www.mtt-group.com

www.mtt-group.com

www.mtt-group.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

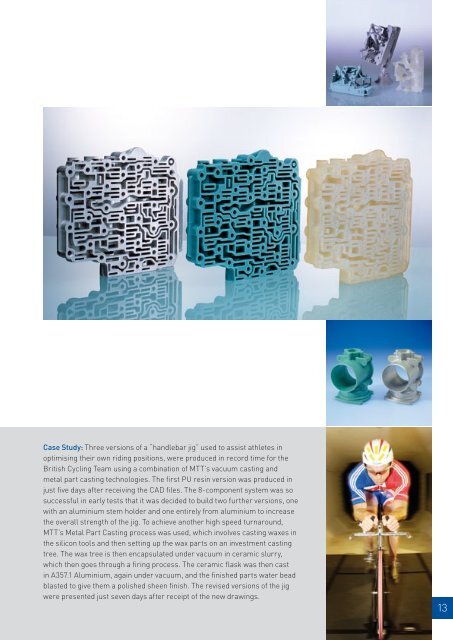

Case Study: Three versions of a “handlebar jig” used to assist athletes inoptimising their own riding positions, were produced in record time for theBritish Cycling Team using a <strong>com</strong>bination of MTT’s vacuum casting andmetal part casting technologies. The first PU resin version was produced injust five days after receiving the CAD files. The 8-<strong>com</strong>ponent system was sosuccessful in early tests that it was decided to build two further versions, onewith an aluminium stem holder and one entirely from aluminium to increasethe overall strength of the jig. To achieve another high speed turnaround,MTT’s Metal Part Casting process was used, which involves casting waxes inthe silicon tools and then setting up the wax parts on an investment castingtree. The wax tree is then encapsulated under vacuum in ceramic slurry,which then goes through a firing process. The ceramic flask was then castin A357.1 Aluminium, again under vacuum, and the finished parts water beadblasted to give them a polished sheen finish. The revised versions of the jigwere presented just seven days after receipt of the new drawings.13