September 2011 (PDF format 670 KB) - Indian Stainless Steel ...

September 2011 (PDF format 670 KB) - Indian Stainless Steel ...

September 2011 (PDF format 670 KB) - Indian Stainless Steel ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

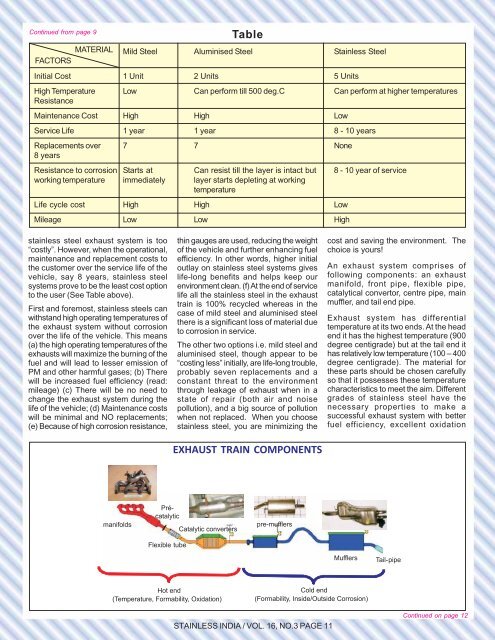

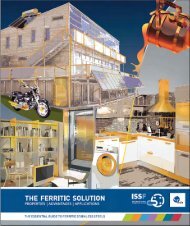

Continued from page 9MATERIALFACTORSTableMild <strong>Steel</strong> Aluminised <strong>Steel</strong> <strong>Stainless</strong> <strong>Steel</strong>Initial Cost 1 Unit 2 Units 5 UnitsHigh Temperature Low Can perform till 500 deg.C Can perform at higher temperaturesResistanceMaintenance Cost High High LowService Life 1 year 1 year 8 - 10 yearsReplacements over 7 7 None8 yearsResistance to corrosion Starts at Can resist till the layer is intact but 8 - 10 year of serviceworking temperature immediately layer starts depleting at workingtemperatureLife cycle cost High High LowMileage Low Low Highstainless steel exhaust system is too“costly”. However, when the operational,maintenance and replacement costs tothe customer over the service life of thevehicle, say 8 years, stainless steelsystems prove to be the least cost optionto the user (See Table above).First and foremost, stainless steels canwithstand high operating temperatures ofthe exhaust system without corrosionover the life of the vehicle. This means(a) the high operating temperatures of theexhausts will maximize the burning of thefuel and will lead to lesser emission ofPM and other harmful gases; (b) Therewill be increased fuel efficiency (read:mileage) (c) There will be no need tochange the exhaust system during thelife of the vehicle; (d) Maintenance costswill be minimal and NO replacements;(e) Because of high corrosion resistance,thin gauges are used, reducing the weightof the vehicle and further enhancing fuelefficiency. In other words, higher initialoutlay on stainless steel systems giveslife-long benefits and helps keep ourenvironment clean. (f) At the end of servicelife all the stainless steel in the exhausttrain is 100% recycled whereas in thecase of mild steel and aluminised steelthere is a significant loss of material dueto corrosion in service.The other two options i.e. mild steel andaluminised steel, though appear to be“costing less” initially, are life-long trouble,probably seven replacements and aconstant threat to the environmentthrough leakage of exhaust when in astate of repair (both air and noisepollution), and a big source of pollutionwhen not replaced. When you choosestainless steel, you are minimizing theEXHAUST TRAIN COMPONENTScost and saving the environment. Thechoice is yours!An exhaust system comprises offollowing components: an exhaustmanifold, front pipe, flexible pipe,catalytical convertor, centre pipe, mainmuffler, and tail end pipe.Exhaust system has differentialtemperature at its two ends. At the headend it has the highest temperature (900degree centigrade) but at the tail end ithas relatively low temperature (100 – 400degree centigrade). The material forthese parts should be chosen carefullyso that it possesses these temperaturecharacteristics to meet the aim. Differentgrades of stainless steel have thenecessary properties to make asuccessful exhaust system with betterfuel efficiency, excellent oxidationSTAINLESS INDIA / VOL. 16, NO.3 PAGE 11Continued on page 12