Instrumentation Process Analyzer Condensed Catalog

Instrumentation Process Analyzer Condensed Catalog

Instrumentation Process Analyzer Condensed Catalog

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

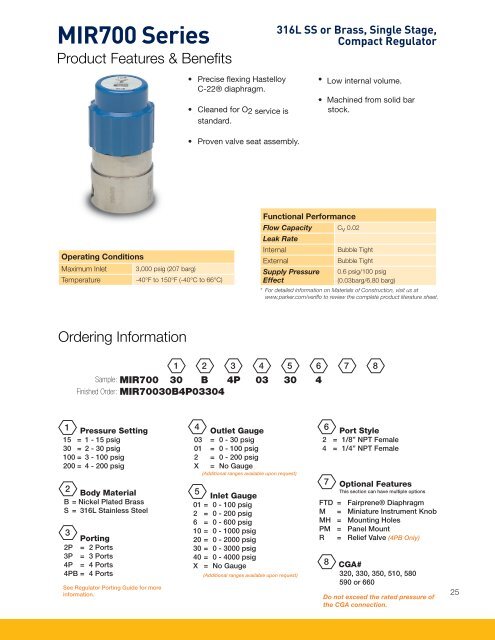

MIR700 SeriesProduct Features & Benefits• Precise flexing HastelloyC-22® diaphragm.• Cleaned for O2 service isstandard.• Proven valve seat assembly.316L SS or Brass, Single Stage,Compact Regulator• Low internal volume.• Machined from solid barstock.Operating ConditionsMaximum Inlet 3,000 psig (207 barg)Temperature-40°F to 150°F (-40°C to 66°C)Functional PerformanceFlow Capacity C v 0.02Leak RateInternalExternalSupply PressureEffectBubble TightBubble Tight0.6 psig/100 psig(0.03barg/6.80 barg)* For detailed information on Materials of Construction, visit us atwww.parker.com/veriflo to review the complete product literature sheet.Ordering Information1 2 3 4 5 6 7 8Sample: MIR700 30 B 4P 03 30 4Finished Order: MIR70030B4P033041 Pressure Setting15 = 1 - 15 psig30 = 2 - 30 psig100 = 3 - 100 psig200 = 4 - 200 psig2Body MaterialB = Nickel Plated BrassS = 316L Stainless Steel3Porting2P = 2 Ports3P = 3 Ports4P = 4 Ports4PB = 4 PortsSee Regulator Porting Guide for moreinformation.4Outlet Gauge03 = 0 - 30 psig01 = 0 - 100 psig2 = 0 - 200 psigX = No Gauge(Additional ranges available upon request)5Inlet Gauge01 = 0 - 100 psig2 = 0 - 200 psig6 = 0 - 600 psig10 = 0 - 1000 psig20 = 0 - 2000 psig30 = 0 - 3000 psig40 = 0 - 4000 psigX = No Gauge(Additional ranges available upon request)6 Port Style2 = 1/8” NPT Female4 = 1/4” NPT Female7Optional FeaturesThis section can have multiple optionsFTD = Fairprene® DiaphragmM = Miniature Instrument KnobMH = Mounting HolesPM = Panel MountR = Relief Valve (4PB Only)8CGA#320, 330, 350, 510, 580590 or 660Do not exceed the rated pressure ofthe CGA connection.25