Mining and Industrial Overview.pdf - Ansys

Mining and Industrial Overview.pdf - Ansys

Mining and Industrial Overview.pdf - Ansys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

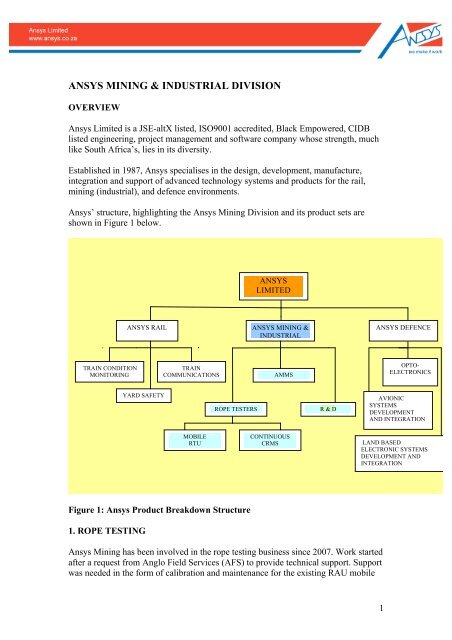

ANSYS MINING & INDUSTRIAL DIVISIONOVERVIEW<strong>Ansys</strong> Limited is a JSE-altX listed, ISO9001 accredited, Black Empowered, CIDBlisted engineering, project management <strong>and</strong> software company whose strength, muchlike South Africa’s, lies in its diversity.Established in 1987, <strong>Ansys</strong> specialises in the design, development, manufacture,integration <strong>and</strong> support of advanced technology systems <strong>and</strong> products for the rail,mining (industrial), <strong>and</strong> defence environments.<strong>Ansys</strong>’ structure, highlighting the <strong>Ansys</strong> <strong>Mining</strong> Division <strong>and</strong> its product sets areshown in Figure 1 below.ANSYSLIMITEDANSYS RAILANSYS MINING &INDUSTRIALANSYS DEFENCETRAIN CONDITIONMONITORINGTRAINCOMMUNICATIONSAMMSOPTO-ELECTRONICSYARD SAFETYROPE TESTERSR & DAVIONICSYSTEMSDEVELOPMENTAND INTEGRATIONMOBILERTUCONTINUOUSCRMSLAND BASEDELECTRONIC SYSTEMSDEVELOPMENT ANDINTEGRATIONFigure 1: <strong>Ansys</strong> Product Breakdown Structure1. ROPE TESTING<strong>Ansys</strong> <strong>Mining</strong> has been involved in the rope testing business since 2007. Work startedafter a request from Anglo Field Services (AFS) to provide technical support. Supportwas needed in the form of calibration <strong>and</strong> maintenance for the existing RAU mobile1

Technical supportNew mobile RTU electronics <strong>and</strong> digital displayCurrent clients include AFS, TAS, AngloGold-Ashanti.Old ElectronicsNew ElectronicsFigure 3: Comparing Old Electronics Performance with New Electronics1.2. Continuous Rope Monitoring (CRMS)With the experienced gained during the mobile RTU development, <strong>Ansys</strong> feltconfident in it's knowledge <strong>and</strong> underst<strong>and</strong>ing to develop a Continuous RopeMonitoring System (CRMS). The CRMS is a permanent installation, usually installedimmediately below the sheave wheel, where rope movement is limited, depending onthe type of winder employed. This means that as the rope moves, any section of ropethat passes the test head will have it's current health analysed <strong>and</strong> stored. Continuousmeasurement of rope health (speed, acceleration <strong>and</strong> load) during dynamicoperational conditions opens a new dimension in rope health monitoring. This has thepotential to improve mine safety as well as productivity. Continuous rope healthmonitoring will provide a tool to better underst<strong>and</strong> the factors influencing ropedegradation (winder crossover points, winder layer crossover, corrosion, worngrooves, poor alignment of sheave wheels, large loads, etc.). This will enable the userto fully underst<strong>and</strong> the influence of rope maintenance, <strong>and</strong> hence may extend ropeserviceable life.3

Figure 4: CRMS Major Components4

Figure 5: CRMS Area Test Data at 16m/s for a Ø54mm 6x33(15/12/6+3T)/F SWRAdvantages of using the CRMS :Increased safetyMay increase the loading/speed – Increase productivityMeasures condition during normal operations – reduced downtimerequired for Electromagnetic Inspection (EMI)Repeatability – No man in the loopProactive preventative maintenance – Increase life span of ropeAssists Mine Engineer during monthly rope inspections – point toproblem areasCorrelates rope condition from supplier after installation (Manufacturingdeficiencies)Build In Test – (BIT) Ensures system performance <strong>and</strong> functionalityRemote Condition Monitoring – Information over LAN / internetContinuously upgrading of condition indicatorsCorrelates dynamic stress with condition deteriorationImproved underst<strong>and</strong>ing of how a rope deteriorates / degrades <strong>and</strong> howone can extend the usable life of a SWR.Current legislation allows for an increase in load if continuous ropemonitoring is employed. The CRMS, which is still undergoing improvements,aimed at improving performance as well as reducing maintenance <strong>and</strong>logistical support requirements, will enable clients to monitor steel wire ropesat operational speeds.Besides their obvious applications in the mining industry, the RTU <strong>and</strong> CRMSmay be invaluable to lift operators in high rise buildings <strong>and</strong> have potentialuse in construction sites, ropeways, metallurgy, power supply, oil, bridges,pressure piping, guy wires on free st<strong>and</strong>ing structures, etc.6

2. AUTOMATED MAINTENANCE MANAGEMENT SYSTEMS (AMMS)In the wider industrial environment <strong>Ansys</strong> <strong>Mining</strong> & <strong>Industrial</strong> Division focuses onmanagement systems, including thermal <strong>and</strong> high performance imaging sensors <strong>and</strong>automated maintenance management systems for critical infrastructures, for theoptimisation of business processes <strong>and</strong> maintenance management.8

2.1 The <strong>Ansys</strong> Maintenance Management Service (AMMS)<strong>Ansys</strong> <strong>Mining</strong> & <strong>Industrial</strong> Division provides a maintenance managementsolution to ensure structured <strong>and</strong> consistent maintenance processes onoperational infrastructures in order to improve return on investment.<strong>Ansys</strong>’ prime system for the industrial environment is an automatedmaintenance system known as the AMMS. The objective of the AMMS is tocombat the decay in infrastructure resulting from inefficient maintenancepractices. Making use largely of precisely configured h<strong>and</strong> held devicesconnected to a central data base, the AMMS enhances the efficiency <strong>and</strong>effectiveness of maintenance staff together with the operational readiness ofindustrial infrastructure resulting in better productivity <strong>and</strong> improved profits.It is a preventive maintenance management software solution based on aPrimer Design Assistant (PDA) <strong>and</strong> web-based database design allowing themaintenance manager to access the progress of his/her maintenance staff <strong>and</strong>the status of assets from basically anywhere.2.2 Process Improvement<strong>Ansys</strong> <strong>Mining</strong> & <strong>Industrial</strong> Division also offers the following systems <strong>and</strong>products aimed at optimising business processes:o Process Monitoring <strong>and</strong> Control Systemso Health/Condition Monitoring Systemso Asset Control Systemso Electronic Identification Systemso Business Information Systemso <strong>Industrial</strong> Computerso Maintenance Managemento Intelligent Platformso Rail Trackside Measurement <strong>and</strong> Signaling3. RAIL SOLUTIONSBesides <strong>Ansys</strong>’ focus on rail technology for the transport sector of South Africa (see<strong>Ansys</strong> Rail), it also applies this technology to maximising the operational efficiency9

of local rail networks operated by mining <strong>and</strong> other large industrial companies such asSasol.<strong>Ansys</strong> offers the following in this respect:Trackside measurementsHot bearing detectionWheel profile monitoringVehicle identificationLoad profile monitoringSignalling systems4. SECURITY APPLICATIONSWithin the industrial security field, <strong>Ansys</strong> <strong>Mining</strong>/<strong>Industrial</strong> has developed low cost,uncooled thermal imaging <strong>and</strong> observation technology as well as pan, zoom <strong>and</strong> tiltunits to enhance security operations. These security applications apply to the miningsector as well as to the broader industrial environment.5. RESEARCH AND DEVELOPMENTCurrently focused on the mining industry, <strong>Ansys</strong> <strong>Mining</strong> & <strong>Industrial</strong> Division pridesitself on being able to take a specific technical operational problem that is beingexperienced by a company <strong>and</strong> finding a solution that works.An example of this is to be found in <strong>Ansys</strong>’ involvement in research <strong>and</strong> developmentto detect tramp metal in mine dumps prior to their rework. Tramp metals can accountfor tens of millions in lost productivity <strong>and</strong> direct equipment replacement costsannually <strong>and</strong> as such continues to be a constant annoyance.Whatever your technical operational problem, <strong>Ansys</strong> <strong>Mining</strong> &<strong>Industrial</strong> Division will find, develop <strong>and</strong> implement a solution thatworks for you.10

![CRMS-AMRE-Mponeng-JK [Compatibility Mode].pdf - Ansys.co.za](https://img.yumpu.com/29100471/1/190x135/crms-amre-mponeng-jk-compatibility-modepdf-ansyscoza.jpg?quality=85)