box).<br />

Vent or GCU<br />

�Non-condensibles,<br />

mainly N 2 , are removed<br />

in a separator ( 4,5 bar)<br />

and exited to a flare<br />

(GCU) or vent mast.<br />

Partial reliq (if N 2<br />

>12%) results in ;<br />

-reduced power req.<br />

-tank pressure control<br />

� From the separator,<br />

the LNG flows back to<br />

the cargo tanks

Process Description – Nitrogen Cycle<br />

The RS system needs to have sufficient capacity to cater for heat ingress to the cargo tanks,<br />

vapour header and LBOG piping, in adition to heat introduced by BOG compressors<br />

� N 2 at 13.5 bar<br />

compressed to 57 bar<br />

in 3-stage centrifugal<br />

compressor with water<br />

cooling.<br />

�The gas is led to the “warm” part of the cryogenic<br />

H/E where it is pre-cooled (–110°C) and send to the<br />

expander<br />

�The gas expanded to<br />

a pressure of 14.5 bar<br />

and temp of –163°C.<br />

<strong>Gas</strong> then introduced<br />

into the “cold” part of<br />

the cryogenic H/E<br />

where it cools and<br />

reliquefies the boil-off<br />

gas to LNG.

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

LNG Reliquefaction systems<br />

23 reliquefaction units contracted<br />

with <strong>Hamworthy</strong> so far…

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

LNG Reliquefaction systems

Normal Cargo Handling Operations<br />

� Operations with the Re-Liquefaction plant<br />

in use;<br />

� Laden voyage – normal boil off rate<br />

� Laden voyage + extra BOG<br />

� Ballast voyage<br />

� Cooling down during ballast voyage<br />

before loading<br />

� One tank operations at sea and Re-Liq<br />

on remaining tanks<br />

� Warming up<br />

� <strong>Gas</strong> freeing<br />

� Aerating<br />

� Drying<br />

� Inerting<br />

� <strong>Gas</strong>sing up<br />

� Cooling down<br />

� <strong>Gas</strong> freeing/warm gas through BOG<br />

compressors to GCU

Dynamic simulation model of RS<br />

Pre-qualification of <strong>Hamworthy</strong> as<br />

a supplier to Qatar <strong>Gas</strong> involved ;<br />

- extensive process discussions<br />

- qualifications of our sub-suppliers<br />

and<br />

- development of a Dynamic model.<br />

Typical dynamic simulation cases;<br />

1. Start-up from warm condition<br />

2. Normal operation<br />

3. Stand-by operation<br />

4. Ballast (40% capacity,<br />

warm BOG (-40degC))<br />

5. Normal shut down<br />

6. Emergency shut down<br />

7. Varying N2 content in BOG

LNG RS simulator<br />

Overview screen

Agenda<br />

LNG <strong>Ship</strong>ping Operations Sept. 27, 2006<br />

• Organization & references<br />

• Why LNG reliquefaction systems ?<br />

• LNG onshore pilot plant and other recent references<br />

• LNG RS recent orders<br />

• Equipement<br />

• Contol principles<br />

• Next generations<br />

• LNG regasification

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

LNG Reliquefaction project<br />

Awarded new contract 9 Sep 05<br />

New add. capacity 84000 tons/year<br />

Ready for operation Feb 2007

LNG Reliquefaction system<br />

New concepts with<br />

15-20 % reduction in<br />

power consumption<br />

developed

Improvements on power consumption<br />

What distinguishes double expander from current Qflex design,<br />

Mark I?<br />

Three major changes:<br />

1. New compander design<br />

1. New cold box geometry<br />

1. New precooling<br />

concept<br />

RESULT:<br />

Typically 15-20% decrease in<br />

specific liquefaction energy (kWh/kg LBOG)<br />

Patent pending

Further improvements – ambient BOG comp<br />

What about Mark III ?<br />

Proposed changes:<br />

1. BOG compressor (3 stages)<br />

works under ambient<br />

temperatures<br />

2. BOG compressor inter- &<br />

after- coolers<br />

3. Removes heat with cooling<br />

water from high temp BOG<br />

4. Can down size Compander<br />

5. Reduce exergy losses in<br />

cold box<br />

Patent pending

Power consumption example Qmax<br />

1 expander versus 2 expander solution verses Mark III<br />

Power cons.<br />

1 exp solution<br />

N2 compander<br />

BOG compressor<br />

Sum<br />

Power cons.<br />

1 exp solution<br />

6356<br />

462<br />

6818<br />

Power cons.<br />

2 exp solution<br />

kw<br />

5406<br />

447<br />

5853<br />

7000<br />

6000<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

0<br />

Power cons.<br />

Mark III<br />

Power consumption<br />

- 14%<br />

4441<br />

1014<br />

5454<br />

- 20%<br />

1 Exp 2 Exp Amb. BOG

Power consumption example Qflex<br />

1 expander Mark I versus Mark III<br />

Power consumption<br />

N2 compander<br />

BOG compressor<br />

Sum<br />

Power cons.<br />

1 exp solution Mark I<br />

4859<br />

332<br />

5191<br />

5200<br />

5000<br />

4800<br />

4600<br />

4400<br />

4200<br />

4000<br />

Power cons.<br />

Mark III<br />

Power Consumption<br />

- 14%<br />

3623<br />

784<br />

4407<br />

-15%<br />

Mark I Mark III

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

Kollsnes II<br />

New refrigerant cycle with double expander<br />

will be commissioned and put in operation<br />

February 2007.<br />

Retrofit installation on existing LNG production site

LNG Reliquefaction system<br />

Summary<br />

• Slow speed diesel engines in combination with<br />

reliquefaction system, results in improved<br />

economy<br />

• LNG business is conservative and typical attitude<br />

has for a long time been;<br />

“We do not want to be the first, but first to follow”<br />

This is now possible !<br />

• Expect several alternative propulsion systems to<br />

be used in the future.<br />

Selection dependant on trade, size of vessels,<br />

charterer’s and owners’ preference, etc<br />

• <strong>Hamworthy</strong> continues improving the system;<br />

- Reduced power consumption<br />

- Improved redundancy configurations<br />

- Improved project execution models

Agenda<br />

LNG <strong>Ship</strong>ping Summit 2006<br />

• Organization & references<br />

• Why LNG reliquefaction systems ?<br />

• Snurrevarden LNG and other recent references<br />

• LNG Reliquefaction <strong>Systems</strong><br />

• Equipement<br />

• Contol principles<br />

• Next generation Mark III<br />

• LNG regasification

LNG regasification system<br />

• Increased import &<br />

spot/short term<br />

LNG trading<br />

in the future<br />

• Capacity in existing<br />

import terminals<br />

booked/limited<br />

• Permission to build<br />

new land terminals<br />

in US/Europe<br />

difficult<br />

• Vaporization plant<br />

onboard LNG<br />

carriers or Floating<br />

Storage Units will<br />

not need “terminals”<br />

Not in my back yard !!

LNG regasification system<br />

Regasification units<br />

on;<br />

Process/system<br />

• Floating Storage<br />

Regasification Unit<br />

(FSRU) permanently<br />

anchored receiving<br />

LNG from LNG<br />

carriers<br />

or<br />

• Shuttle Regasification<br />

Vessels overlapping<br />

at unloading site in<br />

order to ensure<br />

continuous send-out<br />

3 alternative <strong>Hamworthy</strong> Regass systems: unit<br />

- Steam based (closed loops)<br />

- Cascade type using seawater and propane<br />

with or without phase change of propane<br />

- Pure seawater based

<strong>Hamworthy</strong> LNG regasification system<br />

What is a shuttle regasifcation vessel ?

LNG Regasification Unit<br />

Steam/glycol system<br />

Heat to the regas process is taken<br />

from the onboard steam boilers<br />

Pressure & capacity ranges;<br />

40-130 bar<br />

50-1100 t/hr<br />

LNG booster pumps<br />

Printed circuit<br />

heat exchanger<br />

(steam against<br />

water-glycol mix)<br />

Shell & tube<br />

heat exchanger<br />

(water-glycol mix<br />

against LNG)<br />

Water glycol mix<br />

circulation pump

LNG Regasification Unit<br />

Cascade (propane/seawater) system<br />

Propane in closed loop heat LNG<br />

Heat to the regas process from ambient seawater<br />

Reduced regas fuel consumptions<br />

Same pressure & capacity ranges<br />

LNG/seawater<br />

heat exchanger<br />

<strong>Gas</strong> out<br />

Propane /<br />

Seawater HX<br />

(plate type in titanium)<br />

Seawater In<br />

Seawater out<br />

Propane pump<br />

LNG/propane<br />

heat exchanger<br />

(PCHE)<br />

<strong>Gas</strong> in<br />

LNG booster<br />

pump

<strong>Hamworthy</strong> LNG regasification system<br />

Neptune project outside Boston, US (Hoegh LNG for Suez)

<strong>Hamworthy</strong> LNG regasification system<br />

Neptune project outside Boston, US (Hoegh LNG for Suez)

<strong>Hamworthy</strong> <strong>Gas</strong> <strong>Systems</strong> <strong>AS</strong><br />

RE-G<strong>AS</strong>IFICATION TEST PLANT<br />

• Propane 2-phase solution<br />

• Water/Glycol solution<br />

• Placed at Kollsnes, Bergen Norway<br />

• Capacity: abt 200 kg/h (scale abt 1:1000)<br />

• Currently under final commissioning<br />

• Estimated official test run mid September

<strong>Hamworthy</strong><br />

Thank you for<br />

your patience !