Cincinnati Mechanical Press Brake Applications Brochure - Sterling ...

Cincinnati Mechanical Press Brake Applications Brochure - Sterling ...

Cincinnati Mechanical Press Brake Applications Brochure - Sterling ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

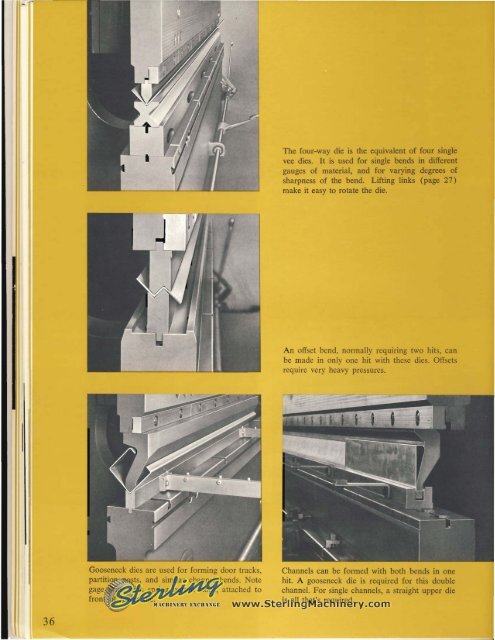

The four-way die is the equivalent of four singlevee dies. It is used for single bends in differentgauges of material, and for varying degrees ofsharpness of the bend. Lifting links (page 27)make it easy to rotate the die.An offset bend, normally requiring two hits, canbe made in only one hit with these dies. Offsetsrequire very heavy pressures.Gooseneck dies are used for forming door tracks,partition posts, and similar channel bends. Notegage arms with spring button stops, attached tofront of lower die.Channels can be formed with both bends in onehit. A gooseneck die is required for this doublechannel. For single channels, a straight upper dieis all that's required.36

section 6APPLICATIONSFORMINGFor this truck body side, corrugations were formedfirst, then curved to concentric radii. <strong>Press</strong>ure padin the die gives smooth bends.This powerful <strong>Cincinnati</strong> <strong>Press</strong> <strong>Brake</strong> is used forstraightening armor plate.Progressive forming one type of bead. Other typesof beads are shown on page 32. Large and smalltubes are formed by similar methods.37

Store shelf formed on two stage die.This closed U bend is a hand rail and stiffener fora playground slide.Forming rims for large steel gears is a good exampleof the variety of work done on <strong>Cincinnati</strong><strong>Press</strong> <strong>Brake</strong>s.Taper, cone, or fade-out work is accurately formedon <strong>Cincinnati</strong> <strong>Press</strong> <strong>Brake</strong>s.Forming boxes may require special die space fordepth. Both short and long dimensions of boxescan be formed without changing dies.38V C::::=E==============-9 U

APPLICATIONS / section 6FORMINGAbout two miles of galvanized gutter per hour areproduced on this machine. Multiple bends areformed in one hit.Cones are readily formed on standard dies.This setup forms a channel and automatically stripsthe work from the dies.Two different bends are made on this double deckerdie. One setup and one handling; no time lostchanging dies or shifting work to another machine.39

1st and 2nd OperationUniversal Gage Bar===Jxpanding Gages~rr= -- 11IU3rd Operation4th OperationWith one handling on one machine, progressive forming compleles operations whichnormally require either several machines or separate setups and handlings on one brake.PROGRESSIVE FORMINGPass-along operation shows how work can move from stationto station to get maximum production from each stroke.40

APPLICATIONS / section 6Steel road guards are formed with one handling and two hits.CORRUGATINGSimplified die for corrugating culvert.Stock is automatically fed for simultaneously corrugating and punching assembly holes.Corrugating galvanized roofing without injury tothe coating. Pilot "P" positions the sheet.41

NOTCHINMetal office furniture and file cabinds are easilynotched and formed on <strong>Cincinnati</strong> brakes.Steel sash member is notched and formed in one stroke of the ram.Notching and forming can be combined on onemachine. One operator can carry the work fromstation to station, or several operators can pass thework in sequence.42

APPLICATIONS / section 6& FORMING.....:::-.1)Notching large trailer sheet and forming rub rail in one setup, one handling.This closeup shows the notching operation on thesheet for truck trailer bodies.43

• • L-0 _~~a:Jj"~:'"Adjustable center punching equipment is used topunch these panels.PUNCHINGHeavy hydraulic strippers are used inpunching this 34" high carbon draw bar.This adjustable multiple punching unit is speciallyarranged for punching angles of any length.Rear view of press brake used in punching pegboard.Machine is equipped with automatic feed.44

APPLICATIONS / section 6This double row setup punches a carline in only 7 hits, producing SO anhour. Punches are easily gagged to give the required combination of holes.Three-stage punching of a car stake forhopper cars produces one stake per stroke.45

Punching and notching a refrigerator "wraparound" cabinet sheet.This machine cuts to length and punches blades forearth moving equipment. Material is high carbon,abrasion-resistant steel, up to ¥S" thick.PUNCHINGNOTCHING &TRIMMINGControl panel blanks are accurately punched andnotched in one hit.Refrigerator parts are economically produced on this multiple setup.46

APPLICATIONS / section 6Producing steel cabinets, this press brake replaced a battery of machines, andchanged repeated floor-to-floor handling to one simple hand-to-hand transfer.PRESS WORKBrackets and bolsters on this brake areused for embossing various highway signs.Bolsters can be removed for standardforming and punching work.Two punching and notching and two forming operations are performedat each stroke, as work progresses from hand to hand.47

PRESS WORKStiffeners for Navy pontoom arc formedrapidly and accurately: 3 bends in 1 hit.Removable angle brackets on ralll andbed provide wide die surface.Steel cabinet parts are formed with minimum handling,negligible marring, little floor space.Water cooler shells are produced prontably withreduced handling and number of machines.These parts demonstrate the type of press workwhich can be done on <strong>Cincinnati</strong> <strong>Press</strong> <strong>Brake</strong>s.48

also manufacturersthe machines shown here. In addition, abroad range of special metal-working machineryis manufactured, and all standard machines canbe modified to customer specification.The <strong>Cincinnati</strong> Shaper Co. also builds a full lineof hydraulic press brakes in a full range of bendingcapacities - from 300 tons up to 1500 tons.In addition, <strong>Cincinnati</strong> has a complete ApplicationEngineering Service available for designingand furnishing all types of press brake tooling.~ \,.. "'I'Hydraulic<strong>Press</strong> <strong>Brake</strong>All-steel interlocked construction. Powerful hydraulicholddowns. Non-float inclined ram maintainsextremely accurate knife clearance. Fast,convenient power back gage. Available in standardsizes from I4" to 1 1 ;4" capacities,<strong>Mechanical</strong>ShearFeature an adjustable rake to the upper knife; platethicker than the nominal capacity can be cut byadjusting the knife to a steeper angle. Reducingthe angle of the knife allows thinner materials tobe cut with minimum bow, twist and camber. Thisversatility in one frame results in substantial savingsin machine investment. Standard sizes availablefrom 12 gauge to 11/2" capacities.HydraulicShearOffering unsurpassed accuracy andversatility, these machines feature a floating dieplaten that retracts to eject the compact. Die-floatstops can absorb full press tonnage, yet are retractedautomatically for cjection. FiJI position foreach part level is individually adjustable. Heavyall-steel frame insures parallelism and repeatabilityunder load. Available in ] 00, 200, and 400 toncapacities.Rigid ReflexCompacting <strong>Press</strong>By releasing stored electrical energy into a fluidmedium in millionths of a second, an extremelyhigh pressure, high velocity pulse is generatedwhich forms metal without a male die. This highenergy-ratetechnique, employed in <strong>Cincinnati</strong>Electroshape, forms difficult as well as simpleshapes with tooling savings as high as 60%.Electroshape machines can be used safely anywhere,without expensive safety precautions.ElectroshapeC nCI'1'1at'~ 9 .::>High strength, slot free ram plus wiele, heavilyribbed column provide extreme rigidity and accuracy. Electro-magnetic brake and clutch result infast, dependable operation. Sizes 16" to 36".Rigid Shaper