Mining and Industrial Overview.pdf - Ansys

Mining and Industrial Overview.pdf - Ansys

Mining and Industrial Overview.pdf - Ansys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

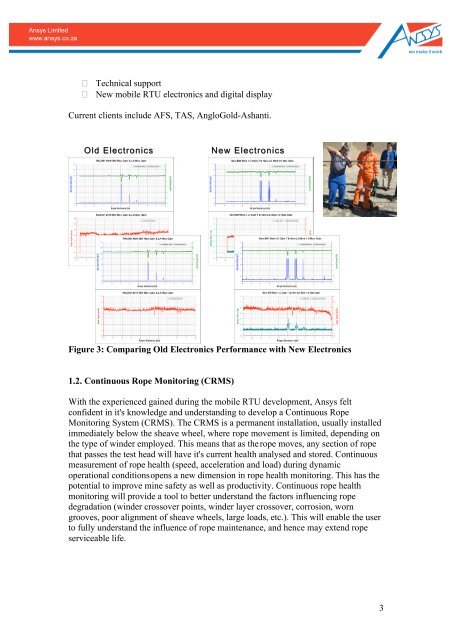

Technical supportNew mobile RTU electronics <strong>and</strong> digital displayCurrent clients include AFS, TAS, AngloGold-Ashanti.Old ElectronicsNew ElectronicsFigure 3: Comparing Old Electronics Performance with New Electronics1.2. Continuous Rope Monitoring (CRMS)With the experienced gained during the mobile RTU development, <strong>Ansys</strong> feltconfident in it's knowledge <strong>and</strong> underst<strong>and</strong>ing to develop a Continuous RopeMonitoring System (CRMS). The CRMS is a permanent installation, usually installedimmediately below the sheave wheel, where rope movement is limited, depending onthe type of winder employed. This means that as the rope moves, any section of ropethat passes the test head will have it's current health analysed <strong>and</strong> stored. Continuousmeasurement of rope health (speed, acceleration <strong>and</strong> load) during dynamicoperational conditions opens a new dimension in rope health monitoring. This has thepotential to improve mine safety as well as productivity. Continuous rope healthmonitoring will provide a tool to better underst<strong>and</strong> the factors influencing ropedegradation (winder crossover points, winder layer crossover, corrosion, worngrooves, poor alignment of sheave wheels, large loads, etc.). This will enable the userto fully underst<strong>and</strong> the influence of rope maintenance, <strong>and</strong> hence may extend ropeserviceable life.3

![CRMS-AMRE-Mponeng-JK [Compatibility Mode].pdf - Ansys.co.za](https://img.yumpu.com/29100471/1/190x135/crms-amre-mponeng-jk-compatibility-modepdf-ansyscoza.jpg?quality=85)