Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

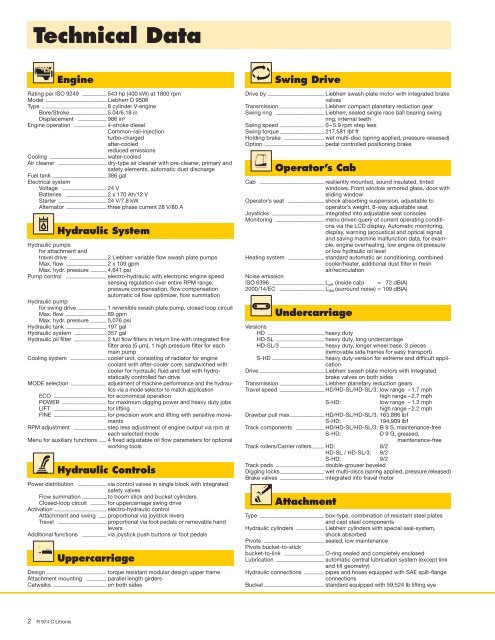

Technical DataEngineRating per ISO 9249 ____________ 543 hp (400 kW) at 1800 rpmModel ______________________________ Liebherr D 9508Type ________________________________ 8 cylinder V-engineBore/Stroke __________________ 5.04/6.18 inDisplacement ______________ 986 in 3Engine operation ________________ 4-stroke dieselCommon-rail-injectionturbo-chargedafter-cooledreduced emissionsCooling ____________________________ water-cooledAir cleaner ________________________ dry-type air cleaner with pre-cleaner, primary andsafety elements, automatic dust dischargeFuel tank __________________________ 386 galElectrical systemVoltage ______________________ 24 VBatteries ____________________ 2 x 170 Ah/12 VStarter ________________________ 24 V/7.8 kWAlternator ____________________ three phase current 28 V/80 AHydraulic SystemHydraulic pumpsfor attachment andtravel drive __________________ 2 Liebherr variable flow swash plate pumpsMax. flow ____________________ 2 x 109 gpmMax. hydr. pressure ________ 4,641 psiPump control ____________________ electro-hydraulic with electronic engine speedsensing regulation over entire RPM range,pressure compensation, flow compensationautomatic oil flow optimizer, flow summationHydraulic pumpfor swing drive ______________ 1 reversible swash plate pump, closed loop circuitMax. flow ____________________ 69 gpmMax. hydr. pressure ________ 5,076 psiHydraulic tank ____________________ 197 galHydraulic system ________________ 357 galHydraulic oil filter ________________ 2 full flow filters in return line with integrated finefilter area (5 µm), 1 high pressure filter for eachmain pumpCooling system __________________ cooler unit, consisting of radiator for enginecoolant with after-cooler core, sandwiched withcooler for hydraulic fluid and fuel with hydrostaticallycontrolled fan driveMODE selection __________________ adjustment of machine performance and the hydraulicsvia a mode selector to match applicationECO __________________________ for economical operationPOWER ______________________ for maximum digging power and heavy duty jobsLIFT __________________________ for liftingFINE __________________________ for precision work and lifting with sensitive movementsRPM adjustment ________________ step less adjustment of engine output via rpm ateach selected modeMenu for auxiliary functions ____ 4 fixed adjustable oil flow parameters for optionalworking toolsHydraulic ControlsPower distribution ______________ via control valves in single block with integratedsafety valvesFlow summation ____________ to boom stick and bucket cylindersClosed-loop circuit ________ for uppercarriage swing driveActivation __________________________ electro-hydraulic controlAttachment and swing ____ proportional via joystick leversTravel ________________________ proportional via foot pedals or removable handleversAdditional functions ____________ via joystick push buttons or foot pedalsUppercarriageDesign ______________________________ torque resistant modular design upper frameAttachment mounting __________ parallel length girdersCatwalks __________________________ on both sidesSwing DriveDrive by ____________________________ Liebherr swash plate motor with integrated brakevalvesTransmission ______________________ Liebherr compact planetary reduction gearSwing ring ________________________ Liebherr, sealed single race ball bearing swingring, internal teethSwing speed ______________________ 0 – 5.9 rpm step lessSwing torque ______________________ 217,581 lbf ftHolding brake ____________________ wet multi-disc (spring applied, pressure released)Option ______________________________ pedal controlled positioning brakeOperator’s CabCab ________________________________ resiliently mounted, sound insulated, tintedwindows. Front window armored glass, door withsliding windowOperator’s seat __________________ shock absorbing suspension, adjustable tooperator’s weight, 6-way adjustable seatJoysticks __________________________ integrated into adjustable seat consolesMonitoring ________________________ menu driven query of current operating conditionsvia the LCD display. Automatic monitoring,display, warning (acoustical and optical signal)and saving machine malfunction data, for example,engine overheating, low engine oil pressureor low hydraulic oil levelHeating system __________________ standard automatic air conditioning, combinedcooler/heater, additional dust filter in freshair/recirculationNoise emissionISO 6396 __________________________ L pA (inside cab) = 72 dB(A)2000/14/EC ______________________ L WA (surround noise) = 109 dB(A)UndercarriageVersionsHD ____________________________ heavy dutyHD-SL ________________________ heavy duty, long undercarriageHD-SL/3 ______________________ heavy duty, longer wheel base, 3 pieces(removable side frames for easy transport)S-HD __________________________ heavy duty version for extreme and difficult applicationDrive ________________________________ Liebherr swash plate motors with integratedbrake valves on both sidesTransmission ______________________ Liebherr planetary reduction gearsTravel speed ______________________ HD/HD-SL/HD-SL/3: low range – 1.7 mphhigh range – 2.7 mphS-HD:low range – 1.3 mphhigh range – 2.2 mphDrawbar pull max. ________________ HD/HD-SL/HD-SL/3: 163,886 lbfS-HD:194,909 lbfTrack components ______________ HD/HD-SL/HD-SL/3: B 9 S, maintenance-freeS-HD:D 9 G, greased,maintenance-freeTrack rollers/Carrier rollers ______ HD: 8/2HD-SL / HD-SL/3: 9/2S-HD: 9/2Track pads ________________________ double-grouser beveledDigging locks______________________ wet multi-discs (spring applied, pressure released)Brake valves ______________________ integrated into travel motorAttachmentType ________________________________ box-type, combination of resistant steel platesand cast steel componentsHydraulic cylinders ______________ Liebherr cylinders with special seal-system,shock absorbedPivots ______________________________ sealed, low maintenancePivots bucket-to-stickbucket-to-link ____________________ O-ring sealed and completely enclosedLubrication ________________________ automatic central lubrication system (except linkand tilt geometry)Hydraulic connections __________ pipes and hoses equipped with SAE split-flangeconnectionsBucket ______________________________ standard equipped with 59,524 lb lifting eye2 R <strong>974</strong> C Litronic