VUTEk Glass Primer - VUTEK Superwide Format Printing

VUTEk Glass Primer - VUTEK Superwide Format Printing

VUTEk Glass Primer - VUTEK Superwide Format Printing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Application Notes<br />

<strong>VUTEk</strong> <strong>Glass</strong> <strong>Primer</strong> System for <strong>VUTEk</strong> PV180 and PV200<br />

<strong>Glass</strong>, while fragile and more difficult to handle and ship than other clear substrates, has<br />

its place in some high-end applications. Decorative dividers, showroom panels, awards,<br />

and shower doors are just a few. <strong>Glass</strong> is used primarily in second-surface applications. If<br />

used as first-surface, moisture will eventually weaken and break down the ink regardless<br />

of its adhesion level. The primer increases adhesion and durability as well as resistance to<br />

moisture, but applications that require the ink to be exposed to outdoor weather conditions<br />

should be avoided.<br />

The <strong>VUTEk</strong> ® <strong>Glass</strong> <strong>Primer</strong> System helps increase the abrasion<br />

resistance of UV curable ink on glass. The system consists of a<br />

cleaning agent and a primer. Both are packaged in aerosol cans.<br />

Refer to the part numbers listed below. Approximate coverage is<br />

200 square feet per can for both the cleaner and the primer.<br />

What is in the kit:<br />

Cleaning agent/aerosol can Part # CC99831-xxx<br />

PressVu <strong>Primer</strong>/aerosol can Part # CC99830-xxx<br />

What you will need:<br />

Lint-free cloths<br />

(same as used with<br />

PressVu) Part # P9450-A<br />

White cotton gloves Part # P3775-A<br />

A darkened area for inspecting glass with UV light<br />

<strong>Glass</strong> (see glass section)<br />

Oven big enough for the glass being used (see oven section)<br />

Short/Long-Wave UV light, 4-watt/115 VAC/60 Hz<br />

(see supplier list)<br />

The Process<br />

The <strong>VUTEk</strong> glass bonding primer process can be broken into five steps.<br />

1. Determine the print side of the glass using the short-wave UV<br />

light in a dark room. (See below on how to determine print side).<br />

2. Clean the glass thoroughly using the supplied cleaner in the kit.<br />

3. Spray the primer on the clean glass and wipe over the surface<br />

using cloth wipes.<br />

4. Print on the primed side as normal with the PV200 printer.<br />

5. Heat the glass to the required temperature for the optimum time.<br />

<strong>Superwide</strong> <strong>Format</strong> Solutions<br />

Safety <strong>Glass</strong>: Safety glass is divided in two types: laminated<br />

and tempered.<br />

Laminated glass: Laminated is made by adhering two or more<br />

Plate glass: The most commonly available type of glass available at local<br />

sheets<br />

distributors.<br />

of plate<br />

It is available<br />

glass together<br />

in many thicknesses.<br />

with thin sheets<br />

It is easy<br />

of<br />

to<br />

clear<br />

break,<br />

film<br />

making<br />

in<br />

it<br />

between hard to handle each. and The ship. film It is holds the least the expensive shards of together all types upon listed breakage. here. It may<br />

It be is unsuitable in some for this instances process where because safety is the an issue. film cannot It works withstand with this<br />

the process temperatures very well. used to set the bonding primer.<br />

Safety <strong>Glass</strong>: Safety glass is divided in two types. Laminated & Tempered.<br />

Tempered glass: Tempering is done by subjecting glass to high<br />

temperatures Laminated glass: using Laminated specialized is made equipment. by adhering 2 It or is more up to sheets seven of times plate<br />

stronger glass together than with plate thin glass sheets and of clear is more film in suitable between for each, applications The film holds the<br />

where<br />

shards together<br />

safety<br />

upon<br />

is an<br />

breakage.<br />

issue. It<br />

It<br />

also<br />

is unsuitable<br />

makes handling<br />

for this process<br />

and shipping<br />

because the film<br />

cannot withstand the temperatures used to set the bonding primer.<br />

easier. Tempered glass is not readily available at the local<br />

supplier, Tempered but glass: is usually Tempering ordered is done through by subjecting them glass from to a high distributor. temperatures<br />

It using has specialized to be cut equipment. to size when It is ordering up to 7 times and stronger prior to than the plate tempering glass and is<br />

process. more suitable Tempered for applications costs where more safety than other is an issue. glass It but also works makes handling well<br />

and shipping easier. Tempered glass is not readily available at the local<br />

with<br />

supplier<br />

this<br />

but<br />

process.<br />

is usually ordered through them from a distributor. It has to be cut<br />

to size when ordering and prior to the tempering process. Tempered costs more<br />

Note: than other <strong>Glass</strong> glass is but manufactured works well with by this rolling process. out liquid glass onto a molten<br />

zinc slab. The glass begins to set and hardens to its solid form.<br />

Note: <strong>Glass</strong> is manufactured by rolling out liquid glass onto a molten zinc slab.<br />

One<br />

The glass<br />

side<br />

begins<br />

is exposed<br />

to set and<br />

to<br />

hardens<br />

the air and<br />

to its<br />

is<br />

solid<br />

called<br />

form.<br />

the<br />

One<br />

air-side.<br />

side is exposed<br />

The other<br />

to the<br />

side air and that is called is in contact the air-side. with The the other zinc side can that contain is in contact contaminants. with the zinc The can<br />

air-side contain contaminants. reflects the The UV air-side light waves reflects while the UV the light zinc waves side while only the returns zinc<br />

a side cloudy only returns reflection. a cloudy The reflection. air-side is The the air-side side is this the process side this process is designed is<br />

designed to work with.<br />

to work with.<br />

Figure 1.<br />

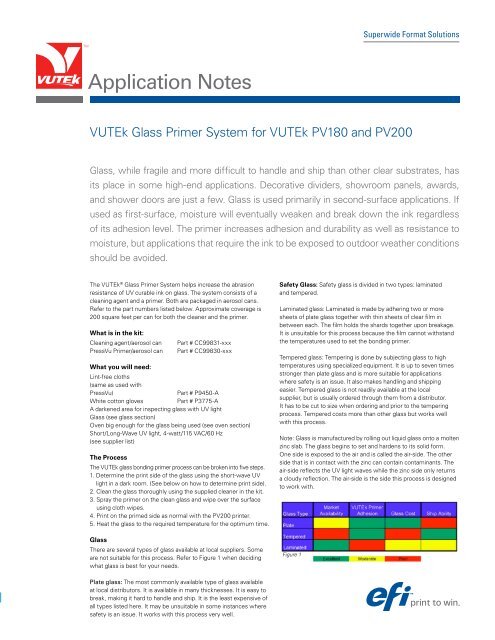

<strong>Glass</strong><br />

There are several types of glass available at local suppliers. Some<br />

Figure 1<br />

are not suitable for this process. Refer to Figure 1 when deciding<br />

what glass is best for your needs.<br />

Directions<br />

Plate glass: The most commonly available type of glass available Follow these 5 steps with the Vutek <strong>Glass</strong> <strong>Primer</strong> for optimum adhesion to glass.<br />

at local distributors. It is available in many thicknesses. It is easy to<br />

1. Determine the print side of the glass. Using the short-wave UV light in a dark room,<br />

break, making it hard to handle and ship. It is the least expensive of shine it on both sides of the glass. One side will be cloudy and the other will reflect.<br />

all types listed here. It may be unsuitable in some instances where The reflective side is called the air-side, while the cloudy side is the zinc side.<br />

safety is an issue. It works with this process very well.

Application Notes<br />

Illustration of typical hand-built oven<br />

Directions<br />

Follow these five steps with the <strong>VUTEk</strong><br />

2. Clean the air-side of the glass thoroughly using the supplied cleaner in the kit. If the<br />

glass is greasy, pre-clean using a spray cleaner like Windex prior to cleaning with<br />

the cleaning agent supplied in the kit. Use lint-free cloth wipes such as the wipes<br />

used on the PressVu printer.<br />

® For low Illustration volume glass of Typical production, Hand-Built an oven Oven can be built in various ways. Determ<br />

<strong>Glass</strong> <strong>Primer</strong> for optimum maximum For low size volume of the glass production, to be used an and oven build can be a box built using in various rigid foam insulatio<br />

adhesion to glass.<br />

heat gun ways. provides Determine the heat the maximum source and size a of thermometer the glass to be stuck used through and the top will<br />

job. See<br />

build<br />

attached<br />

a box using<br />

illustration<br />

rigid foam<br />

of<br />

insulation.<br />

a typical<br />

A<br />

rigid<br />

heat<br />

foam<br />

gun provides<br />

oven.<br />

the heat<br />

1. Determine the print side of the glass. Using the short-wave UV source and a thermometer stuck through the top will do the job.<br />

light in a dark room, shine it on both sides of the glass. Figure One side 3. See attached illustration of a typical rigid foam oven.<br />

will be cloudy and the other will reflect. The reflective side is<br />

called the air-side, while the cloudy side is the zinc side.<br />

2. Clean the air-side of the glass thoroughly using the supplied<br />

cleaner in the kit. If the glass is greasy, pre-clean using a spray<br />

glass cleaner prior to cleaning with the cleaning agent supplied in<br />

the kit. Use lint-free cloth wipes such as the wipes used on the<br />

PV printer.<br />

3. Spray the primer on the clean glass and wipe over the surface<br />

using the cloth wipes. At this point try not to touch the glass<br />

with anything other than white cotton gloves. Set the primed<br />

glass aside or print immediately, there is no time constraint.<br />

4. Print on the primed side as normal with the PV printer. Use a<br />

cure energy setting range of 55% to 75% double cure on PV180<br />

/ Double-Cure High on PV200.<br />

5. Heat the glass to the temperature required in your oven.<br />

See ovens.<br />

3. Spray the primer on the clean glass and wipe over the surface using the cloth wipes.<br />

At this point try not to touch the glass with anything other than white cotton gloves.<br />

Set the Ovens primed glass aside or print immediately, there is no time constraint.<br />

The critical part of the process is baking the glass/primer/ink<br />

4. Print on the primed side as normal with the PressVu printer. Use a cure energy<br />

setting combination range of 55% to to 75% the double appropriate cure on PV180 temperature / Double-Cure to initiate High on the PV200. bond. Figure 3<br />

Assemble using duct tape on all seams.<br />

Once loaded with glass, tape seams around lid.<br />

The working temp/time is 380°-390°F (193°-198°C) for 10 minutes<br />

5. Heat the glass to the temperature required in your oven.<br />

List of Suppliers<br />

for the PV primer. The desired parameters to use in a hand-built<br />

See ovens.<br />

List of Suppliers<br />

foam oven or small lab stove shown in Figure 3 are 250°F (120°C) Short/Long-Wave UV light, 4-watt/115 VAC/60 Hz<br />

Ovens for 30 minutes.<br />

Cole Parmer Instruments, www.coleparmer.com, 1-800-323-4340 (US)<br />

Short/Long-Wave UV light, 4-watt/115 VAC/60 Hz<br />

The critical part of the process is baking the glass/primer/ink combination to the appropriate Cole Parmer Instruments, www.coleparmer.com, 1-800-323-4340 (US)<br />

temperature to initiate For high the bond. volume The working glass production, temp/time is 380-390°F one of several (193-198°C) industrial for 10 ovens Conveyor Oven Dryer, various sizes available<br />

minutes for the PressVu can be primer. purchased. The desired See parameters the list of to use suppliers in a hand-built at the foam end oven of Conveyor this or Oven BBC Dryer, Industries, various Inc. www.bbcind.com, sizes available 1-800-654-4205 (US),<br />

small lab stove shown in figure 3. Are 250°F (120°C) for 30 minutes<br />

document. However, testing needs to take place on the specific BBC Industries, 1-636-343-5600 Inc. www.bbcind.com, 1-800-654-4205 (US), 1-636-343-5600<br />

For high volume glass oven production, to be used. one of several industrial ovens can be purchased. See the<br />

list of suppliers at the end of this document. However, testing needs to take place on the<br />

Oven sizes and pricing from BBC Industries, Inc.<br />

specific oven to be used.<br />

For purposes of development and documentation, we used a<br />

For purposes of development screen print and conveyor documentation, oven, we shown used a screen in Figure print conveyor 2. Using oven, this oven, a<br />

2409-XL-SS 3609-XL-SS 4809-XL-SS<br />

shown in figure 2. temperature Using this oven, of a 650° temperature F (343°C) of 650° for F (343°C) 10 minutes for 10 was minutes found was to work<br />

found to work with great success. This combination yielded a 5 on the ASTM adhesion<br />

with great success. This combination yielded a five on the ASTM<br />

ratings test (0-5, 5 is best). This set of parameters worked for both the PV180/6000 and<br />

PV200/600 primers. adhesion Note: On ratings this oven test a setting (0-5, of 5 650°F is best). is actually This 390°F. set of parameters worked<br />

for both the PV180 and PV200 primers. Note: On this oven a<br />

Oven Length<br />

Oven Width<br />

Belt Width<br />

108”<br />

34”<br />

24”<br />

108”<br />

46”<br />

36”<br />

108”<br />

58”<br />

48”<br />

Figure 2. 2409-XL BBC Industries Conveyor Screen-print<br />

setting of 650°F is actually 390°F.<br />

Dryer.<br />

Belt Material Stainless Steel Stainless Steel Stainless Steel<br />

Oven Chamber<br />

Length 60” 60” 60”<br />

Heater Wattage<br />

Oven Power<br />

8700 11,250 15,000<br />

Requirements 2 40V/36A 240V/47A 240V/62A<br />

Price<br />

12/04 kcc<br />

$4,995.00 $6,930.00 $8,738.00<br />

Figure 2. 2409-XL BBC Industries Conveyor Screen-print Dryer.<br />

One <strong>VUTEk</strong> Place<br />

Meredith, NH 03253<br />

603-279-4635<br />

www.efi.com/<strong>VUTEk</strong><br />

<strong>Superwide</strong> <strong>Format</strong> Solutions<br />

Auto-Count, Bliss, Changing the Way the World Prints, ColorWise, Command WorkStation, DocBuilder, DocBuilder Pro, DocStream, EDOX, EFI, Fiery, the Fiery logo, Fiery Driven, the Fiery Driven logo,<br />

OneFlow, PrinterSite, PrintFlow, PrintMe, PrintSmith Site, Prograph, Proteus, RIP-While-Print, Setting the Standard in Digital <strong>Printing</strong>, Ultravu and <strong>VUTEk</strong> are registered trademarks of Electronics for<br />

Imaging, Inc. in the U.S. Patent and Trademark Office and/or certain other foreign jurisdictions. Bestcolor is a registered trademark of Electronics For Imaging GmbH in the U.S. Patent and<br />

Trademark Office. AutoCal, Balance, BioVu, BioWare, Build, ColorCal, Digital StoreFront, Estimate, Fiery Link, Fiery Prints, Fiery Spark, FreeForm, Hagen, Jetrion, Logic, MicroPress, PhotoXposure,<br />

Printcafe, PrintSmith, PSI, PSI Flexo, Remoteproof, RIPChips, Scan, Screenproof, SendMe, Splash, Spot-On, UltraTex, UV Series 50, VisualCal, WebTools, the EFI logo, the Fiery Prints logo and<br />

Essential to Print are trademarks of Electronics for Imaging, Inc. Best, the Best logo, Colorproof, PhotoXposure, Remoteproof, and Screenproof are trademarks of Electronics For Imaging GmbH<br />

All other terms and product names may be trademarks or registered trademarks of their respective owners, and are hereby acknowledged.<br />

© 2008 Electronics for Imaging