ALUWAY nr 1 - Aluprof

ALUWAY nr 1 - Aluprof

ALUWAY nr 1 - Aluprof

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

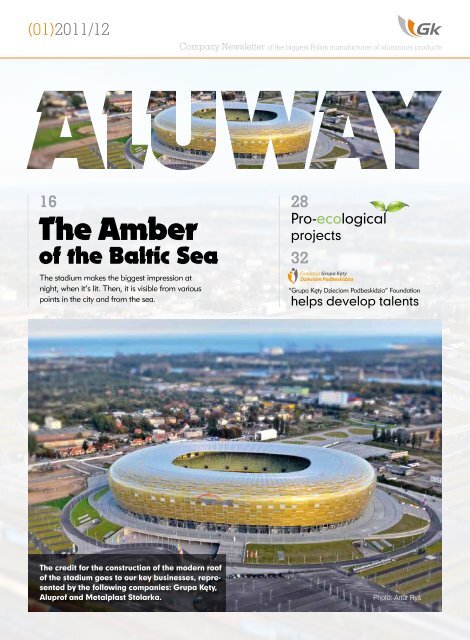

Photo: Mirosław KochZbigniew ParuchWatchfuleyeThe closer we get to EURO 2012, the more changeswe observe in the Polish landscape. Footballstadiums in Gdańsk, Warsaw, Wrocław and Poznańpopped up like mushrooms after the rain. Moderninfrastructure for the city residents, including parks,squares and car parks, followed.The cities are changing their architectural looks. Thenumber of new hotels, office buildings as well asroads and ring roads that one can drive fast to reachthe airports, now being extended and modernised,is increasing. More and more skyscrapers erectedin the centres of huge agglomerations break theheight records, e.g. Sky Tower in Wrocław (212 m)constructed by Metalplast Stolarka.The experts speak of a huge progress in Poland’sdevelopment. If so, all of us, employees of the CapitalGroup, participate in this economic growth. Perhaps,not everybody knows about it, but, as a Group, weplayed our part in the erection of many state-ofthe-artbuildings in Poland. The roof for PGE Arenain Gdańsk is the best example; however, <strong>Aluprof</strong>systems have been used to complete hundreds ofother prestigious buildings, including sports arenas,stadiums, school buildings or museums.And what’s more, we are active on Polish roads.Metalplast Stolarka produces accoustic screensand assembles them along through routes andmotorways. It is a new product group for thecompany with a substantial growth potential.We can also see changes on our own localbackyard. Recently, the Research and DevelopmentCentre and the press shop were visited by aninternational group of specialists from China,USA, Brazil, Australia and RSA, among others,who “dropped in” to Kęty while participating inthe scientific conference at the AGH University ofScience and Technology in Kraków. This visit is aneffect of Grupa Kęty going global.Oddly enough, this event coincided with the openingof the renovated marketplace in Kęty, and of thefirst section of the ring road for the town with a newroundabout near our office building.CONTENTS:Publisher: Grupa Kęty S.A.ul. Kościuszki 111, 32-650 Kęty, www.grupakety.comEdited by: Zbigniew Paruchzparuch@ grupakety.comGraphic design and execution by: PRIMEPHOTO s.c.EPSAn innovative technology forthe extrusion of AlMgSi alloys makesit possible to manufacture complexprofiles on an industrial scale 4Electricity from a gas engine 9ASSThe systems that change the architectureof Polish cities 10BSSAn attack on the green wall 12The Amber of the Baltic Sea 16The skyscraper is 212 metres highWorks at such a height is extremeengineering 20BASThe company from Złotów establishescloser cooperation with <strong>Aluprof</strong> 22TSSTrack Body brand made its debuteat the 3 rd fair of authorized car bodycompanies 26FPSPro-ecological projects from AlupolPackaging 28THE COMPANYThe Foundation helps developchildren’s talents 32Let’s run in the mountains 35People have very responsible jobsRelaxation is the key 36Photos by: fotowójcik (pp. 3, 4, 5, 6, 7, 8, 32-33)Mirosław Koch (pp. 20-21)Artur Ryś (pp. 18-19)Remigiusz Stasiak (p. 16)The archives of the Group and of subsidiariesAn international group of specialists visiting KętyInnovations attractInnovative projects completed in therecent years in Kęty attract engineers andspecialists in aluminium processing fromall over the world.In October 2011, we were visited byan international group of specialists (fromAustralia, Brazil, China, RSA, Thailand,USA, and more), who learned more aboutthe process of extruding aluminiumproducts in the Soft Alloys Plant on the16MN press. The guests also paid a visitto the Research and Development Centre.During the stay, the experts askedmany questions, including questionsabout the process of manufacturing billets,the performance of the presses, therange of the sale of products, etc. Theplant was visited as part of the scientificconference held by BELOS-PLP fromBielsko-Biała (it has been a part of PLPGroup, a global manufacturer and supplierof products, technologies and solutionsfor communications and energysystems, for a few years now), which hadplace at AGH University of Science andTechnology in Kraków on 17-21 October2011. Visits in selected plants in the regionwere a part of the conference.The bestfor shareholders and investorsThe annual report of Grupa Kęty has becomea publication which is more and more recognisedby the professionals from the capital market and stockexchange investors. In the 6 th editionof “The Best Annual Report 2010” competition,our report was awarded as many as three times:• a special award granted by the Individual Investors Association for thebest annual report in the opinion of individual investors;• honourable mention for being the most useful for shareholders andinvestors (it has been already the third award in this category in six editionsof this competition);• 3 rd place in the overall classification in the category of enterprises.The jury of “The Best Annual Report2010” justified their decision in the followingway: “A very good and transparentpresentation of results with a well thoughtoutgraphic form. An elegant and conciseanalysis of the market situation, the presentationof the development strategy by2015 and of the forecast for 2011, and theanalysis of the progress of the strategycompletion in the financial year. An indepthand clear information for shareholders,a good report on the implementationof the corporate governance.”The establishment of recognised standardsfor the preparation of annual reportsaccording to IFRS/IAS pursuant to goodpractices in this area, and hence the promotionof the companies which preparethe best annual consolidated reports fromthe point of view of their usefulness forshareholders and investors is the basicobjective of the contest. In this last category,the annual report of Grupa Kęty hasbeen u<strong>nr</strong>ivalled in the last few years. In sixeditions of the competition, our report wasawarded in 2006, 2009 and 2010.“You actually want to read the report.The texts are written in such a way so thatthe reader could understand them. It isvery important from the point of view of theusefulness of the report which is to helpinvestors and shareholders to understandthe specific nature of thecompany better and facilitatetheir decision-makingprocess. Moreover,one can see constantprogress, as the reportis better and better eachyear,” said KrzysztofGrabowski, the head ofthe team assessing thereports in terms of theirusefulness. Our reportwas evaluated equallyhigh by the Individual InvestorsAssociation.“The selection of theannual report of GrupaKęty S.A. as the mostuseful from the point ofview and according to theexpectations of individualinvestors, was unanimousthis year and raisedno doubts. It is obviousthat the company, whileworking on the report,was aware and wanted it to be read alsoby individual investors. In a word, if thecompanies at Warsaw Stock Exchangewere guided by the report treating it as amodel for their own publications, they wouldcertainly gain a wide group of readerswho are individual investors. The awardfrom our Association is linked to an additionalprize in the form of a full-page ad inAkcjonariusz quarterly worth 5,500 PLN tobe published in the next twelve months,”said Tomasz Bujak from the IndividualInvestors Association.Photo: fotowójcikThe following machines were of special interest to the expertsvisiting the Research and Development Centre: Zeiss 3Dcoordinate measuring machine; Zwick/Roell ZHU 250 top universalhardness tester; Struers Tegramin 30 grinding and polishingmachine; Olympus GX71 inverted reflected light microscope.3(01)2011/12

EPSExtruded Products SegmentProject data:Implementing InstitutionPolish Agency for Enterprise Development (PARP)The presentation of an innovativetechnology for the extrusionof AlMgSi alloys in Grupa KętyProject total valueProject eligible costsPress pressureEmploymentProduction profileProducts86.5 million PLN69 million 609 thousand PLN,including 50% from the grant35MN65 employeesprofiles for the building industrythe ability to manufacture profilesup to 15 metersIn the foreground,the so-calledset of matrixtools composedof bolsters(mountings)and inserts (thecentral row). Airquenching in thebackground.Production room and facilitiesadapted to the needsof disabled employeesGrupa Kęty, owing to the co-financing from the European Union from the ERDFunder the Operational Programme Innovative Economy 2007-2013, completedthe project “The implementation of an innovative technology for the extrusionof AlMgSi alloys in Grupa Kęty”. The project comprised the construction ofa production hall with the area of 9,000 m 2 and the assembly in it of severalmodern devices with technical solutions unique on a global scale. This innovativeline for the production of aluminium profiles will be able to manufacture complexprofiles on an industrial scale.4(01)2011/12EPSPhoto: fotowójcikEUROPEAN UNIONEUROPEAN REGIONALDEVELOPMENT FUNDPROJECTS CO-FINANCED BY THE EUROPEAN UNION FROM THE EUROPEAN REGIONAL DEVELOPMENT FUNDUNDER THE OPERATIONAL PROGRAMME INNOVATIVE ECONOMY 2007-2013The project with the total value of 86.5 million PLNwill result in an innovative production process for aluminiumprofiles in the Extruded Products Segment,and, in consequence, will enable Grupa Kęty tolaunch new products and increase the effectivenessof already existing manufacturing processes, ensuringfull compliance with the sustainable developmentobjectives. The length of extruded aluminiumprofiles (up to 15 metres) is one of the characteristicand distinctive features of the new press shop inKęty distinguishing it from existing competitive pressshops in Poland.5(01)2011/12EPS

An innovative technology for extruding profilesfrom aluminium alloys creates an opportunityfor the Extruded Products Segment to enternew outlet markets and meet the expectationsof the end customers, e.g. from the building orautomotive industries.The indirect association of the projectpresented today with another EUproject implemented by Grupa Kęty,namely the Research and DevelopmentCentre, which will be finally terminatedin 2011 as well, is worth highlighting.Linking the two projects will facilitatefor the company the transfer and applicationin the production process ofthe best solutions, not applied so far inthe industry, and will make it possible toincrease competitiveness through thesourcing and application of the latesttechnical knowledge.Production room heatingand ventillation– ensured with the use of modern ventillation controlrooms, fitted with rotating exchangers, owing to which onecan recover 70% of heat from outlet air.Aging furnacefrom a Dutch company Unifour ensures the uniformcrosswise flow of air. It is composed of two chamberswhich can work independently. Each chamberaccomodates 16 baskets with profiles up to 7.5 m or8 baskets with profiles up to 15 m. The feature of thefast cooling down of aged profiles with the concurrentrecovery of heat is an interesting option. When materialis aged in a given chamber, one may launch a cycle ofcooling down the material in the same chamber andheating the material using the recovered heat in thesecond chamber. During such a process, the materialto be used for aging is pre-heated, which results in thereduced amount of gas used to age it.The most important devicesused in the innovative technologyof the extrusion ofAlMgSialloysGas-fuelled billets heaterfrom a German company Extrutec fitted with the sawfor the hot cutting of billets with the option of heatingand cutting 9- and 10-inch billets. It has 6 heatingzones and, as a result, is able to heat and feed to thepress up to 4.5 tons of billets per hour. The heaterwas additionally equipped with an economizer, which iscapable of recovering over 400 GJ of heat from fumesannually. Depending on the needs, the recovered heatwill be used to support the heating of the productio<strong>nr</strong>oom or will be introduced to the company’s network ofhot process water.The press fed from the frontwith the pressure of 3,500 tons from an Italiancompany Presezzi, fitted with an innovative patentedCastool recipient which ensures the precise extrusionprocess at an optimum temperature. The press isequipped with five main pumps with a technologicallyadvanced hydraulic drive and with motors fitted with frequencyconverters. The profiles extruding press is alsofitted with a pro-ecological solution of a technologicallyadvanced oil filtration process, which makes it possibleto extend its life many times.Press coastingfrom an Italian company Turla fitted with the system ofintensive air cooling of extruded profiles. The lengthof the coasting is almost 60 metres. The coasting wasmade in the double length technology which reducesthe production waste to minimum. The coasting isequipped with two hot cutting saws, three pullers,a drawer the with the power of 90 tons, a finish cutsaw, a stacker and Pinze system, which is a uniquesolution on an international scale. The system, e.g.holds the profile during the cooling process with anadjusted strengh, which prevents the profiles twistingand eliminates the so called ‘banana’ effect, i.e.the bending of the profiles that cool down into anarch-like shape. Due to Pinze system, the presentedmachine is the only system of that type in Poland andDestackerssupport the packing process by eliminating the gruellingand strenuous work of taking out profiles frompacking baskets by people. They are used to handlethe packing of profiles up to 7.5 m at three stations andthe profiles up to 15 m or heavy profiles at one station.67Photo: fotowójcik(01)2011/12EPSEUROPEAN UNIONEUROPEAN REGIONALDEVELOPMENT FUNDPROJECTS CO-FINANCED BY THE EUROPEAN UNION FROM THE EUROPEAN REGIONAL DEVELOPMENT FUNDUNDER THE OPERATIONAL PROGRAMME INNOVATIVE ECONOMY 2007-2013(01)2011/12EPS

(From the left)Dariusz Mańko,President of theManagement Boardof Grupa Kęty S.A.,and Piotr Wysocki,Vice CEO of GrupaKęty S.A.The officialpresentationof the innovativeprofile extrusiontechnologyInnovativeIDEASElectricityfrom a gas engineEng. Krzysztof SiekierskiThe new press shop made hugePhoto: fotowójcikModern Kętyimpression upon the visitors. Theymentioned, first of all, the project sizeand the modernity and innovation ofmachines and devices. They alsoappreciated the fact of building theResearch and Development Centrewhich enables the Extruded ProductsSegment to implement innovativeproducts and cooperate with similarR&D centres as well as with scientificcentres. In the opinion of the visitors,all of this makes the companydevelop, allows it to make constantprogress, which is positive for the cooperationtoday and in the future.Innovative ideas and solutions area chance not only for new products,but also for substantial savings. Ourengineers from the Extruded ProductsSegment had an idea to additionallyproduce, while producingsteam to heat tanks in which profilesare anodized, ecological electricityand heat, e.g. to heat water.The engineers propose to replacethe existing gas furnace with a modernpower generating unit, whichwould comprise a gas engine anda power generator. The fumes fromthe engine would be directed to therecovery boiler that would producesteam, and the generator coupledwith the engine would generateelectricity that would flow to the corporate6KV switching station.Where are the potential benefits?First of all, in the generation of ecologicalelectricity from gas, which,due to the existing financial incentivesand preferences from the government,is purchased obligatorilyby energy distributors. Gaining anindependent, autonomic source ofenergy would also be a great advantageof the project. In the case ofa failure of the industrial power networks(the memorable breakdownin Szczecin in 2010 resulted in theparalysis of the city for a few days),an anodizing plant powered with agas engine would also be able toautonomously generate, apart fromthe steam for production processes,the power and production heat.“In the case of a similar failurein the vicinity, the anodizing plantwould operate as usual, being anindependent island. It would autonomouslyproduce heat and power,which would let us avoid manybreakdowns in such a case, e.g.the defrosting of the heat distributionnetwork or the damage to importantproduction devices,” saidEng. Krzysztof Siekierski. In hisopinion, the money from the sale ofthe electricity could be used for newGas combustion in a gas engine would makeit possible to produce, apart from the steam forproduction processes, additional electricity andproduction heat.projects which would increase theenergy efficiency in the whole plant.And, there is a lot of work to do inthis area, as the plant was built nearly60 years ago.“Similar solutions could be appliedin Alupol Packaging Kęty, wherepower could be generated usingthe fumes from the solvents fromprinters now after burnt in catalyticafterburners. The heat produced inthis process, apart from the heatcirculations, could be used successfullyto prepare the air directedlater to the room with printers. In thiscase, the project value would haveto increase a few times, but the benefitsfrom it would be substantial,”adds Siekierski.8(01)2011/12EPSThe main premises of Grupa Kętyhave had another ‘lifting’ and the surroundingsof the plant have changed beyondrecognition. This year, the buildinghas been completely renovated owingto which its façade and interiors have gaineda modern look. As we were told byMaria Znamirowska, an AdministrationSpecialist, 422 new windows, 151 façadeshutters and a few roller-blind systemshave been assembled in the building duringthe overhaul.The effects of the projects are visible inthe plant. New asphalt roads with comfortablecobbled hard shoulders leadfrom the main gate to the buildings ofthe new press shop and of the Researchand Development Centre. The lawns lookbetter and, generally, the green areasaround the production halls and alongroads have been taken care of. The wholeabove-mentioned infrastructure hasbeen created in relation to the projectsthat were half-financed from EU grants.Moreover, the surroundings of theplant have changed. At the end of October,the first section of the city ring roadwas opened, which was associatedwith the construction of a roundaboutnear our office building. “It called forthe changes in the organisation of thetraffic at our car parks and resulted intemporary problems when entering andleaving the plant. However, the newroundabout will surely make the trafficeasier in this place,” said ArkadiuszBalcarek, the Manager of the AdministrationDepartment.Photo: fotowójcikPhoto: ArchivesGas enginelocationAnodizingplantAccording to the reports of the Organisationfor Economic Co-operation andDevelopment (OECD), Japan is the numberone on the list of the countries classifiedfor the number of innovative patentedideas that are presented to the three mainpatent offices in the world (in the USA,in the European Union and in Japan). Inthis ranking, the top ten countries fromthe OECD list include as many as sevenEuropean countries, with Switzerland as theleader.9(01)2011/12EPS

To build the stadium roof with the area of 48,000 m 2 , we used600 tons of aluminium façade, ca. 18,000 shapes and thesame amount of PC plates in 6 shades of amber.Moreover, 3,000 m 2of façades wereassembled on thefacility.To transfer all the elementsfrom Goleszów to Gdańsk,we used 250 heavygoods vehicles.16(01)2011/12BSSThe Amberof the Baltic SeaThe stadium makes the biggest impression atnight, when is it lit. Then, it is visible from variouspoints in the city and from the sea.Photo: Remigiusz StasiakPGE Arena stadium in Gdańsk is widely recognised asone of the most beautiful facilities for Euro 2012 EuropeanFootball Championships. Unlike other stadiums with “defects”,the completion of the facility in Gdańsk, despite severaldays of delay, was uninterrupted. No serious accidentshad place at the site. In July, the stadium was granted theuse permit and already in August the residents of the Tri-cityand tourists had an opportunity to visit the fine-looking facilitywhose shape resembles alump of amber. It is worthremembering that it wasdesigned, creating an originalarchitectual concept, bya German company Rhode-Kellermann-Wawrowskyfrom Düsseldorf. ThisGrzegorz Dubickicompany also designed,It’s a really nice and modern facilitye.g. Veltins-Arena stadiumwith a very complex and, at thein Gelsenkirchen and AWDsametime, very modern steelArena in Hannover.structure, which shifts and blocks“It’s a really nice anditself autonomously. It’s a sort ofmodern facility with a verya masterpiece.complex and, at the sametime, very modern steelstructure, which shifts andblocks itself autonomously. It’s a sort of a masterpiece,” saidGrzegorz Dubicki, the Site Manager responsible for the assemblyof the roof from PC plates, a construction engineerwith 30 years of experience. Along with Paweł Pochopień,the Contract Manager representing Metalplast Stolarka, hespent almost a year at the construction site. In this period,they supervised the proper contract completion and all theworks related to the roof. They say that they spent a big part17of their lives at the site, but they are also happy with the resultsof their work. They both highlight that the completion ofthe roof is, first of all, a great success of our Capital Group– Grupa Kęty, which delivered to the site several thousand (01)2011/12aluminium shapes complex both in terms of their shape andresistence parameters.BSS

The works during the construction of the stadium.Grzegorz Dubicki in the foreground, and behind him(from the left): Mirosław Siuda and Paweł PochopieńPhoto: Paweł PochopieńGrzegorz DubickiThe stadium, despite the assembly of hugegirders over the house, seems to be light andwarm inside; the green grass, the ambercolouredroof and the olive shade of the seatscreate a colouristically friendly space in whichpeople feel great.Also, the Capital Group and thecompanies forming it, i.e. Grupa Kęty,<strong>Aluprof</strong> and Metalplast Stolarka, playeda crucial role in the constructionof this facility. They combined their effortsto put up the modern roof of thestadium. The general designer of thestadium thanked the contractor. ThePolish Football Association (PZPN)will probably propose the stadium asthe location for the Finals of the UEFAEuropa League.It is a success of <strong>Aluprof</strong>, which created and designed theindividual canopy system, and of Metalplast Stolarka, whichwas responsible for the prefabrication of the elements, theassembly and the whole complicated logistics process.The General Investor had a close eye on everything, andcontrolled, e.g. the press shops in Kęty that are involved inthe extrusion of profiles, and comissioned, to Gdańsk Universityof Technology and AGH University of Science andTechnology, the performance of resistence tests for shapes.“No other company in Poland would take up this task, asthey do not have such a completion, production and financialpotential,” said Grzegorz Dubicki from Metalplast Stolarka.The works on the stadium related to the completion ofthe roof with the area of 48,000 m 2 continued from October2010 till the end of April 2011. Everyday, over 80 fitters fromprivate companies cooperating permanently with MetalplastStolarka, assembled PC plates, working on scaffoldings atthe height of 40 metres.The majority of works were completed in winter, whentemperatures oftentimes dropped below minus 20°C. As thestadium is located ca. 2 km from the sea, the fitters sufferedfrom strong winds blowing from the bay, which hinderedworks at height. Sometimes, the scaffolding was pretty frozenand ice-covered, which resulted in interruptions, sometimeseven for a few days. Under the contract, we also employedmountain climbers and rescuers from the Mountain RescueService from Szczyrk, who spread security nets under movingscaffoldings at the height of 40 metres.In the case of such projects, Metalplast Stolarka cooperateswith experienced assembly teams. “They are true professionals,the best from the best. They are people who oftenworked at construction sites in Germany, Ireland and the UK.They know their profession, have a lot of experience, knowledgeand perfect expertise. The companies are very wellequipped with specialist equipment. As a result, the workswent really smoothly,” said Grzegorz Dubicki.Paweł PochopieńWe did not have any serious accident.We were truly lucky, but it is also about theprofessionalism of people and companies.In total, the fitting teams assembled ca. 600tons of an aluminium façade, 18,000 aluminiumshapes and PC plates as well as ca. 1.5 km ofcircumferential gutters and ca. 14 km of radialgutters through which water flows down fromthe roof surface to an underground tank, whereit is stored and used later for internal purposes.In addition, the assembly teams completed atthe stadium ca. 3,000 m 2 of façades in <strong>Aluprof</strong>systems, which were used in the constructionof shopping facilities, bars and restaurants, staffand office rooms and other small facilities. Theyinclude, e.g. a chapel, a court room and an interrogatio<strong>nr</strong>oom, small conference rooms, aninformation centre, etc.1819(01)2011/12(01)2011/12BSSPhoto: Artur RyśBSS

Photo: Mirosław KochThe works on the façade of Sky Tower skyscraper in Wrocław arecoming to an end. All employees are really satisified that, in oneyear, they built a 212-metre building from reinforced concrete,glass and aluminium.The design of the skyscraper has been a break-through development projectfrom the start, both for Wrocław and for the whole Poland. The buildingdesigned by Studio Architektoniczne Fold S.c. from Wrocław is composedof two high-rise buildings, including the dominant 212-metre tower attachedto the lower building which terraces down from 92 to 54 metres. Bothfacilities are located on the so-called “platform”, which comprises a hugeshopping and service centre. The Polish skyscraper with the façade area ofca. 34,000 m 2 is to be oneof the highest facilities inEurope.Winning the contract byGrupa Kęty for the completionof the façade was arather big surprise, and, atthe same time, a challengefor the Capital Group. Theengineers from <strong>Aluprof</strong> hadto develop customized solutionsfor the project. In theend, they applied MB-SE85 SG semi-structural element-based façade. Also,our press shops in Kęty and Tychy and the contractor, i.e. Metalplast Stolarka,had to face great challenges.“Developing the system of anchoring the curtain wall to the buildingwas the greatest building challenge. With the assumed wind operation of4,500Pa, for this purpose, we used, for the first time in <strong>Aluprof</strong> systems, aspecial aluminium alloy with higher resistence properties.“It’s a unique construction and aunique facility. We are tired, but alsovery satisified. We count down daysuntil the termination of the works,”said employees.20(01)2011/12BSSSKY TOWERWe lived through everythinghere: the assembly of thefaçade elements above theclouds and in the fog, stormsand strong winds, su<strong>nr</strong>ises andsunsets, dangerous operationsand everyday chores.Assembly above the cloudsThe degree of the complexity of thesystem of the curtain wall is best visiblein the fact that, for this one façade,we launched almost 100 elementswhich form the curtain wall system,including aluminium profiles, thermalseparators, EPDM gaskets and otheraccessories,” said Dariusz Ruśniok,the Chief Constructor of <strong>Aluprof</strong>façades sections.Of course, the completion of theSky Tower project called for hugecommitment and flexibility of thewhole supervising team from MetalplastStolarka and the Planning Departmentfrom the plant in Goleszów.“We appointed special quality teams.The aluminium elements transportedto the site in Wrocław werechecked in detail and marked. Thisway, we avoided errors and mistakes,”said Piotr Jakubiec from theManagement Board of MetalplastStolarka.Every day at the site, although seeminglysimilar to one another, wasnonetheless unique just like the facilityitself. It usually started early in themorning when the city was still asleep.Then, two HGVs filled to the brimwith façade elements from Goleszówarrived at the site. All of them describedand controlled in detail. Then, theelements were transported with specialwinches to subsequent storeysof the skyscraper, where they weretaken over by assembly teams whichappeared on the façade of the buil-The completion of the SkyTower project called for hugecommitment and flexibility ofthe whole supervising teamfrom Metalplast Stolarka andthe Planning Department fromthe plant in Goleszów. ŁukaszCzaja was the contractor’s sitemanager, with Eng. WiesławPytyś and Eng. Sławomir Gielnikas his deputies responsible forthe works supervision and safety.ding between 4:00 and 5:00 am.If the weather was good andthe wind was not very strong,they began the assembly ofaluminium segments. One teamwas able to assemble 24-28 elementsa day.“They are exceptional people,exquisite professionals.They move along the edges andwalls of the skyscraper almostlike spidermen. In 11 months,they placed ca. 5,300 aluminiumelements,” said Mirosław Stankowiak,the director supervisingthe contract on behalf of MetalplastStolarka.He remembers that strongwinds which prevented works atheight were the biggest obstacleand hindrance. At the heightabove 100 metres, there weretemporary air drafts which puta stop to safe assembly. As theemployees remember, the fogwas also annoying; first, it spreadaround the tower and later it went down. Then, you had a feeling that peopleworked above the clouds.The longest break in the assembly of the elements lasted 1.5 weeks. In thisperiod, they failed to assemble even one element. Then, the fitters were givenother jobs, e.g. securing tasks.“When they went to the façade again, they assembled as many as 58 segmentsin one day, twice as much than on average,” said Stankowiak.The glass and aluminium segments were manufactured in the plant in Goleszów.Over 100 employees were engaged in the process. “It was a true challengeto us. We appointed special quality teams. The elements were checked usingall methods so as to avoid errors. We were successful and we are happy aboutit,” said Piotr Jakubiec from the Management Board of Metalplast Stolarka.Dropping a scredriver or a screwfrom the top of the skyscraper couldcause a tragedy down there.Luckily, there were no accidents.21(01)2011/12BSS

BASBuilding Accessories SegmentThe company has been operating for over 35 years now, and the manufacture of modernROMB envelope fittings for PVC, wood and aluminium joinery is the core business of the company.For some time now, the company has been developing the production of door locks certified tobe admitted to trade on the EU and Eastern European markets. Apart from proprietary products, thecompany also offers many other solutions applied in the production of windows and doors.Metalplast Karo Złotówexpands the cooperation with the companies from the GorupNew fittingsThe company, by expanding the cooperationwith the partners from the Group, isbuilding its strong position on the market ofAn interviewwith DariuszFilipowiczThe company from Złotów is expanding its cooperation with <strong>Aluprof</strong> and manufacturesmore and more accessories for this biggest Polish distributor of architectural aluminiumsystems. The cooperation between the Development, Logistics and Sales Departmensof both companies improved the dynamics of the process of implementing new systemsrequired to complete such projects as Sky Tower skyscraper or PGE Arena stadium.ROMB envelope fittings for PVC, wood andaluminium joinery. Some time ago, it tookserious measures to develop a new fitting,the production of which will involve a smallernumber of elements and make it possible toassembled it faster, which, as a result, willincrease the competitiveness and efficiencyof the product. “The new fitting passed thePresident of the ManagementBoard of MetalplastKaro Złotów<strong>ALUWAY</strong>: This was the final year of the four-year social packagefor the crew. This fact, naturally, became a source offirst tests in the laboratory, which confirmeduncertainty and of questions from the employees about theirThe figures for the last three years arethe best indicators of the close cooperationbetween the companies. The sales of theaccessories, including aluminium devicesand casts to <strong>Aluprof</strong>, increased from 2.1 to6.7 million PLN. The biggest growth (overMetalplast Karo Złotówis the biggest Polishmanufacturer of buildinghardware and systemaccessories.its high parameters. I am certain that soonwe will offer customers a new type of a fittingwith high quality parameters. Furthermore, itwill be a starting point for the development ofthe subsequent new solutions,” said DariuszFilipowicz, the President of the company.future in the plant. Could you comment on that?Dariusz Filipowicz: We have been preparing for this momentin stages. Already in 2010, we held committee-basedmeetings with the representatives of the workers, which servedthe purpose of working out new payroll rules related tothe appraisal of the competences, work and qualifications of100%) was recorded for accessories, fol-He perceives the innovative nature ofemployees. This way, we created a detailed job evaluationlowed by devices (an increase by ca. 80%)The company completes asthe door and window joinery market as anmodel.The capital expenditure of over 13and aluminium casts (an increase by ca.much as 30% of its sales onopportunity for the company’s further de-I think that, when we launched the works, we all were cer-million PLN in the last four years let60%). This high growth rate is, to a largeforeign markets. It exports buil-velopment. “Having the Measurement andtain about the need to introduce changes and undertake re-the company greatly expand theextent, a result of taking over the produc-ding accessories mainly to theResearch Laboratory with an accreditationstructuring measures. This year, as a result of such measures,cooperation with the companies fromtion, but also of new implementations usingcountries of Eastern Europe andcertificate awarded by the Polish Centre forwe made 45 employees redundant, launched the programmethe Group, at the same time building athe technologies applied in Złotów. The in-South-Eastern Europe.Accreditation in Warsaw, is a great asset. Inof earlier retirement and of shifts between positions. For thestronger and stronger position on thevestment in the plastic injection technologythe area of research, we cooperate with thepurpose of comparison, I will highlight that, in the same year,home market.launched for the needs of the company andBuilding Research Institute (ITB) in Warsawwe hired 117 new employees. We also signed agreementsof other companies of the Group was also“The company continues the develop-as well as the leading German institute IFTwith the Electro-Mechanical Schools Complex in Złotów, as aimportant for this growth. More and morement directions launched in 2010 and writtedRosenheim, improving our competences,”result of which, in the future, we want to acquire employeesoften, the company designs and supplements the assortment to meet thedown in the strategy for 2010-2015. Focusingadds Filipowicz.well-prepared to work with state-of-the-art machines. I alsoneeds of new systems in <strong>Aluprof</strong>. In 2010, the company launched 91 newon the fulfillment of the needs of the partnersTo follow the trends in the building indu-count on greater activity on the part of the local government22items, and as many as 67 in 8 months of 2011, i.e. the total of 158 new items.In the same period, the company also definitely expanded the cooperationwith the plant of <strong>Aluprof</strong> in Opole that manufactures roller-blind systems. Thein the Capital Group is the main direction ofthe company’s development,” said DariuszFilipowicz, President of the Managementstry, the company has expanded its offerby adding fittings with higher load-bearingcapacity of 130 kg. The application of suchin this area and the understanding of the benefits for the localcommunity resulting from such a type of initiatives.23jointly agreed mix of the casts of roller-blind covers made it possible to achieveBoard of Metalplast Karo Złotów.hinges in passive and anti-burglary windows<strong>ALUWAY</strong>: The company was privatized four years ago, but,greater production capabilities and now Metalplast Karo Złotów has a certainIn his opinion, the company, with its po-will allow the company to supplement the of-in this period, the sales still remain at the level of ca. 40 mil-(01)2011/12surplus of production capacity over the needs of the plant in Opole. Measureswere taken to expand the use of production capabilities of the aluminiumtential, is a natural base for the Group, mainlythe companies creating and distributingfer, which will increase its competitivenessand ensure its further stable position onlion PLN annually and the profits do not meet the investors’expectations. In your opinion, has the company managed to(01)2011/12BASpressure foundry. Under a joint project, the companies made a casting mouldfor BSO-165 cover.system-based solutions.the market of fittings for window joinery.make a significant breakthrough?BAS

Dariusz FilipowiczI will invest in people who are determinedto work and learn on a continuous basis.I know that I have many talentedemployees. It is my task to provide themwith proper working conditions and showthem the opportunities to develop their24(01)2011/12An interview with Dariusz FilipowiczPresident of the Management Board of Metalplast Karo Złotówcareers.trated on such tasks and we wasteour energy, completely pointlessly,on solving disputes.For this reason, as soon as possible,the company should terminatethe implementation of operating andmanagement standards existing inother companies of the Capital Group.When looking at the developmentand accomplishments of thesecompanies, one can see that themodels worked out and tested bythe Group really bring about results.The companies are leaders in theirindustries and, due to the unleashingIn my opinion, the company has toprove that the investment of the CapitalGroup made sense and will startbringing about the assumed effects.To make it happen, we have to focuson the implementation of new innovativeproducts, improve the effectivenessand source new customers.At present, we are not fully concenofemployees’ ambitions and creativity,they increase sales and generatehigher profits. And, this is the bestway for employees to participate inprofits.<strong>ALUWAY</strong>: Were the negotiationswith trade unions as sucessfulas expected?The important fact was that, at thebeginning, we agreed that we havea common objective, which complieswith the mission of the CapitalGroup that we joined. This missioninvolves meeting the aspirationsof employees through inspiring,ambitious and well-rewarded jobs.Unfortunately, we faced some disagreementsrelated to the principlesand the path leading to the goal,having regard for the situation of thecompany in the rapidly changingmarket environment.Payroll demands from the unionsovershadowed the goal and intentions.As a result, I decided to terminatethe outdated Corporate CollectiveLabour Agreement (CCLA),at the same time presenting a draftof the new CCLA in the version closeto the one functioning in the remainingcompanies of the CapitalGroup. I assumed that it would beeasier to build a compromise fromscratch, applying tested and approvedmodels.Unfortunately, the draft was acceptedby only one trade union,which made me introduce newpayroll regulations based on the jobvaluation process. I did it, as I didnot want to foil a few months of workin this area, which ended in the developmentof a sound model. Thismodel, when put together with theincentive fund, would serve as thetrigger of the employees’ creativity,hence, making it possible for themto participate in profits.<strong>ALUWAY</strong>: What’s next?We have to create the value ofthis company based on the mottothat united we stand, divided wefall, and develop competitiveness.If we create a good team, we can,with the help and commitment ofthe Capital Group, follow the pathof the development of other companies,for example, the one takenby Metalplast Stolarka, whose salessix years ago were not much higherthan our sales, and today it is a definiteleader on the market of the manufactureof aluminium joinery andthe assembly of façades, with thesales at 130 million PLN, hiring over300 people and with the portfoliofull of orders.Dariusz FilipowiczIf we create a good team,we can, with the helpand commitment of theCapital Group, follow thepath of the developmentof other companies, forexample, the one takenby Metalplast Stolarka,whose sales six years agowere not much higher thanour sales, and today it isa definite leader on themarket of the manufactureof aluminium joinery andthe assembly of façades.RECYCLINGWe collect used baterriesCan one little battery from your watch cause the contamination of 50,000litres of water (two tanks) or can a small AA battery permanently pollute onecubic metre of soil? Sure, they can. Therefore, one should not throw away usedbatteries to a dustbin.Each year, the European marketis flooded with billions of varioustypes of batteries. They are virtuallyeverywhere, in household appliances,watches, computers, remotecontrols, cameras, etc. Poland,which uses 290 million batteriesannually, has almost cought up withthe countries of Western Europe.In Poland, the average comsumptionindex for such types of energysources is ca. 8 batteries per oneperson, as compared to 11 in Europeancountries.In line with the corporate social responsibilitystrategy of Grupa Kęty,the companies of the Capital Groupimplemented the system of collectingwaste in the form of used batteriesand rechargeable batteries. Tothis end, special marked containersOne ton of used batteries contains:270.0 kg manganese dioxide210.0 kg iron160.0 kg zinc60.0 kg graphite35.0 kg ammonium chloride20.0 kg copper10.0 kg potassium hydroxide3.0 kg mercury (mercury oxide)0.5 kg cadmium0.3 kg silver (silver oxide)And also a few kilograms of nickel andlithium, slight amounts of cobalt as well astar, glass, silica, paper and film, and evenhydrogen.were placed in the public places in administrative and office buildings, whereemployees can throw away their used batteries. “To get the employeesinto the habit of showing environmentally friendly behaviour is not easy. Wealways find some excuses, e.g. that we do not have time, that the containeris too far away from us, etc. Now, at least, the employees of Grupa Kętyshould not give such a justification.We placed additional containers forused batteries at the readers of RCP(working time registration) cards, i.e.in the places where each employeestops at least twice a day. It allowsfor the convenient use of the system,also for production workers,” saidMaciej BudzińskiMaciej Budziński, Chief Quality andThe possibility of recovering many valuableEnvirnmental Protection Specialist.components from this product and the potentialGrupa Kęty cooperates with a professionalrecycling company whichharazd to the environment already made thesubject-matter of the collection of used batteriescollects used batteries. Only in Kętybecome the focus of legal regulations in theitself, over 60 kg of waste were disposedof from the launch of thecountries of the European Community. This trendwill probably be developed in the future.system.The system of collecting batteries andrechargeable batteries fromthe employees of Kęty Capital Group.The collection system is an element of the socialresponsibility strategy implemented by Grupa Kęty.Please join the programme.By collecting batteries, you protectthe environment!25(01)2011/12BAS

TSSFrom among many pluses of TruckBody products, the dealers pointedto the following aspects as theirThe fact of being a part of Grupa Kęty,a leading manufacturer of aluminium,was not without significance.greatest assets:26(01)2011/12Transport Systems SegmentTruck BODY brandmade its debute at the 3 rd fairof authorized car body companiesFiat Professional 2011At the fair, Alu Trans System presented an innovativeMax Trans dropside body with the canvas coverfor 10 Euro-palletes, with a light aluminiumsliding roof and curtains on both sides.The roof of the vehicle is independent of its sides andis supported by aluminium CS poles reinforced and adjustedto the assembled frame of the canvas cover andthe aluminium rail guiding the carriages of the roof. Thissystem allows for the loading of goods virtually from allsides; from the sides of the car, from its back and fromthe top (e.g. using an overhead crane). The exhibitedbody was appreciated by dealers as an aesthetic productwith outstanding parameters.Although Alu Trans System established earlier contactswith the dealers from Fiat Professional, many of them heardabout Truck Body brand only at the fair. Substantial interestwas a result of the fact that the company’s offer exceedsthe standard pattern of the behaviour of Polish car bodycompanies, as it makes it possible for dealers to assembleTruck Body bodies by themselves on their own vehicles.The company’s idea is to manufacture bodies againstuncompromised standards. First, the products are assembledfrom the profiles made from top-quality aluminiumalloys originating from the press shops in Kęty andTychy. In addition, all fittings and accessories are basedon the products recognised as the best in their catego-ries. Owing to the stable cooperation with their vendors,we were able to negotiate better prices. As a result of theefforts, we have a top-quality body at an affordable price ascompared to the competitive offers with similar standards.• the low weight of dropsidebodies;• aesthetics;• the possibility of adapting thechassis by themselves, owing towhich dealers can reduce costsand operate autonomously fromcar body companies.The idea of promotinga new Polish brand TruckMarcin RyszkaBody is well received by entrepreneurs.The branding“Our proprietary structure of Truck BODYpolicy of the company consistentlypromotes the pro-dropside bodies was designed in such away so that the sets delivered to dealersducts under its brand, whichare easy to assemble on the chassisfunction with clearly understandablenames: Mini Transwith the use of basic tools. The offerof top-quality products on the market(a dropside body), Max Transand striving to achieve the leading(a dropside body with a canvascover), City Trans (a boxposition among the manufacturers ofready-made bodies up to 3.5 GVW is thevan) and Max Kip (a dumpcompany’s priority,” said Marcin Ryszka,body).President of the Management Board“Our proprietary structureof Alu Trans System since the end ofof Truck BODY dropside bodieswas designed in such aSeptember 2011.way so that the sets deliveredto dealers are easy to assembleon the chassis with theuse of basic tools. The offer of top-quality products on themarket and striving to achieve the leading position amongthe manufacturers of ready-made bodies up to 3.5 GVW isthe company’s priority,” said Marcin Ryszka.The offer and the atmosphere at the fair booth was anothersuccess of the company, which resulted in the honourablemention in the form of the 3 rd place in the competitionfor the booth that was the best during direct meetings withdealers from the whole Poland.The exhibited body was well-received by dealers as anaesthetic product with outstanding parameters.27(01)2011/12TSSTSS

The implementation of OrangeBook is a goodtime to review the existing system documentation,its rationalisation and simplification. We wantto make sure that, in all areas, we deal with adocumented management system and not a systemof documents.30(01)2011/12THE COMPANYOrganizacja(Organisation)– building professionalstructures based on defined rulesReguły (Rules)– a transparent and easilyavailable set of expectationsfor each managerAdaptowalność(Adaptability) – the systemdoes not define detailed instructions,but only the key elements, whichmakes it easy to adapt it to a givenorganisationNadzór (Supervision)– an efficient verification of the existingsystem and of the changes made in itGwarancja (Guarantee)– a uniform policy in the key areasguarantees the operational riskreductionEfektywność(Effectiveness) – greatereffectiveness of management dueto the the more systematic andsimplified system of establishinginternal rules and proceduresMaciej BudzińskiEffective management of the corporationis essential especially in theera of growing global competition.OrangeBook intergrated managementsystem, among other things, isto be the response to the contemporarychallenges.OrangeBook is an ambitious projectof establishing the system of the managementof the most crucial processesin the company with the applicationof ca. 100 procedures. In the future,OrangeBook is to be an exceptionallyimportant platform combining theelements of strategic and operationalmanagement and, at the same time,Qualitymanagementin OrangeBookThe implementation of OrangeBookin such a big organisation as KętyCapital Group, with its disperesedstructure, is a very difficult processwhich calls for the will to introducechanges and significant effortsfrom employees, especially anintellectual effort as well as thecooperation and good organisation.Adam Pielaperform the function of a coherent andefficient control and supervision systemfor the whole organisation. Mostemployees of the Capital Group hada practical chance to learn more aboutthe system, which reflects the vision ofthe Management Board as regards themanagement of the Capital Group andcontains guidelines for the implementationat the level of the Group. Today,the companies, in consultation withthe chief specialists, issue their ownprocedures in an electronic form onpreprepared one-page forms in Excel.The special application used to manageprocedures and audit the systemmakes it possible to obtain fast access to the systematizedset of documents.“The most difficult and also the most important stage ofthe project has begun,” said Adam Piela, CFO and a Memberof the Management Board. “It involves the adaptation,establishment and integration of operational standards inthe companies. This way, new procedures are created,which, on the one hand, are to facilitate the functioning andmanagement of the organisation and, on the other hand,help it grow fast and optimize the operating costs.”The management system operating in the companieswhich meets the requirements of the international ISO 9001standard, i.e. quality, environmental and work safety management,is one of many areas of the companies’ operationssubject to OrangeBook procedures. First of all, thesystem is to meet the customers’ needs, ensure a product“There will be only two types of enterprisesin the future – the ones that introduced totalquality and those which left the business. Youdo not have to do it; survival is not mandatory.”E. Deming- the author of the system-based quality managementconforming to quality standards and observe legal requirements.So far, under the system, we have developed dozensof procedures and instructions, which describe the operationsand introduce the division of competences and responsibilities ofpeople and departments. Due to them, the employees know whatthey are responsible for and whom they should contact in the case ofany difficulties. Under the system, we have implemented a number of continuousimprovement tools and methods, which allow for an active, effective andfast identification and solving of problems. We also ensured that the processesmonitoring mechanisms grant access to the information required to take fast andaccurate decisions.“Incorporating ISO into the key processes management system in the Group basedon OrangeBook is an opportunity for a further increase in the effectiveness andthe reduction of costs as well as for working out uniform standards related to quality,environment and work safety in all subsidairies. The production processes andcustomer service must be better adapted to the strategy through the introductionof innovations in key operations which have the biggest added value. Developinguniform processes metrics and the systematic control of their accomplishment isalso crucial,” said Maciej Budziński, Chief Quality and Environmental ProtectionSpecialist. IT tools facilitating the selection and the use of information will be ofassistance in this process.In the area of ISO, we created 28 procedures at the level of the Capital Groupwhich cover the guidelines to be implemented in the companies. That is not a lotas compared to the existing and valid procedures, but better and more effectiveContinuous improvement is the essence of the quality systemsbased on ISO 9001(also known as Plan-Do-Check-Act (PDCA)).1. PLAN – Plan a better way of doing things, a bettermethod.2. DO – Implement the plan as a trial.3. CHECK – Check whether, in reality, the new method ofdoing things brings about better results.4. ACT – If the new method brings about better results,regard it as a standard (a valid procedure), standardizeit and monitor its application.CHECKACTPDCADOsolutions which allow for faster accomplishmentof the set goals seem to bemore important than the number.“In reality, the integration of the ISOsystem under OrangeBook means itsdevelopment based on a coherent andmore effective management system atthe level of the Capital Group. Finally, italso means the reduction of the operationalrisk resulting from the establishmentof the quality, environmental andH&S standards in the companies, andof the controls of their observance,”said Budziński.PLAN31(01)2011/12THE COMPANY

“Grupa Kęty Dzieciom Podbeskidzia” Foundation“Academy of Entrepreneurship and Success” AssociationCelebrities: Natasha PavluchenkoThey help developtalentsFortune really smiled on the young people from the special educational establishmentat Lompy street in Bielsko-Biała. The yound people were given a unique opportunityto develop their own passions, interests and talents. All of this owing to the joint ideaof “Grupa Kęty Dzieciom Podbeskidzia” (“Grupa Kęty to the Children of PodbeskidzieRegion”) Foundation and the “Academy of Entrepreneurship and Success” Associationas well as celebrities, e.g. Natasha Pavluchenko, Kazimierz Czapla and Adam Małysz.The designer, while preparing for the meeting with the youth, proposeda contest for the dress of one’s dreams. Young people were givenone week to get the designs ready and were promised great rewards.A ticket to the Fashion Week international fair in Łódź on 30 October2011 was the main prize. The winner accompanied by a guardian couldspend the whole day there watching fashion shows, including thecollection prepared by Natasha. An invitation for one day to the artist’sstudio and u<strong>nr</strong>aveling the secrets of the process of designing clothes,furniture and things, was the prize for the runner-up.The Foundation in the cooperation with the Association plans to inviteother great personalities, including Krzysztof Czapla, a celebratedactor from Bielsko-Biała, and Adam Małysz, a ski jumping champion.In the future, we also intend to invite Rev. Piotr Sadkiewicz from Leśna,Tomasz Adamek, a boxer, and famous singers Golec brothers.Natasha PavluchenkoYou may be short of money, live in a tinyflat, but if you feel strength and passionin you, they will guide you to your goal.The idea involves organising meetingsof the youth from the specialeducational establishment with wellknownpeople, who, thanks to theirhard work, determination and passion,Dariusz Mańkowere successful in life, but also gainedthe respect of their own communities.Each pupil who wants to develop theirSuch people can be role models forinterests and talents can expect theyoung people, and life and careerhelp from the Foundation. It’s not trueachievements of celebrities can inspirethe students of the establishment tothat only some people have talents.Everyone has a talent for something;face difficult challenges. “Grupa Kętybigger or smaller, but it’s there. You onlyDzieciom Podbeskidzia” Foundationhave to discover it in yourself and this iswill support and help them accomplishtheir goals and have a better startthe goal of the meetings to be held withthe celebrities from Podbeskidzie Region.in adult life.Natasha Pavluchenko, 35,a well-known fashion designer, who32(01)2011/12THE COMPANYhas lived and worked in Bielsko-Białafor a few years now, was the guest ofthe first meeting. She has won an Oscar in the fashion world for her collections,but also respect and recognition. Before the meeting with Natasha, young peoplewatched a short film about the designer, in which Natasha talked abouther Polish roots (her mother was Polish), her stay in Poland, the establishmentof her own company and about her problems and obstacles. All the time, shetried to infect young people with optimism. She encouraged them to search forpassion, joy and determination to create things in themselves.Photo: fotowójcik“Grupa Kęty DzieciomPodbeskidzia” Foundationestablished in June 2011 helpsstudents of special educationalestablishments by helping themin education and facilitatingtheir difficult start in adult life.The Foundation supports theeducational programme for thepupils of the establishments.In return for their commitment,efforts and better grades, 22pupils went on a two-day trip toBukowina Tatrzańska in the TatraMountains. The organisation ofweekly workshops was anotherinteresting initiative. At suchworkshops, young people learnthow to cook, paint or prepareikebana or a macramé.33(01)2011/12THE COMPANY

Let’s run in the mountainsSebastian Duda, Alupol Packaging Kęty34(01)2011/12THE COMPANYJacek CholewaLogistics Director, <strong>Aluprof</strong>He graduated from the Organisationand Management Faculty at theSilesian University of Technologyin the Department of ProductionOrganisation, with Production ProcessesLogistics as his major. Then,he launched postgraduate studieson the early warning systems inlogistics processes. In the years2000-2003, he was the Logistics Directorin Farmacol S.A. Group, andin 2003-2006, he was the Presidentof the Management Board of ProconSp. z o.o., a logistics operator onthe retail pharmaceutical market.From 2006 to 2007, he was thePresident of the Management Boardof Cerkolor Sp. z o.o., a manufacturerof ceramics (Opoczno), andfrom 2007 to 2011, he was the VicePresident of the Management Boardof Murapol S.A.He is married and has two daughtersand one son. He spends hisfree time actively with his family,travelling.The ranking oflarge companiesRzeczpospolita daily announced its list of 2,000biggest Polish companies in 2010, where, asusual, sales revenue was the main criterion.In this annual ranking, Grupa Kęty was ranked232 nd and was up by 20 places as comparedto 2009. The place in the third hundred wasassured with the revenue of 1.2 billion PLN. Netprofit was not taken into consideration in thisranking, but, in our opinion, it should be noted– 89.7 million PLN. And, in the ranking compiledby Polityka weekly called “The List of 500Biggest Polish Companies”, Grupa Kęty wasranked 190 th , down by 6 places as comparedto 2009.Wiesław RzepińskiIT ManagerHe graduated from the IT andEconometrics Faculty at the CracowUniversity of Economics and MBAstudies for IT staff in the KozminskiUniversity in Warsaw. In the years2004-2011, he worked with StenaRecycling, the Polish headquartersof a Swedish capital group,where he was responsible for all IToperations in Poland and managedprojects which covered all thecountries in the group. Before that,in the years 2000-2004, he worked inthe automotive industry for a Frenchconcern Valeo, in the IT Departmentof the plant manufacturing windscreenwipers systems in Skawina. He ismarried, has a 5-year old son, Eryk.In his free time, he plays squash,travels, also, for the last ten years,on a motorcycle on long and shortdistances.Mariusz MiniorInternal Sales Directorfor Building Systems, <strong>Aluprof</strong>He graduated with an M.A. degreefrom the Faculty of Social Sciences atthe John Paul II Catholic University inLublin. From the beginning of his career,he was associated with the buildingindustry. He started his career inGARBALINSKI POLSKA in Poznań. Inthe years 2002-2007, he worked as asales representative. Since 2007, hehas worked with ALUPROF S.A., first,as a sales representative and later asthe Regional Director. And, since April2011, he has been the Internal SalesDirector.He has two daughters and is anactive sportsman. Aviation andacquarium keeping are his hobbies.He spends his free time with hisfamily, also trying to reconcile it withhis interests.In English from 2015The implemented development strategy for 2010-2015 assumesthe generation in 2015 by Kęty Capital Group of almost 1.9 billionPLN of sales revenue and 325 million PLN of EBITDA. The terminationof the strategy coincides in time with the plans to introduceEnglish as the corporate language in the Capital Group. In practice,it would mean that the communication between Polish and foreigncompanies would take place mostly in English.Today, the eight foreign companies hire over 150 employees; partof them speak Polish and of course their native language. Thereare exceptions, as e.g. in Romania, where the employees of <strong>Aluprof</strong>System Romania do not speak Polish, but they speak English.Then, both the spoken and written communication is only in English.“We do not have any problems with it. Our employees fromsales departments know English well and they are able to understandeverything. Communicating in English is slowly becoming astandard. Improving one’s language skills is the most important issue,”said Tomasz Rada, responsible for foreign companies in <strong>Aluprof</strong>.Many subsidiaries organised English, German and Russianlanguage courses. They are run by Polish and foreign teachers,including former managers and employees of large coporationsfrom the UK or the USA.So as to be in shape as a cyclist, I started running in winter. First, a fewkilometres a day and later more and more. Running became my hobby veryquickly, and, in the end, it turned into my passion.Sebastian Duda works with AlupolPackaging Kęty. He checks the qualityof printouts every day. As most ofus, he does not have too much freetime to follow his passions. He has afamily, a child, his home to run andmany other important things to handle.The running adventure appearedunexpectedly. In high school, togetherwith friends, they rode bikes. Together,they covered long distances,doing 4,000-6,000 kilometres annually.“We travelled around the whole Poland,and later Slovakia and Austria.Bikes were not only our passion, butalso a way to get to know the world,beautiful nature and people,” remembersSebastian.Cycling trips required great shapefrom young people. During the year,high school pupils did not have a lotof problems with that, but winter meantsnow-covered roads and lack ofexercise. “So as not to lose shape, Idecided to run. First, it was a few kilometresa day, in snow and sometimesin the rain. However, running soonabsorbed me and later it became mysecond passion,” said Sebastian.Four years ago, he took part in thefirst half-marathon with the 21-km routearound Lake Żywieckie. A weeklater, he was running in the marathonin Dębno. “I tested myself before, running43 km in the vicinity. I rememberthat the sun was scorching then anda few hundred metres before the end,I had huge cramp in my leg. I thought I wouldn’t make it, but I did,” remembersSebastian. His time for the 42-km marathon was 3 hours and 29 minutes. Twoweeks later, he appeared at the start of the marathon in Kraków. In the rain,his time was 9 minutes better than before. As it soon turned out it was Sebastian’slast marathon, who, from thatmoment, decided to run in the mountainsand climb peaks in the Beskids.He started in “Złota 50-tka” (“Golden50”) competition, very popularamong amateurs and professionalrunners, which comprises four mountai<strong>nr</strong>outes and one half-marathon. InSebastian Dudathe most recent edition of the competition,Sebastian was 11 th among 94 Running is relaxing.competitors. To be classified at such When I run, I can find release for my energya high place, he had to run to RysiankaPilska peak and Żar mountains as the feeling, when I get back home exhaustedmore easily and get rid of bad energy. I likewell as run in the half-marathon. “I like and tired after a run, and inside I feel ansuch competition, because the participationin the competition itself is notunbelieveable will to live.enough for me; the time and positionare also important. Next marathon? If I have real chances to improve my record,I will start,” said Sebastian.35(01)2011/12THE COMPANY

Metalplast Stolarka, although a young company, isCarpspreferred womendeveloping very fast. It already employs as manyas over 300 employees and completes façades ofvery prestigious facilities, such as SKY Tower, footballstadiums, the Museum of the History of Polish Jews,as well as acoustic tunnels over through routes andacoustic screens along motorways. The companyhas been trying to win new contracts all the time andsources profitable projects, e.g. for the façade of thebuilding of the National Forum of Music in Wrocław orAngling contestof the European Solidarity Centre in Gdańsk. In bothcases, the façades will incorporate <strong>Aluprof</strong> systems.for the Cup of the President of Metalplast StolarkaGrażyna Raszka and Renata Krupnik won thefirst anging contest for the Cup of the President ofMetalplast Stolarka. They caught the biggest carpand the most fish. After the contest, they said: “If wehad won with other women, we would have gottenonly satisfaction, but since we won with men, our36(01)2011/12satisfaction is double.”In the summer angling contest held near thepicturesque fish pond near Cieszyn, therewere 13 three-man teams representing variousdepartments of Metalplast Stolarka. There wasonly one female team among the competitors,but, which surprised all organisers and otheranglers, it was the ladies who caught thebiggest carp and the most fish, winning withmany experienced anglers. The ladies, Grażynaand Renata, caught four carps and one cruciancarp with the total weight of 5.25 kg.“We were lucky, as the fish bit on our fishing ground. We caught afew beautiful carps in a short period of time. Our male colleagues werea bit envious, because their corks floated,” said Grażyna. She admitsthat she cuaght the angling bug from her husband whom she often accompaniedin his fishing trips. One day, she decided to try herself and…bingo. She caught her first carp and she came to like angling. A similarthing happened to Renata, who was a passive participant of anglingadventures; she was sitting on her folding stool, reading newspapers.And her husband was angling. “I was not convinced for a long time, butfinally I cast the fishing rod. The cork went to the middle of the pond, andmen around me could not believe that I had cast it so far and in sucha professional way,” admitted Renata, who, since that time, i.e. 5 yearsago, has usually been angling with her husband.The contest took place in beautiful and warm weather. However, it was notgood for the anglers. “The rapid change in the weather is not good for fish.Yesterday, it was raining and the water was dark, and today it is sunny andthe water became more transparent. Fish do not like it and that’s why they are“confused” and won’t bite,” explained Jan Troszok, an angler from Cieszynand an employee of the Element-based Façades Department. His words wereconfirmed on the same day by other anglers, who left the pond empty-handed.They replied: “Sometimes, you catch something, and sometimes you don’t. Themore important thing is that we spent some time outdoors.”Ca. 50 people participated in the contest and the meeting. All of them hadgreat fun. Józef Szczotka, 62, was the oldest contestant, and Janusz Jakubiec,10, was the youngest. “I like watching the water, when the cork floats and suddenlyit goes underwater. I am not bored, unlike my brother, who is not ableto sit in one place for a long time,”admitted Janusz.“We will hold more such events. Moreover,when people know each otherbetter, they cooperate better, which isvery important to us,” said ZbigniewBorowiec, the originator, organiserand manager of the Steel MachiningDepartment in Metalplast Stolarka. Heis an avid angler himself, and, togetherwith his friends, he organises trips toremote places and catches cods, halibutsand lings in Norwegian fjords.Zbigniew JakubiecPeople haveresponsible jobsrelated to thecompletion ofthe elements offaçades, whichare assembled onfacilities. Relievingstress is the key.37(01)2011/12THE COMPANYTHE COMPANYPhoto: Zbigniew Jakubiec

ALUPROF’s art contestWho needs our help the most96 contestants participated in this year’s,already sixth, edition of the art contest held by<strong>Aluprof</strong> for the employees’ children.<strong>Aluprof</strong> – TF Budapest<strong>Aluprof</strong> S.A. expanded its sports sponsoring activities and, in September 2011, decidedto sign a contract with a Hungarian team from the Women’s Volleyball League,<strong>Aluprof</strong> – TF Budapest. The name of the team, i.e. <strong>Aluprof</strong> – TF Budapest, refers to thename of the main sponsor and to the Hungarian Physical Education Academy, whosetraditions go back to 1925. In the first phase of the games, which will end on 5 February2012, <strong>Aluprof</strong> – TF Budapest will play 22 matches with 11 teams.The sponsoring for <strong>Aluprof</strong> – TF Budapest team is a step forward on the road tobuilding <strong>Aluprof</strong> brand in Hungary, where women’s volleyball is one of the most popularsports. It is also to help establish business relations with other renowned sports sponsorsin Hungary, e.g. Suzuki, Decathlon and Legea brands.SKY TOWERThis year, all children with parents were invited to Cinema City inGemini Park shopping mall in Bielsko-Biała, where they were given prizes,e.g. Lego games, GuessWho? games or Falling Monkeygames. Especially for theyoungest children, we were theBożena Ryszkafirst to screen Winnie the Poohfable. Older children couldwatch the second part of a popularfilm about the adventuresWe are happy with the growing interest in thecontest and hope to double the number next of a daring little car, Lightningyear, especially that each time the participants McQueen, titled Cars 2.can get very beautiful and valuable gifts. The subject-matter of thecontest was related to the Foundationfounded by GrupaKęty, whose core objective is toprovide care and assistance to children from children’s homes. By establishingthe Foundation, the company wishes to draw the attention ofthe community, its employees and other companies in the region to theneed to help the young people who are disadvantaged and, at the startof their adult lives, can rely only on themselves.In their pictures, children indicated that, in their opinion, assistance isneeded for the diseased and the disabled, children in children’s homes,homeless animals, children in Africa, the elderly and parents.The jury did not select the winners, claiming that all pictures were beautiful.However, the Jury paid special attention to the designs of logosby Tomasz Surowiec, Klaudia Drzewiecka and Dagmara Wydra, as wellas the works by Borys Ratuszny and Natasza Durajczyk.38(01)2011/12THE COMPANY

Innovations develop........................................................................................................................................................................................................................................................................................................................................................................................EUROPEAN UNIONEUROPEAN REGIONALDEVELOPMENT FUNDPROJECTS CO-FINANCED BY THE EUROPEAN UNION FROM THE EUROPEAN REGIONAL DEVELOPMENT FUNDUNDER THE OPERATIONAL PROGRAMME INNOVATIVE ECONOMY 2007-2013