TOPTIG - Vítejte > Air Liquide Welding Czech

TOPTIG - Vítejte > Air Liquide Welding Czech

TOPTIG - Vítejte > Air Liquide Welding Czech

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6<br />

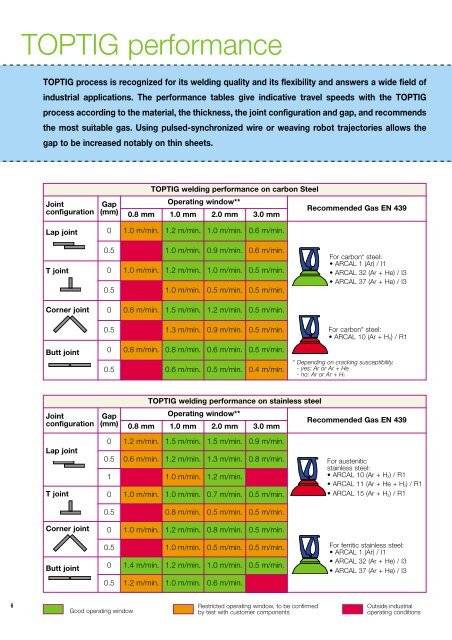

<strong>TOPTIG</strong> performance<br />

<strong>TOPTIG</strong> process is recognized for its welding quality and its flexibility and answers a wide field of<br />

industrial applications. The performance tables give indicative travel speeds with the <strong>TOPTIG</strong><br />

process according to the material, the thickness, the joint configuration and gap, and recommends<br />

the most suitable gas. Using pulsed-synchronized wire or weaving robot trajectories allows the<br />

gap to be increased notably on thin sheets.<br />

Joint<br />

configuration Gap<br />

(mm)<br />

<strong>TOPTIG</strong> welding performance on carbon Steel<br />

Operating window**<br />

0.8 mm 1.0 mm 2.0 mm 3.0 mm<br />

Lap joint 0 1.0 m/min. 1.2 m/min. 1.0 m/min. 0.6 m/min.<br />

0.5 1.0 m/min. 0.9 m/min. 0.6 m/min.<br />

T joint 0 1.0 m/min. 1.2 m/min. 1.0 m/min. 0.5 m/min.<br />

0.5 1.0 m/min. 0.5 m/min. 0.5 m/min.<br />

Corner joint 0 0.8 m/min. 1.5 m/min. 1.2 m/min. 0.5 m/min.<br />

0.5 1.3 m/min. 0.9 m/min. 0.5 m/min.<br />

Butt joint 0 0.8 m/min. 0.8 m/min. 0.6 m/min. 0.5 m/min.<br />

Joint<br />

configuration Gap<br />

(mm)<br />

Lap joint<br />

0.5 0.6 m/min. 0.5 m/min. 0.4 m/min.<br />

<strong>TOPTIG</strong> welding performance on stainless steel<br />

Operating window**<br />

0.8 mm 1.0 mm 2.0 mm 3.0 mm<br />

0 1.2 m/min. 1.5 m/min. 1.5 m/min. 0.9 m/min.<br />

0.5 0.6 m/min. 1.2 m/min. 1.3 m/min. 0.8 m/min.<br />

1 1.0 m/min. 1.2 m/min.<br />

T joint 0 1.0 m/min. 1.0 m/min. 0.7 m/min. 0.5 m/min.<br />

0.5 0.8 m/min. 0.5 m/min. 0.5 m/min.<br />

Corner joint 0 1.0 m/min. 1.2 m/min. 0.8 m/min. 0.5 m/min.<br />

Butt joint<br />

Good operating window<br />

0.5 1.0 m/min. 0.5 m/min. 0.5 m/min.<br />

0 1.4 m/min. 1.2 m/min. 1.0 m/min. 0.5 m/min.<br />

0.5 1.2 m/min. 1.0 m/min. 0.6 m/min.<br />

Restricted operating window, to be confirmed<br />

by test with customer components<br />

Recommended Gas EN 439<br />

For carbon* steel:<br />

• ARCAL 1 (Ar) / I1<br />

• ARCAL 32 (Ar + He) / I3<br />

• ARCAL 37 (Ar + He) / I3<br />

For carbon* steel:<br />

• ARCAL 10 (Ar + H2) / R1<br />

* Depending on cracking susceptibility.<br />

- yes: Ar or Ar + He<br />

- no: Ar or Ar + H2<br />

Recommended Gas EN 439<br />

For austenitic<br />

stainless steel:<br />

• ARCAL 10 (Ar + H2) / R1<br />

• ARCAL 11 (Ar + He + H2) / R1<br />

• ARCAL 15 (Ar + H2) / R1<br />

For ferritic stainless steel:<br />

• ARCAL 1 (Ar) / I1<br />

• ARCAL 32 (Ar + He) / I3<br />

• ARCAL 37 (Ar + He) / I3<br />

Outside industrial<br />

operating conditions