Potter Aluminium Systems - CSR

Potter Aluminium Systems - CSR

Potter Aluminium Systems - CSR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

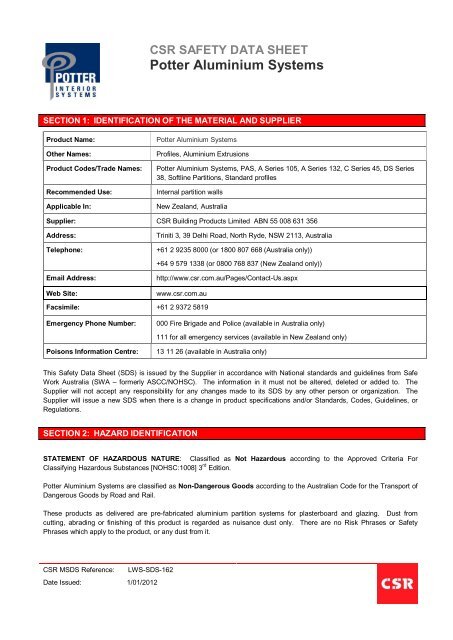

MSDS for <strong>Potter</strong> <strong>Aluminium</strong> <strong>Systems</strong> Page 3 of 6restraints can be found on Tomago <strong>Aluminium</strong> websitewww.tomago.com.au/product-safety.Storage:Incompatibilities:Store away from strong alkalis, halogens, oxidising agents and halogenatedhydrocarbons and any fire or explosion risks, e.g. ammonium nitrate. Preventcontact with all strong acids including hydrochloric acid, sulphuric acid, nitricacid and strong alkalis, e.g. potassium hydroxide and sodium hydroxide.Reaction with acids or alkalis may generate flammable gas.SECTION 8: EXPOSURE CONTROLS / PERSONAL PROTECTIONWorkplace Exposure Standards:Workplace Exposure Standards for Airborne Contaminants, Safe WorkAustralia:Dust from cutting or finishing this product may be treated as a nuisance dust.Exposure should be kept as low as practicable, and below the following WES:Total dust (of any type, or particle size): TWA - 10 mg/m 3 .Notes on Exposure Standards: TWA (Time Weighted Average): the time-weighted average airborneconcentration over an eight-hour working day, for a five-day working week overan entire working life. According to current knowledge this concentration shouldneither impair the health of, nor cause undue discomfort to, nearly all workers.Biological Limit Values:No biological limit allocated.ENGINEERING CONTROLS Ventilation: Keep exposures to dust as low as practicable. Open air work or use of naturalventilation (opening of doors and windows in buildings) generally providesadequate ventilation. Local mechanical ventilation or extraction may berequired in areas where dust standards cannot be achieved.Special Consideration forRepair &/or Maintenance ofContaminated Equipment:Recommendations on Exposure Control and Personal Protection should befollowed.PERSONAL PROTECTION Personal Hygiene Wash hands before eating, drinking, using the toilet, or smoking. Skin Protection: Excessive or repeated skin contact should be avoided by wearing long sleevedshirts and long trousers, a cap or hat, and gloves (standard duty leather orequivalent AS 2161). Wash work clothes regularly. Wash hands before eating,or smoking. Eye Protection: Ventilated non-fogging goggles (dust resistant AS/NZS 1336) should be wornwhen working in a dusty environment. Respiratory Protection: None required if engineering and handling controls are adequate. A suitable P1or P2 particulate respirator chosen and used in accordance with AS/NZS 1715and AS/NZS 1716 may be appropriate in dusty conditions.SECTION 9: PHYSICAL AND CHEMICAL PROPERTIESAppearance:Odour:pH, at stated concentration:Solid metal fabricated forms, silver in colourNoneNot determined<strong>CSR</strong> SDS Reference:Date Issued:LWS-SDS-162

MSDS for <strong>Potter</strong> <strong>Aluminium</strong> <strong>Systems</strong> Page 4 of 6Vapour Pressure/Density:Not applicableBoiling Point/Range (°C): 2467°CFreezing/Melting Point (°C):Solubility In Water:482-660°CInsolubleSpecific Gravity (H 2O = 1): 2.5-2.9FLAMMABLE MATERIALS Flash Point: Not applicable Flammable (Explosive) Limits: Not applicable Autoignition Temperature: Not applicableADDITIONAL PROPERTIES Evaporation Rate: Not applicable % Volatiles: 0%Volatile Organic CompoundsContent (VOC):0% (as specified by the Green Building Council of Australia)SECTION 10: STABILITY AND REACTIVITYChemical Stability:Incompatible Materials:Conditions to avoid:Hazardous Decomposition Products:Hazardous Reactions:Product is stable as delivered. <strong>Aluminium</strong> dust can be highly reactive.Work situations where aluminium dust is created in substantial amountsshould be assessed for safety risks.Store away from strong alkalis, halogens, oxidising agents andhalogenated hydrocarbons and any fire or explosion risks eg. ammoniumnitrate. Prevent contact with all strong acids including hydrochloric acid,sulphuric acid, nitric acid and strong alkalis eg. potassium hydroxide andsodium hydroxide. Fine powder or freshly cleaned metal surface mayreact with water (evolving flammable gas).Dust and fume generationNoneNoneSECTION 11: TOXICOLOGICAL INFORMATIONToxicology data: No specific toxicology data available for this product. The product is delivered as solid fabricatedforms and is Non-Hazardous. The following health effects apply only to dust arising from cutting, sanding or machining ofthe solid product.Health Effects: Acute (short term)Swallowed:Unlikely under normal industrial use, but swallowing large amounts of dust may result inabdominal discomfort.Eyes:Skin:Inhaled:Dust may be irritating to the eyes, causing watering and redness, and may aggravate preexistingeye conditions.Dust may cause mild irritation, and drying to the skin due to its physical characteristics.Dust is mildly irritating to the nose, throat and respiratory tract and may cause coughing andsneezing. Pre-existing upper respiratory and lung diseases including asthma and bronchitis<strong>CSR</strong> SDS Reference:Date Issued:LWS-SDS-162

MSDS for <strong>Potter</strong> <strong>Aluminium</strong> <strong>Systems</strong> Page 5 of 6may be aggravated.Health Effects: Chronic (long term)Skin:Repeated heavy contact with the dust may cause drying of the skin and can result in skin rash(dermatitis) typically affecting the hands. Over time this may become chronic and can alsobecome infected.Inhaled:Repeated exposure to high levels of dust may result in increased nasal and respiratorysecretions and coughing. Inflammation of lining tissue of the respiratory system may followrepeated exposure to high levels of dust with increased risk of asthma, bronchitis andpneumonia.SECTION 12: ECOLOGICAL INFORMATIONEco-toxicity:Persistence and Degradability:Mobility:Product is non-toxic to aquatic and terrestrial organisms.Product is persistent and would have a low degradability.A low mobility would be expected in a landfill situation.SECTION 13: DISPOSAL CONSIDERATIONS<strong>Aluminium</strong> extrusion (and any generated dust) should be recycled as scrap or can be treated as a common waste fordisposal or dumped into a landfill site in accordance with local authority guidelines. Measures should be taken to preventdust generation during disposal and exposure and personal precautions should be observed (see Section 8).SECTION 14: TRANSPORT INFORMATIONProper ShippingName:UN number:DG Class:Subsidiary Risk 1:Packaging Group:HAZCHEM code:Marine Pollutant:None AllocatedNone AllocatedNone AllocatedNone AllocatedNone AllocatedNone AllocatedNoSECTION 15: REGULATORY INFORMATIONPoisons Schedule:Not scheduledSECTION 16: OTHER INFORMATIONFor further information on this product, please contact:<strong>CSR</strong> Building Products Limited (ABN 55 008 631 356), Triniti 3, 39 Delhi Road, North Ryde, NSW 2113, Australia.Phone:Fax:+61 2 9372 5888 or 1800 807 668 (available in Australia only)+61 2 9372 5877<strong>CSR</strong> SDS Reference:Date Issued:LWS-SDS-162

MSDS for <strong>Potter</strong> <strong>Aluminium</strong> <strong>Systems</strong> Page 6 of 6ADDITIONAL INFORMATIONAustralian / New Zealand Standards References:AS/NZS 1020:1995 Control of Undesirable Static ElectricityAS 1076AS/NZS 1336:1997AS/NZS 1715:2009AS/NZS 1716:2003AS/NZS 2161:2008Code of Practice for selection, installation and maintenance of electrical apparatus and associatedequipment for use in explosive atmospheres (other than mining applications) – Parts 1 to 13Recommended Practices for Occupational Eye ProtectionSelection, Use and Maintenance of Respiratory Protective DevicesRespiratory Protective DevicesIndustrial Safety Gloves and Mittens (excluding electrical and medical gloves)AS 2380 Electrical equipment for explosive atmospheres – Explosion Protection Techniques (Parts 1 to 9)AS 3000Other References:NOHSC: 1008 (2004)NOHSC:10005(1999)NOHSC:2007(1994)Model Code ofPracticeModel Code ofPracticeWESADG CodeGHSElectrical installations (known as the Australian/New Zealand Wiring Rules)Approved Criteria for Classifying Hazardous SubstancesList Of Designated Hazardous Substances, April 1999, National Occupational Health andSafety Commission, Sydney.National Code of Practice for the Control of Workplace Hazardous Substances (AustralianStates have similar Codes of Practice in each State).Preparation of Safety Data Sheets for Hazardous Chemicals, December 2011, Safe WorkAustralia.Labelling of Workplace Hazardous Chemicals, December 2011, Safe Work Australia.Workplace Exposure Standards for Airborne Contaminants, December 2011, Safe WorkAustralia.Australian Code for the Transport of Dangerous Goods by Road and Rail, 7th edition,National Transport Commission.Globally Harmonized System of Classification and Labelling of Chemicals (GHS), 3 rd revisededition, United Nations, New York and Geneva, 2009.AUTHORISATIONReason for Issue: Creation of MSDSAuthorised by: Andrew ClemmentDate of Issue: 26.03.12Whilst the information contained in this document is based on data which, to the best of our knowledge, was accurate andreliable at the time of preparation, no responsibility can be accepted by us for errors and omissions. The provision of thisinformation should not be construed as a recommendation to use any of our products in violation of any patent rights or inbreach of any statute or regulation. Users are advised to make their own determination as to the suitability of thisinformation in relation to their particular purposes and specific circumstances. Since the information contained in thisdocument may be applied under conditions beyond our control, no responsibility can be accepted by us for any loss ordamage caused by any person acting or refraining from action as a result of this information.END OF MSDS<strong>CSR</strong> SDS Reference:Date Issued:LWS-SDS-162