JPI-5S-45-95 - Xebex.jp

JPI-5S-45-95 - Xebex.jp

JPI-5S-45-95 - Xebex.jp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

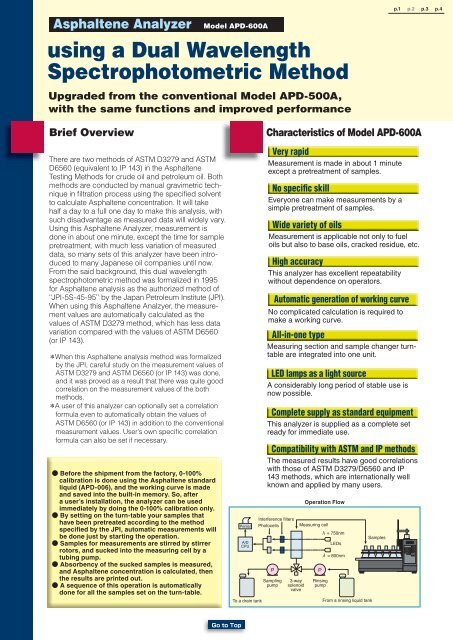

p.1 p.2 p.3 p.4Asphaltene Analyzer Model APD-600Ausing a Dual WavelengthSpectrophotometric MethodUpgraded from the conventional Model APD-500A,with the same functions and improved performanceBrief OverviewThere are two methods of ASTM D3279 and ASTMD6560 (equivalent to IP 143) in the AsphalteneTesting Methods for crude oil and petroleum oil. Bothmethods are conducted by manual gravimetric techniquein filtration process using the specified solventto calculate Asphaltene concentration. It will takehalf a day to a full one day to make this analysis, withsuch disadvantage as measured data will widely vary.Using this Asphaltene Analyzer, measurement isdone in about one minute, except the time for samplepretreatment, with much less variation of measureddata, so many sets of this analyzer have been introducedto many Japanese oil companies until now.From the said background, this dual wavelengthspectrophotometric method was formalized in 19<strong>95</strong>for Asphaltene analysis as the authorized method of‘‘<strong>JPI</strong>-<strong>5S</strong>-<strong>45</strong>-<strong>95</strong>’’ by the Japan Petroleum Institute (<strong>JPI</strong>).When using this Asphaltene Analzyer, the measurementvalues are automatically calculated as thevalues of ASTM D3279 method, which has less datavariation compared with the values of ASTM D6560(or IP 143).When this Asphaltene analysis method was formalizedby the <strong>JPI</strong>, careful study on the measurement values ofASTM D3279 and ASTM D6560 (or IP 143) was done,and it was proved as a result that there was quite goodcorrelation on the measurement values of the bothmethods.A user of this analyzer can optionally set a correlationformula even to automatically obtain the values ofASTM D6560 (or IP 143) in addition to the conventionalmeasurement values. User’s own specific correlationformula can also be set if necessary. Before the shipment from the factory, 0-100%calibration is done using the Asphaltene standardliquid (APD-006), and the working curve is madeand saved into the built-in memory. So, aftera user’s installation, the analyzer can be usedimmediately by doing the 0-100% calibration only. By setting on the turn-table your samples thathave been pretreated according to the methodspecified by the <strong>JPI</strong>, automatic measurements willbe done just by starting the operation. Samples for measurements are stirred by stirrerrotors, and sucked into the measuring cell by atubing pump. Absorbency of the sucked samples is measured,and Asphaltene concentration is calculated, thenthe results are printed out. A sequence of this operation is automaticallydone for all the samples set on the turn-table.PrinterA/DCPUTo a drain tankCharacteristics of Model APD-600AVery rapidMeasurement is made in about 1 minuteexcept a pretreatment of samples.No specific skillEveryone can make measurements by asimple pretreatment of samples.Wide variety of oilsMeasurement is applicable not only to fueloils but also to base oils, cracked residue, etc.High accuracyThis analyzer has excellent repeatabilitywithout dependence on operators.Automatic generation of working curveNo complicated calculation is required tomake a working curve.All-in-one typeMeasuring section and sample changer turntableare integrated into one unit.LED lamps as a light sourceA considerably long period of stable use isnow possible.Complete supply as standard equipmentThis analyzer is supplied as a complete setready for immediate use.Compatibility with ASTM and IP methodsThe measured results have good correlationswith those of ASTM D3279/D6560 and IP143 methods, which are internationally wellknown and applied by many users.Interference filtersPhotocellsSamplingpump3-waysolenoidvalveOperation FlowMeasuring cellRinsingpump = 750nmLEDs = 800nmFrom a rinsing liquid tankSamples