適用上限温度を拡大した液体材料気化器 - 日立金属

適用上限温度を拡大した液体材料気化器 - 日立金属

適用上限温度を拡大した液体材料気化器 - 日立金属

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

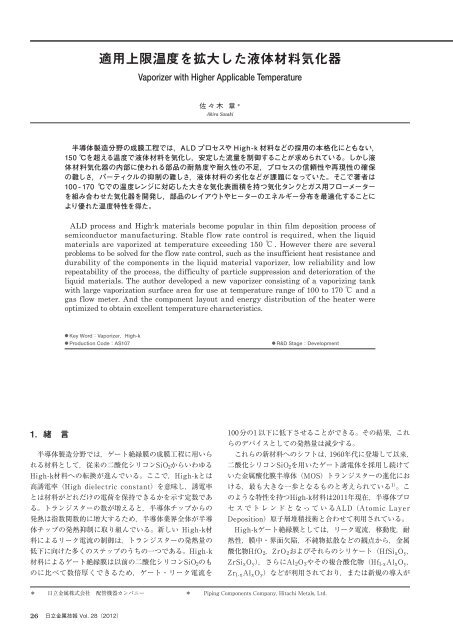

Vaporizer with Higher Applicable Temperature Akira Sasaki ALD process and High-k materials become popular in thin film deposition process ofsemiconductor manufacturing. Stable flow rate control is required, when the liquidmaterials are vaporized at temperature exceeding 150 . However there are severalproblems to be solved for the flow rate control, such as the insufficient heat resistance anddurability of the components in the liquid material vaporizer, low reliability and lowrepeatability of the process, the difficulty of particle suppression and deterioration of theliquid materials. The author developed a new vaporizer consisting of a vaporizing tankwith large vaporization surface area for use at temperature range of 100 to 170 and agas flow meter. And the component layout and energy distribution of the heater wereoptimized to obtain excellent temperature characteristics. Key WordVaporizerHigh-k Production CodeAS107 R&D StageDevelopment 26

Fig. 1 Vapor pressure of TDEAH, TEMAH Fig. 2 Gas flow diagram of the vaporizer modelAS107 Fig. 3 Construction of the flow sensor 27

Fig. 4 Digital mass flow meter for high temperature modelFMT16xxFM series Fig. 5 External view of the vaporizer modelAS10728

Fig. 6 Temperature range at each set point from AV3 to MFM Akira Sasaki 29