ProCell - Process Flow Cells - Specac

ProCell - Process Flow Cells - Specac

ProCell - Process Flow Cells - Specac

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

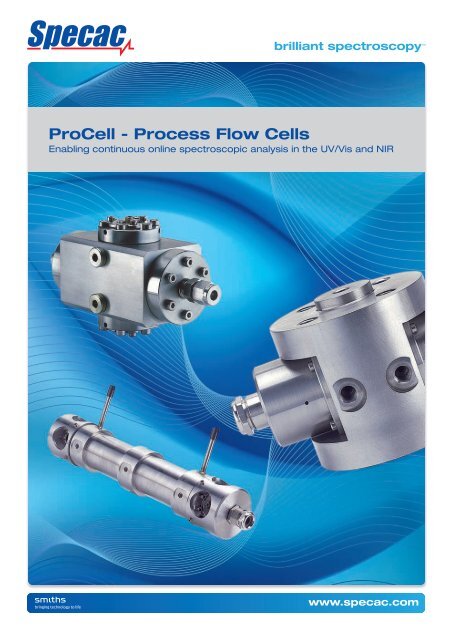

illiant spectroscopy <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong>Enabling continuous online spectroscopic analysis in the UV/Vis and NIRwww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>Process</strong> flow cells for online spectroscopic analysisReliable sampling. <strong>Process</strong> optimization. Safety.Modern process control benefits from access toreal-time information. Fiber-optic coupledprocess flow cells are a key enabling technologyto facilitate the acquisition of continuous onlineUV/Vis and NIR spectroscopic absorbanceprocess measurements. In many instances, thisallows the user to achieve significant cost savingsthrough process optimization. <strong>Process</strong> flow cellscontribute to plant safety by eliminating the needfor the extraction and transportation of potentiallyhazardous process sample to a site laboratoryfor analysis. Further advantages include apossible reduction in the cost of processsampling, and elimination of sample wastage.With state of the art design and materialmodeling tools, and over 15 years of processapplication experience to draw from, <strong>Specac</strong>'srange of process flow cells have a proven trackrecord of reliability and robustness to ensurelong-term operation in the most demandingindustrial environments. Computer-aided opticaldesign ensures that our process flow cells havethe highest levels of optical throughput to ensurethe best quality of spectroscopic data.Tailored to meet your needsMaterials, pathlength, interfacing: Your choice.<strong>Specac</strong> process cells are customized to ensureexact matching with the client’s processrequirements. Material metallurgies, seal types,and window materials are chosen to becompatible with the chemical and environmentalneeds of the application. Optical designs areconfigured for the UV/Vis or NIR spectral regionsas appropriate, and optical pathlengths are set toensure optimum spectral absorbance of thetarget chemical species. A range of pipe fittingsand flange connections are available to interfacethe process flow cell with the process pipe work.Cleaning ports and seal leak warning ports canalso be integrated into the cell design.<strong>Specac</strong>'s application engineers work closely withthe customer to ensure the optimum processflow cell solution for the application.brilliant spectroscopy www.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong>Integration of process flow cellsGetting light through the process sample.Light is transmitted via an optical fiber cable fromthe spectrophotometer source to one port of theprocess flow cell. Collimation optics then directthis light beam through a set pathlength ofprocess stream to a second set of optics whichre-focus the beam to a return optical fiber cableattached to the second process flow cell port.The return optical fiber cable serves to transmitthe light beam back to the spectrophotometerdetector. <strong>Process</strong> flow cells are typically installedas part of the process circuit either directly in theprocess stream or as a “by-pass loop”. Byadopting the process flow cell in a “by-pass loop”configuration, the user has the opportunity toisolate the process flow cell from the process cellfor routine cleaning, servicing, or calibration.<strong>Process</strong><strong>Flow</strong> CellOptical fiberSpectrophotometerSourceDetector<strong>Process</strong><strong>Flow</strong>(i) Direct installationValve<strong>Process</strong><strong>Flow</strong><strong>Process</strong><strong>Flow</strong> CellOptical fiberSpectrophotometerSourceDetector(ii) “By-pass loop” installationwww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong>Optimized construction materialsRugged. Robust. Reliable.<strong>Process</strong> flow cells are designed to withstand therigors of process and environmental conditionswhile maintaining continuous measurementstability. The choice of construction materials isan important consideration to ensure materialcompatibility with a range of substances in theprocess stream, and durability to the temperatureand pressures of operation - this often goesbeyond standard operating conditions, andincludes aggressive cleaning regimes andextreme weather conditions.Cell body material:<strong>Specac</strong> <strong>ProCell</strong> process flow cells aremanufactured from a range of materials, chosento ensure optimum chemical compatibility andenvironmental durability. Typical materials includeStainless Steel 316L, Duplex Stainless Steel,Hastalloy© C276, Zirconium, or Titanium, butothers are available upon request.Window material:Sapphire windows are used as standard toensure the highest level of process cell durability.With outstanding thermal characteristics, coupledwith exceptional abrasion resistance – secondonly to diamond – and strongly resistant againstcorrosive process fluids, sapphire is a clearmaterial of choice for process flow cell windows.Standard sapphire substrates offer excellenttransmission characteristics from the UV to 5microns; for specific UV applications, UV gradesapphire is available. As sapphire is able to bepolished to a high degree, it is less prone tofouling than other lesser materials.Seal material:<strong>Process</strong> flow cells contain a seal between theoptical and mechanical components, and theintegrity of this seal is often critical to the reliabilityof the cell. <strong>Specac</strong> offers a wide variety of sealoptions to meet a broad scope of customerneeds. These include chemically inert perfluoroelastomers(such as Kalrez© or Chemraz©), orgold diffusion bonding for the most demandingapplications.For added peace of mind, perfluoroelastomerseals may be incorporated in a unique dual sealarrangement to guard against the unlikely eventof window seal failure. With the aid of complexmodeling software, <strong>Specac</strong> application engineerscan predict the behaviour of the seal under a widevariety of conditions that may be experiencedduring its lifetime.Optical fiber cablesDelivering light to the point of measurement.<strong>Specac</strong> <strong>ProCell</strong> process flow cells are compatiblewith a range of optical fiber cables, with coresizes of up to 600 microns diameter. Theseshould be selected by the user to be appropriatefor the application. For instance, water-freeoptical fiber is typically used for NIR applications,while special UV-grade optical fiber should beused if enhanced UV transmission is needed.Optical fibers should also be appropriately coatedfor the temperature experienced at the point ofconnection to the process flow cell: polyimidecoatedor metal-coated fibers are recommendedfor higher temperature applications. <strong>Specac</strong>follows the industry standard by using the widelyavailable and popular SMA 905 style of fiberconnector to interfaceoptical fibers with theprocess flow cell.brilliant spectroscopy www.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong>Added featuresTell tale leak ports, fiber termination hoods, cleaning ports.A wide range of added features are offered by<strong>Specac</strong> to further enhance the performance ofour <strong>ProCell</strong> process flow cell product range.For instance, seal leak warning ports can beincorporated for additional process security, andcells can be specified with a cleaning port to alloweasy in-situ cleaning of the windows without theneed to remove the cell from the processenvironment. Furthermore, protective metalhoods (to I.P. 65 rating) can be fitted over thefiber connections to relieve strain from the fiberconnector, to guard against accidental damageat the process cell port, and prevent ingressionof moisture and dust/dirt.Range of <strong>Process</strong> <strong>Cells</strong>Liquids. Vapours.<strong>ProCell</strong> Vortex Liquid Phase <strong>Process</strong> <strong>Flow</strong> Cell:<strong>Specac</strong>'s <strong>ProCell</strong> Vortex liquid phase process cell isdesigned to sample industrial liquid streams bymeans of UV/Vis or NIR. These applicationsusually involve optical pathlengths of 1.0 - 10mm.Typical specifications are 0 to 400°C and vacuumto 1500 psi.<strong>ProCell</strong> Typhoon Gas/Vapour Phase <strong>Process</strong> <strong>Flow</strong> Cell:<strong>Specac</strong>'s <strong>ProCell</strong> Typhoon process cell isdesigned to sample industrial gas / vapour phasestreams by means of UV/Vis or NIR. The gas orvapour stream is sampled through a preset, fixedpathlength (20, 30, and 50 cm available asstandard), and typical specifications are 0 to 280°Cand vacuum to 1500 psi.www.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Vortex data sheet<strong>ProCell</strong> Vortex - Liquid Phase <strong>Process</strong> <strong>Flow</strong> CellRugged flange-mounted spectroscopic transmission cell for industrialliquid process monitoring in the UV/Vis or NIR.<strong>ProCell</strong> VortexThe <strong>Specac</strong> <strong>ProCell</strong> Vortex liquid phase processcell is an extremely robust cell that deliversoptimum sensitivity to process characteristics.Through partnerships with leading multinationalcompanies, <strong>Specac</strong> have developed unrivalledengineering design expertise and manufacturingtechniques for process cells. With a wide choiceof cell metallurgies and sapphire windows asstandard, <strong>ProCell</strong> Vortex process cells have anestablished reputation for ruggedness andreliability. Product solutions customized toindividual requirements are available in additionto the range of standard products.Key Features• Proven reliability in aggressiveenvironments.• Range of cell body and seal materials• Selection of sizes for ease of processintegration• Cleaning port option for in-situ servicing• Capability for high temperatureapplications (up to 400°C)• Factory-aligned optics to ensure optimumstability and cell sensitivitywww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Vortex data sheet<strong>ProCell</strong> Vortex:Tailored for the applicationThe <strong>ProCell</strong> Vortex series process cell isdesigned to be flange mounted directly into theprocess stream or in a by-pass. To ensure easeof process integration, the cell can be configuredfrom a wide range of ANSI and DIN flange sizes.A choice of cell body materials, typically startingwith Stainless Steel, Duplex Stainless Steel, orHastelloy®, and a selection of high performanceperfluoroelastomer window seals or dffusionbonded windows ensures appropriate chemicalcompatibility for the application. Furthermore, toensure optimum UV/Vis or NIR spectroscopicabsorption features for analysis, opticaltransmission pathlengths are available from 1.0 to10 mm. Optical components within the cell areselected to be compatible with the wavelengthrange of interest and the diameter of optical fiberspecified by the user. Optical fiber connectivityis ensured by industry standard SMA 905connectors.<strong>Process</strong> streamSMA connectorProtective hoodFiber optic cableCable glandOptical systemSapphire windowPathlengthFiber optic cable<strong>ProCell</strong> Vortex:Reliability, for peace of mindAll aspects of the <strong>ProCell</strong> Vortex were developedto give long-term reliability under the toughconditions of thermal shock, high operatingtemperatures, and aggressive chemistries thatare often encountered in the processenvironment. The use of sapphire windows givesoutstanding abrasion and chemical resistance,in addition to the ability to withstand severethermal shock (e.g. plant cleaning with highpressure steam).The <strong>Specac</strong> <strong>ProCell</strong> Vortex can be designed witha proprietary dual seal arrangement to giveproven long term reliability (with examples of thecell in continuous use for 15 years). Special“hoods” are included that fit over the optical fiberconnectors and give environmental protection(keeping out water, dust and dirt) as well asphysically supporting the cable outer sheath orarmouring. The latter ensures that stresses fromthe weight of the cable (or from it being moved,pulled, etc.) are not transmitted to the opticalfiber connection interface.www.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Vortex data sheet<strong>ProCell</strong> Vortex:Enhanced Optional FeaturesCleaning PortsAn attractive feature of the <strong>Specac</strong> <strong>ProCell</strong> Vortexprocess cell is the optional “cleaning port”, wherea novel plug arrangement gives access to thewindow surfaces. This allows the internal cellwindows to be cleaned without removing the cellfrom the pipe work, in the event that foulingoccurs (either from long term use or following aprocess upset that caused material to bedeposited within the plant). To assist thisfunctionality, the cell would typically be installed ina ‘by-pass’ loop where valves can isolate it fromthe main process when servicing occurs.plug into the port. The latter has the effect ofstopping the leak and allowing the process topressurise the secondary seal. The user is thenaware that the cell is operating on the back-upseal and needs attention at the first convenientopportunity.Diffusion BondingVersions of the <strong>Specac</strong> <strong>ProCell</strong> Vortex processcell are available with diffusion bonded windows.These versions avoid the use of any polymermaterials and are capable of operation attemperatures up to 400°C or in chemicalenvironments that are incompatible with eventhe high performance perfluoroelastomer seals.‘Tell-tale’ PortsA further propriety optional feature is the ‘Tell-Tale’ ports. These are small passages within thecell body that link the space between the primaryand back-up window seals to an outside port.They can be used in critical or hazardousapplications in several ways: either as a visualindication of leakage from the primary seal, orwith the use of a secondary detection system inthe event of a particularly hazardous material. Ifleakage is observed the user has the option ofdealing with it immediately or fitting a blanking<strong>ProCell</strong> Vortex: Application Support<strong>Specac</strong> endeavor to provide the most reliableand appropriate process cell solution for thecustomer’s application. We ensure that anapplication engineer is always close at handthroughout the product purchase andimplementation stages, so customers can havecomplete confidence in our quality of service.<strong>Specac</strong> has an active program of ongoinginnovation to ensure that our process cellsolutions are at the forefront of the market.Large bore <strong>ProCell</strong> Vortexwww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Vortex data sheetStandard SpecificationOptical rangeSpecify UV/Vis or NIR operationPathlength1 - 10mmWindow materialSapphireBody materialStainless Steel 316, Hastelloy C276, and DuplexStainless Steel (others available on request)Temperature range0 - 280°C (up to 400°C with Gold diffusion bonding)Pressure rangeVacuum to 1500 psi.SealsKalrez 4079, Aluminium Diffusion Bonding, or GoldDiffusion Bonding (others available on request)Standard fiber diameter300 to 600µm (others available on request)Fiber fittingSMA 905Pipe fittingRange of ANSI (150 or 300lb) and DIN flanges (16bar)Thermocouple well1/8” BSPOptional FeaturesPrimary seal leak portsWindow cleaning portsProduct ComplianceVersions of the <strong>Specac</strong> <strong>ProCell</strong> Vortex can bedesigned and manufactured to meet a widerange of international pressure and hazardousarea standards. Please contact <strong>Specac</strong> todiscuss your requirements.<strong>ProCell</strong> VortexLiquid Phase <strong>Process</strong> <strong>Flow</strong> CellANSI coupling flange detailsBore Flange Mounting Fixings Dimension DimensionDesignation Diameter Diameter Hole PCD "UNC" “A” (mm) “B” (mm)“C” (mm) “D” (mm) “E” (mm) Minimum Minimum150 lb 1 /2" 12 89.0 60.3 4 x 1 /2" 120 170150 lb 3 /4" 12 98.4 69.8 4 x 1 /2" 120 180150 lb 1" 24 108.0 79.4 4 x 1 /2" 120 186150 lb 2" 49 152.4 120.6 4 x 5 /8" 120 237150 lb 3" 74 190.5 152.4 4 x 5 /8" 120 288150 lb 4" 97 228.6 190.5 8 x 5 /8" 120 314300 lb 1 /2" 12 95.2 66.7 4 x 1 /2" 100 174300 lb 3 /4" 12 117.5 82.5 4 x 1 /2" 100 181300 lb 1" 24 123.8 88.9 4 x 5 /8" 108 188300 lb 2" 49 165.1 127.0 8 x 5 /8" 108 214300 lb 3" 74 209.5 168.3 8 x 3 /4" 115 240300 lb 4" 97 254.0 200.0 8 x 3 /4" 115 266DIN coupling flange detailsBore Flange Mounting Fixings Dimension DimensionDesignation Diameter Diameter Hole PCD Metric “A” (mm) “B” (mm)“C” (mm) “D” (mm) “E” (mm) “Course” Minimum MinimumDIN 15 12 95 65 4 x M12 120 182DIN 20 20 105 75 4 x M12 120 187DIN 25 25 115 85 4 x M12 120 192DIN 40 40 150 110 4 x M16 120 232DIN 50 50 165 125 4 x M16 120 242DIN 80 80 200 160 8 x M16 120 272DIN 100 100 220 180 8 x M16 120 292Please note: these dimensions are intended for guidance only. The application and other customer requirements will render adjustments to the sizesstated. The dimensions can be approximated upon quotation.www.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Vortex data sheet<strong>ProCell</strong> Vortex - Liquid Phase <strong>Process</strong> <strong>Flow</strong> CellPart Number ConfiguratorC Cleaning Port0 Not selectedC SelectedBody Material MStainless Steel 316L S L Tell-Tale LeakDuplex Stainless Steel D0 Not selectedHastelloy C276 HL SelectedCell Type T A ATEX Certification<strong>ProCell</strong> Vortex B0 Not selectedT M DD - S B B P - C L A A SelectedOpitcal pathlength DDP Flange Class1mm 01 ANSI DIN2mm 02 L 150 lb 16 bar4mm 04 H 300 lb6mm 068mm 08 B B Bore Size10mm 10ANSI A A 1/2 "Seal type S A B 3/4 "Kalrez 4079 P A C 1 "Diffusion bonding - Aluminium A A D 2 "Diffusion bonding - Gold G A E 3 "Customer Specified X A F 4 "DIN D A 15 mmD B 20 mmD C 25 mmD D 40 mmD E 50 mmD F 80 mmD G 100 mmPlease note: Dual seal & Tell-Tale Leak Port are available only with ANSI fittings 1/2" and 3/4" or DIN fitting of 15mmwww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Typhoon data sheet<strong>ProCell</strong> Typhoon - Gas/Vapour Phase <strong>Process</strong> <strong>Flow</strong> CellRugged pipe-mounted spectroscopic transmission cell for gas phaseprocess monitoring in the UV/Vis or NIR.<strong>ProCell</strong> TyphoonThe <strong>Specac</strong> <strong>ProCell</strong> Typhoon gas/vapour phaseprocess cell is an extremely robust cell thatdelivers optimum sensitivity to processcharacteristics. Through partnerships withleading multinational companies, <strong>Specac</strong> havedeveloped unrivalled engineering designexpertise and manufacturing techniques forprocess cells. With a wide choice of cellmetallurgies and sapphire windows as standard,<strong>ProCell</strong> Typhoon process cells have anestablished reputation for ruggedness andreliability. Product solutions customized toindividual requirements are available in addition tothe range of standard products.Key Features• Proven reliability in aggressiveenvironments.• Range of cell body and seal materials• Simple and flexible options for processintegration• Cleaning port option for in-situ servicing• Factory-aligned optics to ensure optimumstability and cell sensitivitywww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Typhoon data sheet<strong>ProCell</strong> Typhoon:Configured for the applicationThe <strong>ProCell</strong> Typhoon series process cell isdesigned for continuous in-situ monitoring of gasor vapour-phase process streams. The ruggeddesign allows simple connection to the cell via ¼“bore stub pipes, and the cell is easily traceheatedand insulated for elevated temperatures.Additional ports can be added to facilitateflexibility in choice of flow arrangement.A choice of cell body materials, typically startingwith Stainless Steel, Duplex Stainless Steel, orHastelloy®, and a selection of high performanceperfluoroelastomer window seals ensuresappropriate chemical compatibility for theapplication. Furthermore, to ensure optimumUV/Vis or NIR spectroscopic absorption featuresfor analysis, standard optical transmissionpathlengths are available at 20cm, 30cm, or50cm. Optical components within the cell areselected to be compatible with the wavelengthrange of interest and the diameter of optical fiberspecified by the user. Optical fiber connectivity isensured by industry standard SMA 905 connectors.<strong>Flow</strong> Ports with1/4” dia. Swagelock unionProtective hoodCable glandSapphire windowOptical systemSMA connectorFibre optic cableThermocouplePortFibre optic cableOptional <strong>Flow</strong>/Cleaning Portswith 1 /4” dia. Swagelock unionwww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Typhoon data sheet<strong>ProCell</strong> Typhoon:Reliability, for peace of mindAll aspects of the <strong>ProCell</strong> Typhoon process cellwere developed to give long-term reliability underthe tough conditions of thermal shock, highoperating temperatures, and aggressivechemistries that are encountered in the processenvironment. Sapphire windows give outstandingabrasion and chemical resistance, in addition tothe ability to withstand severe thermal shock(e.g. high pressure steam cleaning). <strong>Specac</strong> employa design of anti-extrusion seal arrangementto give high pressure capability and long-term reliability.Special “hoods” are included that fit overthe optical fiber connectors and supports thecable outer sheath or armouring. Standardversions of these hoods allow air circulationaround the fiber cable termination in order tolower the cable temperature and extend itslifetime. Enclosed versions of the hoods areavailable where environmental protection isnecessary (keeping out water, dust, and dirt).Special high temperature terminated cables areavailable from <strong>Specac</strong>, if necessary. In situationswhere the cell is already physically protected(e.g. in an enclosure) the hoods can simply beleft off and the cables cable-tied to the inside ofthe enclosure to provide strain relief.<strong>ProCell</strong> Typhoon:Enhanced Optional FeaturesCleaning PortsA unique feature of the <strong>Specac</strong> <strong>ProCell</strong> Typhoonprocess cell is the option for “cleaning ports” togive access to the window surfaces. This allowsthe internal cell windows to be cleaned withoutremoving the cell from the pipe work, in the eventthat fouling occurs (either from long term use orfollowing a process upset that caused material tobe deposited within the plant). To assist thisfunctionality, the cell would typically be installed ina ‘by-pass’ loop where valves can isolate it fromthe main process when servicing occurs. Thesecleaning ports are a major advantage insituations where the cell has been heat-tracedas part of the installation.<strong>ProCell</strong> Typhoon:Application Support<strong>Specac</strong> endeavor to provide the most reliableand appropriate process cell solution for thecustomer’s application. We ensure that anapplication engineer is always close at handthroughout the product purchase andimplementation stages, so customers can havecomplete confidence in our quality of service.<strong>Specac</strong> has an active program of ongoinginnovation to ensure that our process cellsolutions are at the forefront of the market.www.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Typhoon data sheet<strong>ProCell</strong> Typhoon - Vapour Phase <strong>Flow</strong> CellStandard SpecificationOptical rangeSpecify UV/Vis or NIR operationPathlength20, 30, and 50 cm (others available on request)Window materialSapphireBody materialStainless Steel 316, Hastelloy C276, and DuplexStainless Steel (others available on request)Temperature range0 to 280°CPressure rangeVacuum to 1500 psi.SealsKalrez 4079 (others available on request)Cell bore10mmFibre diameter300 to 600µm (contact <strong>Specac</strong> for other options)Fiber fittingSMA 905Inlet/outlet tubing:1/4” (others available upon request)Thermocouple well1/8” BSPOptional FeaturesWindow cleaning portsProduct ComplianceVersions of the <strong>Specac</strong> <strong>ProCell</strong> Typhoon can bedesigned and manufactured to meet a widerange of international pressure and hazardousarea standards. Please contact <strong>Specac</strong> todiscuss your requirements.<strong>ProCell</strong> VortexLiquid Phase <strong>Process</strong> <strong>Flow</strong> CellPlease note: these dimensions are intended for guidance only. The applicationand other customer requirements will render adjustments to the sizes stated.The dimensions can be approximated upon quotation. Cell dimension guideDesignationDimension“A” min.Dimension“B” min.200 mm 410 mm 189mm300 mm 510 mm 289mm500 mm 710 mm 490mmwww.specac.com

<strong>Specac</strong> | <strong>ProCell</strong> - <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong><strong>ProCell</strong> Typhoon data sheet<strong>ProCell</strong> Typhoon - Vapour Phase <strong>Process</strong> <strong>Flow</strong> CellPart Number ConfiguratorC Cleaning Port0 Not selectedC SelectedBody Material MStainless Steel 316L S A ATEX CertificationDuplex Stainless Steel D T M DD - S C - A 0 Not selectedHastelloy C276 HA SelectedCell Type T S Seal type<strong>ProCell</strong> Typhoon C P Kalrez 4079X Customer SpecifiedOptical pathlength DD200 mm 20300 mm 30500 mm 50

<strong>Specac</strong> | <strong>Process</strong> <strong>Flow</strong> <strong>Cells</strong>brilliant spectroscopy <strong>Specac</strong> Ltd. is a market-leading provider ofUV/Vis, NIR, and IR spectroscopic samplehandling accessories to academic, industrial,and research institutions worldwide.With purpose-built facilities in the UK, our teamof design and manufacturing engineers workclosely with our customers to provide the rightproduct for the application. Our products areoften designed to tolerate extremes oftemperature from –190°C to 800°C, pressuresfrom vacuum up to 5000 psi, and corrosivechemical conditions.State of the art CAD/CAM systems and thelatest manufacturing techniques, ensure that ourmanufacturing processes are compliant with thedemanding requirements of ISO 9001. <strong>Specac</strong> isan environmentally aware, ISO14001 accreditedcompany. As part of Smiths Group Plc., <strong>Specac</strong>has its headquarters based in the uk and a salesand support office in the usa. <strong>Specac</strong> also has aglobal network of distributors and dealers.Smiths Group is an international companyemploying 16,000 people in some 50 differentbusinesses located in the UK, USA, and Europe.<strong>Specac</strong> Ltd., River House, 97 Cray Avenue,Orpington, Kent BR5 4HE UK+44 (0)1689 873134 sales@specac.co.uk<strong>Specac</strong> Inc., 50 Sharpe Drive,Cranston, RI 02920 USATollFree 800 447 2558 sales@specac.comwww.specac.com