Pacific Northwest Clean Water Association ... - PNCWA Home

Pacific Northwest Clean Water Association ... - PNCWA Home

Pacific Northwest Clean Water Association ... - PNCWA Home

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

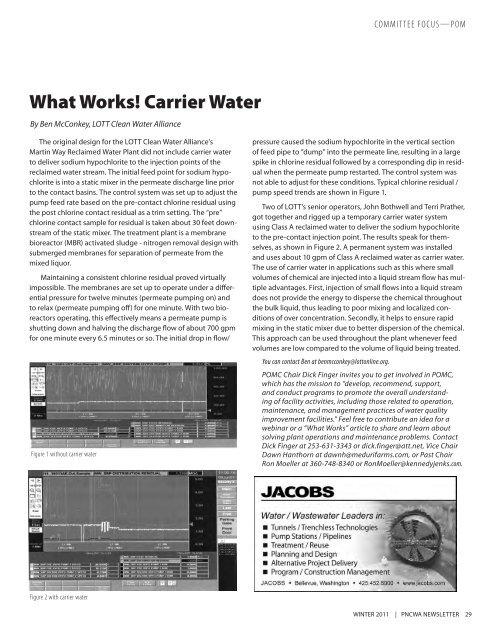

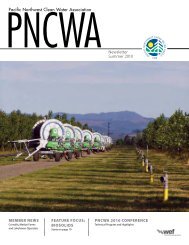

COMMITTEE FOCUS—POMWhat Works! Carrier <strong>Water</strong>By Ben McConkey, LOTT <strong>Clean</strong> <strong>Water</strong> AllianceThe original design for the LOTT <strong>Clean</strong> <strong>Water</strong> Alliance’sMartin Way Reclaimed <strong>Water</strong> Plant did not include carrier waterto deliver sodium hypochlorite to the injection points of thereclaimed water stream. The initial feed point for sodium hypochloriteis into a static mixer in the permeate discharge line priorto the contact basins. The control system was set up to adjust thepump feed rate based on the pre-contact chlorine residual usingthe post chlorine contact residual as a trim setting. The “pre”chlorine contact sample for residual is taken about 30 feet downstreamof the static mixer. The treatment plant is a membranebioreactor (MBR) activated sludge - nitrogen removal design withsubmerged membranes for separation of permeate from themixed liquor.Maintaining a consistent chlorine residual proved virtuallyimpossible. The membranes are set up to operate under a differentialpressure for twelve minutes (permeate pumping on) andto relax (permeate pumping off) for one minute. With two bioreactorsoperating, this effectively means a permeate pump isshutting down and halving the discharge flow of about 700 gpmfor one minute every 6.5 minutes or so. The initial drop in flow/Figure 1 without carrier waterpressure caused the sodium hypochlorite in the vertical sectionof feed pipe to “dump” into the permeate line, resulting in a largespike in chlorine residual followed by a corresponding dip in residualwhen the permeate pump restarted. The control system wasnot able to adjust for these conditions. Typical chlorine residual /pump speed trends are shown in Figure 1.Two of LOTT’s senior operators, John Bothwell and Terri Prather,got together and rigged up a temporary carrier water systemusing Class A reclaimed water to deliver the sodium hypochloriteto the pre-contact injection point. The results speak for themselves,as shown in Figure 2. A permanent system was installedand uses about 10 gpm of Class A reclaimed water as carrier water.The use of carrier water in applications such as this where smallvolumes of chemical are injected into a liquid stream flow has multipleadvantages. First, injection of small flows into a liquid streamdoes not provide the energy to disperse the chemical throughoutthe bulk liquid, thus leading to poor mixing and localized conditionsof over concentration. Secondly, it helps to ensure rapidmixing in the static mixer due to better dispersion of the chemical.This approach can be used throughout the plant whenever feedvolumes are low compared to the volume of liquid being treated.You can contact Ben at benmcconkey@lottonline.org.POMC Chair Dick Finger invites you to get involved in POMC,which has the mission to “develop, recommend, support,and conduct programs to promote the overall understandingof facility activities, including those related to operation,maintenance, and management practices of water qualityimprovement facilities.” Feel free to contribute an idea for awebinar or a “What Works” article to share and learn aboutsolving plant operations and maintenance problems. ContactDick Finger at 253-631-3343 or dick.finger@att.net, Vice ChairDawn Hanthorn at dawnh@medurifarms.com, or Past ChairRon Moeller at 360-748-8340 or RonMoeller@kennedyjenks.com.Figure 2 with carrier waterWINTER 2011 | <strong>PNCWA</strong> NEWSLETTER 29