Powell Continuous Sodium Hypochlorite Process System

Powell Continuous Sodium Hypochlorite Process System

Powell Continuous Sodium Hypochlorite Process System

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

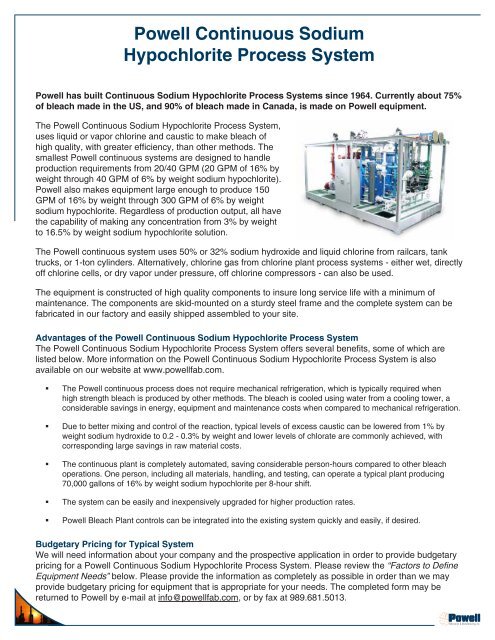

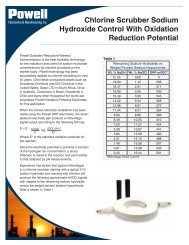

<strong>Powell</strong> <strong>Continuous</strong> <strong>Sodium</strong><strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong><strong>Powell</strong> has built <strong>Continuous</strong> <strong>Sodium</strong> <strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong>s since 1964. Currently about 75%of bleach made in the US, and 90% of bleach made in Canada, is made on <strong>Powell</strong> equipment.The <strong>Powell</strong> <strong>Continuous</strong> <strong>Sodium</strong> <strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong>,uses liquid or vapor chlorine and caustic to make bleach ofhigh quality, with greater efficiency, than other methods. Thesmallest <strong>Powell</strong> continuous systems are designed to handleproduction requirements from 20/40 GPM (20 GPM of 16% byweight through 40 GPM of 6% by weight sodium hypochlorite).<strong>Powell</strong> also makes equipment large enough to produce 150GPM of 16% by weight through 300 GPM of 6% by weightsodium hypochlorite. Regardless of production output, all havethe capability of making any concentration from 3% by weightto 16.5% by weight sodium hypochlorite solution.The <strong>Powell</strong> continuous system uses 50% or 32% sodium hydroxide and liquid chlorine from railcars, tanktrucks, or 1-ton cylinders. Alternatively, chlorine gas from chlorine plant process systems - either wet, directlyoff chlorine cells, or dry vapor under pressure, off chlorine compressors - can also be used.The equipment is constructed of high quality components to insure long service life with a minimum ofmaintenance. The components are skid-mounted on a sturdy steel frame and the complete system can befabricated in our factory and easily shipped assembled to your site.Advantages of the <strong>Powell</strong> <strong>Continuous</strong> <strong>Sodium</strong> <strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong>The <strong>Powell</strong> <strong>Continuous</strong> <strong>Sodium</strong> <strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong> offers several benefits, some of which arelisted below. More information on the <strong>Powell</strong> <strong>Continuous</strong> <strong>Sodium</strong> <strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong> is alsoavailable on our website at www.powellfab.com.• The <strong>Powell</strong> continuous process does not require mechanical refrigeration, which is typically required whenhigh strength bleach is produced by other methods. The bleach is cooled using water from a cooling tower, aconsiderable savings in energy, equipment and maintenance costs when compared to mechanical refrigeration.• Due to better mixing and control of the reaction, typical levels of excess caustic can be lowered from 1% byweight sodium hydroxide to 0.2 - 0.3% by weight and lower levels of chlorate are commonly achieved, withcorresponding large savings in raw material costs.• The continuous plant is completely automated, saving considerable person-hours compared to other bleachoperations. One person, including all materials, handling, and testing, can operate a typical plant producing70,000 gallons of 16% by weight sodium hypochlorite per 8-hour shift.• The system can be easily and inexpensively upgraded for higher production rates.• <strong>Powell</strong> Bleach Plant controls can be integrated into the existing system quickly and easily, if desired.Budgetary Pricing for Typical <strong>System</strong>We will need information about your company and the prospective application in order to provide budgetarypricing for a <strong>Powell</strong> <strong>Continuous</strong> <strong>Sodium</strong> <strong>Hypochlorite</strong> <strong>Process</strong> <strong>System</strong>. Please review the “Factors to DefineEquipment Needs” below. Please provide the information as completely as possible in order than we mayprovide budgetary pricing for equipment that is appropriate for your needs. The completed form may bereturned to <strong>Powell</strong> by e-mail at info@powellfab.com, or by fax at 989.681.5013.<strong>Powell</strong>Fabrication & Manufacturing, Inc.

Factors to Define Equipment Needs1. Information About Company Requesting PricingIf you are an agent requesting information about <strong>Powell</strong> equipment on behalf of another company, pleaseprovide the information requested below about your company.Contact Person:Company Name:Address:Subsidiary of:City:State: Zip: Country:Phone:e-mail:Fax:Website:2. Information About End User of <strong>Powell</strong> EquipmentPlease provide the information requested below about the company that will be the end user of the <strong>Powell</strong>equipment.Company Name:Subsidiary of:Address:City:State: Zip: Country:Phone:e-mail:Fax:Website:Number of years under company name listed above:Other names company does business under:Number of years at location listed above:Incorporated in the Country of:Company description and level of experience with sodium hypochlorite, i.e. bleach?Type of product/products manufactured or sold:Name of product/products manufactured or sold:Country in which equipment will be located:Port equipment will be shipped to:<strong>Powell</strong>Fabrication & Manufacturing, Inc.

3. <strong>System</strong> Requirements3.1 Type of ProjectMarket EntryExisting <strong>Process</strong> ReplacementExpansion3.2 Bleach Skid LocationInsideOutsideHighest Temperature °C/ °FLowest Temperature °C/ °F3.3 Bleach MarketTypically, bleach is used to disinfect drinking water, for treatment of industrial and municipal waste streams,and for other applications such as cooling tower treatment, pulp and paper, intermediate processes, etc.Bleach is also sold to the customer for washing clothes. Typically it is sold in bottles of all sizes all strengths upto approximately 6% by weight sodium hypochlorite. Where will the bleach you produce be sold?IndustrialEnd User3.4 Bleach Strength RequiredThe bleach strength is adjustable by the operator from 3% by weight sodium hypochlorite through 16.58% byweight sodium hypochlorite. What is the bleach strength required?% by weight3.5 Bleach Flow Rate<strong>Powell</strong> builds units of almost any flow rate capability. Typically, they will be 1-ton, 3-ton, 6-ton or 9-ton per hourof chlorine. Within these approximate values there are options.What is the maximum flow rate in US gallons of the highest strength bleach you wish to produce?What is the maximum flow rate in US gallons of the lowest strength bleach you wish to produce?3.6 Excess <strong>Sodium</strong> HydroxideThe <strong>Powell</strong> continuous system can be adjusted from 0.2% by weight excess sodium hydroxide to 1.5% byweight excess sodium hydroxide, normally using the ORP controller on the system. If lower or higher excesssodium hydroxide is required, it can be easily achieved with minor equipment changes.What is the maximum percent by weight excess sodium hydroxide required?What is the minimum percent by weight excess sodium hydroxide required?<strong>Powell</strong>Fabrication & Manufacturing, Inc.

4. Raw Materials4.1 Chlorine<strong>Sodium</strong> hypochlorite can be produced using liquid chlorine, typically purchased in railcars, iso containers, or1-ton containers. The <strong>Powell</strong> continuous system can also use gas (vapor) chlorine - either wet vapor, directlyoff chlorine cells, or dry vapor under pressure, off chlorine compressors.If liquid chlorine will be used, please complete Section 4.1.1 below. If gas (vapor) chlorine will be used, pleasecomplete Section 4.1.2 below. If you do not have the information requested, please state “Unknown”.4.1.1 Liquid ChlorineIf liquid chlorine is to be supplied out of vessels without external air or nitrogen pressurizing systems,the temperature of the storage vessel will determine the pressure and the pressure will be unknown.If the pressure is unknown please state “unknown”. What is the pressure of the liquid chlorine in thesystem or from the storage vessel?Psig (pounds per square inch)What is the highest ambient temperature the storage vessel will experience?4.1.2 Gas ChlorineChlorine gas may be used to make bleach. In order for <strong>Powell</strong> to supply the appropriate equipment foryour application, it is very important complete and accurate information be provided in this section. Willwet or dry chlorine gas be used?WetDryThe pressure of the chlorine can be at a slight negative off the cells or it can be any positive pressure.Wet chlorine vapor can be off the cells directly and may be pulled off the cells under a slight vacuumsuch as 0-5 inches of water column vacuum. If it is dry chlorine it can be at any inlet pressure to thesystem but in order to design this the pressure must be known. This dry chlorine can be under vacuumor pressure and for budget pricing an approximate pressure will be sufficient.What is the pressure of the gas chlorine? Pounds per square inch (psig)What is the density of the vapor chlorine at operating pressure and temperature?Pound per cubic feet at operating pressure? TemperatureThere is no limitation on the chlorine gas stream including the amount of inert gases. Thedesign will change a small amount, depending on the operating conditions. Liquid chlorinecan be used in the process without the need for vaporization. What is the composition of gasstream?If desired, <strong>Powell</strong> can supply a system that will use all available vapor chlorine going to scrubbers offcells and other sources. In addition, extra capacity to increase production of bleach by using extraliquid chlorine from other sources can be accommodated. <strong>Powell</strong> equipment can make bleach with allavailable chlorine gas using caustic, then continue the process with liquid chlorine to provide additionalsodium hypochlorite. These modified processes can easily be achieved, but details are needed forbudget pricing.<strong>Powell</strong>Fabrication & Manufacturing, Inc.

4.2 Caustic Soda (<strong>Sodium</strong> Hydroxide)The <strong>Powell</strong> continuous system uses a ratio to blend the caustic to reach the desired lower strength forchlorination, and it works extremely well. The ratio can be a simple system without density compensation onthe strong caustic or a mass flow meter can be added to compensate for variations of strong caustic strength.<strong>Powell</strong> equipment can use either 32% or 50% caustic and if you want the option to go from 32% to 50%, itis not a problem. Many of our units run 50% in the summer and 25-30% in the winter, so they do not have toworry about freezing the 50%. Other strengths of caustic will work well as long as the strength is known in thedesign phase of the system. We will want steady pressure of the caustic. This will be normally accomplishedwith a separate feed pump that starts when the system turns on. If the caustic is supplied from a common pipeheader under pressure, this is acceptable.MembraneDiaphragmMercury4.3 WaterThe <strong>Powell</strong> continuous system can use soft water from a standard commercial softener (