ERIKS Maintenance and Condition Monitoring Technical ... - Eriks UK

ERIKS Maintenance and Condition Monitoring Technical ... - Eriks UK

ERIKS Maintenance and Condition Monitoring Technical ... - Eriks UK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

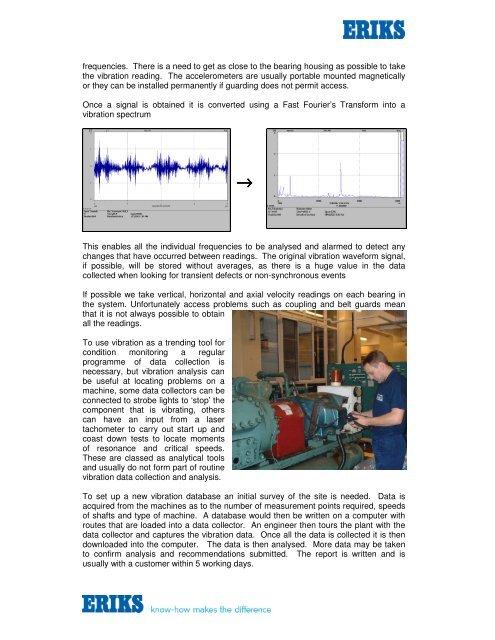

frequencies. There is a need to get as close to the bearing housing as possible to takethe vibration reading. The accelerometers are usually portable mounted magneticallyor they can be installed permanently if guarding does not permit access.Once a signal is obtained it is converted using a Fast Fourier’s Transform into avibration spectrum→This enables all the individual frequencies to be analysed <strong>and</strong> alarmed to detect anychanges that have occurred between readings. The original vibration waveform signal,if possible, will be stored without averages, as there is a huge value in the datacollected when looking for transient defects or non-synchronous eventsIf possible we take vertical, horizontal <strong>and</strong> axial velocity readings on each bearing inthe system. Unfortunately access problems such as coupling <strong>and</strong> belt guards meanthat it is not always possible to obtainall the readings.To use vibration as a trending tool forcondition monitoring a regularprogramme of data collection isnecessary, but vibration analysis canbe useful at locating problems on amachine, some data collectors can beconnected to strobe lights to ‘stop’ thecomponent that is vibrating, otherscan have an input from a lasertachometer to carry out start up <strong>and</strong>coast down tests to locate momentsof resonance <strong>and</strong> critical speeds.These are classed as analytical tools<strong>and</strong> usually do not form part of routinevibration data collection <strong>and</strong> analysis.To set up a new vibration database an initial survey of the site is needed. Data isacquired from the machines as to the number of measurement points required, speedsof shafts <strong>and</strong> type of machine. A database would then be written on a computer withroutes that are loaded into a data collector. An engineer then tours the plant with thedata collector <strong>and</strong> captures the vibration data. Once all the data is collected it is thendownloaded into the computer. The data is then analysed. More data may be takento confirm analysis <strong>and</strong> recommendations submitted. The report is written <strong>and</strong> isusually with a customer within 5 working days.