Flat Lapping - Kemet International

Flat Lapping - Kemet International

Flat Lapping - Kemet International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

B e n e f i t s o f K e m e t ’ sA d v a n c e d L a p p i n g T e c h n o l o g y<strong>Kemet</strong> offers a complete range of lapping and polishing systems for industry. Special purpose machinescan be developed for specific applications.• Significant reduction in lapping costs• Cleaner environment conditions• Reduced inspection requirements• One operation surface finish• Semi skilled operation• Faster material removal• Faster polishing process• Pre set parameters• Reduced rejections• Optimum geometry and surface finish• Easier product cleaning• Better utilisation of machine timeKEMET BALL POLISHING MACHINE3

<strong>Kemet</strong>Diamond Abrasives<strong>Kemet</strong> <strong>International</strong> is one of the world’s leading manufacturers of Diamond Abrasive Products usedin research and industry. The wide range of standard formulations include liquids, pastes, suspensions,gels and sticks. Our laboratories have over 50 years experience and have developed specialformulations for most lapping and polishing processes. These range from basic hand lappingoperations to fully automatic double sided lapping systems.4

Features• Consistency of PerformanceManufactured under a Quality System registeredby BSI Cert No QO5919 ISO 9001:2008• Precise and Superfine Surface FinishesAvailable in an extensive range of differentmicron sizes, containing only virgin DiamondPowder, graded to closer tolerances than theinternationally recognised standardsStandard <strong>Kemet</strong> Liquid Diamond ProductsType KAn excellent, general purpose, low viscosity oil/wateremulsion suitable for most applications.Type W SeriesWater soluble Liquid Diamond available invarious viscosities. Recommended where lapping/polishing must be carried out in the absence ofoil based materials.Type OLow viscosity oil soluble Liquid Diamond withenhanced cleaning properties.• Efficiency and EconomyUniform suspension of Diamond Powders inspecially formulated chemical carriers, ensuresthat the diamond cuts and polishes withmaximum effectiveness• Reduction in <strong>Lapping</strong> CostsSuitable for dispensing with the <strong>Kemet</strong>Electronic System, thus eliminating wastage andreducing lapping costs• Easy Product CleaningSpecially formulated Liquid Diamond Productsenable parts to be cleaned easily.Technical DataMicron SizeFinal Polishing 1 /101/41/21<strong>Lapping</strong> & 6Pre-Polishing 8231014Rapid Stock Removal 2545<strong>Kemet</strong> Liquid Diamond isnormally supplied in unitsof 400g, 2000g or 2500g.Special micron sizes,formulae, colour coding andother packaging sizes forspecific applications areavailable.Concentrations are standardstrong and extra strong.Specials are manufactured.<strong>Kemet</strong> Lubricating FluidsSpecially developed to ensure that <strong>Kemet</strong>Liquid Diamond cuts and polishes with maximumefficiency. Two Lubricating Fluids arerecommended – Type K, a mineral oil basedlubricant, and Type W, a water based lubricant.5

<strong>Kemet</strong><strong>Flat</strong> <strong>Lapping</strong> Plates<strong>Kemet</strong> composite lapping plates are manufactured Featuresfrom a homogeneous mixture of synthetic resins,• Holds diamond particles firmly, ensuring bothmetal particles and other materials. The plates areefficient stock removal and repetitiveideal for today’s advanced lapping technology,component surface finish.especially when used with <strong>Kemet</strong> Liquid Diamond.• Ductile qualities cushion the diamond particles,preventing damage to the workpiece.• Produced in varying hardness values sothat even the softest material can, withoutimpregnation, be safely lapped with diamondparticles.• Dissipates heat and prevents laminar flowof lapped surfaces.• Easy control for optimum flatness.• <strong>Lapping</strong>/polishing plates available to fit allmakes of lapping machines with platediameters up to 3000mm.• Supplied with a cast iron backing plate formaximum stability.<strong>Kemet</strong> <strong>Lapping</strong> Plates<strong>Kemet</strong> IronThe most commonly used plate. For general purposestock removal and lapping operations<strong>Kemet</strong> XPGives improved flat polished surfaces on manymaterials. <strong>Flat</strong> mirror surfaces can be producedon many hard materials<strong>Kemet</strong> CopperUsed to lap softer materials where fine lappingand polishing are the primary requirements<strong>Kemet</strong> TinOne of the softest <strong>Kemet</strong> Plates used for mirrorpolishing with fine grades of <strong>Kemet</strong> LiquidDiamond.6

<strong>Kemet</strong> <strong>Flat</strong> <strong>Lapping</strong> PlatesStandard <strong>Kemet</strong> <strong>Lapping</strong> PlatesThese plates are normally supplied mountedon a cast iron backing plate for maximumstability. They are recommended for generaland heavy-duty work where high precisionflatness and surface finish are required.Standard Plate<strong>Kemet</strong> Lift Off Disc System<strong>Kemet</strong> <strong>Lapping</strong> Plates are also available asLift Off Discs, for machines up to 610mm (24")diameter. Discs are supplied mounted on analuminium backing plate, which locates on to analuminium drive plate by means of three pegs.Lift Off Discs can be easily changed and arerecommended for light duty work where generalflatness and precision finish are required.Lift Off Disc AssemblyGrooving<strong>Kemet</strong> <strong>Lapping</strong> Plates can be supplied grooved tosuit specific applications.SquareConcentricSpiral<strong>Kemet</strong> Annular Grooved PlatesThese plates are designed for precision shoulderlapping of a wide range of parts, such as fuelpump gear faces and pressure relief valve caps.Groove width and depth of plates need to bespecified when ordering.DepthWidthAnnular Groove7

<strong>Kemet</strong><strong>Flat</strong> <strong>Lapping</strong> MachinesKEMET 15/20 MODELSFeaturesBench Mounted Precision Diamond <strong>Flat</strong><strong>Lapping</strong> and Polishing MachinesBoth <strong>Kemet</strong> 15 and 20 models are benchmounted machines with rigid metal constructionand height adjustable work tables.The machines incorporate digital processtimers and automatic Liquid DiamondDispensing Systems.Options• Suitable for lift off disc system• Fixed speed• Pneumatic lift on model 20"Other versions• Variable speed• Suitable for bench mounting• Produces optically flat surfaces with highprecision surface finish• Reduces lapping costs – fully controllable <strong>Kemet</strong>Electronic Dispensing System accurately metersdiamond abrasive onto the lapping plate• Reduces waste – only small quantities ofdiamond abrasive and non-toxic fluids are used• Built in abrasive system for conditioning<strong>Kemet</strong> plates• Electrical System complies with EN 60 204• Easy to adapt for special lapping applications• Transportable• COL-K Chemical polishing version• Clipper Blade sharpening machineKEMET 15 KEMET 208

KEMET 24/36 MODELSFeaturesBoth <strong>Kemet</strong> 24 and 36 machines have rigidwelded tubular section steel frames, supportingthe gearbox, drive motor and worktable. They alsohouse a integral abrasive compound feed andwaste tanks behind lift-off panels. The machinesincorporate soft starting features, which smoothlyaccelerate the lapping plate from stand still to fullspeed, over a pre-determined time period.Options• Variable speed• Produces optically flat surfaces with highprecision surface finish• Reduces lapping costs – fully controllable <strong>Kemet</strong>Electronic Dispensing System accurately metersdiamond abrasive onto the lapping plate• Built in abrasive system for conditioning<strong>Kemet</strong> Plates• Suitable for large parts or large volumeproduction• Electrical System complies with EN 60 204• Temperature control• Drop table• Pneumatic lift or open face• 3 or 4 ring versions• COL-K Chemical Polishing versions• Light beam guardingKEMET 24 OPEN FACEKEMET 36 PNEUMATIC LIFT9

<strong>Kemet</strong><strong>Flat</strong> <strong>Lapping</strong> MachinesK e m e t L a p p i n g M a c h i n eCapacity Chart15 20 24 36 48 56 72 84Components per conditioning ring based on typical loading of approximately 60% ring surface area.KEMET MODELDIA OF PARTSMM IN15 20 24 24 36 36 48 56 72 843 Ring 3 Ring 3 Ring 4 Ring 3 Ring 4 Ring 4 Ring 4 Ring 4 Ring 4 Ring6 0.25 2757.5 0.29 1759 0.35 11810.5 0.42 8612 0.47 60 150 210 15013.5 0.53 50 114 165 11415 0.59 40 90 132 9018 0.71 27 63 87 63 204 15622 0.87 18 39 57 39 93 72 132 20426 1.00 12 33 42 33 93 72 132 20430 1.19 10 21 33 21 69 54 99 15034 1.31 8 17 24 17 60 39 75 117 20438 1.5 6 14 18 14 42 33 60 100 16442 1.62 5 10 15 10 33 25 48 76 132 18546 1.81 4 9 13 9 29 33 39 62 108 15250 1.97 3 7 10 7 24 20 33 52 92 12954 2.12 2 6 9 6 21 15 29 44 78 10960 2.37 2 5 7 5 17 12 24 35 62 8870 2.75 2 3 5 3 12 10 17 26 44 6380 3.12 1 3 4 3 10 8 14 20 35 4790 3.31 1 2 3 2 7 5 12 16 26 38100 3.94 1 2 3 2 6 5 8 12 21 30110 4.31 1 1 2 1 5 3 7 10 18 24120 4.72 1 1 2 1 4 2 5 8 16 20130 5.12 1 1 1 1 3 2 5 8 14 17140 5.5 1 1 1 1 2 2 4 6 10 15The above data is for using standard loading procedures. It is often possible to extend the capacity of a machine utilising special workholding arrangementsand fixtures.10

K e m e t M a c h i n eSpecifications15 20 24 36 48 56 72KEMET m/c MODEL15202436485672LAPPING PLATEmm381508610914121814221828OUTSIDE DIAMETERin15202436485672LAPPING PLATE SPEED70rpm70rpm58rpm58rpm48rpm48rpm30rpmNO OF CONDITIONINGRINGS333 or 43 or 43 or 43 or 44CONDITIONING RINGmm140191248 209368 322505 432578 530692INSIDE DIAMETERin5.57.59.75 8.2514.5 126919.9 1722.7 20.927.25HEIGHT OF OPEN FACEmm670648940940991991914MACHINEin26.525.53637393936HEIGHT OF PNEUMATICmm--16302000235027682820LIFT MACHINEin--64.278.7592.5109111WORKING HEIGHTmm31031094094010001000912in12.212.2373739.439.436WIDTH OF MACHINEmm76088312201600142220572120in3034.754863568183.5DEPTH OF MACHINEmm62068613501620200021842667in242753.263.778.786105STANDARD ELECTRICALSUPPLY220v-1Ph-50Hzor 380v or415v3Ph-50Hz220v-1Ph-50Hzor 380v or415v3Ph-50Hz220v or380v or415v3Ph-50Hz220v or380v or415v3Ph-50Hz220v or380v or415v3Ph-50Hz220v or380v or415v3Ph-50Hz220v or380v or415v3Ph-50HzMAIN DRIVE MOTOR0.37kW0.75kW1.5kW4.1kW7.5kW11kW15kWABRASIVE PUMP MOTOR0.2kW0.05kW0.18kW0.18kW0.18kW0.18kW0.18kWGROSS WEIGHTOPEN FACEEXPORT PACKED156kg388kg730kg1220kg3800kg4000kg6650kgNETT WEIGHTOPEN FACE116kg195kg555kg1000kg2845kg3700kg5359kgGROSS WEIGHTPNEUMATIC LIFTEXPORT PACKED--997kg1880kg3570kg5573kg9876kgNETT WEIGHTPNEUMATIC LIFT--700kg1530kg3145kg5273kg7930kgNOTE:- Metric/Imperial conversions are approximate. All dimensions are for machines fitted with KEMET Electronic Spray Systems.In the interests of development we reserve the right to change specifications without notice.11

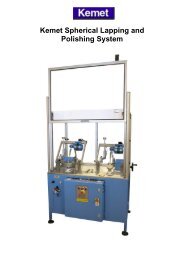

<strong>Kemet</strong>Spherical <strong>Lapping</strong> and Polishing SystemCapabilities• Fully guarded with auto lifting door access.To lap and polish pre-machined spherical balls andcups to a mirror finish with roundness usuallybetter than 3 microns.System Features• 6 motors all with independent variable speed toprovide complete control.• <strong>Lapping</strong> and Polishing pressures appliedpneumatically.• Simple change from ball to cup polishing action.• Average process time less than 5 mins.• Low running costs.• Manual and Jogging facility provided for setting up.• Dual process timers.• Single button process start.• Lighting provided.• Smooth and silent running.• Comes complete with initial tooling set• CE marked.• Full manual and training provided.• Size: 1600mm (W) x 820mm (D) x 2500mm (H)• Electrical: 230.1.50 supply• Air: 3 Bar Max.12

<strong>Kemet</strong>Dispensing SystemsThe <strong>Kemet</strong> Electronic Dispenser distributes <strong>Kemet</strong>Liquid Diamond and Lubricating Fluid by means oftouch sensitive settings. The digital display showsdispensing intervals, durations and air pressure ata glance. Dispensing is achieved to an accuracyof 0.2 gm, eliminating wastage and simplifyingcost control.The <strong>Kemet</strong> Liquid Diamond Stirrer Unit maintainsa consistent distribution of diamond particleswithin the slurry by using a small non-contaminantplastic coated paddle magnet, which ensureseven diamond suspension. The <strong>Kemet</strong> DualDispensing Bar can be positioned to dispenseLiquid Diamond and Lubricating Fluid accuratelyon to the plate without spray bounce.Features• Supplied as standard with <strong>Kemet</strong> <strong>Flat</strong> <strong>Lapping</strong>and Polishing Machines and Plates• Easily fitted to existing conventional <strong>Flat</strong> <strong>Lapping</strong>Machines to improve productivity• Fully controlled metering of <strong>Kemet</strong> LiquidDiamond and Lubricating Fluid usingindependent pressure and time settings• Easy to install and operate• Electrical system complies with EN 60 204.<strong>Kemet</strong> Electronic DispenserDispenses <strong>Kemet</strong> Liquid Diamond and Lubricating Fluid automatically at pre-set intervals in conjunction with a lapping andpolishing machine cycle timer.HeightWidthDepth (exc. air filter)Nett Weight150mm230mm150mm3.74kgAir requirementsAir pressureAir pressure display1 Bar min5 Bar maxDual circuitBar or psiAdjustable durationof sprayAdjustable intervalsof spraySpray memory1-9 seconds1-999 secondsStandardCODE 360499Manual overrideStandardElectrical supply 110V or220V - 240V50Hz or 60Hz(self adjusting for supply voltage & frequency)<strong>Kemet</strong> Dual Dispensing Bar & BottlesSupplied complete with two bottles and plastic tubing. Fullyadjustable head for vertical and radial positioning.StandardLongLength 340mm 495mmReach 260mm 415mmAdjustable height 100mm 100mmSection of head20mm x 20mmBottle capacity 400ml 400ml<strong>Kemet</strong> Liquid Diamond Stirrer UnitQuiet electric unit has fully variable speed control and isprovided with a magnetic stirrer paddle.HeightWidthDepthElectrical supply120mm90mm215mm50Hz or 60Hz230V110VCODE 360534 360536CODE 360511 360510<strong>Kemet</strong> Single Spray HeadSupplied with bottle, cap and plastic tubing.Standard Long Extra LongLength 130mm 250mm 380mmCODE 360517 360514 360512Electronic DispenserLiquid Diamond Stirrer UnitDual Dispensing Bar & BottlesSingle Spray Head13

<strong>Kemet</strong><strong>Flat</strong>ness Measuring EquipmentFor use with <strong>Kemet</strong> <strong>Flat</strong> <strong>Lapping</strong> and Polishing Optical <strong>Flat</strong> Light Box Stands are available for useSystems, <strong>Kemet</strong> <strong>Flat</strong>ness Measuring Equipment with large Optical <strong>Flat</strong>s.is designed to assist in the measurement andmaintenance of surface flatness.<strong>Kemet</strong> Monochromatic LightProduces clear flatness readings when used with<strong>Kemet</strong> Optical <strong>Flat</strong>s. The compact designed Lightis easily transportable and uses a sodium long-lifelight source. Supplied with a flatness readinginterpretation chart.<strong>Kemet</strong> Monochromatic LightCODEMonochromatic Light230V50Hz or 60Hz361201110V50Hz or 60Hz361211<strong>Kemet</strong> Monochromatic Light14

<strong>Kemet</strong> <strong>Flat</strong>ness GaugesThe <strong>Flat</strong>ness Gauges are used to monitor lappingplate flatness, which, in turn, gives an indicationof component flatness. Available for most machinesizes, in metric calibration, the gauges aresupplied in a case with a master setting block.Full instructions are provided.<strong>Kemet</strong> Optical <strong>Flat</strong>sProduced from Quartz, <strong>Kemet</strong> Optical <strong>Flat</strong>sare available in single and double sided,standard sizes from 25mm up to 300mmdiameter. They are supplied with Certificateof Conformity together with full instructions.National Physical Laboratory Certificates arealso available. Special optical flats are availableon request. <strong>Kemet</strong> offers an optical flatreconditioning and calibration service.<strong>Kemet</strong> Optical <strong>Flat</strong>s CODE CODEDiameter Accuracymm in Light Bands Single sided Double sided25 1 1 /4 361220 36123725 1 1 /10 361221 36123850 2 1 /4 361222 3612159" <strong>Flat</strong>ness Gauges50 2 1 /10 361223 36123975 3 1 /4 361224 36170575 3 1 /10 361225 361240<strong>Kemet</strong> <strong>Flat</strong>ness GaugeType LSuitable for <strong>Lapping</strong> Plates380mm (15") dia and aboveCODEMETRIC361304100 4 1 /4 361226 361210100 4 1 /10 361227 361241125 5 1 /4 361228 361242125 5 1 /10 361229 361214150 6 1 /4 361123 361216150 6 1 /10 361231 361243200 8 1 /4 361232 361219200 8 1 /10 361233 361244250 10 1 /4 361234 361217250 10 1 /10 361235 361245300 12 1 /4 361218 361246300 12 1 /10 361236 361247Larger Optical <strong>Flat</strong>s on request.<strong>Flat</strong>ness Reading Wall Charts are availableupon request<strong>Kemet</strong> Optical <strong>Flat</strong>s15

<strong>Kemet</strong>Consumables, Spares and Accessories<strong>Kemet</strong> Abrasive ProductsKEMET supply the widest range of Abrasive Products, including Liquids, Pastes, Suspensions andPowders. Aluminium Oxide and Silicon Carbide are available in all grit sizes.KemoxA range of suspension treated abrasives where the abrasive and carrier are pre-mixed in thecorrect proportions, resulting in a cleaner and more efficient <strong>Lapping</strong> Process. Other abrasive typesare available.Description Size Code DetailsKemox 0-950 5 Ltr 300102 Oil Based Aluminium Oxide. Finer surface finishon soft componentsKemox 0-800S 5 Ltr 300112 Oil Based. General Aluminium oxide lapping wherea scratch free matt lap is requiredKemox 0-400S 5 Ltr 300111 Oil Based. General Aluminium oxide lapping wheregood stock removal and a matt lap is requiredKemox W-950 5 Ltr 300152 Water based Aluminium Oxide where oil can't beused. Finer surface finish on soft componentsKemox W-800 5 Ltr 300143 Water based fine Aluminium OxideKemox W-400 5 Ltr 300141 Water based medium Aluminium Oxide18

Col-KA liquid polish used on KEMET CHEM CLOTH to produce the ultimate in highquality mirror polishes on polishing machines. A part abrasive part chemicalpolishing action makes COL-K well suited to polishing difficult materialssuch as Stellite and Cobalt Chrome.Description Micron Size CodeCol-K Colloidal Silica Suspension for use on mostmaterials at polishing stage.0.06 5 Litres 60019920 Litres 600202Abrasive Pastes<strong>Kemet</strong> manufacture a wide range of abrasive lapping pastes. Our range of Silicon Carbide andAluminium Oxide pastes have many applications but are particularly suited to the lapping ofmechanical seals and valve seats. The pastes are water soluble and safe to useSilicon Carbide PasteMicron Size Fepa Grit Size Code75 F180 36154936.5 F280 36153829.2 F320 36155822.8 F360 36154817.3 F400 361551Aluminium Oxide PasteMicron Size Fepa Grit Size Code22.8 F360 36154212.8 F500 3615469.3 F600 3615436.5 F800 3615453 F1200 3615449.3 F600 3615144.5 F1000 3615523 F1200 361547<strong>Lapping</strong> PlatesWe offer a part exchange service for all worn<strong>Kemet</strong> <strong>Lapping</strong> Plates. Cast iron and soft metalplates are available for most machines.Conditioning RingsConditioning Rings wear naturally as part of thelapping process. Replacements are available tofit most flat lapping machine models.<strong>Lapping</strong> PlatesConditioning Rings<strong>Kemet</strong> can supply <strong>Kemet</strong> lapping plates for all lapping machine models including segmented plates for48 inch machines and larger. Ceramic or Plastic faced rings are available for use on polishing cloths.19

<strong>Kemet</strong>Industrial Cleaning SystemsIndustry and manufacturers with lappingThere is also a range of Rinse / Dryer /processes increasingly require more efficient Dewatering / Filtration equipment to tailor aand environmental methods of cleaningsystem to achieve the required cleaning standard.precision parts.Fully 'automatic' systems are also available.<strong>Kemet</strong> can supply ultrasonic cleaning systems In applications where only solvent will achievefrom 3 to 3,000 litres for use with Aqueousthe required performance, we have fully enclosedultrasonic detergents.solvent systems available.Selection of the popular Si (Semi-Industrial Range)ModelTank Volume / litresExternal Dimensions / mmTank Dimensions / mmBasket Dimensions / mmLoad /kgUltrasonic Frequency / kHzUltrasonic Power / WHeating Power / WVoltage Frequency / V/ HzConnected load / WSi-25 Si-40Si-80, 12 Si-120Si-160, 2425540Lx 400W x 500H385Lx 280W x 250H345Lx 240W x 195H5303001000230/50130040640Lx 390W x 540H475Lx 265W x 300H420Lx 225W x 225H5306001500230/50210080760Lx 460W x 720H585Lx 330W x 400H540Lx 290W x 340H203012002000230/503200120740Lx 580W x 745H585Lx 450W x 450H540Lx 400W x 390H353012004000400/5052001601340Lx 460W x 770H1180Lx 330W x 400H1110L x 280W x 300H403024006000400/508400<strong>Kemet</strong> Programme:• Full range available from laboratory to heavy industrial• Automatic or manual systems• Aqueous or solvent systems• Full design, technical, testing and support Programme• Comprehensive range of fluids to suit most applications• See more details at www.kemet-cleaning.co.uk20

Other <strong>Kemet</strong> Catalogues available on requestPRODUCTS FORTHE TOOLROOMAND PRECISIONENGINEERKEMET CLEANINGSYSTEMSMETALLOGRAPHICCONSUMABLESTRAINING COURSES AREAVAILABLE FOR ALLKEMET PRECISION PROCESSES23

<strong>Kemet</strong>The World Over<strong>Kemet</strong> <strong>International</strong> Ltd. Subsidiary CompaniesUnited Kingdom<strong>Kemet</strong> <strong>International</strong> LtdNetherlands<strong>Kemet</strong> Europe B.V.Belgium and Luxembourg<strong>Kemet</strong> Europe B.V.B.A.China<strong>Kemet</strong> China LtdJapan<strong>Kemet</strong> JapanCompany LtdKorea<strong>Kemet</strong> KoreaAustralia<strong>Kemet</strong> Australia Pty LtdSingapore<strong>Kemet</strong> Far East PTE LTDMalaysia<strong>Kemet</strong> Precision (M) SDN BHD<strong>Kemet</strong> Products are available through a WorldwideNetwork of Authorised Distributors inEuropeAsiaAfricaU.S.A.Middle EastAustralasia<strong>Kemet</strong><strong>Kemet</strong> <strong>International</strong> LimitedCuxton Road Parkwood Trading EstateMaidstone Kent ME15 9NJ United KingdomTel: +44 (0) 1622 755287 Fax: +44 (0) 1622 670915E-mail: sales@kemet.co.uk Website: www.kemet.co.uk