Euronavy ES301 - Protective Coatings, Protective & Marine Coating ...

Euronavy ES301 - Protective Coatings, Protective & Marine Coating ...

Euronavy ES301 - Protective Coatings, Protective & Marine Coating ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

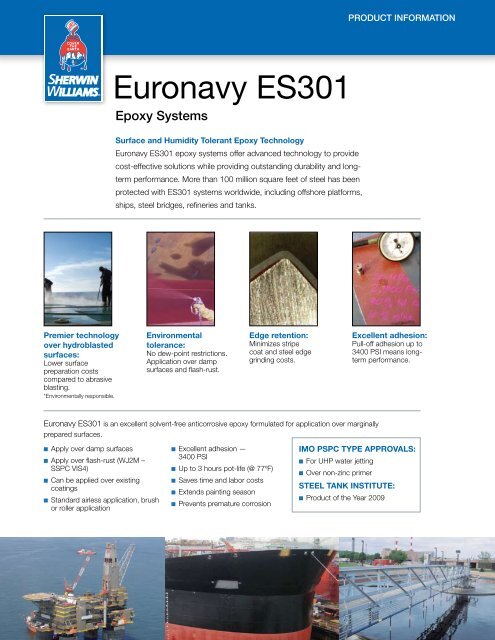

product information<strong>Euronavy</strong> <strong>ES301</strong>Epoxy SystemsSurface and Humidity Tolerant Epoxy Technology<strong>Euronavy</strong> <strong>ES301</strong> epoxy systems offer advanced technology to providecost-effective solutions while providing outstanding durability and longtermperformance. More than 100 million square feet of steel has beenprotected with <strong>ES301</strong> systems worldwide, including offshore platforms,ships, steel bridges, refineries and tanks.Premier technologyover hydroblastedsurfaces:Lower surfacepreparation costscompared to abrasiveblasting.*Environmentally responsible.Environmentaltolerance:No dew-point restrictions.Application over dampsurfaces and flash-rust.Edge retention:Minimizes stripecoat and steel edgegrinding costs.Excellent adhesion:Pull-off adhesion up to3400 PSI means longtermperformance.<strong>Euronavy</strong> <strong>ES301</strong> is an excellent solvent-free anticorrosive epoxy formulated for application over marginallyprepared surfaces.■■ Apply over damp surfaces■■ Apply over flash-rust (WJ2M –SSPC VIS4)■■ Can be applied over existingcoatings■■ Standard airless application, brushor roller application■■ Excellent adhesion —3400 PSI■■ Up to 3 hours pot-life (@ 77ºF)■■ Saves time and labor costs■■ Extends painting season■■ Prevents premature corrosionIMO PSPC TYPE APPROVALS:■■ For UHP water jetting■■ Over non-zinc primerSTEEL TANK INSTITUTE:■■ Product of the Year 2009

PERFORMANCEENVIRONMENTCOSTSAFETYEURONAVY <strong>ES301</strong> ADVANTAGES• Coat immediately after hydroblasting or other waterbasedpreparation, without drying, assures the lowestpossible salt level.• Edge retention for long-term performance.• Excellent adhesion.• Surface tolerant.• No solvent release.• Hydroblasting is not only possible but also preferable.• Lower overall cost.• No abrasive removal costs.• No dew point restrictions.• No need for dehumidification equipment.• Less environmental delays.• Minimizes need for stripe coating.• Non-flammable.• No abrasive dust when hydroblasting.• No solvents, low odor.<strong>ES301</strong> SYSTEMS APPROVALSNAVSEA/US NAVY MIL-PRF 23236C APPROVEDas Type VII coating (no solvent added), for the following classes:Class 7 (seawater ballast tanks for high durability — 20 years service life)Class 15b (use over wet surfaces prepared to bare metal)Class 17 (bilges)IMO PSPC TYPE APPROVEDBY ABS, LLOYDS REGISTER AND GERMANISCHER LLOYDSType Approved as compliant with IMO MSC.215(82) for ballast tank coatingwith a target useful life of 15 years.Products:PHYSICAL TESTINGAdhesion (Pull Off) (ASTM D4541)Wet surface: 120 Kg/cm2 (1706 PSI)Dry surface: 170 Kg/cm2 (2417 PSI)Abrasion Strength (ASTM D4060)6 x 10-3 g /cycle (1000 cycles / 1 Kg)Coefficient of Thermal Expansion15 x 10-6 /cm2Impact Resistance853 KgF/cm2 (12,132 PSI)Barcol Resistance (ASTM D2583) 28Elasticity Modulus (ISO/R 527)100,000 KgF/cm2Salt spray resistance (ASTM B117)2000 hr – No defectsHumidity (ASTM D2247)No defectsMaximum elongation (ISO/R 527) 3%Compressive Strength (ISO 844)1.050 KgF/cm2 (~15,000 PSI)Flexural Strength (ISO 178)650 KgF/cm2 (9245 PSI)Condensation Resistance (ASTM D4585) 2000 hours – No defectsExterior Exposure (ASTM D1014) 2 years – “Chalking” (ASTM D659): rating 4Immersion in water (ASTM D870)4000 hr. – No defectsImmersion in salt water (ASTM D870)4000 hr. – No defectsQUV (Using A340 & B313 bulbs) 2000 hr. “Chalking” (ASTM D659) rating 4Adhesion (Tape test, ASTM D3359)Rating – 5BDeformation/Impact test (ASTM D2794) 30 Kg.cmFlexibility (ASTM D522 – Mandrel bend) No defectsAbsorption (ASTM D570) 0,30%Prohesion (ASTM G85)2000 hr – No defects<strong>Euronavy</strong> <strong>ES301</strong>L – Standard Temperature Application<strong>Euronavy</strong> <strong>ES301</strong>K – High Temperature Application<strong>Euronavy</strong> <strong>ES301</strong>S – Edge Retentive TopcoatA complete line of products. Market expertise. On-time distribution.What else would you expect from a world leader in protective coatings and linings?It starts with a complete line of time-tested, high-performance products and some of the most innovative and greenest technologiesin the coatings industry. But we know that it takes more than product alone to be a world leader in protective coatings and linings.And so do the customers that rely on us every day as we help them protect their business.That’s where over 140 years of coatings industry experience comes in. Add to that a NACE-trained workforce with a combined3,700 years of experience in corrosion control. And the market-specific knowledge that our experts provide to evaluate, recommendand deliver the highest-performance coatings and linings that protect our customers’ assets.It also means that we deliver on time, every time from 5,500 company-owned distribution points worldwide. Leave nothing tochance. Your single source of supply. Sherwin-Williams.To learn more, visit us atwww.sherwin-williams.com/protectiveor call 1-800-524-5979to have a representative contact you.©2010 The Sherwin-Williams Company<strong>Protective</strong> & <strong>Marine</strong> <strong><strong>Coating</strong>s</strong> 4/10