FP-912-1 Cookers - Paul Mueller Company

FP-912-1 Cookers - Paul Mueller Company

FP-912-1 Cookers - Paul Mueller Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

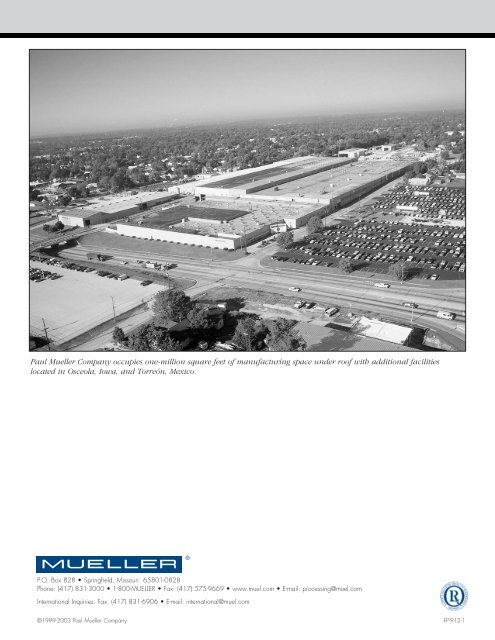

<strong>Paul</strong> <strong>Mueller</strong> <strong>Company</strong> occupies one-million square feet of manufacturing space under roof with additional facilitieslocated in Osceola, Iowa, and Torreón, Mexico.®P.O. Box 828 • Springfield, Missouri 65801-0828Phone: (417) 831-3000 • 1-800-MUELLER • Fax: (417) 575-9669 • www.muel.com • E-mail: processing@muel.comInternational Inquiries: Fax: (417) 831-6906 • E-mail: international@muel.com©1999-2003 <strong>Paul</strong> <strong>Mueller</strong> <strong>Company</strong> <strong>FP</strong>-<strong>912</strong>-1

MUELLER ®COOKERS®PROCESSING SYSTEMS AND EQUIPMENT

Cook ’N Cool<strong>Mueller</strong> ® Temp-Plate ® heat transfer surface maximizes heat transferefficiency, heating, or cooling in the <strong>Mueller</strong> cook ’n cool unit. Itcan be used for cooking with steam and cooling with water inthe same unit or cooling only with glycol, ammonia, or Freon ® .Double-action agitation scrapes the heat transfer surface toprevent burn-on and a high-speed, counter-rotating turbineprovides shear action for blending.Standard Features◆ Double-action agitation assembly includes bothscraping and turbine-type agitators.◆ <strong>Mueller</strong> Temp-Plate heat transfer surface onbottom head for heating or cooling.◆ Large diameter provides maximum efficiencyof heat transfer surface.Top and Front Views◆ Rated capacity plus 10" freeboard.◆ Type 304 stainless steel inner liner and outer jacket.◆ 3" clamp-type outlet ferrule.◆ Stacked mixer drive, dual agitation, single speed,230/460 volt, 60 hertz, 3-phase gear motor(s).A◆ 2" inswool (low chloride) insulation.◆ One thermometer well.◆ Adjustable stainless steel legs.◆ Easy to clean with large radius corners.◆ Sanitary construction includes No. 4 finish oninterior and exterior with internal and externalwelds ground and polished.BHeating and Cooling CurvesCProduct Temperature °F1801601401201008060HeatTime (minutes)Cool400 15 30 45 60 75 90Based on 500-gallon capacity:◆ Heating with 60 psig steam.◆ Cooling with 60 gpm and 35°F water.Blue shaded area refers to thedouble-action agitator assembly.If viscosity of product is greater than 100 cP, multiply the cooling timefor water by (viscosity, cP).D

“SCI” Cooker<strong>Mueller</strong>’s Model “SCI” cooker is very versatile, featuring a full range ofaccessories including special racks for rolled meat or individual meatparts, perforated baskets, and reinforced transfer carts designedespecially for use with these cookers. Hinged bottom with quickreleaseprovides easy unloading of product.Roll RackThis rack insert for our “SCI”cooker is designed for cookingroll cuts or briskets, etc., and ispolished to a No. 4 sanitaryfinish.Standard Features◆ Approximate capacity of 1,000 pounds.◆ Stainless steel construction with No. 2B finishinside and out. Exterior welds are blasted andinterior welds are ribbon polished to meet USDArequirements.◆ <strong>Mueller</strong> Temp-Plate heat transfer surface onbottom and lower sides, along with an outerjacket over the heating area, assures quickheating and constant temperature control.◆ Mill-finished stainless steel legs with adjustablestainless steel ball feet make leveling easy.◆ A stainless steel fat skimmer with a 2-inchthreaded ferrule and a 1-inch steam temperatureregulator connection are provided for yourgrease trap and heating system.◆ Removable stainless steel basket supports.Optional Features◆ Two-piece, stainless steel cover.◆ Steam temperature regulator with indicatingthermometer.42"45"45"53 1 /4"60"Cook ‘n Cool Sizing ChartVolume* I.D. Dim. A Dim. B Dim. C Dim. D Bottom Scrape Turbine No. of Bottom(gallons / liters) (in) O.D. (in) (in) (in) (in) HP RPM HP RPM Impeller Legs Cone**250 / 946 72 76.5 90 18 37.5 5 21.0 1.5 86 26" Dia. 4 25 ft 2500 / 1,893 108 112.5 96 11 48.0 10 15.6 2.0 86 27" Dia. 4 52 ft 2750 / 2,839 108 112.5 105 18 48.0 10 15.6 3.0 58 38" Dia. 4 52 ft 21,000 / 3,785 108 112.5 111 24 48.0 10 15.6 3.0 58 38" Dia. 4 52 ft 21,500 / 5,678 144 148.5 121 18 58.25 15 12.0 5.0 43 48" Dia. 6 110 ft 22,000 / 7,570 144 148.5 128 25 58.25 15 12.0 5.0 43 48" Dia. 6 110 ft 2Standard sizes are listed above in blue.*10" of straight wall above rated capacity to prevent spillage during agitation.**Heat transfer area.