Technical information for cylindrical curved glass

Technical information for cylindrical curved glass

Technical information for cylindrical curved glass

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

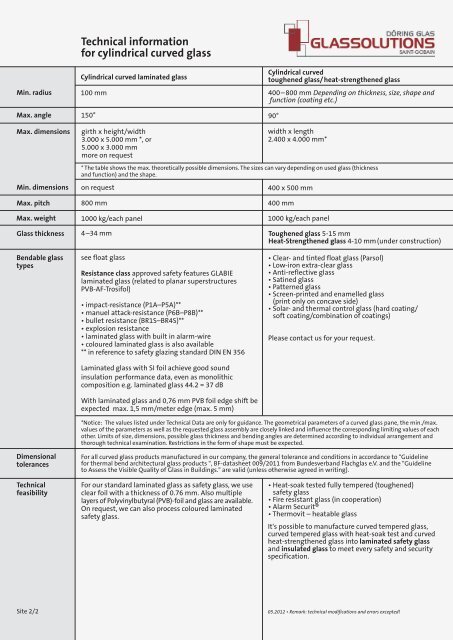

Min. radius<br />

Max. angle<br />

Max. dimensions<br />

Min. dimensions<br />

Max. pitch<br />

Max. weight<br />

Glass thickness<br />

Bendable <strong>glass</strong><br />

types<br />

Dimensional<br />

tolerances<br />

<strong>Technical</strong><br />

feasibility<br />

Site 2/2<br />

<strong>Technical</strong> <strong>in<strong>for</strong>mation</strong><br />

<strong>for</strong> <strong>cylindrical</strong> <strong>curved</strong> <strong>glass</strong><br />

Cylindrical <strong>curved</strong> laminated <strong>glass</strong><br />

Cylindrical <strong>curved</strong><br />

toughened <strong>glass</strong>/heat-strengthened <strong>glass</strong><br />

100 mm 400–800 mm Depending on thickness, size, shape and<br />

function (coating etc.)<br />

150°<br />

girth x height/width<br />

3.000 x 5.000 mm *, or<br />

5.000 x 3.000 mm<br />

more on request<br />

* The table shows the max. theoretically possible dimensions. The sizes can vary depending on used <strong>glass</strong> (thickness<br />

and function) and the shape.<br />

on request<br />

800 mm<br />

1000 kg/each panel<br />

For our standard laminated <strong>glass</strong> as safety <strong>glass</strong>, we use<br />

clear foil with a thickness of 0.76 mm. Also multiple<br />

layers of Polyvinylbutyral (PVB)-foil and <strong>glass</strong> are available.<br />

On request, we can also process coloured laminated<br />

safety <strong>glass</strong>.<br />

width x length<br />

2.400 x 4.000 mm *<br />

400 x 500 mm<br />

400 mm<br />

1000 kg/each panel<br />

4–34 mm Toughened <strong>glass</strong> 5-15 mm<br />

Heat-Strengthened <strong>glass</strong> 4-10 mm ( under construction)<br />

see float <strong>glass</strong><br />

Resistance class approved safety features GLABIE<br />

laminated <strong>glass</strong> (related to planar superstructures<br />

PVB-AF-Trosifol)<br />

• impact-resistance (P1A–P5A)**<br />

• manuel attack-resistance (P6B–P8B)**<br />

• bullet resistance (BR1S–BR4S)**<br />

• explosion resistance<br />

• laminated <strong>glass</strong> with built in alarm-wire<br />

• coloured laminated <strong>glass</strong> is also available<br />

** in reference to safety glazing standard DIN EN 356<br />

Laminated <strong>glass</strong> with SI foil achieve good sound<br />

insulation�per<strong>for</strong>mance data, even as monolithic<br />

composition e.g. laminated <strong>glass</strong> 44.2 = 37 dB<br />

With laminated <strong>glass</strong> and 0,76 mm PVB foil edge shift be<br />

expected max. 1,5 mm/meter edge (max. 5 mm)<br />

• Clear- and tinted float <strong>glass</strong> (Parsol)<br />

• Low-iron extra-clear <strong>glass</strong><br />

• Anti-reflective <strong>glass</strong><br />

• Satined <strong>glass</strong><br />

• Patterned <strong>glass</strong><br />

• Screen-printed and enamelled <strong>glass</strong><br />

(print only on concave side)<br />

• Solar- and thermal control <strong>glass</strong> (hard coating/<br />

soft coating/combination of coatings)<br />

Please contact us <strong>for</strong> your request.<br />

*Notice: The values listed under <strong>Technical</strong> Data are only <strong>for</strong> guidance. The geometrical parameters of a <strong>curved</strong> <strong>glass</strong> pane, the min./max.<br />

values of the parameters as well as the requested <strong>glass</strong> assembly are closely linked and influence the corresponding limiting values of each<br />

other. Limits of size, dimensions, possible <strong>glass</strong> thickness and bending angles are determined according to individual arrangement and<br />

thorough technical examination. Restrictions in the <strong>for</strong>m of shape must be expected.<br />

For all <strong>curved</strong> <strong>glass</strong> products manufactured in our company, the general tolerance and conditions in accordance to "Guideline<br />

<strong>for</strong> thermal bend architectural <strong>glass</strong> products ", BF-datasheet 009/2011 from Bundesverband Flachglas e.V. and the "Guideline<br />

to Assess the Visible Quality of Glass in Buildings." are valid (unless otherwise agreed in writing).<br />

90°<br />

• Heat-soak tested fully tempered (toughened)<br />

safety <strong>glass</strong><br />

• Fire resistant <strong>glass</strong> (in cooperation)<br />

• Alarm Securit®<br />

• Thermovit – heatable <strong>glass</strong><br />

It's possible to manufacture <strong>curved</strong> tempered <strong>glass</strong>,<br />

<strong>curved</strong> tempered <strong>glass</strong> with heat-soak test and <strong>curved</strong><br />

heat-strengthened <strong>glass</strong> into laminated safety <strong>glass</strong><br />

and insulated <strong>glass</strong> to meet every safety and security<br />

specification.<br />

05.2012 • Remark: technical modifications and errors excepted!