Pacific Northwest Clean Water Association ... - PNCWA Home

Pacific Northwest Clean Water Association ... - PNCWA Home

Pacific Northwest Clean Water Association ... - PNCWA Home

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSIDE FCOUR PARTNERSAPSCO, Inc, provides top tier equipment to the <strong>Northwest</strong> <strong>Water</strong>and Wastewater industry. We offer a full service shop and fieldservice to assist you with quality repairs, OEM parts, and rentalpumping for limited downtime. Our knowledgable staff can assistyou with all your pumping and treatment process solutions.Thank you to all of thewastewater and waterprofessionals in the<strong>Pacific</strong> <strong>Northwest</strong> for thepast 25 years! Lookingforward to many moreyears of excellence!APG-Neuros:NX Turbo BlowerAPG-Neuros, Inc. offers efficient andaffordable Direct Drive high speedturbo blowers and aeration systemsfor municipal and industrial customers.Over 360 units installed and more than160 currently on order in North America.• Energy savings of up to 35%• Up to 20,000 SCFM & 15 PSIG• No heat rejection into the blower room• Vibration-free operation• Up to 50% smaller foot-print• Very low noise• Lower installation costs• Up to 74% flow turn-downProudly made in the USAWEMCOWEMCO-HidrostalFlowserveKSBMoynoNeptune ChemicalPump Co., Inc.ScrewSuckerSmith & LovelessChemineerAPG-NeurosAtlas CopcoContinentalStoddardJWC EnvironmentalAndritzGE <strong>Water</strong> and ProcessTechnologiesInfilco Degremont Inc.OzoniaWhipps Inc.Gabriel Novac & Assoc, Inc.Fluid DynamicsEntex Inc.Custom ConveyorBioWorksEnvirodyneAWIScrewSucker:Lift Station RedundancyReliable Standby Pumping and ALL yourredundancy in one efficient package.SCREWSUCKER TMAPSCO, Inc.PO BOX 2639, 1120 8th St. Kirkland, WA 98033ph: 425-822-3335 | fax: 425-827-6171email: apsco@apsco-inc.com | www.apsco-inc.com2 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

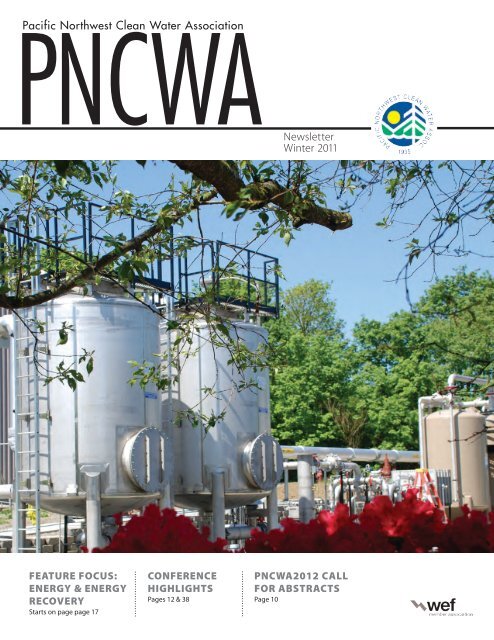

CONTENTSFront row: Shannon Ostendorff, treasurer; Cyndy Bratz, president; Heather Stephens, secretary; Kay Hust, outgoing W WA regionaldirector; John Shawcroft, past president; Doug Allie, outgoing WEF director; Max Hildebrand, WEF director. Back row: Gil Bridges,W WA regional director; Mark Poling, president elect; Andy O’Neill, past president; Ron Gearhart, Idaho regional director; Thomas“Bud” Ruther, outgoing E WA regional director; Tom Hastings, E WA regional director and Steve Miles, OR regional directorNot pictured: Mike Ollivant, vice president and Rick Shanley, WEF directorTABLE OF CONTENTSENERGY EFFICIENCY INTRODUCTION 17EFFICIENCY AUDIT SAVES MONEYand Energy for Your Community 18HEAT EXTRACTION FROM PLANT EFFLUENT:Pumped Up Heat Pumps 20PGE’S NEW ENERGY PARTNER INCENTIVES 21WHAT ELSE CAN YOU PUT IN THERE?Unconventional Feedstock HelpsMake the Most of Anaerobic Digesters 22ENERGY EFFICIENCY IMPROVES TREATMENTPlant Operations and Saves Tens ofThousands of Dollars Per Year 23WWTPS PROVIDING TRANSPORTATION FUEL?Feasibility Study Underway In Oregon 24O&M ENERGY EFFICIENCY CHECKLISTfor Wastewater Treatment Plants 25WEF BOARD ADOPTS POSITION STATEMENTon Renewable Energy Generationfrom Wastewater 28DEPARTMENTSFrom the President 5To the Editor 6New <strong>PNCWA</strong> Board Members 7Committee Focus—Collection Systems 9<strong>PNCWA</strong> 2012 Call for Abstracts 10Committee Focus—Asset Management 11<strong>PNCWA</strong> Annual Conference Highlights 12, 38Committee Focus—<strong>Water</strong> for People 142011 In-Kind Contributions 15Committee Focus—POM 29Section News 31Committee Focus—Membership 31Committee Focus—Scholarship 32Committee Focus —Safety 33Committee Focus—Public Education 34From the Office 35Key Volunteers-Contacts 36COVER PHOTO: COGENERATION FACILITIES AT THE COLUMBIA BOULEVARD WASTEWATER TREATMENT PLANT, BUREAU OF ENVIRONMENTAL SERVICES, PORTLAND, OREGON. TWO 800 KW INTERNAL COMBUSTIONENGINE-DRIVEN GENERATORS, EQUIPPED WITH LEAN-BURN TECHNOLOGY AND HEAT RECOVERY WERE HOUSED WITHIN A NEW BUILDING, WITH A 600 SCFM GAS CONDITIONING SYSTEM ON A GAS TREATMENT SKIDOUTSIDE. THE INSTALLATION WAS STARTED UP IN 2008 TO PROVIDE 1.7 MW OF POWER. THE SYSTEM HAS REDUCED THE PURCHASED ELECTRICITY AT THE PLANT BY AS MUCH AS 40 PERCENT. Photo courtesy of CDM.MISSION STATEMENT<strong>Pacific</strong> <strong>Northwest</strong> <strong>Clean</strong> <strong>Water</strong> <strong>Association</strong> (<strong>PNCWA</strong>) is dedicated to preserving andenhancing the water quality in the states of Idaho, Oregon and Washington. We promotethe professional development of our members, the dissemination of information to thepublic, and the advancement of science and technology needed to protect public healthand the environment.VISION STATEMENTThe <strong>Pacific</strong> <strong>Northwest</strong> <strong>Clean</strong> <strong>Water</strong> <strong>Association</strong> will ensure clean, sustainable watersheds forfuture generations.WINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 3

CALL FOR ABSTRACTS

<strong>PNCWA</strong> ANNUAL CONFERENCE HIGHLIGHTS<strong>PNCWA</strong>2011ConferenceOperationsChallengeRiver Ranger Bob Fitzgerald makesa rescue (far left)W4 Wonder Women of Wastewaterteam Dawn Hanthorn, PamelaRandolph, Catherine Dummer and ShannonOstendorff (top, middle)King County Poofighters (top right)New Ops Challenge competitors (bottom right)WINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 13

FOCUS—ENERGY AND ENERGY RECOVER YEnergy Efficiency IntroductionBy Jennifer Belknap Williamson, P.E., LEED AP, City of Gresham and <strong>PNCWA</strong>Sustainability Committee ChairThis issue of the <strong>PNCWA</strong> newsletter is focused on energy—acritical commodity in the water and wastewater sectors. The U.S.Department of Energy predicts that worldwide energy consumptionwill grow by a whopping 44 percent in the next 20 years, driven inlarge part by economic growth in the developing world.This continued increase in demand for energy is driving up thecosts of oil, coal, natural gas and other resources used to makeenergy. Even those of us in the <strong>Northwest</strong> who have access to relativelyinexpensive hydropower are still subject to the impacts ofhigh energy costs, such as when our utilities must purchase peakdemand power on the open market and when we purchase fuelfor fleet vehicles.Fortunately, the wastewater and water sectors have becomeincreasingly savvy about energy efficiency and renewable energygeneration as energy costs continue to rise, and we have wonderfulopportunities at our facilities to continually improve our energyperformance. Whether your facility has a long history of energy efficiencyor you are just embarking on efforts to reduce your energyuse, there’s always more to learn and new problems to solve.Read on to learn about success stories and innovative ideas forconserving and generating energy at WWTPs and other municipalfacilities. Highlights include:••The City of Vancouver, WA describes their successes as apart of BPA’s Energy Smart Industrial Program, which hasresulted in saving approximately 1 million kWhrs and tensof thousands of dollars per year.••The Oregon Department of Energy provides an overviewof a new feasibility study investigating the opportunitiesto use wastewater biogas as a transportation fuel at fourOregon WWTPs.••The City of West Lafayette, Indiana’s exploration of unconventionalfeedstocks to generate more biogas through apilot project illustrates opportunities in the <strong>Northwest</strong> as well.••The Washington Department of Ecology and Public WorksBoard describe the new state requirements for energy efficiencyaudits as a condition of funding from state agencies.••Opportunities for using heat pumps to extract heat fromplant effluent are expanding with improving technologyand a range of applications.••An extensive O&M Energy Efficiency Checklist for WWTPsidentifies the collective ideas of many wastewaterprofessionals to reduce energy use through no cost or lowcost operational improvements.We hope this issue spurs your continued efforts to reduceenergy use and expand renewable energy generation. We are allpart of developing new solutions to our energy challenges. The<strong>PNCWA</strong> Sustainability Committee is currently developing plans fora webinar series on renewable energy lessons learned at municipalwater and wastewater facilities. Look for the first webinar inFebruary 2012! Please let us know if there are any topics youwould like to learn more about.You may contact Jennifer at j.belknap.williamson@greshamoregon.gov.WINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 17

FOCUS— ENERGY AND ENERGY RECOVERYEfficiency audit saves money andenergy for your communityBy David Dunn, WA State Dept. of Ecology and Stephen Dunk, WA State Dept. of CommercePerforming an audit of your utility’spower usage is an excellentidea for both the operations andbusiness management arms of yourutility. In fact, starting this year, theWashington State Legislature is requiringInvestment Grade Efficiency Auditsas a condition of funding from theDepartment of Health, Department ofEcology, or the State’s Public WorksTrust Fund.An investment grade efficiencyaudit is a detailed technical studyof a facility’s systems and processes.An experienced energy engineer willidentify opportunities such as controlsystem improvements, pumping or fansystem modifications, methane captureand use strategies, lighting systemupgrades or other measures that reduceenergy use. The study includes an evaluationof the economic performance andinvestment value of potential upgrades.Armed with this information, a utilitycan make decisions about if, when,and how to implement some or all of theenergy efficiency measures.There are many reasons for a wastewaterutility to invest in energy efficiency:1. Energy is money. Wastewater treatmentis a very energy intensiveprocess. Savings in energy costs couldmean extra funding for training, maintenance,capital improvements, orpreventing rate increases.2. Energy is Carbon. Utilities are focusingon greenhouse gas emissionsand the carbon footprint of facilities.Reducing the energy used atwastewater facilities often reducesthe carbon emissions associated withelectricity production.3. Incentives are available. Mostelectricity providers offer grantsand incentives for energy efficiencyupgrades.4. Financing is available. Ecology andthe Public Works Trust Fund offerlow interest loans and financing forcapital improvements, includingenergy efficiency upgrades. The StateTreasurer’s Office may also providelow interest financing for energyefficiency to qualified borrowers.5. Expertise is available. The Stateof Washington’s Department ofEnterprise Services, Energy Programprovides expert assistance throughthe Energy Savings PerformanceContracting program (more on thatin a moment). In addition, mostpower providers offer no-cost or lowcostaudit services that are meantto help you identify conservationopportunities within your facility.Scoping audits are often available atlow or no cost from the power providers.In Washington, power is deliveredeither through investor-owned utilities,(e.g., Puget Sound Energy, Avista,& <strong>Pacific</strong> Power) or through publiclyownedutilities, (municipal and countyPUDs such as Tacoma Power, ClallamCounty PUD, Inland Power, etc.)Wastewater utilities should contact theirlocal power provider and ask if assistanceis available. Scoping audits providea list of potential energy conservationopportunities, and generally identifycurrent energy consumption as well asan estimate of energy savings availablethrough modifications.Washington’s Department ofEnterprise Services (DES) EnergyProgram offers wastewater utilitiesan option for obtaining an InvestmentGrade Efficiency Audit throughtheir Energy Savings PerformanceContracting (ESPC) program. TheESPC program allows wastewater utilitiesto contract with Energy ServicesCompanies (ESCOs) through an interagencyagreement with DES. The ESCOwill initially prepare a scoping audit,and if that preliminary audit indicatesthat substantial energy savingsare possible at the facility, will preparean investment grade audit. UsingESPC performance based contracting,the ESCO will guarantee projectcosts, energy savings, and equipmentperformance for the energy efficiencymeasures identified in the investmentgrade efficiency audit. More informationon the State’s ESPC program is availableon the web at: http://www.ga.wa.gov/EAS/epc/espc.htm.Washington State has seen an excellentrecord of success in employingenergy efficiency audits. Since 1986 theState has completed over 500 projectsvalued at over $300 million in constructioncosts. Those projects have resultedin documented energy savings valuedat over $100 million to public sector customers.Those projects also receivedover $30 million in electric and naturalgas company incentives.18 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

FOCUS— ENERGY AND ENERGY RECOVERYHeat Extraction from Plant Effluent:Pumped Up Heat PumpsBy Eron Jacobson, Bo Vestergaard-Hansen and Rick Kelly of Brown and CaldwellWhile wastewater effluent has been used as a heatsource for heat pumps for well over 30 years, theavailability of digester gas to produce heat for processand space heating loads coupled with the small range ofheat pump sizes, temperatures and technologies that wouldwork with wastewater effluent kept the use of effluent heatpumps low. Digester gas produced at facilities with anaerobicdigestion has traditionally provided process and space heatingdemands through boilers or cogeneration. Some facilitiesare finding it more profitable to use digester gas methane inalternative applications, such as a fuel source for municipalfleet vehicles, as a biomethane source for natural gas utilities,or for biosolids drying. Heat pump technologies haveadvanced in recent years to provide high temperature hotwater (up to 180°F), and in instances where there is insufficientor alternative uses for digester gas or at facilities thatdon’t have anaerobic digesters, effluent-source heat pumps canprovide an economical alternative heat source.Treated effluent from a wastewater treatment plant(WWTP) offers a convenient and reliable source of heat at arelatively high temperature (compared to surface or groundwaters). Effluent temperatures are above 50°F throughout theyear for most plants. The relatively stable and high temperatureof wastewater effluent can make effluent heat recoverybeneficial under conditions where there is a demand for theheat external to the plant, such as nearby district heatingopportunities or industrial users, and relatively low electricitycost. Heat pumps can also provide cooling in the summer forutilities located in warmer areas.Most heat pumps run on a closed-loop mechanical vaporcompression refrigeration cycle. In this cycle, a liquid coolantHot <strong>Water</strong>Return(ECWT)60˚CEffluent Out(LEWT)4.5˚CFigure 1. Heat pump schematicWarm Coolant(liquid)THROTTLINGVALVECold Coolant(liquid)20 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011CONDENSERHot Coolant(vapor)Cool Coolant(vapor)EVAPORATORCOMPRESSOR(S)at a temperature below that of the effluent is vaporized byextracting heat from the wastewater effluent in an evaporatingheat exchanger. The vaporized coolant is then compressedby one or more compressors, resulting in a high-pressure hotvapor. The hot vaporized coolant is then run through the condensingheat exchanger, where heat is transferred to the hotwater loop and the coolant is partially condensed. After thecoolant leaves the condenser, it drops in pressure and temperatureacross an expansion valve and again enters theevaporating heat exchanger at a temperature colder than thatof the effluent. Heat pumps consist of four pieces of equipment:the compressor, condenser, evaporator, and expansionvalve. Figure 1 shows a schematic of a water-to-water heatpump for effluent applications.Aheat pump’s efficiency is measured by its coefficientof performance (COP). The COP is a comparison ofthe valuable heat out of the heat pump compared tothe power used to generate this heat. The high temperaturewastewater effluent heat pumps available on the market todayhave COPs between 2.0 and 3.5 at temperatures between 160°Fand 175°F. This means that for every 1 kilowatt (kW) of electricpower sent to an ideal heat pump, 2 to 3.5 kW of valuableheat is provided out of the unit. The COP is dependent on theeffluent temperature, hot water temperatures to be generated,and efficiency of the cycle. Since hot water system temperaturesat WWTPs often operate between 160°F and 200°F to provideadequate temperatures for process heating, the heat pumps thatproduce these temperatures are considered high-temperatureheat pumps. When high temperature hot water is not a priority,heat pumps that provide lower temperature hot water (e.g., 130 to150°F) can be used as these have much higher COPs.Hot <strong>Water</strong>Supply(LCWT)71˚CEffluent In(EEWT)10˚CThe market for high-temperature heat pumpshas been growing in the U.S. over recent years.At least four U.S. manufacturers now offer heatpumps that can produce hot water at 160°F andhigher with typical effluent source temperatures.Heat pumps are able to achieve higher hotwater temperatures by virtue of greater compressionratios, typically through the use of multistagecompression. The U.S. manufacturers of high-temperatureheat pumps include McQuay, Trane, York,and Multistack, while there are also a number ofEuropean and Japanese manufacturers of these units.The McQuay heat pumps are relatively newto the high-temperature market (only since 2009)and have relatively small capacities, but can workin parallel to provide larger net capacities. Thecapacities for the high-temperature units range

FOCUS—ENERGY AND ENERGY RECOVERYContinued from previous pagethe WWTPs for the City of Vancouver.“Now we can get by with a single turboblower at each treatment plant most of thetime.” The city also installed a variablefrequency drive (VFD) on the water recyclingsystem at its Marine Park facility.Instead of running continuously,the VFD automates pump operation basedon demand, saving an estimated 220,000kilowatt-hours per year (kWh/y).In addition to capital improvements,the city and Veolia learned how to optimizeenergy usage for various systemconditions. By fine-tuning the set pointsof its UV arrays based on flow and dailywater tests, the team reduced its UVenergy consumption by 27 percent, representingnearly 15 percent of the entireload at the WWTPs. “No pun intended,but our UV usage was a matter of overkill,”says Kraft. “We partnered with theESI team, who helped us measure contacttime in relation to flow. We found that wecan use less UV during low flow periodsand still meet our permit requirements.”These changes are saving the facilitiesroughly one million kilowatt hours andtens of thousands of dollars per year. Also,ESI support and utility incentives coveredabout 30 percent of the project’s capital costs.“It’s been great working with ClarkPublic Utilities and BPA,” said Dick. “TheESI program is unbelievably well organized.They included and motivated ourentire staff. They were actively engagedthroughout the process, from baselinetesting to ongoing monitoring. And theycontinually look for additional energy efficiencyopportunities. We’ve been thrilledwith the results.”You may contact Layne McWilliams atlayne.mcwilliams@energysmartindustrial.com.WWTPs providing transportation fuel?Feasibility study underway in OregonBy Matt Krumenauer, Oregon Department of EnergyThis summer Janet Gillaspie from the Oregon<strong>Association</strong> of <strong>Clean</strong> <strong>Water</strong> Agencies (ACWA), ThadRoth from Energy Trust of Oregon and I were discussingenergy conservation and renewable energy opportunitiesat wastewater treatment facilities. As broad as the opportunitiesare and the depth that Janet and Thad bring to the table,you can imagine the wide ranging discussion we had. Onetopic we discussed in depth was the number of treatmentplants that have recently evaluated their Anaerobic Digestionsystems or would be in the near future. The reasons for theevaluations varied but they all had a decision point in common.Oregon wastewater treatment plants use biogas for processheat and power, and some generate electricity using biogas turbines.But what other opportunities for biogas use existed?One area that has generated interest across the countryis the use of biomethane as a transportation fuel. Janet suggestedthat a few of her members would be interested inspeaking further about this opportunity; therefore we set up abrainstorming session to gage interest. During the meeting, itbecame clear there is interest in evaluating biogas opportunities,and there are other facilities that would benefit.Back at the Oregon Department of Energy, we determinedthat this was definitely an area of interest for the State andan area that we could assist by building a body of knowledgeabout the technology and its application and offer assistanceto not only the clean water industry in the region, but morebroadly to the growing <strong>Northwest</strong> biogas industry. We were ableto partner with ACWA and its members, Metro, NW Natural,Energy Trust of Oregon, Washington State University, andothers to fund a detailed biogas technology evaluation andfeasibility study.The group selected TetraTech NUS, Inc. to complete the studyand it is currently underway. The first step is to complete atechnology assessment. This will involve a detailed evaluationof biogas purification and upgrading technologies, inventoryhandling and storage requirements, and evaluate available technologiesfor use of biogas in two ways: Injection of upgradedbiogas into the existing natural gas grid, and refueling of naturalgas-powered vehicles. The second step will be an economicevaluation of the available markets, life-cycle analysis and riskassessment, and an analysis of the environmental attributesincluding all regulatory requirements.With this information, a more detailed feasibility analysiswill be completed at four Oregon wastewater treatment plantsin Portland, Gresham, Salem, and Klamath Falls. The feasibilityanalysis will also include an assessment of the currentand potential fleet use and necessary fueling infrastructure.This approach will provide a base of knowledge and a methodologythat can be utilized and replicated by other facilities,including wastewater treatment plants, in the region. We willcomplete the study by the end of February. The final reportwill be released shortly thereafter.You may contact Matt Krumenauer at 503-383-8694 or matt.krumenauer@state.or.us.24 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

FOCUS—ENERGY AND ENERGY RECOVERYO&M Energy Efficiency Checklistfor Wastewater Treatment PlantsThe purpose of this list is to help identify no cost or lowcost electricity savings through operation and maintenancepractices at wastewater treatment plants. The list is organizedby System (blower aeration, mechanical aeration, mixing,pumping, etc.) in approximate order from highest to lowestenergy use. Therefore, start at the top of the list and workdown. Because some measures are common to multiple systems,they are repeated, so that each system has a complete list. Pleasereview “Other Measures” on last page, which lists importantideas applicable to the entire plant.Please distribute this open source document to anyone who might be interested, andplease provide comments, suggestions, and new ideas to Walt Mintkeski, P.E., atmintkeski@juno.com, 503-771-0232, in Portland, Oregon.BLOWER AERATION SYSTEM■■Fix air piping leaks. For exposedpipes, apply soapy water to createbubbles. For underground pipes, lookfor air bubbles surfacing through soilduring or just after rain events.■■Reduce air demand—reduce or eliminateair flow to aerated channels andempty aeration basins; reduce airflow to aerated grit chamber; takeexcess aeration basins off line.■■Eliminate air flow restrictions cleanintake air filters, fix sticking checkvalves, open or eliminate throttlingvalves, enlarge undersizedvalves or piping.■■Minimize inlet air temperaturefor centrifugal blowers, especiallythose which draw air from insidebuildings (such as turbo blowers).■■Dissolved Oxygen (DO) ControlSensors—clean and check DOProbe calibration twice a month;airflow meters and pressure sensorsannually.■■Check placement of DO probein basin for representativeDO reading.■■Lower DO set point to lowestpossible setting which results inproper treatment. (That should beless than 2 PPM. However, if eitherammonia or nitrogen removal isrequired, higher set point maybe required, especially duringcold weather).■■Lower blower output pressure byfully opening air valve to highestdemand aeration zone, and thenbalancing other air valves to obtainuniform DO set point concentrationacross remainder of aeration basin;check and tune the settings annually.Use Most Open Valve control strategyfor plants with centrifugal blowersand more than 3 aeration basins.■■Monitor Blower Performance—checkair flow and pressure against blowercurve to determine if units are operatingat most efficient point.■■Identify most efficient blower (highestSCFM/kW) and program controlsto run that unit as primary blower.■■If different capacity blowers are available,program blower operation tomatch diurnal air demand. If blowersare positive displacement units,adjust belts and sheaves to matchoutput to diurnal air demand.■■Monitor SCADA System to identifyif 2 or more blowers operate atreduced speed. Determine if oneunit at higher speed will satisfydemand while drawing less kW. Ifso, take excess equipment off line.■■Diffuser air flow—check CFM/diffuser rate. If it exceeds manufacturer’srecommendation, adddiffusers or reduce air flowper diffuser to restore oxygentransfer efficiency.■■Diffuser maintenance—every week,look for air “boils” which couldindicate broken pipes or diffusers;measure air pressure of eachdrop leg at a set SCFM blowerair flow rate, to detect distributionpiping resistance and diffuserfouling. Remove blockages; flex diffusermembranes with air pulsesor clean diffusers as needed toreduce pressure and increase oxygentransfer efficiency.■■If nitrification is not required, lowerMean Cell Residence Time to 4–5days and turn off aeration systemfrom 1 to 2 hours during the earlymorning low flow period in order toinhibit nitrifying bacteria.■■Convert first zone of aeration basinto anoxic selector. Anoxic zone helpsremove surfactants, which increasesoxygen transfer efficiency.MECHANICAL AERATION SYSTEMS■■Check that the submerged depthof the mechanical aerator is set toproduce the maximum mixing andaeration at a lowest amperage draw.■■Stage unit operation to match DOdemand. If different capacity unitsare available, program operation tomatch diurnal air demand. Use timersto turn units ON/OFF or VFDsto change speed. Take excess unitsoff line.■■Monitor SCADA System to identifyif 2 or more aerators operate atreduced speed. Determine if oneunit at higher speed will satisfydemand while drawing less kW. Ifso, take excess equipment off line.■■Dissolved Oxygen (DO) Controls—Lower DO set point to lowestpossible setting which results inproper treatment (less than 2.0 PPMfor aeration basins and as low as 0.2PPM for aerobic digesters).■■DO probe—clean and check calibrationtwice per month, replaceparts as needed.■■Identify most efficient unit (lbs of O2transferred/kWh) and program controlsto run that unit as primary unit.WINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 25

FOCUS—ENERGY AND ENERGY RECOVERY■■If nitrification is not required, lowerMean Cell Residence Time to 4–5days and turn off aeration systemfrom 1 to 2 hours during the earlymorning low flow period in order toinhibit nitrifying bacteria.■■Monitor units for excessive vibrationand amp draw to detectfowling. <strong>Clean</strong> and recheck.SECONDARY TREATMENTMIXING SYSTEM (in anoxic oranaerobic cells of aeration system)AND ANAEROBIC DIGESTERMIXING SYSTEM■■Reduce number of aeration basinmixers and/or speed of units topoint where solids settling is justbeginning to be observed (visuallyon the surface or by tube samplerthrough tank depth). Take excessequipment off line.■■Reduce number of anaerobicdigester mixers (or pumps) and/orspeed of units to optimize methaneproduction. Take excess unitsoff line.■■Identify most efficient unit (GPM/kW) and program controls to runthat unit as primary unit.■■Monitor units for excessive vibrationand amp draw to detectfowling. <strong>Clean</strong> and recheck.PUMPING SYSTEMS—LIFTSTATIONS, RAS; WAS; TRICKLINGFILTER AND AERATION BASINRECIRCULATION■■Reduce RAS, WAS, and PrimarySludge flow rates to minimumneeded. This increases solids concentrationsand reduces pumpingof excess water.■■Reduce Trickling Filter andAeration Basin recirculation ratesto minimum needed. This reducespumping of excess water.■■Fix piping leaks and pump leaks(packing & seals).■■Eliminate piping restrictions, throttlingvalves, unnecessary valves,sticking check valves.■■Flush scum and sludge piping periodicallyto reduce headloss.■■Reduce pumping head—raise liquidlevel at pump inlet to maximizesuction pressure.■■Monitor pump performance—check flow and total head(discharge pressure minus suctionpressure) against pump curve todetermine if units are operatingon the curve and at most efficientpoint on the curve.■■Calculate wire to water (W2W) efficiencyusing flow, total head, andmeasured kW of pump & motor.Efficiencies should be at least 65%for raw sewage pumps, 70% forRAS & recycle pumps, and 75% forsecondary effluent & reclaimedwater pumps.■■If pump produces more flow thanneeded, consider trimming impellerinstead of throttling.■■Where there are multiple pumps,identify most efficient pump (GPM/kW) and program controls to runthat unit as primary pump. Takeexcess units off line.■■Monitor SCADA System to identifyif 2 or more pumps operate atreduced speed. Determine if oneunit at higher speed will satisfydemand while drawing less kW. Ifso, take excess equipment off line.■■Monitor pumps and motors forexcessive vibration and amp drawto detect plugging and excessivewear. <strong>Clean</strong> and check clearancebetween impeller and volute.Replace impeller and/or wear ringsif necessary.■■Reduce seal water pressure to nomore than 10 psi above pumpvolute pressure.PLANT WATER SYSTEM FORNON-POTABLE USE■■Reduce demand—adjust spray nozzlesin clarifiers and aeration basins;use quick ON/OFF/adjustable flownozzles on wash down hoses; adjustpump seal water flow to lowest recommendedsetting; reduce chlorine gasdilution water flow rate.■■Fix piping leaks.■■Eliminate piping restrictions, throttlingvalves, unnecessary valves,sticking check valves.■■Tune pump control system—adjustpressure set point to minimumneeded.■■Install accumulator pressure tank toallow system to turn off when thereis no demand.■■If pump produces excessive pressure,consider eliminating a pump stage.■■If pump produces excessive flow orhead, consider trimming impeller.■■Identify most efficient unit (GPM/kW) and program controls to runthat unit as primary unit.■■Monitor SCADA System to identifyif 2 or more pumps operate atreduced speed. Determine if oneunit at higher speed will satisfydemand while drawing less kW. Ifso, take excess equipment off line.■■Monitor pumps and motors forexcessive vibration and amp drawto detect plugging and excessivewear. <strong>Clean</strong> and check clearancebetween impeller and volute.Replace impeller and/or wear ringsif necessary.■■Program SCADA system to displaytotal daily usage and to alarm forexcessive use of plant water.UV DISINFECTION SYSTEM■■Replace lamps with low pressure,high output lamps, if possible.■■Keep lamps clean andremove scaling.■■Program light bank control for ON/OFF operation and intensity variationin proportion to plant flow.■■Check quarterly that UV intensitymeter, water turbidity meter, andflow meter are clean, calibrated,and operating correctly.ODOR CONTROL SYSTEM■■Reduce air flow to minimumneeded to control odor and corrosionduring warm weather.■■Consider turning system off duringcool weather when odor productionis minimal.26 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

FOCUS—ENERGY AND ENERGY RECOVERYWEF Board adopts positionstatement on renewableenergy generation fromWastewaterThe <strong>Water</strong> Environment Federation’s(WEF) Board of Trustees approved aposition statement on the recoveryof resources from wastewater duringWEFTEC® 2011. The statement,“Renewable Energy Generation FromWastewater”, calls for wastewatergeneratedenergy to be widely recognizedas a renewable resource and for a greaterdrive for innovation in the water sector.“With the passage of this statement,WEF is encouraging our sector to leadthe way in helping communities recoverresources from wastewater,” said formerWEF President Jeanette Brown. “Itcouldn’t be more fitting for this significantstep to take place at WEFTEC, whichhas long showcased progressive thinkingand new ideas in water. Moving forward,we want WEF and WEFTEC to help catalyzethe wider adoption of innovativeapproaches in the water field.”WEF believes that recognizing wastewatergenerated energy as a renewableresource could have positive, long-termimpacts by stimulating greater productionfrom water resource recovery activities,creating more clean energy jobs, and helpingto reduce greenhouse gas emissionsby alleviating electricity demand fromfossil fuel-based power plants. It couldalso assist advocates in future policydiscussions and encourage widespreadadoption by making the practice eligiblefor federal funding.Many wastewater utilities worldwideare already involved in all areasof renewable energy, from traditionalsources—wind, solar, and hydropower—to more innovative approaches such asbiomass and emerging technologies. Withthe energy contained in wastewater andbiosolids greater than the energy requiredfor treatment, wastewater facilities havethe potential to be energy neutral or evennet energy producers, with some plantshaving already achieved that status.WEF believes that reaching the goal ofenergy neutrality relies upon achievinga holistic energy management approach,incorporating conservation practices, andgenerating renewable energy through themanagement of water resource recoveryand its by-products.“WEF leaders believe that emergingtechnologies can surely advance thepotential for renewable energy fromwastewater,” said WEF Executive DirectorJeff Eger. “WEF will work with stakeholdersand partners who share our vision forresource recovery and will also help buildunderstanding of the potential role ofwastewater treatment facilities. It’s excitingto consider where the future could take usin terms of water quality innovation andI’m proud to be a part of that process.”28 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

COMMITTEE FOCUS—POMWhat Works! Carrier <strong>Water</strong>By Ben McConkey, LOTT <strong>Clean</strong> <strong>Water</strong> AllianceThe original design for the LOTT <strong>Clean</strong> <strong>Water</strong> Alliance’sMartin Way Reclaimed <strong>Water</strong> Plant did not include carrier waterto deliver sodium hypochlorite to the injection points of thereclaimed water stream. The initial feed point for sodium hypochloriteis into a static mixer in the permeate discharge line priorto the contact basins. The control system was set up to adjust thepump feed rate based on the pre-contact chlorine residual usingthe post chlorine contact residual as a trim setting. The “pre”chlorine contact sample for residual is taken about 30 feet downstreamof the static mixer. The treatment plant is a membranebioreactor (MBR) activated sludge - nitrogen removal design withsubmerged membranes for separation of permeate from themixed liquor.Maintaining a consistent chlorine residual proved virtuallyimpossible. The membranes are set up to operate under a differentialpressure for twelve minutes (permeate pumping on) andto relax (permeate pumping off) for one minute. With two bioreactorsoperating, this effectively means a permeate pump isshutting down and halving the discharge flow of about 700 gpmfor one minute every 6.5 minutes or so. The initial drop in flow/Figure 1 without carrier waterpressure caused the sodium hypochlorite in the vertical sectionof feed pipe to “dump” into the permeate line, resulting in a largespike in chlorine residual followed by a corresponding dip in residualwhen the permeate pump restarted. The control system wasnot able to adjust for these conditions. Typical chlorine residual /pump speed trends are shown in Figure 1.Two of LOTT’s senior operators, John Bothwell and Terri Prather,got together and rigged up a temporary carrier water systemusing Class A reclaimed water to deliver the sodium hypochloriteto the pre-contact injection point. The results speak for themselves,as shown in Figure 2. A permanent system was installedand uses about 10 gpm of Class A reclaimed water as carrier water.The use of carrier water in applications such as this where smallvolumes of chemical are injected into a liquid stream flow has multipleadvantages. First, injection of small flows into a liquid streamdoes not provide the energy to disperse the chemical throughoutthe bulk liquid, thus leading to poor mixing and localized conditionsof over concentration. Secondly, it helps to ensure rapidmixing in the static mixer due to better dispersion of the chemical.This approach can be used throughout the plant whenever feedvolumes are low compared to the volume of liquid being treated.You can contact Ben at benmcconkey@lottonline.org.POMC Chair Dick Finger invites you to get involved in POMC,which has the mission to “develop, recommend, support,and conduct programs to promote the overall understandingof facility activities, including those related to operation,maintenance, and management practices of water qualityimprovement facilities.” Feel free to contribute an idea for awebinar or a “What Works” article to share and learn aboutsolving plant operations and maintenance problems. ContactDick Finger at 253-631-3343 or dick.finger@att.net, Vice ChairDawn Hanthorn at dawnh@medurifarms.com, or Past ChairRon Moeller at 360-748-8340 or RonMoeller@kennedyjenks.com.Figure 2 with carrier waterWINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 29

AWARDSWEF & <strong>PNCWA</strong> Safety AwardsPaul Proctor and Richard Ludlow (center) received the Burke award for the City of Gresham fromChris Browning (left) and Andy O’NeillBased on applications received listing 2010 safety records,Veolia <strong>Water</strong> NA/City of Gresham, OR is the recipient of thisyear’s George W. Burke, Jr. award from the <strong>Water</strong> EnvironmentFederation. The award was established to encourage active andeffective safety programs in municipal and industrial wastewaterfacilities. For the <strong>PNCWA</strong> Divisional Awards for zero lost timerecords, there was plenty of recognition in Division B for some frequentrecipients. The plaque was awarded to CH2M HILL/City ofTwin Falls, Idaho. Certificates were awarded to Veolia <strong>Water</strong> NA/City of Gresham, OR and CH2M HILL/City of Walla Walla, WA. Somefamiliar names received recognition in Division C, with a plaquefor EMC/City of Quincy, WA and certificates awarded to the City ofLynden, WA and the City of Silverton, OR. In Division D, the City ofTacoma/North End was a new recipient of a plaque. Perennial winnersin Division E were recognized, with a plaque awarded to theCity of Carlton, OR for zero lost time, and certificates to the City ofHoquiam, WA and City of McCleary, WA. And for ten consecutiveyears without a lost time accident, the City of Lynden, WA receiveda special recognition plaque.It’s quick and easy to apply for Safety Awards, so what areyou waiting for? Start now, and get a pat on the back from yourpeers—you deserve it. The WEF George W. Burke award applicationis a short form that you can enhance with supplementalinformation. The <strong>PNCWA</strong> divisional awards are for zero lost timethe previous year and the application is just one page.Submit safety award applications online at the <strong>PNCWA</strong> webpagewww.pncwa.org or by hard copy to the <strong>PNCWA</strong> office.CREDIT: KIEFFERPHOTOGRAPHY.COM<strong>PNCWA</strong> members who receivedawards at WEFTEC 2011Jon Randall, Justine George, Jim O’Reilly and Bob Fitzgerald of <strong>Clean</strong> <strong>Water</strong> Services competed inthe Operations Challenge at WEFTEC2011Camp Applied Research Award: Henryk MelcerRecognizes a WEF member who demonstrates a unique applicationof basic research or fundamental principles through the designor development of a wastewater collection or treatment systemPublic Education Award: LOTT <strong>Clean</strong> <strong>Water</strong> AllianceFor significant accomplishments in promoting awareness andunderstanding of water environment issues among the generalpublic, through the development of and implementation of publiceducation programsOperations Challenge, Second place overall Division II: <strong>Clean</strong><strong>Water</strong> Services’ River Rangers30 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

SectionNEWSSection Leaders—email your news and pictures toyour Regional Director and copy the newsletter editor,wantlands@cleanwaterservices.org.SECTION NEWSSouthwest IdahoOperators Section (SWIOS)Congratulations to SWIOS2011 award recipients:••Operator of the Year—John Prigge, SorrentoLactalis••Collections Operatorof the Year—Juan Pena, City of Nampa••Laboratory Analystof the Year—Karen Griffin, City of Boise••Corporate Sponsorof the Year—Rain for Rent (Cody Jensen)••Member of the Year—Laurelei Ball, City ofMeridianSWIOS thanks outgoingpresident Gilbert Flores (Veolia<strong>Water</strong>, Caldwell) for four yearsof dedication and service tothe members of the SWIOSsection. We are pleased toannounce our incoming presidentfor the 2012 year, LaureleiBall (City of Meridian). Asalways, SWIOS has a full year ofCEU approved training classeslined up for its members.Please join us for our first trainingclass of 2012, Introductionto Programmable Controllers(0.3 WW/DW CEUs), presentedby Advanced Control Systemson Feb. 15 from 8 a.m. to 1 p.m.at the Meridian WWTP. Pleaseemail lball@meridiancity.orgwith any questions.SouthEast IdahoOperators Section (SEIOS)SEIOS has been very busythis year and is working on theIdaho Operators Conferencein May at Idaho Falls. Weheld a well-attended oneday training at the Burley CSIcampus, offering .6 CEUs. Wealso held trainings in IslandPark and Soda Springs. Both ofthese trainings had great attendanceas well. We are gettingready to bring in new membersto the board in December,and choosing our Operator,Collection and Lab people forthe year. It has been a greattime working with the boardmembers who are all very interestedin doing everything wecan to help section memberswith the training and CEUsthey need for the licensesthey hold. Thanks to greatsponsors, we have been ableto offer trainings with mealsat no cost to members.Olympic Section combinedwith Southwest atthe LOTT learning center onSept. 8 to learn from MarkDoyle of Associated Specialtiesand Robert Stuart of PumpDynamics. The Dec. 7 meetingin Port Townsend will featureAlan Rue of DOE on lab accreditation/microbiology,PumpTech’s Joe Evans with VFD101, Energy Efficiency by BobBrennand w/Energy Smart andPretreatment Do’s and Don’ts byBob Mackey of Port Townsend.We will also tour the PortTownsend WWTP (14 DOE outstandingperformance awards!)and elect an incoming VP.Lunch provided. CEU there!Lower Columbia Sectionselected Dave Gehring, senioroperator at the City ofMcMinnville’s <strong>Water</strong> ReclamationFacility (WRF) for TreatmentPlant Operator of the Year.Dave was also selected asOregon Region Operator ofthe Year. McMinnville’s WRFhosted a Section luncheonand tour where we learnedabout the ongoing capacityimprovements to the collectionand treatment facilities.The Section hosted a meetand-greethappy hour at theLucky Labrador Pub for socializingand shop talk. The YoungProfessionals of the LowerColumbia Section are puttingtogether technical tours andsocial events; students and YPsshould contact Dana Devin-Clarke at ddclarke@brwncald.com.The Lower Columbia Sectionhas Board Positions Open andwe want you. If you are interestedin actively participatingin the Section, please see theSection website at http://lowercolumbia.pncwa.org/ or contactJoel Borchers atborchersj@cleanwaterservices.org.Welcome to new members of <strong>PNCWA</strong>!The people listed below have become members of <strong>PNCWA</strong> since our last issue. The listrepresents both WEF/<strong>PNCWA</strong> new members and transfers from other Member <strong>Association</strong>sto <strong>PNCWA</strong> as well as new <strong>PNCWA</strong>-only members. Welcome to all of you. Let us know howwe can best serve your needs and interests and how you would like to be involved.COMMITTEE FOCUS—MEMBERSHIPDerrek Amburgey, City of EdmondsR Christopher Anderson, City of YakimaSanjay Barik, WA Dept. of EcologyJohanna Bell, StudentMichelle Cahil, City of Eugene/MWMCRick Clark, City of EugeneHeath Coppedge, StudentScott Delibero, Southwest Suburban SewerDistrictJoe Dvorak, <strong>Clean</strong> <strong>Water</strong> ServicesAngie Estey, TraneJordi Figueras, Pharmer EngineeringRoger Flint, CH2M HILLElizabeth Gillard,Kennedy/Jenks ConsultantsSpencer Goodro, City of EugeneMatthew Green, City of EugeneMark Henley, WA Dept. of EcologyBill Huhta, <strong>Northwest</strong> EnvironmentalTraining CenterMike Kebbe, <strong>Clean</strong> <strong>Water</strong> ServicesThomas Keown,Kennedy/Jenks ConsultantsLouis Kitchens, City of Lynden WALiz Li, StudentKen Loucks, Schier Products CoRichard Ludlow,Veolia <strong>Water</strong> North AmericaMollie Mangerich, City of MeridianAaron Markham, Larch Correctional CenterRalph Martini, City of HeyburnLee McGinnis,South Suburban Sanitary DistrictIan McKelvey, Brown and CaldwellTed Mikowski, City of AlbanyTodd Miller, City of DundeeChris Minton, Larry Walker AssociatesNebojsa Mucibabic, HDR EngineeringBrittany Park, City of RedmondWilliam Pavlich, PACE EngineersNicki Pozos, HDR EngineeringJustin Schmidt, G E Roots DivisionWendy Schmidt, Wallis EngineeringDaniel Shafar, Wallis EngineeringKevin Shults,South Suburban Sanitary DistrictRobert Smith, StudentCari Stieglitz, Faithful & GouldGary Still, City of EugeneDon Whitehead, Winzler & KellyAngela Wieland, Brown and CaldwellKenneth Ziebart, WA Dept. of EcologyWINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 31

COMMITTEE FOCUS—SCHOLARSHIPScholarship recipients Larry Littrell, Katie Sheldon and RyanRehder with Steve James (2nd from left).32 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011Thanks to the generosityof our <strong>PNCWA</strong>members and the<strong>PNCWA</strong> Board, thescholarship fund wasable to award three$1,500 scholarships in 2011. The committee narrowed the pool of 11applicants down to our three exceptional winners, all of whom werepresent at this year’s conference:Larry Littrell—Operator for Lake Stevens Sewer District and vicepresident of the NW Washington Section. Larry will be pursuing a 4 yearengineering degree beginning this fall at Everett Community College.Katie Sheldon—Currently pursuing a master’s degree at Oregon$4,500 in ScholarshipsGranted in 2011!By Steve James, J-U-B Engineers, <strong>PNCWA</strong> Scholarship Committee ChairState and interested in storm water treatment OVER $1000••CH2M HILL••Doug Allie<strong>PNCWA</strong> EnvironmentalStewardship ScholarshipsNOT TOO LATE FORYEAR-END CHARITABLEDONATIONS!Donations to the scholarship fund arefully tax deductible.WAYS TO DONATE••Send checks to:<strong>PNCWA</strong> Scholarship FundPO Box 100Hansen, ID 83334••Make a donation at www.pncwa.orgClick the Scholarships link (on left of homepage)Ryan Rehder—Currently pursuing a graduate degree in civil/environmentalengineering at the University of Idaho, focusing on moresustainable waste management practicesOur donors are the real heroes here. Even after awarding thesescholarships, our fund balance now sits at a record $11,100! Thesefunds were raised through individual donations, our annual conferencesilent auction, and dedicated funds from the <strong>PNCWA</strong> generalfund. We are still a long way from our fund goal of $150,000 by 2016,but have made a great start!Please take a minute to thank the following people and companiesfor giving generously to the scholarship fund. The list representsdonations of cash as well as items for the silent auctions:••J-U-BENGINEERS, Inc.••<strong>PNCWA</strong> Board••Veolia <strong>Water</strong> NA$500–$1000••<strong>Water</strong>EnvironmentFederation••HDREngineering,Inc.••Oregon Region••GE <strong>Water</strong>& ProcessTechnologies$250–$500••RichwineEnvironmental,Inc.••Adam Zabinski••AEI Engineering••CarolloEngineers••J. Michael andDia Read••Kay Hust••SSSSS—SelectSociety ofSanitary SludgeShovelers••Walt MintkeskiUNDER $250••Andy O’Neill••Anonymous••APSCO Inc.••Barney & Worth,Inc.••Cindy BeckettKehoe &GordonWoodward••<strong>Clean</strong> <strong>Water</strong>Services••In Memorium ofJohn S. Cluss••Jeanette Brown••Jeff Eger••John Poppe••John Shawcroft••Jon Herrick••Marcus Lopez••Meduri Farms,Inc.••Mike Rainey &Nan Cluss••Paul Proctor••Paul Schuler••Paula Arsenault••Rick Shanley••Robert Pailthorp••Severn Trent••ShawnRedmond••Stephen James••Stoney CreekGemware••SW WAOperatorsSection••TreatmentEquipmentCompany••Umpqua BasinOperatorsSection••<strong>Water</strong> QualityLab AnalystsSection of W WA••West CentralOperatorsSectionNone of this would have been possible without the dedicationof the Scholarship Committee. Our hard working ScholarshipCommittee members include: Adam Zabinski, Karen DeBaker, DaleRichwine, Lynne Chicoine, Erik Coates, Owen Boe, John Poppe andRick Shanley. Thank you for all of your support!

COMMITTEE FOCUS—SAFETYCosts of workplace accidents and injuries, Part IBy Paul Proctor, Gresham WWTP/Veolia <strong>Water</strong> NAAs we come to the close of 2011, it is a good idea to lookback and review what was accomplished and what we couldhave done better. Even if you had a perfect year, most likelyyou experienced some near misses. A list of do’s and don’ts isnot enough to bring safety into the workplace as a dynamicand ever improving mission. It is good to understand the costof safety, or the cost of not being safe. Accidents and injuriesat work have the direct impact of the pain, suffering and costrelated to returning a worker back to 100% condition, the family,and the extra workload placed on coworkers who have topick up the extra duties. When you consider that millions ofAmerican spend almost 40–50% of their day at work, it is no surprisethat thousands in our field go to work each day and returnhome injured. I cannot imagine any person goes to work thinkingthis will be my last day of good health or my last day onearth, and yet it happens—too often. Not only is there the obviouscost of lost work, compensation and medical cost involved,there are many hidden costs associated with workplace accidentsand injuries.and medical payments employers paid in 2008 (the last year datais available), and provided guidelines to reduce them. Based onclaims and data from Bureau of Labor Statistics and the NationalAcademy of Social Insurance, the Safety Index found the topproblem is overexertion or injuries caused by excessive lifting,pulling, pushing, holding, carrying, or throwing an object whichresulted in $9.8 billion in direct costs. Repetitive motion injuriesaccounted for $2.3 billion.When the indirect cost of workers’ compensation claimsare added to the $38.7 billion in direct costs identified by thereport, the total economic burden of workplace injuries and illnessis far greater, with estimates ranging between $125 billionto $155 billion.This is Part 1 of a 2-part article to be continued in the next newsletter.You may contact Paul Proctor, a project manager at the Gresham WWTPat paul.proctor@veoliawaterna.com.The obvious direct costs of workplace accidents and injuriesinvolve the immediate cost of treatment, associated medicalcosts, hospital and physician bills, occupational therapy, prescriptionmedicine and medical equipment. Most workers’compensation insurance will cover these direct costs. Federal lawrequires most businesses with five or more employee to carryworkers’ compensation insurance, but this may not apply to parttimeworkers. Indirect costs associated with workplace accidentsand injuries include damage to equipment, loss of work time, andcost to hire and train a permanent or temporary replacement,and potential increases in the employer’s insurance premium.Indirect costs can exceed direct costs by up to 30 times dependingon the accident.Companies that focus on safety programs tend to have feweraccidents, better employee morale and increased productivity.Many companies offer incentives for no workplace safety incidents,but this may encourage employees not to report minoraccidents or injuries to earn the reward.Other costs of workplace accidents and injuries may includelegal services if the employee sues the company, accident investigation,implementation of measures to correct causal factors,and perhaps more safety training. The first annual Liberty MutualWorkplace Safety Index listed ten leading causes of injuries andillness that account for 86 percent of the $38.7 billion in wageWINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 33

COMMITTEE FOCUS—PUBLIC EDUCATIONAdopt-a-School AwardsBy Karen DeBaker, <strong>Clean</strong> <strong>Water</strong> Services,<strong>PNCWA</strong> Public Education Committee ChairThanks to the support of <strong>PNCWA</strong> members and attendees of the Public Communicationsworkshop, we have awarded $5,000 to students who will engage in water-related studiesduring the 2011–2012 school year. Congratulations to these schools for their exciting projects!2010-2011 school projects pictured above:Century High School, Hillsboro Oregon(top left), North Albany Middle School,Albany, Oregon (top right) Rachel CarsonEnvironmental Middle School, Beaverton,Oregon (bottom)••Albany Options School,Oregon$350 for Plant Science/SchoolSwale/Service Learning••Aloha High School, Oregon$700 for Schoolyard Habitatalong Butternut Creek••Ashland Middle School,Oregon$700 for Rain Garden &Wetland Project••Century High School, Oregon$100 for Honors BiochemistryResearch Projects••Corvallis High School,Oregon$500 for Dixon CreekRestoration••Gordon Russell MiddleSchool, Oregon$500 for <strong>Water</strong> SlopeSlowdown••Kings Valley CharterSchool, Oregon$850 for Maxfield CreekRestoration••Mountain View HighSchool, Idaho$500 for Hyatt Lakes Reserve<strong>Water</strong> Quality MonitoringProject••South Eugene High School,Oregon$300 for Principles ofEnvironmental Science••South Kitsap High School,Washington$400 for Integrated ScienceProgram••Washington Middle School,Washington$100 for LOTT Field Trip34 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

From the OfficeBy Nan Cluss, <strong>PNCWA</strong> ManagerWEFTEC is the largest annual water qualityevent in the world. This year, there were18,000 attendees from more than 70 countries.I can’t always attend, but this year I onceagain had the opportunity to be inspired onso many levels by being a part of it.First was the Sunday <strong>PNCWA</strong> reception.What a great turnout! Our members certainlyNan Clusshave no problem keeping the conversationsflowing. Thanks to this year’s reception sponsors(APSCO, Brown and Caldwell, Beaver Equipment, GE, GobleSampson, HDR, Kennedy/Jenks, Pure Air Filtration and Wm. H.Reilly) for providing this great opportunity for interaction.“WATER’S WORTH IT”—the new public awareness campaignWEF is developing to spread the word about the value and importanceof water—was introduced on Monday. By using variouskeywords to define what the “it” means (e.g., My Effort, YourRespect, My Health, Our Future), the campaign will illustrate theconnection between water and our actions, attitudes and thethings we value most. Plans include a campaign website and a fullsuite of materials that will emphasize very basic ideas about howwater is inextricably tied to our quality of life. “WATER’S WORTH IT”will launch in March 2012 and WEF Member <strong>Association</strong>s, utilitiesand other interested parties will be encouraged to incorporate it asa part of their own tools to enhance public awareness.A hot topic of the MA Professional Staff Luncheon was thebook Race for Relevance. It challenges standard associationFROM THE OFFICEmanagement practices, and asks that we think about new and differentapproaches to managing our associations. It says, “Morethan ever, the way associations become more successful is to helptheir members do the same.” How to do that in today’s work environmentis the book’s focus, offering “radical” changes to someoutdated association practices. My copy just arrived and I’m lookingforward to what it has to offer.Tuesday’s Leadership Day had a focus on communications. JackDozier, Georgia AWP executive director, shared information onhow to respond when approached by the media. Jack explainedhow crafting the right message can help turn the moment intopublic education opportunities. Terry Cole, communications practicedirector at Jacobs Engineering Group, offered techniques forhoning messages and crafting a story that will stick with a publicmore focused on reality television than reality itself. She stressedthat if you’re developing messaging for the “general public” youneed to break that down into audience subsets and develop yourmessaging from there. Focus on the bottom line first; relate it to a person’sown experience; tie it to something concrete; then tell a story.I went to a session designed for elected officials on Wednesday.A combination of classroom instruction and exhibit floor exposureoffered policy makers (and budget decision makers) a betterunderstanding of wastewater fundamentals. A morning sessionentitled Decisions Facing Public Officials in the Next Five Yearswas also a part of a larger agenda to provide appropriate-levelinformation to elected officials who are an important part of thewastewater landscape.The nature of WEFTEC is that regardless of your position in theworld of water, there is vast opportunity for learning and interaction.With WEFTEC’s online planner tool, you can create a highlyspecialized agenda just for you. If you have never attended, I hopeyou will have the chance sometime. It’s inspiring.Upcomingfocus topic:2012 Q1 Threats to<strong>Water</strong> Quality—deadline February 15<strong>PNCWA</strong> Newsletter Submission GuidelinesThe <strong>PNCWA</strong> quarterly newsletter is built on articles contributed by <strong>PNCWA</strong> members. Each issue hasa focus topic selected by the <strong>PNCWA</strong> Board and refined by the Editorial Advisory Group to addresstechnical, community-based, case study and regulatory themes. If you have a story idea or an articleto submit, please use the following guidelines.••200 to 500 words (longerarticles may be accepted,space permitting)••No overt marketing, but it’sfine to talk about yourcompany’s achievements••High resolution color photosor graphics, if possible••Provide author email forreaders to contactPlease submit articles to Sheri Wantland at wantlands@cleanwaterservices.orgWINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 35

KEY VOLUNTEERS—CONTACTS<strong>PNCWA</strong> BOARD OF DIRECTORSPresident—Cyndy Bratz208.389.7700cbratz@brwncald.comPresident Elect—Mark Poling503.681.3600polingm@cleanwaterservices.orgVice President—Mike Ollivant253.863.5128mollivant@parametrix.comSecretary—Heather Stephens503.295.4911heatherstephens@kennedyjenks.comTreasurer—Shannon Ostendorff541.504.5072shannon.ostendorff@ci.redmond.or.usWEF Director—Max Hildebrand503.244.7005mhildebrand@brwncald.comWEF Director—Rick Shanley503.227.1885rshanley@carollo.comPast President—Andy O’Neill509.926.5762aoneill@rcac.orgOR Regional Director—Steve Miles541.679.5152steve.miles@winstoncity.orgW WA Regional Director—Gil Bridges425.355.6637gilb@mukilteowwd.orgE WA Regional Director—Tom Hastings509.674.4368tom.hastings@veoliawaterna.comID Regional Director—Ron Gearhart208.365.6059Rgearhart@qwestoffice.net<strong>PNCWA</strong> COMMITTEE CHAIRSAsset Management—Marc Yarlott425.355.6637gilb@mukilteowwd.orgAwards—Mike Ollivant253.863.5128mollivant@parametrix.comBiosolids—Brian Hemphill503.423.3700Brian.Hemphill@hdrinc.comCollection Systems—Bob Swarner206.684.2072bob.swarner@kingcounty.gov2012 Conference—Haley Falconer208.387.7022haley.falconer@hdrinc.com2012 Conference Program—Jeff Bandy208.327.2613jbandy@carollo.comEmerging Technology—Susanna Leung206.684.6532sleung@carollo.comConstitution and Bylaws—Ron Moeller360.748.8340ronmoeller@kennedyjenks.comFutures—Andy O’Neill509.926.5762aoneill@rcac.orgManufacturers and Reps—Joe Kernkamp425.822.3335jkernkamp@apsco-inc.comMember Services—Adam Zabinski646.416.2502adamzab@aol.comNewsletter—Sheri Wantland503.681.5111wantlands@cleanwaterservices.orgOdor & Air Quality—Mark Smith503.977.6673mmsmith@brwncald.comOperations Challenge—Preston Van Meter503.295.4911prestonvanmeter@kennedyjenks.comPlant Operations and Maintenance—Dick Finger253.631.3343dick.finger@att.netPublic Education—Karen DeBaker503.681.3643debakerk@cleanwaterservices.org5S—Thomas (Bud) Ruther509.527.4509thomas.ruther@ch2m.comSafety and Occupational Health—Mike Myers360.537.0060mikeandila.myers@comcast.netScholarship—Steve James208.762.8787sjames@jub.comSource Control—Celeste Schlegel503.681.5131schlegelc@cleanwaterservices.orgStudents & Young Professionals—Steven Drangsholt425.450.6378steven.drangsholt@hdrinc.comSustainability—Jennifer Belknap Williamson503.618.2250j.belknap.williamson@greshamoregon.gov<strong>Water</strong> for People—Irene Wall206.883.9438irene.wall@tetratech.com<strong>Water</strong> Reuse—Clint Dolsby208.898.5500cdolsby@meridiancity.orgIDAHO SECTION PRESIDENTSNorthern—Shirley Carter208.772.9505scarter@harsb.orgSoutheast—Jeremy Coles208.359.3035jeremyc@rexburg.orgSouthwest—Gilbert Flores208.455.3041gilbert.flores@veoliawaterna.comOREGON SECTION PRESIDENTS<strong>Water</strong> Quality Lab Analysts—Kristen Thomas503.823.9593kristen.thomas@portlandoregon.govLower Columbia—Joel Borchers503.547.8177borchersj@cleanwaterservices.orgSouth Central—Chris Miccolis541.504.5076Chris.Miccolis@ci.redmond.or.usEastern Oregon - Jeff Brown541.276.3078jeff.brown@ci.pendleton.or.usUmpqua Basin—Jim Baird541.672.1551jbaird@rusa-or.orgMaintenance—Kevin Bruton541.673.6570kevin.bruton@ch2m.comWest Central—Robert Jones503.879.3019robert.jones@spiritmtn.comSouthwest—Pat Kavan541.267.3966patrick.kavan@ch2m.comWESTERN WA SECTION PRESIDENTS<strong>Northwest</strong>—Gil Bridges425.355.6637gilb@mukilteowwd.orgOlympic Peninsula—Al Chrisman360.683.3883achrisman@ci.sequim.wa.usPuget Sound—Jim Pitts206.684.2477jim.pitts@kingcounty.govSouthwest—Dan Chitwood360.767.6458dchitwood@ci.chehalis.wa.usW WA <strong>Water</strong> Quality Lab Analysts—Jeff Young360.417.4841jyoung@cityofpa.usEASTERN WA SECTION PRESIDENTSColumbia Basin—Troy Zerb509.754.2992wrpwater@ephrata.orgInland Empire—Jeff Elkins509.625.4600jelkins@spokanecity.orgYakima Valley—Tom Helgeson509.967.7531tom.helgeson@ch2m.com<strong>PNCWA</strong> OFFICE<strong>Association</strong> Manager - Nan Cluss208.455.8381nancluss@pncwa.org36 <strong>PNCWA</strong> NEWSLETTER | WINTER 2011

Incentives availablefor water & wastewatersystem improvementsFinancial incentives may be available if your plans to upgrade your wateror wastewater system result in electrical energy efficiency improvements.The Energy Smart Industrial program offers incentives through your localpublic utility for projects that result in verifiable energy savings.Experienced wastewater specialists are available to help identify eligibleprojects, provide project support and answer any questions you may have.FOR MORE INFORMATION, PLEASE CONTACT:Layne McWilliams, PE, JD<strong>Water</strong> & Wastewater Sector Specialist971-244-8581Layne.McWilliams@EnergySmartIndustrial.comThe Energy Smart Industrial program is sponsored by your local public utility and the Bonneville Power Administration.ESI_HalfPG_Ad_0310.indd 12/8/11 6:05 AMWINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 37