Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

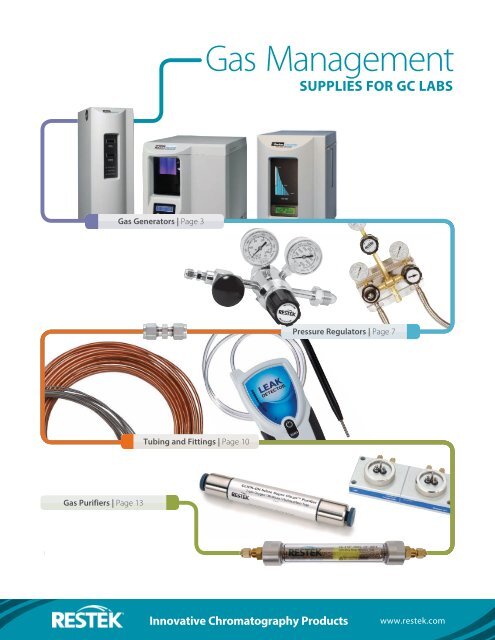

<strong>Gas</strong> <strong>Management</strong>SUPPLIES FOR GC LABS<strong>Gas</strong> Generators | Page 3Pressure Regulators | Page 7Tubing and Fittings | Page 10<strong>Gas</strong> Purifiers | Page 13Innovative Chromatography Productswww.restek.com 1

<strong>Gas</strong> <strong>Management</strong> for Your LabA clean gas stream is critical to the quality ofyour GC analysis and the reliability of youranalytical results. Carrier gas must contain lessthan 1 ppm of oxygen, water vapor, and othertrace contaminants for stable baselines on alldetectors and to prevent column degradation,shortened column lifetime, and increasedstationary phase bleed. Clean fuel gases andmakeup gases are also essential for stable detectorbaselines. Your gas management system mustdeliver a high-purity gas stream from your sourceto your instrumentation without introducingcontaminants. Restek offers the products youneed to assure a clean, leak-free gas managementsystem. If you need assistance in configuring yoursystem, contact your Restek representative todiscuss your application requirements.Questions to consider when building yourgas management system:1. What gases do you require and at what purity?2. What flow rates and/or pressures are required?3. Are you using gas generators or high-pressure cylinders?4. What type of tubing and fittings are needed to buildyour system?5. What type of gas purifiers should you install in your system?Once the components needed for your system are established, youwill need to determine the most appropriate way to configure your gasmanagement system. Figures 1 and 2 are typical configurations: Figure 1illustrates a system that uses gas generators and Figure 2 shows a systemconfigured for use with high-pressure cylinders.Figure 1: <strong>Gas</strong> management system configuration using gas generators.Zero Air GeneratorAirCompressorInlineRegulatorInlineRegulatorsShut-OffValveShut-OffValveIndicatingMoistureTrapShut-OffValveFIDShut-OffValveIndicatingMoisture TrapHydrocarbonTrapNitrogen GeneratorHydrogenGeneratorHigh PurityHydrogen GeneratorShut-OffValveIndicating Oxygen TrapFlashArrestorIndicating Moisture TrapShut-OffValveFigure 2: <strong>Gas</strong>management systemconfiguration usinggas cylinders.Air CylinderDual-StageRegulatorsShut-OffValveShut-OffValveFIDNitrogen CylinderFlashArrestorHydrogen CylinderDual-StageRegulatorsShut-OffValveShut-OffValveCarrier <strong>Gas</strong> CylinderIndicating Moisture TrapHydrocarbonTrapIndicating Oxygen Trap2 www.restek.com

<strong>Gas</strong> Generators | Product ListingHYDROGEN GAS GENERATORSSafer alternative tohigh-pressure gas cylinders!• Dimensions: 17.12" x 13.46" x 17.95"• 59 lb. dry weightParker Balston® PEM Hydrogen Generators• Proton Exchange Membrane (PEM) cell eliminates the need for liquidelectrolytes.• Reliably generate 99.9995% pure hydrogen—for better chromatography.• Eliminates high-pressure cylinders—greater convenience and improvedlab safety.• Compact unit, requiring only one square foot of bench space.• Quick and easy to service and maintain; unique display lighting changescolor for easy status checks and water level indication.• Comes with a set of universal power adapters for U.S., European, andAsian plug types.• Automatic safety feature shuts the generator down if a hydrogen leak isdetected.SpecificationsPurity:Delivery Pressure:Outlet Port:99.9995% pure hydrogen5-100 psig ± .05 psig(69-689 kPa ± 7kPa)1/8" compressionElectrical Requirements:Physical Dimensions:Shipping Weight:100-230 VAC/50-60 Hz17.12"h x 13.46"w x 17.95"d(43.48 x 34.19 x 45.6 cm)59 lbs. (27 kg) dryDescription Model # Capacity qty. cat.#Hydrogen Generator H2PEM-100 100 cc/min. ea. 23065Hydrogen Generator H2PEM-165 165 cc/min. ea. 23066Hydrogen Generator H2PEM-260 260 cc/min. ea. 23067Hydrogen Generator H2PEM-510 510 cc/min. ea. 23068Parker Balston® H2PEMPD Hydrogen Generators• Proton Exchange Membrane (PEM) cell eliminates the need for liquidelectrolytes.• Maintenance-free palladium purifier removes oxygen to

ZERO AIR GAS GENERATORSParker Balston® Zero Air Generators• Turn in-house compressed air into ultra-pure air (

<strong>Gas</strong> Cylinder AccessoriesWhen using high-pressuregas cylinders there are anumber of accessories thatshould be used in order tosafely handle and installcylinders in your gasmanagement system.Handling <strong>Gas</strong> CylindersWhen using high-pressure gas cylinders there are a number of accessoriesthat should be used in order to safely handle and install cylinders in yourgas management system. Dropped gas cylinders are very dangerous and canbecome flying projectiles if the cylinder valve is damaged. A cylinder holderwill safely secure your cylinder to a wall in your lab, preventing it fromaccidentally toppling over and discharging its contents.Manifolds and Switchover SystemsHigh-purity automatic switchover systems provide a continuous supply ofhigh-purity gas to your gas management system. Continuous gas supplyis achieved by setting the two regulators at slightly different pressures anddischarging one side of the system at a time. This allows for the replacementof a depleted gas cylinder without interrupting the gas supply.Description qty. cat.#WALL MOUNTED CYLINDER HOLDERSCylinder Holder, Wall Mounted, Single ea. 21333Cylinder Holder, Wall Mounted, Double ea. 2340021333Cylinder Holder, Wall Mounted, Triple ea. 23401Cylinder Holder, Wall Mounted, Quadruple ea. 23402TOOLS21321Cylinder Valve Wrench ea. 21321Universal Cylinder Wrench ea. 21322Flexible Stainless Steel Hose, 1 /4" Female NPT, 36" ea. 21339Flexible Stainless Steel Hose, 1 /4" Female NPT, 18" ea. 21340FLASH ARRESTORS21334Flammable <strong>Gas</strong> Flash Arrestor, Brass Body, 1 /4" NPTF ea. 21334PROTOCOL STATIONS*Chrome-Plated Brass, CGA 580 (N2, He, Ar) ea. 21347Chrome-Plated Brass, CGA 350 (H2, P5) ea. 21348Chrome-Plated Brass, CGA 590 (Air) ea. 2134921347Stainless Steel, CGA 580 (N2, He, Ar) ea. 21327*Pressure regulator not included. Order separately.6 www.restek.com

Pressure RegulatorsThe job of a pressure regulator is simple: it reduces the pressure of a gas source to a safe working pressure. However, there aremany variables that need to be considered when choosing a pressure regulator. Does your application require a stainless steelor brass regulator? Do you need a single or dual stage regulator? What type of gas are you regulating and what is the desireddelivery pressure? Your choice in a pressure regulator will depend on your application and where it is placed in your gasmanagement system.Ultra-High Purity RegulatorsRestek offers ultra-high purity (UHP) pressure regulatorsin brass and stainless steel bodies. The UHP brass pressureregulators are the best choice for gases with a purity of99.995% or greater, such as those used in carrier and fuelgas supplies. These pressure regulators feature a reducedinternal dead-volume relative to stainless steel bodies. TheUHP stainless steel pressure regulators are the standard forultra-high-purity and corrosion-resistant pressure regulation.Dual-Stage Pressure RegulatorsA dual-stage pressure regulator provides more precisepressure control by reducing the gas source pressure to thedesired delivery pressure in two steps. They are recommendedfor supplying gas where constant delivery pressureis critical, especially if your gas source is a high-pressurecylinder. As the cylinder gas is used, the inlet pressure tothe regulator from the cylinder decreases. A dual-stageregulator compensates for the decrease and maintains aconstant delivery pressure; whereas, a single-stage regulatordoes not.Single-Stage Pressure RegulatorsA single-stage pressure regulator reduces the pressure ofthe gas source to the desired delivery pressure in one step.It does not provide the precise control of delivery pressurethat can be achieved with a dual-stage pressure regulator.Single-stage pressure regulators should be used for applicationswhere you can monitor and regulate the pressuredownstream.In-Line RegulatorsLine regulators are single-stage pressure regulators that are usedto provide point-of-use pressure monitoring and control. Thesepressure regulators are installed directly into gas lines, immediatelybefore your instrumentation, to ensure the appropriategas pressure is being delivered to your instrument. A dual-stageor single-stage pressure regulator should always be installedupstream of the in-line regulator to ensure adequate pressurecontrol.Pressure Regulator ConnectionsRestek ultra-high purity pressure regulators come with a varietyof different connection fittings for attachment to different highpressuregas cylinders. In the United States, Compressed <strong>Gas</strong>Association (CGA) fittings are used and designed for differentgas service. In the European Union, German Institute forStandardization (DIN) fittings are used to make these connectionsand British Standard (BS) fittings are used in the UnitedKingdom. Table I indicates the appropriate fitting for each typeof gas typically used in setting up your gas management system.Table I: Choose fittings for your pressure regulatorbased on gas type.CGA DIN 477 BS341Helium 580 #6 #3Hydrogen 350 #1 #4Nitrogen 580 #10 #3Air 590 #9 #3Argon 580 #6 #3P5 (Argon:Methane) 350 #1 #4Need help selecting apressure regulator?Contact Ben MacLeod at <strong>LECO</strong> <strong>Australia</strong> on+61 2 9849 5900, mobile 0488 021 143 orvia email ben_macleod@leco.comor 1-814-353-1300, ext. 4.www.restek.com 7

Pressure Regulators | Product ListingULTRA-HIGH PURITY (UHP) BRASS BODY GAS REGULATORSDual-Stage Ultra-High PurityChrome-Plated Brass <strong>Gas</strong> Regulators with CGA Fittings• Oxidation-resistant, chrome-plated.• Most stable outlet pressure control.• Secondary pressure regulation not needed.• Most widely used regulator.• Less internal volume than stainless steel gas regulators.Fitting Outlet Pressure Outlet Gauge qty. cat.#CGA 580 (N2, He, Ar) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 21667CGA 350 (H2, P5) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 21668CGA 590 (Air) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 21669DIN 477 #1 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22369DIN 477 #6 (He, Ar) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22368DIN 477 #9 (Air) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22370DIN 477 #10 (N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22371BS 341 #3 (He, Ar, Air, N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22136BS 341 #4 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22137Note: CGA fittings are for U.S. use; DIN fittings are for European use; BS fittings are for use in the UK.All regulators are rated to 3,000 psig(20,684 kPa) maximum inlet pressure.Inlet gauge: 0 to 4,000 psig (0–27,579 kPa)Outlet assembly: diaphragm valve, 1/4" tube fittingSingle-Stage Ultra-High PurityChrome-Plated Brass <strong>Gas</strong> Regulators with CGA Fittings• Oxidation-resistant, chrome-plated.• Use when there is secondary pressure regulation downstream.• Identical gas purity protection as with dual-stage gas regulators.Fitting Outlet Pressure Outlet Gauge qty. cat.#CGA 580 (N2, He, Ar) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20646CGA 350 (H2, P5) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20647CGA 590 (Air) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20648DIN 477 #1 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22373DIN 477 #6 (He, Ar) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22372DIN 477 #9 (Air) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22374DIN 477 #10 (N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22375BS 341 #3 (He, Ar, Air, N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22138BS 341 #4 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22139Note: CGA fittings are for U.S. use; DIN fittings are for European use; BS fittings are for use in the UK.PRESSURE REGULATOR CONNECTIONSSwitching pressure: 200 psig/170 psig (1,379/1,172 kPa)Inlet connections: flexible SS pigtails (36")Line regulator: 0 to 100 psig (0-689 kPa)Automatic Switchover System for Noncorrosive <strong>Gas</strong>es(Critical Purity)Brass Automatic Switchover System with Line Regulator qty. cat.#CGA 580 (N2, He, Ar) ea. 20668580CGA 350 (H2, P5) ea. 20668350CGA 590 (Air) ea. 20668590Stainless Steel Automatic Switchover System with Line Regulator qty. cat.#CGA 580 (N2, He, Ar) ea. 215935808 www.restek.com

ULTRA-HIGH PURITY (UHP) STAINLESS STEEL BODY GAS REGULATORSDual-Stage Ultra-High PurityStainless Steel <strong>Gas</strong> Regulators with CGA Fittings• Most stable outlet pressure control.• Secondary pressure regulation not needed.Fitting Outlet Pressure Outlet Gauge qty. cat.#CGA 580 (N2, He, Ar) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20662CGA 350 (H2, P5) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20663CGA 590 (Air) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20664DIN 477 #1 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22377DIN 477 #6 (He, Ar) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22376DIN 477 #9 (Air) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22378DIN 477 #10 (N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22379BS 341 #3 (He, Ar, Air, N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22140BS 341 #4 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22141Note: CGA fittings are for U.S. use; DIN fittings are for European use; BS fittings are for use in the UK.Single-Stage Ultra-High PurityStainless Steel <strong>Gas</strong> Regulators with CGA Fittings• Use when there is secondary pressure regulation downstream.• Identical gas purity protection as with dual-stage gas regulators.Fitting Outlet Pressure Outlet Gauge qty. cat.#CGA 580 (N2, He, Ar) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20665CGA 350 (H2, P5) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20666CGA 590 (Air) 0 to 100 psig (0–689 kPa) 30" – 0 to 200 psig (0–1,379 kPa) ea. 20667DIN 477 #1 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22380DIN 477 #6 (He, Ar) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22445DIN 477 #9 (Air) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22446DIN 477 #10 (N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22447BS 341 #3 (He, Ar, Air, N2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22142BS 341 #4 (H2) 0 to 7 bar (0–100 psig) 30" – 0 to 14 bar (0–200 psig) ea. 22143Note: CGA fittings are for U.S. use; DIN fittings are for European use; BS fittings are for use in the UK.All regulators are rated to 3,000 psig(20,684 kPa) maximum inlet pressure.Inlet gauge: 0 to 4,000 psig (0–27,579 kPa)Outlet assembly: diaphragm valve, 1/4" tube fittingIN-LINE GAS REGULATORSUltra-High Purity Chrome-Plated Brass Line <strong>Gas</strong> Regulator• Oxidation-resistant, chrome-plated.• Use where you need to reduce the line pressure by 20 psig (138 kPa) or more.• Same purity protection as high-pressure cylinder regulators.Fitting Outlet Pressure Outlet Gauge qty. cat.#1 /4" female NPT ports* 0-50 psig (0-345 kPa) 30" - 0 to 100 psig (0-689 kPa) ea. 216661 /4" female NPT ports* 0-100 psig (0-689 kPa) 30" - 0 to 200 psig (0-1,379 kPa) ea. 22452*Order appropriate male connector, pipe-to-tube fittings.Inlet connections: 1/4" FPTOutlet assembly: 1/4" FPT portwww.restek.com 9

Tubing and FittingsPre-Cleaned Tubing from RestekThe integrity of a gas management system can becompromised by using tubing that has not been precleaned.Residual dirt, machine oil, and polycyclic aromatichydrocarbons from the manufacturing process often foundin different types of tubing will lead to problems later on.Restek offers pre-cleaned copper and stainless steel tubing forplumbing your gas management system.TubingThe best choice for plumbing your gas management system isstainless steel tubing. Copper tubing can be used as well, andRestek offers both types pre-cleaned and ready to use. Type304 stainless steel tubing is the most commonly used varietyof stainless steel tubing. Copper tubing is the most economicalchoice for plumbing your gas management system.FittingsWhen assembling your gas management system, all ofyour connections should be metal-to-metal connections.This ensures a leak-free connection, which is importantfor preventing contaminants from entering the gas stream.O-rings, gaskets, and sealing reagents should be avoided whenplumbing your system to avoid contamination of the tubingand gas chromatograph. Swagelok® compression fittings areideal for making your connections, and both stainless steel andbrass fittings are offered in ¼" and ⅛" sizes.Setting <strong>Gas</strong> Flows and Checking for LeaksOnce your gas management system is assembled itshould be checked for leaks. Leaks allow moisture,oxygen, and other airborne contaminants to enter yoursystem, as well as accelerating the consumption your gassupply. Detecting leaks with soap-based liquids shouldbe avoided as they can contaminate your gas streamand gas chromatograph. The Restek electronic leakdetector is the ideal accessory for inspecting your gasmanagement system for leaks. The Restek leak detectorcan be used to determine if your system is leakinghelium, hydrogen, argon, and even nitrogen.Once you have determined that your system is leak-free,you can set your gas flows with the Restek ProFLOW6000 electronic flowmeter. This flowmeter provides anaccuracy of ± 2% and measures volumetric flow ratesfrom 0.5 mL/min up to 500 mL/min. The ProFLOW6000 flowmeter is even Ex rated so that it can be usedto measure flow rates of flammable gases, such ashydrogen.Need help selectingtubing and fittings?Contact your local Restek representative or ourTechnical Service group at support@restek.comor 1-814-353-1300, ext. 4.10 www.restek.com

PRE-CLEANED TUBING FROM RESTEKRinsed and Cleaned 304 Stainless Steel TubingUse for providing carrier, fuel, make-up, or auxiliary gases to laboratoryinstruments.Tubing Length (per-foot pricing on 26 feet or more)Dimensions 25 Feet 26–100 Feet >100 Feet*ID (in.) OD (in.) cat.# cat.# cat.#0.01" 1/16" 21500 21501 215020.02" 1/16" 21503 21504 215050.03" 1/16" 21506 21507 215080.04" 1/16" 21509 21510 215110.085" 1/8" 21512 21513 215140.21" 1/4" 21515 21516 21517*The availability of long lengths (continuous lengths up to 500 feet) is subject to inventory constraints.Please inquire before ordering.TUBINGCopper TubingUse for plumbing GC systems.ID OD Wall Max Operating Pressure qty. cat.#0.065" 1 /8" 0.030" 2,800 psig 50 ft 226280.190" 1 /4" 0.030" 1,000 psig 50 ft 22629FITTINGSSwagelok® Fittings (Brass & Stainless Steel)Brass316 Grade Stainless SteelFitting Type Size Swagelok # qty. cat.# qty. cat.#Nut & Ferrule Set 1 /8" — 20-pk. 23110 5-pk. 231601 /4" — 20-pk. 23111 5-pk. 23161Union 1 /8" 200-6 5-pk. 23116 2-pk. 231661 /4" 400-6 5-pk. 23117 2-pk. 23167Tee 1/8" 200-3 2-pk. 23122 ea. 231721/4" 400-3 2-pk. 23123 ea. 23173*Includes self-sealing shutoff valve.Shut-Off <strong>Gas</strong> Valves Swagelok®1 /8"Brass1 /4"Brass1 /8"Stainless Steel1 /4"Stainless SteelValve Type cat.# cat.# cat.# cat.#Toggle 23142 23143 23198 23199Ball 23144 23145 23200 23201www.restek.com 11

Essential Tools | Product ListingCHECKING FOR LEAKSRestek Electronic Leak Detector Don't let a small leak turn into a costlyrepair—protect your analytical column by using a Restek Leak Detector.Leak Detector Specifications:Detectable <strong>Gas</strong>es: Helium, nitrogen, argon, carbon dioxide, hydrogenBattery: Rechargeable lithium ion internal battery pack (12 hours normaloperation)Operating Temp. Range: 32–120 °F (0–48 °C)Humidity Range: 0–97%Warranty: One yearCertifications: CE, Ex, JapanLimits of DetectionThese gases can be detected with the Restek Electronic Leak Detector atthe following leak rates:Minimum Detectable <strong>Gas</strong> Limits and Indicating LED Color:• Helium, 1.0 x 10-5, red LED• Hydrogen*, 1.0 x 10-5, red LED• Nitrogen, 1.4 x 10-3, yellow LED<strong>Gas</strong> detection limits measured in atm cc/sec.• Argon, 1.0 x 10-4, yellow LED• Carbon Dioxide, 1.0 x 10-4,yellow LEDFeatures & benefits include:• Audible tone indicates the severityof a leak.• Redesigned circuitry offers 12 hoursof operation between charges.• Detects a broad range of gases;Ex rated for use with hydrogen andother explosive gases.*• Ergonomic, handheld design.• Rugged side grips for addeddurability.• Handy probe storage forcleanliness and convenience.• Long-lasting battery; up to 12hours of continuous use.• Automatic shutoff.• A convenient carrying and storagecase.• Easy-to-clean probe assembly.• A universal charger set (U.S., European,UK, and <strong>Australia</strong>n plugs included).Backed by a 1-year warranty, the Restek Leak Detector is the industry standard for performance andaffordability in handheld leak detectors.Description qty. cat.#Leak Detector With Hard-Sided Carrying Case and Universal Charger Set(U.S., UK, European, <strong>Australia</strong>n)ea. 22655Small Probe Adaptor for Leak Detector ea. 22658Dynamic Duo Combo Pack (Restek Leak Detector and ProFLOW 6000 Flowmeter) kit 22654Soft-Sided Storage Case for Leak Detector or ProFLOW 6000 Flowmeter ea. 22657Avoid using liquid leak detectors on a GC! Liquids can be drawn into the system and/or into the leak detector.*Caution: The Restek Electronic Leak Detector is designed to detect trace amounts of hydrogen in a noncombustibleenvironment. It is NOT designed for determining leaks in a combustible environment. A combustible gas detectorshould be used for determining combustible gas leaks under any condition. When using it to detect hydrogen, theRestek Electronic Leak Detector may only be used for determining trace amounts in a GC environment.**Routine maintenance includes inspection of the probe tip, internal/external tubing, and a battery replacement.Flowmeter Specifications:Type of Flowmeter: VolumetricBattery:2-AAOperating Temp. Range: 32–120 °F(0–48 °C)12 www.restek.comWarranty: One yearCertifications: CE, ExCompliance: WEEE, RoHSSETTING GAS FLOWSRestek ProFLOW 6000 Electronic FlowmeterState-of-the-art features include:• Measures volumetric flowfor gases across a range of0.5–500 mL/min.• NIST traceable calibration.• Ex rating (electrical apparatus forexplosive gas atmospheres) forhydrogen and related gas types.• Accuracy of ± 2% of flow readingor ± 0.2 mL/min, whichever isgreater.• Over-range warning indicator.• Auto shutoff feature.• Use as a benchtop or handheldunit.• Ergonomic design and side gripsfor comfort.• Measures most gas types.*• Convenient carrying/storage caseincluded.• Uses 2-AA batteries (included).• Data output via USB port.• 1-year warranty.• Recalibration service available.Description qty. cat.#Restek ProFLOW 6000 Electronic Flowmeter With Hard-Sided Carrying Case ea. 22656ProFLOW 6000 Recalibration Service ea. 22656-RSoft-Sided Storage Case for Leak Detector or ProFLOW 6000 Flowmeter ea. 22657*The flowmeter is designed to measure clean, dry, non-corrosive gases. Patented.

<strong>Gas</strong> Purifiers | Product ListingSUPER-CLEAN BASEPLATE GAS FILTERSEach base plate unit measures:4" x 4" x 1 7 /8" (10.2 x 10.2 x 4.8 cm)All traps measure:10 5 /8" x 1 3 /4" (27 x 4.4 cm)22031Restek Super-Clean <strong>Gas</strong> Filter Kits and Replacements• High-purity output ensures 99.9999% pure gas (at max. flow of 2 L/min).• “Quick connect” fittings for easy, leak-tight cartridge changes.• Glass inside to prevent diffusion; polycarbonate housing outside for safety.• All traps measure 10 ⅝" x 1 ¾" (27 x 4.4 cm).• Each base plate unit measures 4" x 4" x 1 ⅞" (10.2 x 10.2 x 4.8 cm).Description qty. cat.#Carrier <strong>Gas</strong> Cleaning KitIncludes: mounting base plate, 1 /8" inlet/outlet fittings, and oxygen/moisture/kit 22019hydrocarbon triple gas filterFuel <strong>Gas</strong> Purification KitIncludes: mounting base plate, 1 /8" inlet/outlet fittings, and hydrocarbon/moisture fuel gas filterkit 22021Ultra-High Capacity Hydrocarbon Filter ea. 22030Ultra-High Capacity Moisture Filter ea. 22028Ultra-High Capacity Oxygen Filter ea. 22029Replacement Triple <strong>Gas</strong> Filter (removes oxygen, moisture, and hydrocarbons) ea. 22020Replacement Fuel <strong>Gas</strong> Filter (removes moisture and hydrocarbons) ea. 22022Helium-Specific Carrier <strong>Gas</strong> Cleaning KitIncludes: mounting base plate, 1 /8" inlet/outlet fittings, and oxygen/moisture/hydrocarbon kit 21983helium-specific filterReplacement Helium-Specific <strong>Gas</strong> Filter (removes oxygen, moisture, and hydrocarbons) ea. 21982<strong>Gas</strong> Filter Bundle KitIncludes: one triple gas filter (cat.# 22020) and two fuel gas filters (cat.# 22022)kit 22031Restek Filter Base Plates• Standard base plate fittings are ⅛". To adapt to ¼", order ⅛" to ¼" tubeendunions.• End fittings available in brass or stainless steel.• Base plates fit all stand alone Super-Clean gas filters offered.22026BrassStainless SteelDescription qty. cat.# qty. cat.#Filter Base Plate, Single-Position ea. 22025 ea. 22344Filter Base Plate, 2-Position ea. 22026 ea. 22345Filter Base Plate, 3-Position ea. 22027 ea. 22346IN-LINE SUPER-CLEAN PURIFICATION GAS TRAPSRestek Click-On In-Line Super-Clean <strong>Gas</strong> Traps and Connector KitsClick-On traps measure:8 1 /2" x 1 1 /4" (21.6 x 3.2 cm)Description qty. cat.#Carrier <strong>Gas</strong> Purification KitIncludes: (2) 1 /8" SS connectors and (1) oxygen/moisture/hydrocarbon triple trap kit 22456Includes: (2) 1 /8" brass connectors and (1) oxygen/moisture/hydrocarbon triple trap kit 22457Includes: (2) 1 /4" SS connectors and (1) oxygen/moisture/hydrocarbon triple trap kit 22458Includes: (2) 1 /4" brass connectors and (1) oxygen/moisture/hydrocarbon triple trap kit 22459Fuel <strong>Gas</strong> Purification KitIncludes: (4) 1 /8" SS connectors and (2) hydrocarbon/moisture traps kit 22460Includes: (4) 1 /8" brass connectors and (2) hydrocarbon/moisture traps kit 22461Includes: (4) 1 /4" SS connectors and (2) hydrocarbon/moisture traps kit 22462Includes: (4) 1 /4" brass connectors and (2) hydrocarbon/moisture traps kit 2246314 www.restek.com

IN-LINE GAS TRAPSIndicating Oxygen Trap• Indicator changes from light green to grey as oxygen is trapped.• 100 psi (689 kPa) maximum operating pressure.• Reduces oxygen to 0.1 ppm.• 10 µm frits at inlet and outlet.Description Fittings qty. cat.#Indicating Oxygen Trap 1/8" Brass ea. 22010Indicating Oxygen Trap 1/4" Brass ea. 22011Dimensions:10" x 1 1 /4" (25.4 x 3.2 cm)Indicating Moisture Trap• Reduces water to less than 10 ppb; indicator changes fromyellowish-green to blue at 5% relative humidity.• Reduces noise from high-sensitivity detectors.• 10 µm frit prevents microparticulate damage to needle valves andflow controllers.• Maximum operating pressure: 100 psi (689 kPa).Description Fittings qty. cat.#Indicating Moisture Trap 1 /8" Brass ea. 22014Indicating Moisture Trap 1 /4" Brass ea. 22015Dimensions: 13" x 2" (33 x 5.1 cm)Moisture capacity: 6 g of waterMaximum flow: 1 L/minHigh-Capacity Oxygen Trap• Long life—typically purifies more than five 200 ft 3 cylinders.• Reduces oxygen to 15 ppb.• Maximum operating pressure: 250 psi (1,724 kPa).• Flow: 3 L/min @ 32 psi (221 kPa).Description Fittings qty. cat.#High-Capacity Oxygen Trap 1 /8" Nickel-Plated Brass ea. 20601High-Capacity Oxygen Trap 1 /4" Nickel-Plated Brass ea. 20600Dimensions:11" x 1 1 /2" (27.9 x 3.8 cm)High-Capacity Moisture Trap• Reduces water to less than 15 ppb.• Maximum operating pressure: 250 psi (1,724 kPa).• Maximum flow: 1.25 L/min.Description Fittings qty. cat.#High-Capacity Moisture Trap 1 /8" Nickel-Plated Brass ea. 21997High-Capacity Moisture Trap 1 /4" Nickel-Plated Brass ea. 20638Dimensions: 11" x 1 1 /2" (27.9 x 3.8 cm)Moisture capacity: 16 g of waterCapillary-Grade Hydrocarbon Trap• Reduces organics to 0.1 ppm (assuming 100 ppm input).• Maximum operating pressure: 250 psi (1,724 kPa).Description Fittings qty. cat.#Capillary-Grade Hydrocarbon Trap 1 /8" Nickel-Plated Brass ea. 21991Capillary-Grade Hydrocarbon Trap 1 /4" Nickel-Plated Brass ea. 21992Dimensions:11" x 1 1 /2" (27.9 x 3.8 cm)www.restek.com 15

ChooseRestek forChromatographySolutionsGet the most out of your GC and LCsystems with analytical solutions fromRestek. We supply the products andtechnical support you need to get reliableresults quickly and efficiently.• GC and LC columns• Supplies and accessories• Certified reference materials• Sample prep suppliesLearn more atwww.restek.comPATENTS & TRADEMARKSRestek patents and trademarks are the property of Restek Corporation. (See www.restek.com/Patents-Trademarks for full list.) Other trademarks appearing in Restek literature or on its website arethe property of their respective owners. The Restek registered trademarks used here are registered in the United States and may also be registered in other countries.Lit. Cat.# GNBR1758-UNV© 2013 Restek Corporation. All rights reserved.Printed in the U.S.A.Restek U.S. • 110 Benner Circle • Bellefonte, PA 16823 • 1-814-353-1300 • 1-800-356-1688 • fax: 1-814-353-1309 • www.restek.comRestek France • phone: +33 (0)1 60 78 32 10 • fax: +33 (0)1 60 78 70 90 • www.restek.frRestek GmbH • phone: +49 (0)6172 2797 0 • fax: +49 (0)6172 2797 77 • www.restekgmbh.deRestek Ireland • phone: +44 (0)2890 814576 • fax: +44 (0)2890 814576 • e-mail: restekireland@aol.comRestek Japan • phone: +81 (3)6459 0025 • fax: +81 (3)6459 0025 • e-mail: restekjapan@restek.comThames Restek U.K. LTD • phone: +44 (0)1494 563377 • fax: +44 (0)1494 564990 • www.thamesrestek.co.ukRestek China • phone: +86-10-5629-6620 • fax: +86-10-5814-3980 • cn.restek.com