Microsoft Word - DRIMS-#4627288-v1-Pluto_LNG_ ... - Woodside

Microsoft Word - DRIMS-#4627288-v1-Pluto_LNG_ ... - Woodside

Microsoft Word - DRIMS-#4627288-v1-Pluto_LNG_ ... - Woodside

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

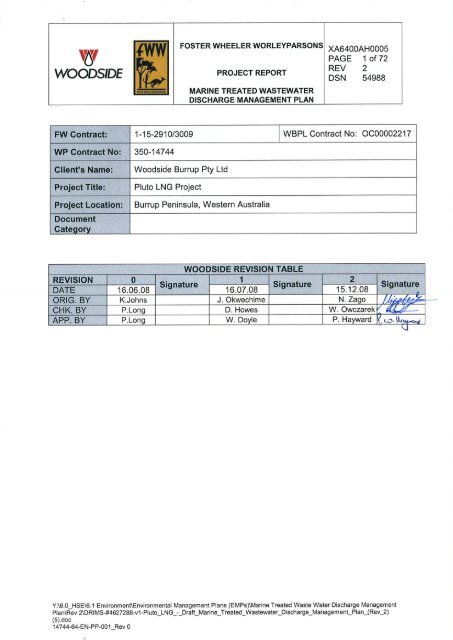

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 3 of 70REV 2DSN 54988TABLE OF CONTENTS1. INTRODUCTION 41.1 Purpose 41.2 Approval and Distribution 41.3 Acronyms and Abbreviations 82. OVERVIEW OF WASTEWATER COLLECTION, TREATMENT ANDDISPOSAL 102.1 Re-use and Disposal Philosophy 102.2 Wastewater Collection, Treatment and Disposal Systems Design 113. MARINE TREATED WASTEWATER DISCHARGE MANAGEMENT PLAN173.1 Management Plan Objectives 173.2 Multi-User Brine Return Line Outfall Zone - Environmental Values,Environmental Quality Objectives, Levels of Ecological Protection 183.3 Discharge Regime and Flow Rate 183.4 Material Balance and Inventories from Effluent Treatment Plant 203.5 Compliance with Relevant Guidelines and Environmental Impacts 283.6 Water Quality Monitoring Programme 353.7 Implementation of the Marine Treated Wastewater Discharge ManagementPlan 374. CONTINGENCY WASTEWATER MANAGEMENT PLAN 404.1 Availability and Sparing Philosophy 404.2 Emergency Preparedness and Response 404.3 Management Options for Out of Specification Effluent 415. DOCUMENTS 425.1 References 425.2 Figures 445.3 Appendices 44Appendix A Assessment of Best Practice Technologies for Contaminant and NutrientMinimisationAppendix B Assessment of <strong>Pluto</strong> Toxicity Effluent and Fate (SKM 2008)Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 4 of 70REV 2DSN 549881. INTRODUCTION1.1 PurposeThis Marine Treated Wastewater Discharge Management Plan (MTWDMP) hasbeen developed to ensure that disposal of treated wastewater from operation ofthe <strong>Pluto</strong> <strong>LNG</strong> Project (the Project) is undertaken and managed in a way thatreduces the environmental impacts to as low as reasonably practical (ALARP).The MTWDMP also incorporates the requirements of Ministerial StatementNo. 747, subsequently updated to 757. Table 1 outlines the sections within theMTWDMP where each of these requirements is addressed.1.2 Approval and DistributionThe MTWDMP will be implemented upon approval of the Western AustralianMinister for the Environment.Once approved, it will be made publicly available via <strong>Woodside</strong>’s <strong>Pluto</strong> <strong>LNG</strong>Project website:http://www.woodside.com.au/Our+Business/Projects/<strong>Pluto</strong>/Approval+Process/Environmental+Approval.htmThis MTWDMP will be reviewed prior to commencement of operations andperiodically throughout the life of the <strong>Pluto</strong> Project to ensure that anyimprovements and/or changes in wastewater management are reflected in thisPlan. Revised Plans will be provided to the DEC for approval where significantchanges in wastewater management are proposed and when the <strong>Pluto</strong> Onshore<strong>LNG</strong> Processing Plant Licence, issued under Part V of the EnvironmentalProtection Act 1986 (EP Act), is obtained (projected 2010).Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 5 of 70REV 2DSN 54988Table 1: Cross Reference of the MTWDMP with Ministerial Statement No. 757 - Section 7Deepwater Marine Outfall Conditions under Ministerial Statement No. 7577-1 If a marine wastewater discharge is required by the proponent, the proponent shallconstruct the associated infrastructure so that wastewater is discharged into water of depthgreater than 30 metres outside the Dampier Archipelago, unless otherwise determined bythe CEO under Part V of the Act.7-2 Prior to construction of the wastewater treatment plant or the marine outfall, whichever isthe sooner, the proponent, in consultation with Department of Environment andConservation, shall prepare a Marine Treated Wastewater Discharge Management Plan tothe requirements of the Minister for the Environment on advice of the EnvironmentalProtection Authority.The objective of this Plan is to ensure that the discharge of treated wastewater is managedto achieve simultaneously the following Environmental Quality Objectives as described inthe document, Pilbara Coastal Water Quality Consultation Outcomes: EnvironmentalValues and Environmental Quality Objectives (Department of Environment, March 2006):• Maintenance of ecosystem integrity with spatially-assigned levels of protection;• Maintenance of aquatic life for human consumption assigned to all parts of the marineenvironment surrounding the ocean outlet;• Maintenance of primary contact recreation values assigned to all parts of the marineenvironment surrounding the ocean outlet;• Maintenance of secondary contact recreation values assigned to all parts of the marineenvironment surrounding the ocean outlet;• Maintenance of aesthetic values assigned to all parts of the marine environmentsurrounding the ocean outlet;• Maintenance of cultural and spiritual values assigned to all parts of the marineenvironment surrounding the ocean outlet; and• Maintenance of Industrial Water Supply.This Plan shall address the following:1. determination of the effect of wastewater flow rate on the number of dilutions the diffuseris predicted to achieve within the zone of initial dilution at maximum flow rate;2. setting of environmental values, environmental quality objectives and levels of ecologicalprotection to be achieved around the outfall;3. identification of a range of feasible and practical management options and theenvironmental quality indicators and associated “trigger” levels for the implementation ofremedial, management and/or preventative actions to protect the water quality and themarine environment based on the guidelines and recommended approaches inANZECC/ARMCANZ (2000);4. Whole Effluent Toxicity (WET) testing of wastewater, consistent with ANZECCrequirements, and addressing the items in schedule 5 (attached);5. redesign and incorporation of a new diffuser, including timelines, in the event that theWET testing results show that the original wastewater diffuser is not achieving sufficientdilutions to meet a high level of ecological protection at the edge of the mixing zone;6. verification of diffuser performance in terms of achieving the required number of initialdilutions under low energy/calm meteorological and sea-state conditions to achieve a highlevel of ecosystem protection (99% species protection) at the edge of the approved mixingzone;MTWDMP SectionSection 2.1(NB: WorksApproval includedin separateapplicationdocument)Section 3 andSection 4Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 6 of 70REV 2DSN 54988Table 1: Cross Reference of the MTWDMP with Ministerial Statement No. 757 - Section 7Deepwater Marine Outfall Conditions under Ministerial Statement No. 7577. a monitoring program to permit determination of whether the water quality objectives arebeing met; and8. protocols and schedules for reporting performance against the Environmental QualityObjectives using the environmental quality trigger levels.7-3 The proponent shall implement the Marine Treated Wastewater Discharge ManagementPlan required by condition 7-2.7-4 The proponent shall make the Marine Treated Wastewater Discharge Management Planrequired by condition 7-2 publicly available in a manner approved by the CEO.7-5 Prior to submitting a Works Approval application for the wastewater treatment plant, theproponent shall:1. characterise in detail the physical and chemical composition and flow rates of allwastewater streams within the site and, using the toxicity of mixtures principles, predict thetheoretical toxicity of the combined wastewater after treatment;2. determine, for all contaminants and nutrients, the total annual loads of contaminants andnutrients in the wastewater discharge exiting the site; and3. determine, for normal and worst-case conditions, the concentrations of contaminantsand nutrients (for agreed averaging periods) in the wastewater discharge exiting the site.7-6 Prior to submitting a Works Approval application for the wastewater treatment plant, theproponent shall demonstrate that the wastewater discharge will meet “best practicabletechnology” and waste minimisation principles for contaminants and nutrients.7-7 Prior to submitting a Works Approval application for the wastewater treatment plant, theproponent shall design, and subsequently operate, plant and equipment on the site suchthat:1. the contaminant concentrations in the wastewater effluent from the site, just prior to entryto the wastewater discharge system, meet (in order of preference):• the ANZECC/ARMCANZ (2000) 99% species protection level; or• the ANZECC/ARMCANZ (2000) 99% species protection level at the edge of anapproved mixing zone;2. the concentrations of contaminants in the wastewater effluent which can potentially bioaccumulate/ bio-concentrate meet the ANZECC/ARMCANZ (2000) 80% speciesprotection trigger levels just prior to entry into the wastewater discharge system; and3. mass balances and inventories of toxicants can be maintained throughout the life of theplant so that their fate can be traced.7-8 Within three months following commissioning and stabilising of plant operations, theproponent shall conduct an analysis of effluent properties and contaminant concentrations,to an analytical limit of reporting agreed by the Department of Environment andConservation, demonstrating that they are substantially consistent with predictions.7-9 Prior to operation, the proponent shall develop a Contingency Wastewater ManagementPlan which considers alternate options for wastewater disposal in the event that theEnvironmental Quality Objectives are not met as determined through Whole EffluentToxicity testing, diffuser performance monitoring or environmental quality monitoring, to therequirements of the Minister for the Environment.7-10 In the event that the treatment plant malfunctions or goes off-line, the proponent shallinclude within the Contingency Wastewater Management Plan required by condition 7-9alternative options for wastewater disposal to the timing and other requirements of theMinister for the Environment.MTWDMP SectionSection 1.2 andSection 3.7Section 1.2 andSection 3.7Section 3 andAppendix B(NB: WorksApproval includedin separateapplicationdocument)Appendix ASection 3.4 and3.5(NB: WorksApproval includedin separateapplicationdocument)Section 3.6Section 4Section 4Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 7 of 70REV 2DSN 54988Table 1: Cross Reference of the MTWDMP with Ministerial Statement No. 757 - Section 7Deepwater Marine Outfall Conditions under Ministerial Statement No. 7577-11 In the event that the Environmental Quality Objectives are not being met, the proponentshall implement the Contingency Wastewater Management Plan required by condition 7-9.7-12 The proponent shall review and revise the Contingency Wastewater Management Planrequired by condition 7-9, as and when directed by the CEO.7-13 The proponent shall make any revisions of the Contingency Wastewater ManagementPlan, as required by condition 7-12, publicly available in a manner approved by the CEO.MTWDMP SectionSection 4Section 4Section 4Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 8 of 70REV 2DSN 549881.3 Acronyms and AbbreviationsALARPaMDEAANZECCAOCARMCANZBATBOD 5 / BODBPMBTEXCDCDFCFUCOCCODCO 2CPIDCSDECDOEOFEPAAs Low As Reasonably Practicalactivated Methyl Di-Ethanol AmineAustralian and New Zealand Environment and Conservation CouncilAccidentally Oil Contaminated (drainage system)Agriculture and Resource Management Council of Australia and New ZealandBest Available TechnologyBiochemical Oxygen Demand (5 day)Best Practicable MeasuresBenzene, Toluene, Ethyl Benzene, XyleneClosed Drainage (system)Controlled Discharge FacilityColony-Forming UnitsContinuously Oil Contaminated (drainage system)Chemical Oxygen DemandCarbon DioxideCorrugated Plate interceptorDistributed Control SystemDepartment of Environment and ConservationDissolved OxygenEntirely Oil-Free (drainage system)Environmental Protection AuthorityEP Act Environmental Protection Act 1986EQCEQGEQMFEQOETPEVFWWHATLATLEP<strong>LNG</strong>MBRMCCMEGEnvironmental Quality CriteriaEnvironmental Quality GuidelineEnvironmental Quality Management FrameworkEnvironmental Quality ObjectiveEffluent Treatment PlantEnvironmental ValueFoster Wheeler WorleyParsonsHighest Astronomical TideLowest Astronomical TideLevel of Ecological ProtectionLiquefied Natural GasMembrane BioReactorMotor Control CentreMono Ethylene GlycolY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 9 of 70REV 2DSN 54988MLMPNMPPEMUBRLMTWDMPPACPEPSUPWRASRORWPSTPTDSTOCTIDSTSSUVMega litreMost-Probable-NumberMacro Porous Polymer ExtractionMulti User Brine Return Line (part of Water Corporation’s infrastructure for BurrupPeninsula Desalinated Water and Seawater Supplies Project).Marine Treated Wastewater Discharge Management PlanPowdered Activated CarbonPopulation EquivalentPractical Salinity UnitProduced WaterReturn Activated SludgeReverse OsmosisRecovered Water PlantSewage Treatment PlantTotal Dissolved SaltsTotal Organic CarbonTotal Inorganic Dissolved SaltsTotal Suspended SolidsUltra violetµL Micro litresWAWBPLWETWWWWTPWestern Australia<strong>Woodside</strong> Burrup Pty LtdWhole Effluent ToxicityWaste WaterWastewater Treatment PlantY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 10 of 70REV 2DSN 549882. OVERVIEW OF WASTEWATER COLLECTION, TREATMENT ANDDISPOSAL2.1 Re-use and Disposal PhilosophyThroughout the <strong>Pluto</strong> Project environmental assessment process, both State andCommonwealth regulators advised that wastewater discharges to Mermaid Soundshould be avoided and all options for reuse to be exhausted before a discharge iscontemplated (refer to Environmental Protection Authority (EPA) Bulletin 1259).As a consequence, various water recovery studies and re-use options have beenassessed by <strong>Woodside</strong> (FWW 2006, FWW 2008). The most significant outcomeof these investigations included the revision of the reference case for wastewatertreatment to provide for extensive treatment of all wastewater streams to meetplant service water specifications. This enables extensive reuse of treatedwastewater within the <strong>Pluto</strong> <strong>LNG</strong> plant resulting in substantially reduced surplusvolume requiring disposal.However, water balance studies indicate that treated effluent will at times be inexcess of on-site service water demand. Furthermore, no re-use application hasbeen identified for the concentrate stream from the <strong>Pluto</strong> demineralised (Demin)water plant. Thus “zero discharge” is impractical without considering otherdisposal options.Initial discussions between <strong>Woodside</strong> and third parties on the potential market for<strong>Pluto</strong>'s excess treated reuse water were positive. However, any agreement with athird party to accept <strong>Pluto</strong>'s treated water requires a reliable/predictable supply. Inthe short to medium term the <strong>Pluto</strong> facilities will utilise all of the normal producedvolume of reuse water. Volumes in excess of the <strong>Pluto</strong> site requirements will onlybe available on an infrequent and unplanned basis, primarily associated with stormevents. Therefore, given the uncertainty associated with volumes that could bemade available for third party reuse, discussions with third parties have beensuspended. However, as the <strong>Pluto</strong> wellfield ages, produced water quantities areexpected to increase and will eventually result in reuse water quantities thatconsistently exceed <strong>Pluto</strong> site service water requirements. At that stage,<strong>Woodside</strong> commit to re-commence discussions with interested parties.Thus, the option to discharge to the ocean needs to be retained to provide adisposal route for demineralised water plant concentrate and infrequent volumes ofexcess treated effluent. Options for ocean discharge considered (<strong>Woodside</strong> 2008)included:1. Discharge into water of depth greater than 30 m outside the DampierArchipelago (refer to Ministerial Condition 7-1),2. Discharge via a purpose built diffuser located at the end of the <strong>Pluto</strong> exportjetty, andY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 11 of 70REV 2DSN 549883. Discharge into Water Corporation’s existing multi-user brine return line(MUBRL) with outfall located in King Bay.Option ‘2’ was included as the base case in the PER; however, in line withregulatory and stakeholder preference (refer to EPA Bulletin 1259), option ‘3’ wasalso taken forward for detailed consideration. In summary, discharge to WaterCorporation’s existing MUBRL has now been adopted as the preferred approachbased on environmental grounds given:• the outfall and mixing zone has environmental approval (refer to MinisterialStatement 594);• ANZECC (2000) guidelines are met at the point of discharge into the MUBRLfor most contaminants, and at the edge of the approved mixing zone for allcontaminants;• the option utilises an existing outfall and support infrastructure; and• the outfall has sufficient line capacity to receive surplus treated effluent fromthe <strong>Pluto</strong> Project.Option ‘1’ would involve construction of a pipeline on the seabed, approximately25 to 35 km long. This option has been eliminated from further assessment due topotential seabed and coral impacts associated with pipeline construction, capitalexpenditure (estimated to be in excess of $50 million) and the operational costsassociated with pumping and maintenance. In addition, the ETP has beendesigned to maximise reuse of wastewater, as plant service water, hence, it isconsidered unwarranted to require <strong>Woodside</strong> to construct a 25 – 35 km pipeline todischarge surplus or non-routine discharges of wastewater treated to meet a highspecification.2.2 Wastewater Collection, Treatment and Disposal Systems DesignProvided in Sections 2.2.1 to 2.2.7 is a brief summary of the systems selected forthe collection, treatment, re-use and disposal of wastewater streams for the <strong>Pluto</strong>Project.A wastewater process flow diagram is provided in Figure 1. Further detail relatingto the design and selection of best practice technologies is contained withinAppendix A.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 12 of 70REV 2DSN 54988Figure 1 – <strong>Pluto</strong> Effluent Treatment and Reuse Process SchematicY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 13 of 70REV 2DSN 549882.2.1 Effluent Streams, Collection and Drainage SystemsDrainage systems shall be provided to ensure the segregation and direction toappropriate treatment and/or disposal facilities of effluent from the process, utilitiesand contaminated surface water streams, as well as domestic effluent from the<strong>LNG</strong> Plant site. These effluent streams and collection systems are described inthe following paragraphs below.Entirely Oil-Free (EOF) - open surface water drainage system designed to collectand direct clean water from outside of kerbed areas around process facilities (SiteB) and bunded areas around the storage tanks (Site A and B). There is no risk ofcontamination of EOF water from the <strong>Pluto</strong> <strong>LNG</strong> facilities. The EOF drainagesystem shall direct EOF water via a network of open channels, ditches, sumps andpipes where it can be disposed of to natural drainage lines around the site, withouttreatment. In the event of a spill within EOF areas, implementation of spillresponse procedures will ensure immediate cleanup of spills from EOF surfacesand maintain clean EOF areas.Accidentally Oil-Contaminated (AOC) - collection of surface water run-off bymeans of a network of surface drain channels and liquid filled underground pipeheaders, which discharge effluent under gravity to the Controlled DischargeFacility (CDF). AOC drainage areas are considered to be areas in which an oilyemission is not expected to occur during normal operation, but which is at risk ofaccidental contamination with oil or other contaminants, i.e. accidental spills.Accidental spillages shall be contained by kerbs or floor slopes in the processareas and bunds for storage tank areas. AOC areas are designed to limit ingressof rain and prevent overflow to the surrounding paved areas. Implementing spillresponse procedures will also ensure immediate clean-up of spillages from AOCsurfaces and maintain clean kerbed and bunded areas. Once collected in theCDF, AOC water will be tested and either forwarded for treatment if contaminatedor released to the environment if not contaminated.Continuously Oil-Contaminated (COC) - drainage system collects any oilyleakages from equipment by localised kerbs, drip trays, drain trays, funnels, etc.Collected COC effluent shall be directed (via vacuum tanker or direct pumping) tothe oily water equalisation tanks within the effluent treatment plant (ETP) for furtherprocessing. COC sources include equipment or packages with a high potential forlubrication oil leakage (e.g. pumps, gearbox, compressor skids and hydraulicpackages) and the jetty head (condensate loading arm).Process Closed Drainage systems (CD) – includes closed process drainagesystems within the acid gas removal area containing amine compounds (aMDEA),and within the mono ethylene glycol (MEG) regeneration area containing MEG.CD systems are considered part of the unit, whereby drainage is recovered intothe process, and fluids are not discharged to the oily water drainage systems orETP.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 14 of 70REV 2DSN 54988Produced Water (PW) – is primarily condensed water with a small amount offormation water. The condensed water flow is expected to be relatively consistent;however, formation water is expected to increase in volume with time as thewellfield ages. PW will be dissolved into the MEG phase in the offshore trunk lineand will be carried onshore as a multiphase mixture of gas, condensate andMEG/water. Onshore, the MEG/water phase shall be separated from thehydrocarbon gas and condensate in the slug catcher and the MEG/water phasesent to the MEG regeneration system.The aqueous vapour phase overhead from the MEG distillation process shall becondensed to produce, effectively, distilled water with some MEG and benzene,toluene, ethyl benzene and xylene (BTEX), which is pumped directly to the ETP fortreatment.2.2.2 Process Effluent Management and Treatment SystemsThe process effluent management and treatment systems include:• Effluent segregation and drainage collection (as described above).• Controlled Discharge Facility (CDF) - all AOC effluents from the plant areasshall be discharged through an under ground header and/or open channels tothe central CDF inlet channel. The function of the CDF is to segregate AOCdrainage and direct it to the ETP; this system also caters for rain water runoffand allows for segregation, inspection and testing of water quality before adecision is taken to discharge to the EOF surface water system if notcontaminated, or to the ETP for further treatment if contaminated. The basinswill be constructed from reinforced concrete and incorporate a first flushcompartment and a peak overflow compartment.• Effluent Treatment Plant (ETP) - for treatment of COC, contaminated AOC andproduced water. The <strong>Pluto</strong> ETP provides primary, secondary and tertiarytreatment of contaminated water prior to reuse or marine discharge via theMUBRL. These treatment systems are detailed further in the sections below.2.2.3 Primary Waste Water Treatment• Oily Water Equalisation - equalisation of the COC effluents, MEG Overheads(PW) and contaminated AOC effluent shall be provided within the oily waterequalisation tanks, which ensures homogeneity of influent flow and reducescontaminant load variations to provide a relatively consistent feed stream todownstream processes.• Oil Slops Tanks - collect free hydrocarbons separated from within the ETP.Free hydrocarbons shall arise from the CDF (from floating oil skimmers), oilywater equalisation (from in-tank oil skimmers), oily floats from the corrugatedplate interceptor (CPI) and recovered hydrocarbons from the macro porouspolymer extraction (MPPE) unit. Aqueous supernatant from the oil slops tanksshall be decanted into the effluent treatment plant COC drainage system. Oilslops shall be pumped to the condensate storage tanks.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 15 of 70REV 2DSN 54988• Corrugated Plate Interceptor (CPI) - provides removal of free hydrocarbonsand settleable sludges. Free hydrocarbons (oily floats) will drain to the oilslops tanks. Silty sludges shall be either transferred by vacuum tanker to thesludge digester tanks or tankered offsite for disposal at an approved facility.• Effluent Neutralisation - pH correction is provided for upstream of MPPE,with further pH correction prior to secondary treatment.• Effluent Cooling - to achieve stable operation and optimise biologicaltreatment, the effluent temperature shall be cooled by two-stage cooling usingevaporative cooling water and chilled water cooling.• Macro Porous Polymer Extraction (MPPE) - the BTEX compounds presentin the condensed overhead phase from the MEG regeneration process arepotentially inhibitory to bacterial growth. The MPPE unit shall reduce theBTEX contaminant levels prior to subsequent biotreatment.2.2.4 Secondary (Biological) Waste Water TreatmentBiological treatment to degrade soluble hydrocarbons and MEG shall be providedby the use of membrane bioreactors (MBR). The MBR package is an activatedsludge process which uses a semi-permeable membrane barrier system toseparate the treated effluent from the organics degrading micro-organisms. Theactivated sludge micro-organisms degrade the soluble organics to generate CO 2and excess biomass cells.Given there are no significant nutrient sources for the biomass identified in thefeed effluent stream to the ETP, the effluent will normally be dosed with nutrientsto sustain the biological treatment process, which is required to degrade solublehydrocarbons and MEG. Optimal dosing will ensure that a minimum nutrient levelis maintained to sustain biological growth within the MBR, whilst also minimisingexcess nutrient discharge via the MUBRL (Multi User Brine Line). Furtherdiscussions relating to nutrients are included in Section 3.51.2.2.5 Sludge Treatment and Disposal• Sludge Digestion - excess biosludge from the industrial biological treatmentMBR shall be pumped direct to the aerobic biosludge digester. Oily watersludges shall be transferred by vacuum tanker from the CPI sludge or offsitefor disposal by an approved contractor. The aerobic biosludge digester hastwo functions; it reduces sludge mass by aerobic endogenous degradationand provides biosludge holding capacity.Sludge Handling - the stabilised sludge shall be tankered offsite fordisposal by and approved contractor.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 16 of 70REV 2DSN 549882.2.6 Tertiary Waste Water TreatmentThe membranes contained in the MBR are ultrafiltration membranes capable ofremoving suspended solids and bacteria solids down to virus size (

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 17 of 70REV 2DSN 549883. MARINE TREATED WASTEWATER DISCHARGE MANAGEMENT PLAN3.1 Management Plan ObjectivesIn accordance with Ministerial Condition 7-2, the objective of this Plan is to ensurethat the discharge of treated wastewater is managed to achieve the followingEnvironmental Quality Objectives, as described in the document Pilbara CoastalWater Quality Outcomes: Environmental Values and Environmental QualityObjectives (DoE 2006):• Maintenance of ecosystem integrity with spatially-assigned levels ofprotection;• Maintenance of aquatic life for human consumption assigned to all parts of themarine environment surrounding the ocean outlet;• Maintenance of primary contact recreation values assigned to all parts of themarine environment surrounding the ocean outlet;• Maintenance of secondary contact recreation values assigned to all parts ofthe marine environment surrounding the ocean outlet;• Maintenance of aesthetic values assigned to all parts of the marineenvironment surrounding the ocean outlet;• Maintenance of cultural and spiritual values assigned to all parts of the marineenvironment surrounding the ocean outlet; and• Maintenance of Industrial Water Supply.To achieve the above objectives, the proposed wastewater treatment and disposaloperations will be managed to reduce the risk of environmental impacts to ALARP.This will be achieved through implementation of “best practicable technology” inwastewater treatment, whole effluent toxicity (WET) testing to determine thetoxicity of the wastewater, day to day operational environmental management, acomprehensive monitoring programme and contingency measures.An assessment of worldwide best practicable technology for wastewater treatmentand the application of best practicable technology for <strong>Pluto</strong> wastewatermanagement is included in Appendix A.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 18 of 70REV 2DSN 549883.2 Multi-User Brine Return Line Outfall Zone - Environmental Values,Environmental Quality Objectives, Levels of Ecological ProtectionThe Pilbara Coastal Water Quality Consultation Outcomes: Environmental Valuesand Environmental Quality Objectives was released in March 2006 (DoE 2006).This document establishes an Environmental Quality Management Framework(EQMF) and presents interim environmental goals (Environmental Values, EVs,and Environmental Quality Objectives, EQOs) and spatially allocates these goals(Levels of Ecological Protection, LEPs) for state waters of the Pilbara coast.While there are no specific levels set for water quality parameters, the aim of theratings of high, moderate and low LEPs are considered to be equivalent to theANZECC (2000) guidelines for species protection, such that the high LEP isequivalent to the 99% Species Level of Protection and the moderate LEP isequivalent to the 90% Species Level of Protection, and the low LEP is equivalentto the 80% Species Level of Protection from ANZECC (2000).The 0.01 km 2 mixing zone around the MUBRL outfall has been afforded a low LEPand, at the edge of the mixing zone, a high LEP has been assigned (refer to DoE2006, Map 9, note 4). <strong>Woodside</strong> intend to use a moderate LEP (90% SpeciesLevel of Protection) in the mixing zone as a trigger level for further investigation.<strong>Woodside</strong> intends to implement the following trigger levels:- meeting ANZECC 90% species protection at end of pipe (contaminants)- meeting ANZECC 80% species protection at end of pipe (bioaccumulants/bioconcentratation)- meeting ANZECC 99% species protection at end of mixing zone.The discharge of wastewater through the MUBRL into King Bay is regulatedthrough Ministerial Statement 594 as part of Water Corporation’s DesalinatedWater and Seawater Supplies Project. As a result, <strong>Woodside</strong> has a contractualrequirement with the Water Corporation to achieve specified criteria fortemperature, concentration of biocide and antiscalent at the point of discharge intothe MUBRL.3.3 Discharge Regime and Flow Rate3.3.1 Discharge from <strong>Pluto</strong> ETP to the MUBRLThe current design assumes batch discharge to the MUBRL from the finalinspection tanks. The discharge will be intermittent and each batch will be testedor characterised prior to release. Any batch of effluent that does not meetdischarge criteria will not be discharged to the brine line. Given that discharge willbe batch discharge, instead of continuous discharge, averaging periods are notconsidered to be applicable.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 19 of 70REV 2DSN 54988When discharging, the discharge flow will be 104 m 3 /hr and will vary in frequencydepending on a number of operational parameters including:• <strong>Pluto</strong> well-field water production (i.e. during early years of operation wellfieldproduced water volume is low, and as the wellfield ages produced watervolume increases);• Status of MEG recovery operations;• Significant rainfall in past 3 days; and• Service water and demineralised water demand.Note that the following assumptions have been made:• Flow into final inspection tanks is of constant composition, and• “Shut-down” events are not regular or prolonged enough to significantly raisecontaminant concentrations or volumes to the MUBRL and subsequentlybreach guidelines.Summarised below in Table 2 are operating scenarios that typify the minimum,maximum and average discharge scenarios over the life of the <strong>Pluto</strong> Project.Table 2 – Operating Discharge ScenariosScenario1 - Min PW flow anddry weather2 - Min PW flowand wet weather3 - High PW flowand dry weather4 - High PW flowand wet weatherScenarioDescriptionAll treated effluentrecovered & reusedas service water anddemin feed.Only a portion oftreated effluentreused as servicewater, i.e. excessto requirements.Slight excess oftreated effluentproduced beyondservice waterrequirements.Only a portion oftreated effluentreused as servicewater, i.e. excessto requirements.EffluentStream(s)dischargedto MUBRLRO concentrate andbrine wastes fromdemin plant.Excess treatedeffluent, ROconcentrate andbrine wastes fromdemin plant.Excess treatedeffluent, ROconcentrate andbrine wastes fromdemin plant.Excess treatedeffluent, ROconcentrate andbrine wastes fromdemin plant.DischargeVolumeAverage 40 m 3 perday (intermittentdischarge).Average 600 m 3per day(intermittentdischarge).Average 170 m 3per day(intermittentdischarge).Average 600 m 3per day(intermittentdischarge).TDS ofdischargedeffluent2,000 - 10,000 mg/L < 1,000 mg/L < 2,000 mg/L < 1,000 mg/LY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 20 of 70REV 2DSN 54988It is estimated that approximately 30,000 kL of treated effluent will be discharged tothe MUBRL annually. This equates to approximately 0.04% of the total capacitydischarge rate from the MUBRL (based on approved maximum discharge of208,000 kL per day).3.3.2 Discharge from MUBRL into King BayThe Water Corporation has provided the following information with regard to itsMUBRL and ocean outfall infrastructure (pers comm. S. Wilke, CEE 2003):1. Outfall infrastructure consists of one brine break tank (2 ML capacity) locatedadjacent to Mermaid Marine, with valve opening for batch discharge once thetank is full.2. Infrastructure discharge design capacity is 208 ML/day and is estimated to becurrently operating at one third capacity with Burrup Ammonia Plant being theonly other current user of the infrastructure.3. Hydrodynamic and dispersion modelling has been undertaken to evaluate thediffuser design, effects of flow rate, and also assess impacts of tidal and windconditions on effluent dispersion.4. The MUBRL outfall and diffuser extends approximately 800 m from the end ofthe Mermaid Marine groyne. The diffuser consists of 28 nozzles at 10 mspacing (total length 280 m), with a discharge angle of 30° above horizontal.To maximise mixing of the discharge with ambient seawater, the diffuser portsare directed alternately into and away from the dominant current, anddischarge occurs at a fixed exit velocity of 4.5 m/s.5. The approved mixing zone area is 0.01 km 2 and dispersion modelling indicatesthat the diffuser arrangement achieves a 19:1 dilution at the edge of this mixingzone. This dilution rate has been verified by Water Corporation.3.4 Material Balance and Inventories from Effluent Treatment PlantFigure 2 below shows all inputs, outputs and toxicants from the proposed <strong>Pluto</strong>effluent treatment facilities.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 21 of 70REV 2DSN 54988Figure 2 – <strong>Pluto</strong> Effluent Treatment facilities inputs and outputsThe inputs and outputs shown in Figure 2 have been assessed to determine:• the type and concentration of contaminants present;• the required treatment technology for removal (refer to Appendix A foradditional information); and• the resulting contaminant levels in the various ETP output streams.Table 3 shows the outcome of this assessment for each of the main classes ofcontaminants. This assessment assists in determination of fate for allcontaminants.Inputs to the ETP are high in hydrocarbons (free and dissolved), primarily from theMEG Overhead and the COC. However, following treatment, all toxicants indischarge streams are reduced to trace concentrations.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 22 of 70REV 2DSN 54988Table 3 – Contaminants entering <strong>Pluto</strong> Effluent Treatment Plant – Sources,Treatment & OutputsETP Input ToxicantsTH*1AOCCOCCondensedMEGOverheadETP Inputs Treatment ETP OutputsDeminWater PlantWastesETP ProcessChemicalsDomesticSewageOilSkimmingCPIVentFiltersMPPE MBREmergencyAdsorptionBTEX T T H Nil Nil Nil T T T H H Nil T* Nil NilMEG T Nil T T Nil Nil T T T T Nil Nil Nil Nil NilLube Oils T T Nil Nil Nil Nil N N T H Nil Nil Nil Nil NilOther Free Hydrocarbons T H Nil Nil Nil T T T T H T Nil Nil Nil NilOther Dissolved Hydrocarbons T H T T Nil T T T T H H Nil T* T TMetals T T T T T T T T T T T T1 Nil T TAntiscalants T Nil T T T Nil T T T T Nil Nil Nil Nil NilCorrosion Inhibitors T Nil T Nil T Nil T T T T Nil Nil Nil Nil NilOther Production Chemicals T Nil Nil Nil Nil Nil T T T T Nil Nil Nil Nil NilNutrients T T Nil T H H T T T T Nil T1 Nil T TTrace levels of Toxicant may or will be present in the corresponding ETP output. For streams discharge to the environment, dischargeconcentration will be below Ministerial requirements.High Concentration of Toxicant will be present in the corresponding ETP outputAtmospheric emissions of hydrocarbons are practically minimised by use of activated carbon vent filters.Treatment process is effective for removal / reduction of this contaminant.Naturally occuring background concentrations of this contaminant are unnaffected by <strong>Pluto</strong> facility.ReuseWaterEffluentto MUBRLETPSludges /CakeOilySlopsSpentActivatedCarbonCleanSurfaceWaterDischargeAtmosphericEmissionsTreatedDomesticWastewaterSewageSludgeFlows and contaminant concentrations for all the above streams shall bemonitored and recorded for the life of the facility enabling the mass balance andfate of all contaminants to be determined.The other streams directed to the MUBRL are the combined RO concentrate andion exchange waste stream. The RO concentrate contains concentrated salts fromservice water, antiscalent and possibly biocide residues.The predicted average effluent concentrations and annual loading of the chemicalconstituents are listed in Table 4 (Table 1 in Appendix B). This data is based oncurrently available information from vendors and the Water Corporation. The datarepresent a conservative approach, by using a set of assumptions, in estimatingthe effluent inputs and quality.The following assumptions have been made in predicting contaminantconcentrations at the edge of the approved mixing zone:1. All constituent concentrations refer to the <strong>Pluto</strong> ETP wastewater streamconcentrations prior to entry to the MUBRL and at end of pipe as being thesame value: that is, no cross-subsidy, interaction or dilution effects from non-<strong>Pluto</strong> discharges (within the MUBRL) are considered.2. Assessment is based on <strong>Pluto</strong> discharge as a stand alone discharge to theMUBRL; hence, dilution with other effluents in the MUBRL has not been takeninto account.3. The effects of weathering processes and biodegradation in the mixing zone arenot accounted for.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELERWORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 23 of 70REV 2DSN 549884. Hydrodynamic and dispersion modelling undertaken by the Water Corporationindicates that the diffuser arrangement achieves at least a 19:1 dilution at theedge of the 0.01km 2 mixing zone. This dilution rate has been verified in thefield by the Water Corporation. Given the relatively small effluent volumecontribution from <strong>Pluto</strong>, the resulting change in MUBRL effluent density, andthus buoyancy, is insignificant. As such, the dispersion modelling undertakenby Water Corporation remains valid and a 19:1 dilution is applied to <strong>Pluto</strong>treated effluent concentrations.5. Constituent concentrations have also been predicted at the edge of the mixingzone following dilution with seawater, and taking into account respectivebackground seawater concentrations.Assumptions 1 and 2, in particular, show the conservatism used in estimating theeffluent outputs and quality. If these assumptions are not valid, the effluent will befurther diluted before reaching the end of pipe and being discharged; hence, theconcentration at the entry to the MUBRL is reduced further, as is the concentrationat the edge of the mixing zone. Assumption 3 is important also as, over time,weathering processes and biodegradation will reduce concentrations.Production chemicals expected in the treated wastewater are also included inTable 4 including those production chemicals that may be used in the wastewatertreatment process (for example to balance pH or enhance flocculation) but will notbe discharged. That is, they will be re-circulated and/or consumed in the treatmentprocess.Table 4 provides for all constituents comparisons against appropriate water qualityguidelines (at end of pipe and at edge of mixing zone) and/or predicted no-effectconcentrations based on ecotoxicity information.Table 4 also includes the maximum expected produced wastewater concentrationsfrom the ETP. As stated in Section 3.3.1, wastewater will not be discharged if it isabove the 90% species protection threshold specification; hence, contingencieswill be implemented (Refer to Section 4) to ensure discharge meets the requiredthreshold levels.The theoretical maximum concentrations have also been calculated at the edge ofthe mixing zone. It can be seen in Table 4 that if maximum concentrations werecontinually discharged to the marine environment, the 99% species protection atthe edge of the mixing zone would still be met for all constituents.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGEMANAGEMENT PLANXA6400AH0005PAGE 24 of 70REV 2DSN 54988Table 4 – Expected Constituents, Concentrations and Loadings in <strong>Pluto</strong> Treated Wastewater Stream Assessment Against Guidelines and ToxicityCriteriaConstituentHydrocarbons (HCs)Total free HCsPrimary Source(s)HC Spills within AOC(Accidental OilContaminated) &COC (ContinuouslyOil Contaminated)catchment areasMain Control/Removal/ TreatmentProcessesContainment, oilretention baffles, oilskimming, Corrugateplate interceptors(CPI), Moving BedBioreactor (MPPE) &Membrane Bioreactor(MBR).UnitsAverage(Maximumproduced ETP)Concentrationat Entry to BRL(and at end ofpipe)ANZECC/ARMCANZ90% SpeciesProtectionLevels (endof pipe)BackgroundConcentrationDampierArchipelago(NWSJEMS2006)Average (theoreticalMaximum)Concentration atEdge of MixingZone (19 dilutions +backgroundconcentration)ANZECC/ARMCANZ 99%SpeciesProtection Levels(at edge ofmixing zone)Loading(kg/yr)µg/L 194 (1000) ID Negligible 10 (50) ID 1 5.8TotaldissolvedHCs, incl. Condensed MEGµg/L 238 (1000) ID Negligible 13 (50) ID1 7.1BTEX Overhead from U-2100 & HC spills MPPE & MBR µg/L 11 (50) 900 Negligible 0.56 (2.5) 500 0.32Benzene within AOC & COCcatchment areas.Total PAHs 1 µg/L 19 (100) 90 Negligible 0.95 (5) 51 0.58Phenolµg/L 195 (1000) 520 Negligible 10 (50) 270 5.8MetalsTotalChromium 2Chromium(VI) 2Water CorporationPotable Watersupply, pipelinecorrosion products &produced formationwaters.Pipeline corrosionproducts &Expected to be belowlimits. Some minimaladsorption / removalin physical &µg/L 0.38 (1.5) 48.6 0.18 0.19 (0.25) 7.72 0.01biological treatmentprocesses.Emergencyadsorption available µg/L 0.02 (0.06) 20 ND 0.001 (0.003) 0.14 0.001Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGEMANAGEMENT PLANXA6400AH0005PAGE 25 of 70REV 2DSN 54988ConstituentPrimary Source(s)Main Control/Removal/ TreatmentProcessesUnitsAverage(Maximumproduced ETP)Concentrationat Entry to BRL(and at end ofpipe)ANZECC/ARMCANZ90% SpeciesProtectionLevels (endof pipe)BackgroundConcentrationDampierArchipelago(NWSJEMS2006)Average (theoreticalMaximum)Concentration atEdge of MixingZone (19 dilutions +backgroundconcentration)ANZECC/ARMCANZ 99%SpeciesProtection Levels(at edge ofmixing zone)production chemicals if required.LeadWater CorporationPotable Water supply& producedµg/L 0.5 (1.5) 6.6 0.01 0.03 (0.08) 2.2 0.015formation waters.Nickel Water Corporationµg/L 0.84 (3.3) 200 ND 0.04 (0.17) 7 0.03ZincPotable Watersupply, pipelinecorrosion products &µg/L 6.87 (36) 23 0.14 0.48 (1.93) 7 0.21produced formationwaters.Cadmium µg/L 0.10 (1.5) 14 0.005 0.01 (0.08) 0.7 0.003Copper Produced formationµg/L 0.92 (3.6) 3 0.12 0.16 (0.29) 0.3 0.027Mercury 3 waterµg/L 0.01 (0.03) 1.43 0.0004 0.001 (0.002) - 0.0003Silverµg/L 1.1 (3) 1.8 ND 0.06 (0.15) 0.8 0.03OthersTemperatureCondensed MEGEvaporative coolingoverhead, ambient& refrigerativeC Compliant 4 - ND Compliant 4 Not-conditions & solarApplicablecooling.radiation.pHAcids & bases usedfor water treatmentprocesses (deminplant & effluenttreatment plant).Acid baseneutralisation.pHunits7.4 (6.0-9.0) 8.0 - 8.4 ND 8.1 (7.3-8.2) 8.0 - 8.4Loading(kg/yr)NotApplicableY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGEMANAGEMENT PLANXA6400AH0005PAGE 26 of 70REV 2DSN 54988ConstituentSulphidePrimary Source(s)No significantsources.Main Control/Removal/ TreatmentProcessesNo treatmentrequired but anypresent would bestripped / oxidisedwithin MBR.UnitsAverage(Maximumproduced ETP)Concentrationat Entry to BRL(and at end ofpipe)ANZECC/ARMCANZ90% SpeciesProtectionLevels (endof pipe)Process AdditivesMEGUnit 2100 MEGregenerationdistillation columncondensedoverheads.Production chemicalspillage.Containment, MBR µg/L 4,225 (15,000) IDaMDEAProduction chemicalContainment, MPPEspillage / leaks / loss& MBRof containment.µg/L 185 (1,000) IDLiquidPolyelectrolyteSodium Utilised in batch cleaning of MBR membranes with noHypochloriteresidual chlorine expected in discharge.Citric AcidUtilised in batch cleaning of MBR membranes with noresidual expected in discharge.Sodium Utilised for pH dosing with no residual expected inHydroxidedischarge.BiocideVery low volumes used in closed loop cooling watersystems - not discharged.Calcium Utilised in sludge press as a filtration aid – notHydroxidedischargedBackgroundConcentrationDampierArchipelago(NWSJEMS2006)Average (theoreticalMaximum)Concentration atEdge of MixingZone (19 dilutions +backgroundconcentration)ANZECC/ARMCANZ 99%SpeciesProtection Levels(at edge ofmixing zone)Loading(kg/yr)µg/L 5 (10) ID ND 0.26 (0.5) 1 0.15ND (assumedto benegligible)ND (assumedto benegligible)Not expected in discharge222 (750) 50,000 1279.25 (50) 200 5 5.6Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGEMANAGEMENT PLANXA6400AH0005PAGE 27 of 70REV 2DSN 54988ConstituentNutrientsTotalPhosphorusTotal NitrogenAmmoniaNitrogen (asN)Primary Source(s)Phosphoric acid(phosphorus sourcefor MBR)Urea solution(nitrogen source forMBR)Urea solution(nitrogen source forMBR)Main Control/Removal/ TreatmentProcessesConsumed duringMBR processesUnitsAverage(Maximumproduced ETP)Concentrationat Entry to BRL(and at end ofpipe)ANZECC/ARMCANZ90% SpeciesProtectionLevels (endof pipe)BackgroundConcentrationDampierArchipelago(NWSJEMS2006)Average (theoreticalMaximum)Concentration atEdge of MixingZone (19 dilutions +backgroundconcentration)ANZECC/ARMCANZ 99%SpeciesProtection Levels(at edge ofmixing zone)µg/L 1350 (10,000) Annual load 6 ND Not applicable 15 7 41Loading(kg/yr)µg/L 4125 (25,000) Annual load 6 ND Not applicable 100 8 124µg/L 325 (1,000) 1200 ND Not applicable 500 10ND = Background data not available (background concentrations were assumed to be zero for the purpose of calculation of edge of mixing zone concentration)ID = Insufficient Data (ANZECC/ARMCANZ 2000)1. 99% Species protection level guideline for Naphthalene (ANZECC/ARMCANZ 2000)2. 99% Species protection level guideline for CR III (ANZECC/ARMCANZ 2000). Chromium VI is the highly toxic form of Chromium, so when total Cr is given it is usuallycompared to ANZECC/ARMCANZ criteria for Cr III. If and when Cr VI is measured, then it is compared directly to the Cr VI criteria3. ANZECC/ARMCANZ 80% Species Protection Level applied to end of pipe concentration is applicable as mercury has the potential to bioaccumulate4. Water Corp criteria for temperature - temperature differential at <strong>Pluto</strong>/BRL tie in point < 2 degrees C for 80% of the time and never exceeds 5 degrees C. NB:Temperature differential measured between Water Corporation inlet pipe (measured by Water Corp) and <strong>Pluto</strong> tie in point to BRL - TBC.5. Lowest EC 50 for aMDEA (from Table A1 in Appendix B) with application factor (safety factor) of 100 applied6. Assessment of annual load on receiving environment (refer to Section 3.5.2)7. Tropical Australia Marine Nearshore Trigger for TP (ANZECC/ARMCANZ 2000)8. Tropical Australia Marine Nearshore Trigger for TN (ANZECC/ARMCANZ 2000)Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 28 of 70REV 1DSN 549883.5 Compliance with Relevant Guidelines and Environmental ImpactsAs per Section 3.2, the 0.01 km 2 mixing zone around the MUBRL outfall has beenafforded a low LEP (80% species protection) and, hence, it is considered that atrigger level equivalent to a moderate LEP (90% species protection) is appropriatefor risk assessment of discharges from the <strong>Pluto</strong> ETP to the MUBRL.However, in accordance with Ministerial Statement 757, Condition 7-7:1. the contaminant concentrations in the wastewater effluent from the site, justprior to entry to the wastewater discharge system, meet (in order ofpreference):• the ANZECC/ARMCANZ (2000) 99% species protection level; or• the ANZECC/ARMCANZ (2000) 99% species protection level at the edgeof an approved mixing zone;2. the concentrations of contaminants in the wastewater effluent which canpotentially bio-accumulate/bio-concentrate meet the ANZECC/ARMCANZ(2000) 80% species protection trigger levels just prior to entry into thewastewater discharge system;Hence, presented in Table 4 are the predicted contaminant concentrations fordischarge to the MUBRL compared against both the 99% species protectiontrigger levels (at entry to the mixing zone), as well as 99% species protectionspecies protection level at the edge of 0.01 km 2 mixing zone.Predicted concentrations shown in Table 4 indicate that:1. Average hydrocarbon concentrations meet ANZECC guideline for 99% speciesprotection at point of discharge to the MUBRL.2. Average heavy metals meet 90% species protection at point of discharge to theMUBRL and meet 99% species protection at the edge of the mixing zone.3. Contaminants with the potential to bioaccumulate, i.e. mercury, meet 80%species protection at point of discharge to MUBRL.4. Sulphide meets 99% species protection at the edge of the mixing zone.5. Average concentrations for the process additives, MEA and aMDEA, meet 99%species protection at the entry to the MURBL.6. Total load of nutrient discharge to the environment is low and is not expectedto promote algal growth (see Section 3.5.2).Hence, <strong>Pluto</strong>’s contaminant concentrations meets condition 7-7 of <strong>Pluto</strong>’sMinisterial Conditions.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 29 of 70REV 1DSN 549883.5.1 Environmental Fate and Predicted Toxicity of <strong>Pluto</strong> EffluentThe Assessment of <strong>Pluto</strong> Treated Effluent Toxicity and Fate report by SKM (2008)outlines the assessment of environmental impact associated with discharging <strong>Pluto</strong>effluent to the Mermaid Sound (Appendix B). A weight of evidence approach hasbeen undertaken to assess the likely effects of the proposed discharge on themarine environment.Following discharge, the wastewater effluent is subject to further processes suchas dilution, evaporation, adsorption, biodegradation and photodegradation in themarine environment. An outline of the likely environmental fate of the differentcontaminant types are outlined below:1. Dissolved hydrocarbons will further volatilise and evaporate if at surface and incontact with the atmosphere. Dissolved hydrocarbons do no adsorb strongly tosuspended particles and are unlikely to be transported via seabed.2. Dispersed oil, removed through adsorption to particles, followed bysedimentation and biodegradation. It is predicted that dispersed oils willbiodegrade quickly in environment.3. Poly Aromatic Hydrocarbon (PAH) concentrations are low, and consideredunlikely to bioaccumulate. The levels are sufficiently low to allow rapid dilution.4. Given the low concentrations of metals discharged and the widespread natureof the plume, which will further dilute metal concentrations to well belowchronic toxic thresholds, it is unlikely that precipitates will form in quantities thatmay have an impact on sediment quality.5. Process chemicals (aMDEA and MEG), which are present in the dischargestream, will be discharged at concentrations below predicted no-effectconcentrations. Both these chemicals are miscible in water and readilybiodegradable.A theoretical assessment of toxicity was calculated based on available guidelinesand toxicity of mixtures principles. The assessment identified that for all chemicalclasses, the predicted toxicity is

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 30 of 70REV 1DSN 54988relatively low in both species richness and abundance. As the MUBRL has beenin operation since 2006, the marine environment in the vicinity of the MUBRL is notpristine. Discharge of <strong>Pluto</strong> effluent via the MURBL is unlikely to significantlyimpact upon the marine environment or King Bay.3.5.2 Nutrient LoadingsWhilst the ANZECC water quality guidelines may be used to assess theenvironmental significance of some wastewater contaminant concentrationsentering King Bay, load-based guidelines for nutrients are considered moreappropriate than a discharge concentration. This is because environmentalimpacts arise from secondary effects, such as excessive algal growth due toelevated nutrient concentrations; biomass is controlled primarily by the total massof these nutrients available to the growing algae rather than the concentration ofthe nutrients.Annual discharges of 41 kg and 124 kg for Total Phosphorous and Total Nitrogen,respectively, are not expected to influence algal growth. The treated effluent willbe discharged into King Bay upon which it will rapidly disperse into MermaidSound as a result of a combination of strong tidal currents and wind drivencirculation. It is therefore unlikely that a build-up of nutrient concentrations willoccur.As a comparison, nitrogen loadings from Bunbury and Perth metropolitanwastewater treatment plants are in the order of many tonnes per annum. Impactson the marine environment of King Bay due to nutrient loadings provided inTable 4 are not expected.3.5.3 Compliance with Social Environmental ValuesTable 5 includes an assessment of compliance with ecological (based on Table 4concentrations at edge of mixing zone) and social values that are based ondischarging into an area with a Low LEP (mixing zone) surrounded by an area ofHigh LEP (King Bay) (SKM 2008).Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 31 of 70REV 1DSN 54988EnvironmentalValue (EV)EcosystemHealthFishing andAquacultureEnvironmentalQuality Objective(EQO)Maintenance ofecosystemIntegritySeafood forHumanConsumptionEnvironmental QualityCriteria (EQC)Table 5 – Assessment of Compliance with Social ValuesEnvironmental Quality Guideline (EQG) /Environmental Quality Criteria (EQC)Assessment of Treated Waste WaterDischargeRefer to Table 4 Refer to Table 4 As per Table 4 all EQGs fall within guidelines atedge of mixing zone.WET testing will determine the toxicity of thewastewater and evaluate the potential risks to themarine environment associated with marinedischarge.• Thermotolerant faecalcoliforms in water.• Thermotolerant faecalcoliforms in fish flesh.• Metals and organics in fishflesh.• EQG: The median thermotolerant faecal coliformbacterial concentration should not exceed 14CFU/100 mL, with no more than 10% of thesamples exceeding 21 CFU/100 mL measuredusing the membrane filtration method.• EQS: Fish destined for human consumption shouldnot exceed a limit of 2.3 MPN E. coli /g of flesh (wetwt.) in four out of five representative samples, andthe fifth sample should not exceed 7 MPN E. coli /g,with a maximum total plate count of 250 000organisms/g.• EQG: A range of metals and organics haveenvironmental quality guidelines for levels in fishflesh.Treated effluent from the domestic STP will bedischarged via land application and will not bedischarged to the MUBRL.Hence, the median thermotolerant faecal coliformbacterial concentration is not expected to exceedEQGs.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 32 of 70REV 1DSN 54988Table 5 – Assessment of Compliance with Social ValuesEnvironmentalValue (EV)EnvironmentalQuality Objective(EQO)Environmental QualityCriteria (EQC)Environmental Quality Guideline (EQG) /Environmental Quality Criteria (EQC)Assessment of Treated Waste WaterDischargeFishing andAquacultureAquaculture• Metals, inorganics andpesticides in water• Dissolved oxygen• pH• EQG for toxicants: The 95th percentile of thesample concentrations from the area of concern(either from one sampling run or all samples overan agreed period of time, or from a single site overan agreed period of time) should not exceed theenvironmental quality guideline value.EQGs for potential toxicants of concern for a highprotection of the marine ecosystem are morestringent than those for aquaculture values (withthe exception of zinc) and will therefore beprotected through adherence to the ecosystemEQGs.There are presently no active aquaculture leasesin King Bay.pH and DO levels at end of pipe are highlyunlikely to vary significantly outside of the EQG.• EQG for physio-chemical stressors: The median ofthe sample concentrations from the area of concern(either from one sampling run or all samples overan agreed period of time, or from a single site overan agreed period of time) should not exceed thefollowing environmental quality guideline values.- Dissolved Oxygen ≥5 mg/L- pH 6-9Recreation andaestheticsPrimary contactrecreation values• Faecal Pathogens• pH• Water clarity• Toxic Chemicals – a rangeof chemicals includingmetals, inorganics andorganics.• EQG: Faecal Pathogens: The 95%ile bacterialcontent of marine waters should not exceed 200enterococci/100mL• EQS: The median of the sample concentrationsfrom the area of concern (either from one samplingrun or from a single site over an agreed period oftime) should not exceed the range of 5 – 9 pH units.• EQG: To protect the visual clarity of waters used forswimming, the horizontal sighting of a 200 mmdiameter black disc should exceed 1.6 m.• EQG: Toxic Chemicals - The 95%ile of the sampleconcentrations from the area of concern (eitherTreated effluent from the domestic STP will bedischarged via land application and will not bedischarged to the MUBRL.Hence, it is considered unlikely that dischargedwastewater will cause faecal pathogens toexceed EQG in the vicinity of the discharge.EQGs for potential toxicants of concern (metals)for a high protection of the marine ecosystem aremore stringent than those for primary contactrecreation values (except for Benzene – seebelow) and will therefore be protected throughadherence to the ecosystem EQGs.pH levels at end of pipe are highly unlikely to varyY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 33 of 70REV 1DSN 54988Table 5 – Assessment of Compliance with Social ValuesEnvironmentalValue (EV)EnvironmentalQuality Objective(EQO)Environmental QualityCriteria (EQC)Environmental Quality Guideline (EQG) /Environmental Quality Criteria (EQC)from one sampling run or from a single site over anagreed period of time) should not exceed theenvironmental quality guideline values.Assessment of Treated Waste WaterDischargesignificantly outside of the EQS.Primary contact recreation EQGs for metals willbe met immediately after discharge. Expectedconcentrations for benzene will be well below theprimary recreation EQG (0.02 mg/L), withinmetres of the discharge under worse conditions.Recreation andaestheticsSecondary contactrecreation values• Faecal pathogens• pH• Toxic chemicals• EQG: The 95%ile bacterial content of marinewaters should not exceed 2000 enterococci/100mL.• The median of the sample concentrations from thearea of concern (either from one sampling run orfrom a single site over an agreed period of time)should not exceed the range of 5 – 9 pH units.• Water should contain no chemicals atconcentrations that can irritate the skin of thehuman body.Treated effluent from the domestic STP will bedischarged via land application and will not bedischarged to the MUBRL.Hence, it is considered unlikely that dischargedwastewater will cause faecal pathogens toexceed 2000 enterococci/100mL in the vicinity ofthe discharge.pH levels at end of pipe are highly unlikely to varysignificantly outside of the EQS.Given the high level of treatment proposed, it ishighly unlikely that treated waste water willcontain chemicals at concentrations that canirritate the skin of the human body.Recreation andaestheticsAesthetic Values• Water Clarity• Fish Tainting Substances(large range of chemicalsimplicated in fish tainting;related to concentration inwater column).• The natural visual clarity of the water should not bereduced by more than 20%.• The 95%ile of the sample concentrations from thearea of concern (either from one sampling run or allsamples over an agreed period of time or from asingle site over an agreed period of time) shouldnot exceed the environmental quality guidelinevalues.Given the high level of treatment proposed, it ishighly unlikely that treated waste water will resultin impact on water clarity or fish flesh qualityrelevant to aesthetic values.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATER DISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 34 of 70REV 1DSN 54988Table 5 – Assessment of Compliance with Social ValuesEnvironmentalValue (EV)EnvironmentalQuality Objective(EQO)Environmental QualityCriteria (EQC)Environmental Quality Guideline (EQG) /Environmental Quality Criteria (EQC)Assessment of Treated Waste WaterDischargeCultural andSpiritualMaintenance ofcultural andspiritual valuesNo guidelines are relevant tothe area within the vicinity ofthe discharge for cultural andspiritual values.No guidelines are relevant to the area within thevicinity of the discharge for cultural and spiritualvalues.No impacts are expected from the discharge oftreated waste water on cultural and spiritualvalues.Industrial WaterSupplyMaintenance ofindustrial watersupply valuesNo guidelines are relevant tothe area within the vicinity ofthe discharge for industrialwater supply values.No guidelines are relevant to the area within thevicinity of the discharge for industrial water supplyvalues.No impacts are expected from the discharge oftreated waste water discharge on industrial watersupply values.Y:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge Management Plan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2) (5).doc14744-64-EN-PP-001_Rev 0

FOSTER WHEELER WORLEYPARSONSPROJECT REPORTMARINE TREATED WASTEWATERDISCHARGE MANAGEMENT PLANXA6400AH0005PAGE 35 of 70REV 1DSN 549883.6 Water Quality Monitoring ProgrammeAn Operations Water Quality Monitoring Procedure (OQWMP) will be developedprior to commissioning, which will outline the procedures for Whole EffluentToxicity (WET) testing, monitoring and sampling of ETP treated wastewater prior todischarge to the MUBRL.Water quality monitoring conducted by <strong>Woodside</strong> and will focus on <strong>Woodside</strong> endof-pipemonitoring, to ensure that discharge meets ANZECC guideline formoderate LEP (90% Species Level of Protection) as outlined previously in theMTWDMP.Monitoring in the marine environment will be coordinated via the Burrup UsersGroup (BUG). Constituents which are currently not being measured via the widermonitoring program (BUG) will be added to the program; these are yet to bedetermined.3.6.1 EcotoxicityWET testing will be undertaken on the untreated <strong>Pluto</strong> produced water and treated<strong>Pluto</strong> wastewater as soon as first water becomes available. In accordance withtheir Outlet Operational Monitoring Program (SKM 2005), the Water Corporationalso undertakes annual ecotoxity testing on the co-mingled effluent beingdischarged to King Bay.ObjectivesThe objectives of the WET testing program are:• to determine the toxicity of the wastewater;• to evaluate the potential risks to the marine environment associated with themarine discharge; and• to determine the number of dilutions of the wastewater which would berequired to meet a high level of ecological protection (99% species protectionlevel).Guidelines1. WET testing will be undertaken in accordance with the protocols andprocedures recommended in ANZECC (2000).2. <strong>Woodside</strong> will co-ordinate with the Water Corporation to ensure consistencywith ecotoxicity testing undertaken by Water Corporation as part of the MUBRLOutlet Operational Monitoring Program (SKM 2005).3. Following commissioning of the drainage and effluent treatment plant, worstcasewastewater composition operating conditions will be identified andY:\6.0_HSE\6.1 Environment\Environmental Management Plans (EMPs)\Marine Treated Waste Water Discharge ManagementPlan\Rev 2\<strong>DRIMS</strong>-<strong>#4627288</strong>-<strong>v1</strong>-<strong>Pluto</strong>_<strong>LNG</strong>_-_Draft_Marine_Treated_Wastewater_Discharge_Management_Plan_(Rev_2)(5).doc14744-64-EN-PP-001_Rev 0