Energy Saving Equipment List (Version3 1)-July09-sent - smallB

Energy Saving Equipment List (Version3 1)-July09-sent - smallB

Energy Saving Equipment List (Version3 1)-July09-sent - smallB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

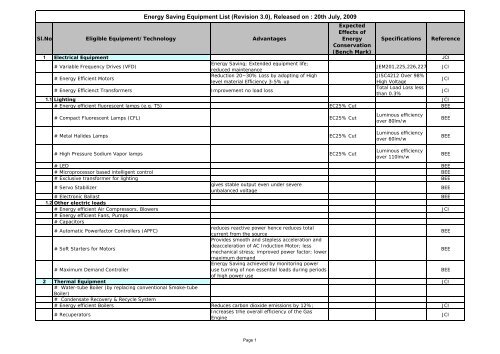

Sl.No Eligible <strong>Equipment</strong>/Technology Advantages# Single Jersey Auto Striper Machines# Terry Knitting Machines# Float Plating Denim Machine# Double Knit electronic Jacquard Machine# Woven Like Corduroy Machine# High Speed Circular Knitting Machines <strong>Energy</strong> saving 20 - 25%14.6 Modern <strong>Energy</strong> Efficient Dyeing System# Grey Heat SettingExpectedEffects of<strong>Energy</strong>Conservation(Bench Mark)SpecificationsReference# Soft Flow / Jet Flow Dyeing Machine (low MLR of 1:5 or lower)# Squeezer with Slit Opener# Balloon Padding# Relax Dryer# Specialty Fabric Finisher such as Brushing, Sueding, Raising,and Compacting# PLC based Package Dyeing Machine# Automatic Hank / Yarn Dyeing Machine14.7 Sewing/Stitching# Direct-drive, High Speed, Lockstitch Machine with AutomaticThread Trimmer# Lockstitch Machine with Automatic Thread Trimmer# Semi-dry-head, High Speed, Overlock Stitch Machine# Computer-controlled, High Speed, Lockstitching ButtonholingMachine# Computer-controlled, High-speed, Lockstitch, Button SewingMachine# High-speed, Flatbed, Top & Bottom Coverstitch Machine# High-speed, Cylinder-bed, Top & Bottom Coverstitch Machine# Computer-controlled, High-speed, Bartacking Machine# Servo-motor Stitching Machines# Clutch Motor Stitching Machines with 3-phase Motor# Computerized Embroidery Machine# Automatic Printing Machine# Industrial Washing / Drying Machine / Tumble Dryers14.8 Yarn ProcessingIndividual inverter driven motor drive system# Draw Winderoffers stepless parameter setting in runningconditions and helps to save energyIndividual inverter driven motor drive system# Air Draw Texturising Machineoffers stepless parameter setting in runningconditions and helps to save energyMaintain leadership in <strong>Energy</strong> Conservation, has# Draw Texturising Machineinverter driven closed loop speed control forindividual drives# Filament Twisting Soultions Electronic NXG Power Saver Control System# Spun Twisting Solutions Electronic NXG Power Saver Control System# Industrial Twisting Solutions Electronic NXG Power Saver Control SystemPage 8

Sl.No Eligible <strong>Equipment</strong>/Technology Advantages# Thread manufacturing Solutions Electronic NXG Power Saver Control System# Crepe Yarn Solutions Electronic NXG Power Saver Control System14.9 Weaving# Water Jet Looms Lowest power per meter of fabric# Air Jet Looms Lowest power per meter of fabricLowest Production cost due to high efficiency# Rapier Looms(90%) then power looms (60%)14.9 Utilities# Water-tube boilers (by replacing conventional Smoke-tubeBoiler)# Condensate Recovery & Recycle System# Heat Recovery Systems for Boilers (E.g. Economizer, Air Preheater)# High efficiency Diesel Generating Sets with high specific energygeneration ratio# <strong>Energy</strong> efficient Fans, Blowers, Pumps# <strong>Energy</strong> efficient Motors# Variable Frequency Drives for Fans, Blowers, Pumps# Automatic Power Factor Controller (APFC)ExpectedEffects of<strong>Energy</strong>Conservation(Bench Mark)Specifications15 Engineering Industry CII# <strong>Energy</strong>-efficient Air CompressorsSEC reduces by0.13 KW/cfmCII# VFDs for Screw Compressors CII# Heat of Compression Air Dryers (Replacing Desiccant Air-45 Deg Dew pointDryer)AchieveCII# VFDs for Oil Pimp in Hydraulic Power Pacs CII# <strong>Energy</strong> efficient Exhaust Fans CII# VFD for Hot Air Circulation Fans in Preheating Furnaces30% speedreductionCII# Ceramic Fiber Insulation for Batch FurnacesOuter temp.50~60 deg C.CII# Air Preheater (for furnace flue gas waste heat recovery) Reduction Oil Consumption CII# CNC Cutting Machine with End Former45%~50% energysaving# Full Automatic CNC Return Bender45%~50% energysaving# Automatic Ring Sizing and Loading Machine45%~50% energysaving# CNC Verticial Machining Centre# Vacuum Holding for Non-Ferrous Components for High SpeedMilling25%~30% energysaving# CNC Co-ordinate measuring machine25%~30% energysaving# CNC SP (Sharpening and Profile Grinding), Automatic BroachShappening Machine# Turning Machine with VFD with Regenerative Braking System# Servo Electric Turret Punch Machine# Abrasive assisted High pressure Water Jet cutting <strong>Energy</strong> <strong>Saving</strong> 20 - 30%Page 9Reference

Sl.No Eligible <strong>Equipment</strong>/Technology AdvantagesExpectedEffects of<strong>Energy</strong> Specifications ReferenceConservation(Bench Mark)# Falling film Evaporator (Re-refining of lubricating oil) Eco-friendy technology CLCSS list# Wiped film evaporator (Re-refining of lubricating oil)# Fine Grinding (CBN Surface Grinding Machine)19 Castings & Forging Industry# Mechanical pneumatic clutch operated Crank type Billetshearing press (Stock Cutting)High Productivity, Low cutting lossCLCSS list# Pneumatic double acting hammer (Forge shop) High production rate, reduced maintenance cost CLCSS list# Microprocessor based energy controlled, pneumatic clutchoperated, Screw friction Presses (Forge shop)# Hydraulic double acting Hammer (Forge shop)# Multi station horizontal Formers (Forge shop)High production rate; controlled blow pattern;low investment; Improved press stiffness; lessspace requirement; good off loading capabilitiesPrecision forging with high production rate &reduced maintenansePrecision forging with post forging operationsminimized; less raw material wastage; highproduction rate; automation feasibleCLCSS listCLCSS listCLCSS list# Hot Shearing Automatic Forging Presses (Forge shop) Microprocessor control, high productivity. CLCSS list# Reduce Rolling Machine (Forge shop)# Gas fired high temperature Furnace with automatictemperature controller & recorder (Heat Treatment)# Fluidized bed heat treatment line with controlled atmosphere &Recuperators (Heating Treatment)Higher production rate, less skill requirement.Capable of making performs of various crosssectional areas and lengths, high productivity.Eco-friendly, reduced scale losses, facilitateautomation, quality improvementEco-friendly; highly energy efficient; minimumtime /energy to come on line; Flexible operationswith adaptability to handle small batches;controlled atmosphere minimizingdecarburisation as well provides flexbilityCLCSS listCLCSS listCLCSS list# Medium Frequency Induction Heaters (Heating Treatment)For controlled depth surface hardening of toolssuch as pipe wrenches jaws, hammers, pliersCLCSS listteeth etc. Improved quality.# Natural Gas fired power generating set (Utility) Eco-friendly, low power cost CLCSS list# CNC Turning Center (Tool Room)Improved quality,high productivity, precisionmachining, eco-friendly.CLCSS list# CNC Milling Machine (Tool Room)Improved quality,high productivity, precisionmachining, eco-friendly.CLCSS list# Electro Discharge Machine (Tool Room)Improved quality,high productivity, precisionmachining, eco-friendly.CLCSS list# CNC Wire Cut Machine (Tool Room)Improved quality,high productivity, precisionmachining, eco-friendly.CLCSS list# Fully Automatic CNC Injection Moulding machine (Tool Room)Modern version, for making handle of screwdrivers and sleeves of pliers.CLCSS list20 Tanning & Leather Processing Industry20.1 Leather and Leather Products# Hydraulic/pneumatic Automatic Counter moulding Machine Faster production and less messy.Page 11

Sl.No Eligible <strong>Equipment</strong>/Technology Advantages# Automatic Seat Lasting Machine (Heal Seat lasting)Accurate, faster and less spacey. Requires lesspeople and also environment friendly.# Automatic Pounding Machine Improves quality of the final products.# Automatic Buffing & Roughing machine with Microprocessorcontrol mechanismPrecision buffing and faster production# Automatic Combined Rougher and Cementer (Buffing andadhesive application)# Cement Dryer & Flash Activator Machine (Drying andReactivation)# Thermo Cementing Machine for Upper & SoleBoth the operations are done by one machine,results in less messy and faster production. Alsoreduce the adhesive wastage.Reduce the space required of the workshop.Increases the production by several fold.Reduce the wastage of adhesive, accurateapplication.# Mackey Sole Stitcher Faster production.# Fine Turning machine (for last) Increase the production of last.# Roughing Machine for plastic blocks Increase the production of last.# Computerized Lasting Turning CAD/CAM CNC controlledMachine including designing and interface softwareEs<strong>sent</strong>ial for last development, accurately copyof any last sampling. A major boon to newproduct development.ExpectedEffects of<strong>Energy</strong>Conservation(Bench Mark)SpecificationsReference# CNC Milling Machine with 3/5 Axis & EDM (CNC sole moulddevelopment)Es<strong>sent</strong>ial for right quality sole mould20.2 Pre-Tanning Section# Single/Double width Fleshing MachineAccuracy and higher productivity will offset thecost.# Single/Double width Uhairing MachineAccuracy and higher productivity will offset thecost.20.3 Tanning Section# Through Feed Double width Machine (Shaving) Split the leather uniformly.# Through Feed Double width Machine (Setting)Speed of production and final quality of leatherimproves.# Double width through feed splitting Machine (Splitting)Speed of production and final quality of leatherimproves.20.4 Finishing Section CLCSS <strong>List</strong># Vacuum DryerUniform and quick drying. Improves the qualityof leather.CLCSS <strong>List</strong># Hydraulic Press with Automatic time and temperaturecontrollerCLCSS <strong>List</strong># Auto Spray with Dryer Uniform spraying & drying. CLCSS <strong>List</strong># VFDs for Pumps for Hot & Cold Water Supply (Pre-tanningSection)<strong>Energy</strong> <strong>Saving</strong>CII <strong>List</strong># Steam Heating (Replacing Electrical Heating) <strong>Saving</strong> <strong>Energy</strong> CII <strong>List</strong># VFD for Screw compressors (Dyeing section) Reduce of overall operating presure. CII <strong>List</strong># VFD for Hydraulic oil system in Vacuum Drier Reduction of <strong>Energy</strong> cost. CII <strong>List</strong># Combined Through Feed Single/Double width Buffing Machinewith Dusting operationAccurate buffing action.# Roto Press and Roto Print Uniform pressing.20.5 Others# <strong>Energy</strong> Efficient Chiller <strong>Energy</strong> <strong>Saving</strong>21 Pharmaceutical & Bulk Drug IndustryPage 12

Sl.No Eligible <strong>Equipment</strong>/Technology Advantages21.1 Tablet and Capsule section# Flash Dryers or Rotary Vacuum Dryers (Product Drying)# Use of Biomass Gasifier with Slurry Economizer (Incinerator)# Nauta Mixers (Blenders)Low cost drying with minimum or no handling;Instant drying with no pulverizing; low initialinvestment as compared to Spray DryerUse of alternative fuels like rice husk, saw millwaste; heat recovery; less cost;<strong>Energy</strong> Efficient; no breaking of Grains; lessdusting and no manual charging & dischargingExpectedEffects of<strong>Energy</strong>Conservation(Bench Mark)SpecificationsReferenceCLCSS <strong>List</strong>CLCSS <strong>List</strong>CLCSS <strong>List</strong>21.2 Industry based on medicinal and Aromatic Plants CLCSS <strong>List</strong># VFD for fluidized bed boiler blower CII <strong>List</strong># Condensate recovery & recycle system for boiler feedwater CII <strong>List</strong>22 Dyes & Intermediates CLCSS <strong>List</strong># Flaker with Silo and Screw Conveyer (Ice Flaker)Automatic operation; no spillage and loss ofenergy; no water losses and latent heat lossCLCSS <strong>List</strong>23 Cement Industry CII# High efficiency Dynamic Separator for Raw Mill Increased output CII# Air lift to Bucket Elevator CII# Low Pressure drop Cyclone Increase of output CII# Use alternative fuel storage, conveying & firings system assupplement to coal in Calciner FiringCII# VFDs for Cooler Fans Avoid damper loss CII# Low pressure Air Burner CII# High efficiency Crusher Increase in capacity CII# Cogeneration from Kiln Preheater and Cooler Exhaust CII# Pre-Grinder# Waste Heat Recovery Power Generation from Kiln ExhaustUtilisation of waste heatgases# Power Generation from Kiln Exhaust gases# Slip Power Recovery System# Soft Starters for Motors# <strong>Energy</strong> efficient Fans# Vertical Roller Mill# Pre-Grinder / Roller Press# Multi-channel Burner# Bucket Elevator (in place of pneumatic conveying)# Fuzzy Logic/Expert Kiln Control System# Improved Ball Mill Internals# High Efficiency Grate Cooler24 Chloro Alkali Industry CII# Vacuum Pump (replacing Steam Jet Ejector) CII# VFD for Chlorine Compressor CII# Centrifugal Screw Compressor for HVAC system (replacingReciprocating system)CII# Cogeneration System CII# Membrane technology (replacing Mercury Cell) CIIPage 13

Sl.No Eligible <strong>Equipment</strong>/Technology AdvantagesExpectedEffects of<strong>Energy</strong> Specifications ReferenceConservation(Bench Mark)25 Fertilizer Industry CII# VFD for Sulfur Pump Saves <strong>Energy</strong> CII# Pipe Reactor in Complex Plant CII# Vapor Absorption Refrigeration Reduction of Power CII# Replace Old PRDS Valves with Superior Valves Reduction of Steam CII# Waste Heat Boiler for Diesel Generating Set Exhaust CII# Mechanical Conveying instead of Pneumatic conveying(Phosphoric Acid Plant)CII26 Sugar Mills CII# Diffusers in lieu of Milling Tandem<strong>Energy</strong> Consumption gets reduced by 6.4 kWhper ton caneCII# Conical Jet Nozzles for mist Cooling System Reduction of Cooling <strong>Energy</strong> CII# Jet Condenser with External Extraction of Air Drops of Water Consumption gets reduced CII# Electric DC Motor Drives in place of Steam Driven Mill Drives 850kW/mill saving CII# Extensive Vapor Bleeding system at Evaporators CII# VFD for weighed Juice Pump 30~40% reduction in power CII# Hydraulic Drives for Mill Prime Movers Stable operation, Reduced Maintenance CII# Fully Automated Continuous Vacuum Pans CII27 Mini Steel Plants# Blast Furnace Hot Stove Heat Recovery NEDO Model# Coal Moisture Control System NEDO Model# Power Generation from Blast Furnace Exhaust gases NEDO Model# Sinter Cooler Waste Heat Recovery NEDO Model# Coke Dry Quenching NEDO Model# Waste Gas Recovery from Oxygen Converter NEDO Model# High efficiency Combustion Control System in Pre-HeatingFurnaceNEDO Model# Heat Recovery from Blast Furnace Hot Stove Waste Gases NEDO Model28 Metal Industry NEDO Model# High efficiency Industrial Furnace in Aluminum Factory NEDO Model29 Chemicals# Regenerative furnace & refractory recuperator <strong>Energy</strong> saving 25-30%# Co2 Flue gas Recovery Plant based on Flue gas system <strong>Energy</strong> saving 30%30 Plastics & Polymers# Multi Layer film extruder <strong>Energy</strong> saving 25-30%# Solvent less lamination Machine# Servo Motor Plastic Injection Machine <strong>Energy</strong> saving 30-70%# PET Moulding machine <strong>Energy</strong> saving 40-45%31 RETs# Wind energy (Windmills)# Solar energy (Photovoltaic)# Micro hydro# Biomass / Bagasse (Gasifier or Cogeneration)# Municipal solid waste# Biomass Gasifier based hot water Generator# Solar Water HeaterPage 14

Sl.No Eligible <strong>Equipment</strong>/Technology Advantages32 Steel Rerolling Mills# Pusher type reheating furnace with suspended roof, multi fuelcapacity and automated temperature controlsHighly efficient over conventional arch rooffurnace with single fuel firing limitation, energysaving 20 - 30 %# Provision of IR sensors for material movementMinimum heat loss, automation with feedbackcontrol# AC and DC drives for control of fuel and air energy saving 10 - 30 %# Liquid and gaseous fuel ratio controllers, ratiotrols energy saving 10 - 15 %# Heating and pumping units energy saving 5- 10 %# High efficiency burners with multifuel capacity energy saving 5 - 10 %# Semi automatic high speed rolling stands with DC drivesautomation, high speed production, energysaving 20 - 30 %# <strong>Energy</strong> efficient motors with VFD energy saving 10 - 30 %# Dry type starter for slip ring motor energy saving 4 - 5 %ExpectedEffects of<strong>Energy</strong>Conservation(Bench Mark)SpecificationsReferencePage 15