Rapport nr. 52 - Elkem

Rapport nr. 52 - Elkem

Rapport nr. 52 - Elkem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

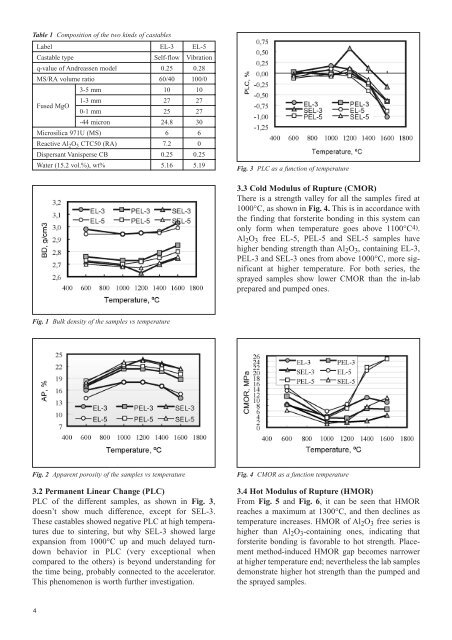

Table 1 Composition of the two kinds of castablesLabel EL-3 EL-5Castable type Self-flow Vibrationq-value of Andreassen model 0.25 0.28MS/RA volume ratio 60/40 100/03-5 mm 10 10Fused MgO1-3 mm 27 270-1 mm 25 27-44 micron 24.8 30Microsilica 971U (MS) 6 6Reactive Al 2 O 3 CTC50 (RA) 7.2 0Dispersant Vanisperse CB 0.25 0.25Water (15.2 vol.%), wt% 5.16 5.19Fig. 3 PLC as a function of temperature3.3 Cold Modulus of Rupture (CMOR)There is a strength valley for all the samples fired at1000°C, as shown in Fig. 4. This is in accordance withthe finding that forsterite bonding in this system canonly form when temperature goes above 1100°C4).Al 2 O 3 free EL-5, PEL-5 and SEL-5 samples havehigher bending strength than Al 2 O 3 , containing EL-3,PEL-3 and SEL-3 ones from above 1000°C, more significantat higher temperature. For both series, thesprayed samples show lower CMOR than the in-labprepared and pumped ones.Fig. 1 Bulk density of the samples vs temperatureFig. 2 Apparent porosity of the samples vs temperature3.2 Permanent Linear Change (PLC)PLC of the different samples, as shown in Fig. 3,doesn’t show much difference, except for SEL-3.These castables showed negative PLC at high temperaturesdue to sintering, but why SEL-3 showed largeexpansion from 1000°C up and much delayed turndownbehavior in PLC (very exceptional whencompared to the others) is beyond understanding forthe time being, probably connected to the accelerator.This phenomenon is worth further investigation.Fig. 4 CMOR as a function temperature3.4 Hot Modulus of Rupture (HMOR)From Fig. 5 and Fig. 6, it can be seen that HMORreaches a maximum at 1300°C, and then declines astemperature increases. HMOR of Al 2 O 3 free series ishigher than Al 2 O 3 -containing ones, indicating thatforsterite bonding is favorable to hot strength. Placementmethod-induced HMOR gap becomes narrowerat higher temperature end; nevertheless the lab samplesdemonstrate higher hot strength than the pumped andthe sprayed samples.4