Rotary Products 2012 Brochure - Carter Day International, Inc.

Rotary Products 2012 Brochure - Carter Day International, Inc.

Rotary Products 2012 Brochure - Carter Day International, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

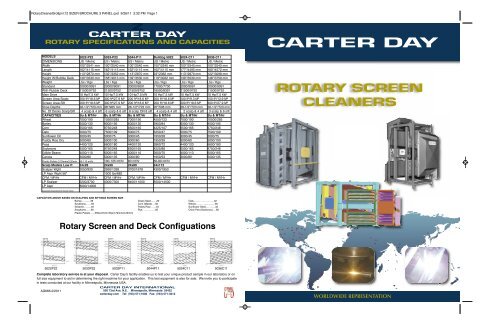

<strong>Rotary</strong>CleanerBro8pnl:12 SIZER BROCHURE 3 PANEL.qxd 9/26/11 3:32 PM Page 1ZCARTER DAYROTARY SPECIFICATIONS AND CAPACITIESMODELS 5022-P22 5033-P22 5044-P11 Bulldog 5022 5024-C11 5036-C11DIMENSIONS US / Metric US / Metric US / Metric US / Metric US / Metric US / MetricWidth 100"/2541 mm 100"/2540 mm 100"/2540 mm 100"/2540 mm 100"/2540 mm 100"/2540 mmLength 162"/4115 mm 162"/4115 mm 162"/4115 mm 162"/4115 mm 177"/4495 mm 180"/4572 mmHeight 113"/2870 mm 132"/3352 mm 113"/2870 mm 93"/2362 mm 113"/2870 mm 122"/3098 mmHeight W/Rubble Deck 139"/3530 mm 158"/4013 mm 139"/3530 mm 119"/3022 mm 139"/3530 mm 148"/3759 mmWeight Lbs / Kgs Lbs / Kgs Lbs / Kgs Lbs / Kgs Lbs / Kgs Lbs / KgsStandard 20000/9091 20000/9091 20000/9091 17000/7700 2000/9091 20000/9091With Rubble Deck 21500/9752 21500/9752 21500/9752 18500/8391 21500/9752 21500/9752Main Drive 10 Hp/7.5 kW 10 Hp/7.5 kW 10 Hp/7.5 kW 10 Hp/7.5 kW 10 Hp/7.5 kW 10 Hp/7.5 kWScreen Area Scalp 200 ft²/18.6 M³ 300 ft²/27.9 M³ 200 ft²/18.6 M³ 200 ft²/18.6 M³ 100 ft²/9.3 M³ 150 ft²/13.9 M³Screen Area Sift 200 ft²/18.6 M³ 300 ft²/27.9 M³ 200 ft²/18.6 M³ 200 ft²/18.6 M³ 200 ft²/18.6 M³ 300 ft²/27.9 M³Shoe Depths 28-1/2"/723 mm 38"/965 mm 28-1/2"/723 mm 20"/508 mm 28-1/2"/723 mm 28-1/2"/723 mmNo. Of Decks Scalp/Sift 4 scalp & 4 sift 6 scalp & 6 sift 8 scalp OR 8 sift 4 scalp & 4 sift 2 scalp & 4 sift 3 scalp & 6 siftCAPACITIES Bu & MT/Hr Bu & MT/Hr Bu & MT/Hr Bu & MT/Hr Bu & MT/Hr Bu & MT/HrWheat 7000/190 10500/285 7000/190 4550/123 7000/190 10500/285Barley 6000/130 9000/195 6000/130 3900/84 6000/130 9000/195Corn 6500/165 9750/248 6500/165 4225/107 6500/165 9750/248Oats 5000/75 7500/109 5000/75 3250/47 5000/75 7500/109Sunflower Oil 3000/45 5000/75 3000/45 1950/28 3000/45 5000/75Paddy Rice Dry 3000/60 5000/100 3000/60 1950/39 3000/60 5000/100Peas 4400/120 6600/180 4400/120 2860/72 4400/120 6600/180Soybeans 6500/165 9750/248 6500/165 4225/88 6500/165 4750/248Edible Beans 4000/110 6000/165 4000/110 2600/70 4000/110 6000/165Canola 3000/80 5000/135 3000/80 1950/53 3000/80 5000/135Plastic Pellets 3.79mmx3.20mm 80-110 mt/hr 100-125 mt/hr 80 mt/hr 60-80 mt/hrScalp Models Low P. 24x28 24x56 24x80 24x112Scalper Wght 2050/930 2950/1338 3700/1678 4300/1950LP Aspr Wght 56"1500 lbs/682CFM / M³/Hr CFM / M³/Hr CFM / M³/Hr CFM / M³/Hr CFM / M³/Hr CFM / M³/Hr CFM / M³/HrLP Scalper 2200/3700 4300/7300 6400/11000 8500/14500LP Aspr 8000/14000CARTER DAYROTARY SCREENCLEANERSCapacities Dependend On Screen SizesCAPACITIES ABOVE BASED ON SCALPING AND SIFTINGS SCREEN SIZEBarley………..48 Grass Seed…….20 Oats…………………….32Soybeans…….56 Corn (Maize)….56 Wheat…………..............60Sesame………46 Paddy Rice…….45 Sunflower Seed……...…32Sorghums……56 Rye…………….56 Chick Pea (Garbonzo)….58Plastic Pellets ......35lbs/cft,No Slip(3.79mmx3.20mm)<strong>Rotary</strong> Screen and Deck Configuations5022P22 5033P22 5033P11 5044P11 5024C11 5036C11Complete laboratory service is at your disposal. <strong>Carter</strong> <strong>Day</strong>'s facility enables us to test your unique product sample in our laboratory or onfull size equipment to aid in determining the right machine for your application. This test equipment is also for sale. We invite you to participatein tests conducted at our facility in Minneapolis, Minnesota USA.AG666-2/2011CARTER DAY INTERNATIONAL500 73rd Ave. N.E. Minneapolis, Minnesota 55432carterday.com Tel: (763) 571-1000 Fax: (763) 571-3012WORLDWIDE REPRESENTATION

<strong>Rotary</strong>CleanerBro8pnl:12 SIZER BROCHURE 3 PANEL.qxd 9/26/11 3:32 PM Page 2CARTER DAYROTARYCARTER DAYLow Profile Scalperators Aspirators Rubble DecksFor more than 125 years <strong>Carter</strong> <strong>Day</strong> has been manufacturing quality processing equipment. We continuethis tradition over last 25 years with the manufacture of the <strong>Carter</strong> <strong>Day</strong> <strong>Rotary</strong>.The <strong>Carter</strong> <strong>Day</strong> <strong>Rotary</strong> is designed to meet your high capacity cleaning requirements. The <strong>Carter</strong> <strong>Rotary</strong> isa versatile separator that is suitable for virtually any screening operation. It is available in several deck sizesand configurations. Each machine is capable of many possible screen arrangements and combinations.The <strong>Rotary</strong> can be equipped with one scalping deck and up to five fines decks. You can scalp andremove fines all in one pass in one machine. The many combinations permit a range of optimumcleaning capacities from 3,000 BPH to 13,000 BPH (80 to 325 MT/HR). The <strong>Carter</strong> <strong>Rotary</strong>is an ideal machine for county elevators and export terminals, as well as processingplants.The <strong>Carter</strong> <strong>Day</strong> <strong>Rotary</strong> Screen Cleaner offers effective efficient use of the rotary screenmotion for high volume precision screening applications. The efficient removal ofdockage from corn, wheat and many other free flowing granular materials is dependenton the level of dockage or FM of the incoming product, the burden depth ofproduct on the screen and the consistency of the dockage. The rotary motionensures the highest possible efficiency compared to reciprocating or linear typescreen machines and can provide double or more the loading and throughput rates on most screen openings.Designed for floor mounting, having its' own suspension. For ease of installation, particularly when accessis restricted, all models may be shipped knocked down into components; inner frame with drive unit, decksand support stand are assembled in heavy all-bolted construction.PARALLEL FLOW: All screen decks are in parallelarrangement. Ideal for single-pass cleaningoperations such as primary cleaning of barley,oats, west coast corn and pre-scalped wheat.Coarse scalping decks to remove oversize foreignmaterial are optional.COUNTER FLOW: Upper and lower decks are atreversed angles to permit use of entire length of allscreens. Especially useful with products thatrequire two-pass cleaning, such as canola and flax.Coarse scalping decks to remove oversize foreignmaterial are optional.ScalpingReelCleaningWheelsWeightedGateRockPlatePositiveFeed RollAspirationColumnSettlingChamberLiftingsConveyorThe 24” Low Profile Scalper features scalpingand sifting in a single machine to provide a highcapacity method for removing roughage and finesin a single pass.High capacity stand-alone scalping and siftingwhere installation conditions demand a low-profilemachine.We use all of the features of our 24” Scalperatorin our low profile size less the feed roll gate andaspiration.Using the Perforated Reels minimizes theRotaries scalping blinding which increases capacitypotential and performance.<strong>Carter</strong> <strong>Day</strong> Rubble Deck for coarse removal offield trash, cans and oversized foreign materialsprior to flow splitting and precision cleaning.The 24” Low Profile Scalperator features scalpingand aspiration in a single machine to provide a highcapacity method for removing roughage, light fines andchaff in a single pass.High capacity stand-alone pre-cleaning where installationconditions demand a low-profile machine.We use all of the features of our 24” Scalperator in ourlow profile size less the feed roll gate.Using the Perforated Reels and Aspiration of theScalperator minimizes the Rotaries scalping and siftingblinding which increases capacity potential and performance.CleaningWheelsRockPlateScalpingReelPositiveFeed Roll<strong>Carter</strong> <strong>Day</strong> High Capacity Low Profile Aspirator offersmeter feeding with expansion chamber. Designed forFloor Mounting.Parallel FlowCounter FlowCARTER DAY INTERNATIONALCARTER DAY INTERNATIONAL

<strong>Rotary</strong>CleanerBro8pnl:12 SIZER BROCHURE 3 PANEL.qxd 9/26/11 3:33 PM Page 3CARTER DAYBULLDOG ROTARYCARTER DAYDRIVE SYSTEM AND CENTER OF GRAVITYThe <strong>Carter</strong> <strong>Day</strong> Bulldog <strong>Rotary</strong> 5022P11 Parallel Flow is designed to meet your high capacity cleaningrequirements. This <strong>Rotary</strong> is a versatile separator that is suitable for virtually any screening operation.Each shoe consists of 2 decks which include scalping screen and sift screen. Other configurations areavailable to meet your application requirements.<strong>Carter</strong> <strong>Day</strong> Drive System uses a 3/4 to 1 1/8”orbital stroke providing the most reliable HTDlow horse power requirement drive package inthe industry.Virtually maintenance free because of onemoving part, HTD timing belt, replaceable singlebearing and no expensive gearbox drive.<strong>Carter</strong> <strong>Day</strong> drive uses a non-protrudingmotor, drives or braces,which maximizes clearances.High Speed flat gyratory action, induced upon the full length of each screen by a counterweighted drive, presents maximum screen surface to the grain. Dynamic balancing, both horizontallyand vertically, assures high speed, low stress operation, with a minimum of vibrationtransfer to the structure. Overall stroke distance is 1-1 1/8”. Additionally various stroke distancesand RPM's are used to maximize cleaning/sifting, capacity and screening efficiencies.CARTER DAY ROTARY CENTER OF GRAVITYIn order to maximize reliability, minimize stress and vibration, the drive assembly must be locatednear the center of gravity of the machine. <strong>Carter</strong> <strong>Day</strong> engineering has achieved near perfect balanceby following this strategy.CARTER DAY ROTARY HIGH CAPACITY CLEANING SYSTEM1- 3”Scalping and 1.5” Sifting burden depths on the screen critically effect proper sizing separation.However there are situations of flooding the scalping decks and over sifting on sifting decks. The UnderScalped is then reclaimed by a supporting <strong>Carter</strong> <strong>Day</strong> system. The Over Sifted product is also reclaimed bya supporting <strong>Carter</strong> <strong>Day</strong> system.CATERDAY ROTARY HIGH CAPCITY CLEANING AND RECLAIM ON WHEATUsing the latest design software, <strong>Carter</strong> <strong>Day</strong> engineering has optimized the physics of the rotaryby modeling the entire machine in a 3D, virtual environment. This ensures that the mass propertiesand moments of inertia can be precisely evaluated. Once the machine center of gravity islocated, the gyrator drive is installed within very tight tolerances of the calculated center. Whenlocated properly, unwanted vibration forces are minimized and long-life is ensured.In addition to complete balancing, <strong>Carter</strong> <strong>Day</strong>uses several innovative methods to ensure robustperformance, including:*Multiple fastener U-Joint Connections: Severalfasteners are used on the universal joint connectionsto resist loosening during install, service, andoperation.*Oversized, gusseted frame: The frame of the<strong>Carter</strong> <strong>Day</strong> rotary has been refined over decades ofuse in demanding applications. Gussets and highstrengthtubular steel is used in areas of highstress.CARTER DAY INTERNATIONALCARTER DAY INTERNATIONAL

<strong>Rotary</strong>CleanerBro8pnl:12 SIZER BROCHURE 3 PANEL.qxd 9/26/11 3:33 PM Page 4CARTER DAYSCREEN CONFIGURATIONS AND OPTIONSCARTER DAYINLET AND OUTLET DOOR DESIGNSQuick Change Screens and Screen Removal with out removingball tray assures ease of maintenance and screen changes.Screen decks are continually cleaned by bouncing balls (seephoto on right) that strike the underside of the screen surfacedislodging any particles that could cause binding.<strong>Carter</strong> <strong>Day</strong> <strong>Rotary</strong> Inlet Spreader Box is a unique design full of internal chambers which evenly split theflow of product to the screens. The inlet spreader box is also a swing away door which allows you fullaccess to the inlet area of the screens. This allows for quick screen replacement or repairs of areas of theinlet from product wear.Aluminum extruded Sieve Runner provides quickchange screens with a unique clamp down featureallow the screen sections to be easily removed. Theball box frames are separate and can stay in themachine. They also are easily removed because ofthe full length swing away door. Spare screens forreplacement or changing to a different product are nowsimple to install.<strong>Carter</strong> <strong>Day</strong> <strong>Rotary</strong> Outlet Door is a unique design full of internal spouting which collects and distributes thescalpings,good product and siftings for collection at the bottom discharge of the machine. The dischargedoor is also a swing away door which allows you full access to the discharge area of the screens. Thisallows for quick screen replacement or repairs of areas of the discharge from product wear.A molded urethane feed roll gate accurately controls theprocess feed rate as the product enters the air wash. TheVFD controlled variable speed drive of the feed roll controlsthe feed roll and feed roll gate RPM to accommodate varietyof feed rate ranges.Product Wear Liners are a great option to increase machine life. Weoffer replaceable bolt in AR and Rhino Hyde® with Ceramic Panels.Plus permanently installed high wear resistant Ceramic Tile.CARTER DAY INTERNATIONALCARTER DAY INTERNATIONAL